VEGETABLE, FRUIT PRODUCTS

This system is specifically designed for facilitating the direct transfer of pulp to a press.

- Capacity: 2000 kg/h

- Weight: 28

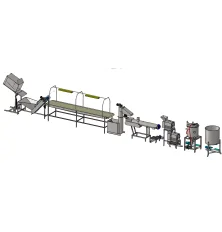

Production line for vegetarian vegetable-based formed or molded products such as falafel. The line is based on the classical method of producing semi-finished products for their subsequent freezing and packaging.

- Compact line suitable for both professional kitchens and industrial production.

- Fully automatic operation with minimal manual labor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

A production line designed for processing core fruits with seeds, such as apples or pears, into puree, with a capacity of up to 2000 kg/hour based on the volume of raw materials processed.

- Capacity: 1000 kg/h/ 2000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Our hydrodynamic extraction line is designed for extracting various components from plant materials, including biologically active substances, proteins, fats, carbohydrates, antioxidants, dyes, and flavors.

- Effective ŌĆ£softŌĆØ continuous hydrodynamic extraction ŌĆō percolation from finely crushed raw materials.

- Extraction without the need for pre-drying the product, resulting in savings on labor and energy costs.

- Utilizing raw materials without heat treatment, preserving all of their valuable substances and enzymes.

- Possibility of performing vacuum-pulse extraction (optional).

- Additional income from processing ŌĆ£wasteŌĆØ products - extracting valuable components from pulp and pomace.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A production line for thermostable fruit-based fillings, widely used in the production of pastries, baked goods, and various semi-finished products, as well as curd cheeses, creams, and even ice cream.

- Obtaining top-notch thermostable fillings while preserving essential nutrients and vitamins.

- Compact system featuring a unified control panel, ensuring easy and straightforward operation.

- Swift and efficient recycling included as a standard feature.

- Modular design with numerous additional options for customization.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Equipment for mixing multi-component mixtures of products, such as vegetable salads with various dressings, including thick and viscous ones like mayonnaise, thick sour cream and other similar sauces.

- Hydraulic tilting system is included in the basic version

- The controls are located directly on the frame supporting structure

- Eccentrically offset working shaft for rotating/tilting the working tank

- Low loading height

- The installation is made entirely out of food grade stainless steel

- Material: Stainless steel

- Operation mode: Mixed

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 600l/ 1000l

Used for blanching products in water, it is suitable for processing various vegetables, legumes, grains, mushrooms and other products. This versatile machine also functions as a water separator centrifuge which is activated after the blanching processes.

More information: sales@foodtechprocess.com

- Capacity: 30l/ 90l

- Material: Stainless steel

The special price offer is valid until the end of May 2024!

The combination of the compact 400/1100/12 model fryer along with the secondary upper pressure conveyor allows you to broaden the variety of fried products. It is suitable for ensuring uniform, high-quality frying of products in small-scale industries, professional kitchens and street food outlets by fully submerging the product in oil throughout the frying process. The fryer's compact dimensions make it easy to install on a tabletop work surface.

- The maximum height of the fried product is - up to 50 mm.

- Immersion thermometer for visual monitoring of the oil temperature

- Frying time can be set from a few seconds up to an hour!

- High temperature ŌĆō up to 200C

- The conveyor belt is made out of a food-grade stainless steel thin mesh

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

Universal cooking kettle with a built-in mixer, used for stirring and cooking all kinds of food, cosmetic emulsions, creams, sugar pastes and much more.

- Easily removable self-adjusting Teflon scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l

- Voltage: 220-230V

This 550 l professional tilting kettle is gas-fired and is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams. With this tilting version, you can make your life even easier.

For a price quote, send us an email to sales@foodtechprocess.com

- Heating: Gas

- Capacity: 500 l

- Material: Stainless steel

This 160L or 220L professional cooking pot is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams.

For a price quote, send us an email to┬Āsales@foodtechprocess.com

This professional cooker is gas powered and is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams.

Thanks to the indirect heating system, this electric kettle is ideal for cooking liquid foods. It is completely made of stainless steel and equipped with a convenient drain valve.

For more information, please contact us at sales@foodtechprocess.com

This stainless steel cooking pot will always ensure cooking, baking or boiling different foods.

For more information, please, send us an email at sales@foodtechprocess.com

This 265 liter stainless steel cooker is great for boiling or roasting a variety of ingredients. This gas cooker with indirect heating system is ideal for cooking liquid food. It is made of stainless steel and equipped with a convenient drain valve.

Thanks to the indirect heating system, this kettle is ideal for cooking liquid dishes. It is completely made of stainless steel and equipped with a convenient drain valve.

For more information, please, send us an email at sales@foodtechprocess.com

This premium kettle is gas-fired and has a volume of 160 liters. Ideal for preparing a wide variety of dishes.

For more information, please contact us at sales@foodtechprocess.com

This premium kettle is gas-fired and has a capacity of 120 litres. Ideal for preparing a wide variety of dishes.

For more information, please, send us an email to sales@foodtechprocess.com

This electric cooking pot has a volume of 60 liters and is used to prepare a large number of dishes. It is comfortable to use and easy to clean.

For more information, please, send us an email to sales@foodtechprocess.com

This 60 liter cooking kettle is indispensable for cooking large amounts of food. Runs on gas and handles all basic cooking tasks with ease.

For more information, please, send us an email to sales@foodtechprocess.com

This kettle with a radiator cooling system ranging from 30 to 500 liters is ready to cook according to the principle of a water bath.

A modern cooking and mixing device with a wide range of applications in confectionery, bakeries, catering establishments.

Fast, sleek, quiet, user-friendly, safe, smooth-running commercial salad dryer, designed to efficiently dry up to 6 Kg.

For more information, send us a request.┬Ā

The conveyor is made out of strong and highly-resistant stainless steel. It is also additionally reinforced for reliability during operation.

For additional information, please contact us at sales@foodtechprocess.com

This equipment set can be used for the production of a diverse array of sauces, as well as various vegetarian products based on nuts, soy and rice. It is capable of processing around 300/600 liters of product per batch.

For further details, contact us at sales@foodtechprocess.com

For frying foods in oil, deep-frying, suitable for frying onions, seeds, nuts, vegetable snacks and chips, and other products, including breaded or covered in liaison. Can also be used as an oil separating centrifuge for deep fryer.

- Two in one: a deep fryer and a centrifuge to remove excess oil

- Possibility of frying small and fragile products

- Obtaining a ŌĆ£dry productŌĆØ after frying

- Low carbonization of oil due to the cleaning feature after frying

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l/ 90l

- Total power, kW: 11

- Voltage: 380-400V

Designed for "cold" vacuum drying of products sensitive to high temperatures, also suitable for liquid and viscous products.

For more information contact us at: sales@foodtechprocess.com

The set of individual equipment for the production of French fries may differ depending on the initial raw materials. We offer various modifications from washing to frying with subsequent dehumidification starting from 50 kg/h for the final product.

For more information, please contact us at: sales@foodtechprocess.com

This jam production line allows you to get ready-made jam at the exit from whole fruits at the entrance!

Equipment options may vary depending on the customer's technology.

The vegetable spin dryer has been designed for drying leafy vegetables rapidly and efficiently, both raw and boiled, prepared in medium-large sized professional kitchens and in food industries.

The price is set for the basic version, without additional options.

The infrared dryer is suitable for drying a wide range of products: nuts, apples, plums, strawberries, raspberries, blueberries, mushrooms, carrots, onions, garlic, herbs, meat, figs, bananas, marshmallows. If additional options are selected, it can also be used for curing and drying whole meat and fish.

- Compact installation

- Fast and efficient drying

- Possibility of selecting individual settings for drying

- Made entirely out of stainless steel

- The interior surface of the cabinet has a mirror coating

- Quiet operation of the installation

- Low energy consumption per drying cycle

- Heating: Electricity

- Material: Stainless steel

- Operation mode: Mixed

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 7l/ 10l/ 14l

- Total power, kW: 10/ 15/ 20

- Area, m2: 3,5/ 5,2/ 6,9

- Number of shelves: 10/ 15/ 20

Potato and root vegetable peelers are manufactured in all-stainless steel casing. The device is directly ready for use (no installation required), it is supplied for a 3x400 V power supply.

For more information on the device and a price offer, contact the sales department of sales@foodtechprocess.com

The price is set for the model with an area of 7 m┬▓

Compact dryer, heat pump powered dehydrator for drying vegetables, fruits, berries, mushrooms, legumes and grains.

- Energy saving, low consumption model (consumption up to 0.9 kW/h)

- Possibility of increasing the drying area in this model up to 14 m┬▓ (optional)

- Intensive drying, each section is equipped with a heat pump

- Automatic drying system control

- Delicate drying at low temperatures

- Preservation of most nutrients and the products natural color

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 0,9

- Voltage: 220-230V

- Area, m2: 7

- Number of shelves: 22

The mincer-destemmer is used for processing grapes. It comes in a stainless steel version.

For more information about the equipment and processing options, please contact our company's sales department at sales@foodtechprocess.com

Multifunctional pans function as a frying, cooking, and mixing device in one installation.

For more information on our automatic Wok-style frying pan with a built in mixer, please contact our sales department at sales@foodtechprocess.com

The cutter is designed for cutting into cubes, stripes or slices.

For more information, contact our sales department at sales@foodtechprocess.com

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

For more information or a price quote, please contact our sales department at┬Āsales@foodtechprocess.com

Excellent help in the kitchen, which will allow you to combine your experience and creativity with the requirements for an excellent product. Caramel cooker is offered in two volumes, 50 and 100 liters.

For more product information, contact sales@foodtechprocess.com

- Heating: Electricity Gas

- Capacity: 50 l 100l

- Material: Stainless steel

This is a cost-effective solution that meets the special cooking requirements of the Horeca segment. Fitted with a built-in mixer to reduce labor and prevent the product from sticking.

For more information about the frying pan, contact our sales department at sales@foodtechprocess.com

Create natural shapes of nuggets, pieces that have the appearance of a "hand-formed" product.

For more information, contact the company's sales department at sales@foodtechprocess.com

Vibrating conveyors suitable for arranging the product before further processing.

For more information, please contact our sales department at sales@foodtechprocess.com

The nut grinding machine is used for processing sesame seeds to produce a tahini or a sesame paste.

For more information, please contact our sales department at sales@foodtechprocess.com

The KPM-400 Commercial Knife Potato Peeler: Effective equipment for peeling potatoes and similar vegetables, delivering high-quality results.

The brush washer/scraper is an industrial device for washing and scraping root vegetables depending on the degree of contamination.

For more information, contact sales@foodtechprocess.com

The CAF 65 cabbage shredder is designed for large processing plants, for a daily production of about 60 tons.

For more information about the equipment, contact our sales department at sales@foodtechprocess.com

The device was primarily designed to increase dough adhesion (adhesion) by using a thin layer of dust - flour. The device is available in four widths of 200, 300, 400 and 600 mm.

For more information on the breading machine, contact our sales department at sales@foodtechprocess.com

Breadcrumb breading has never been easier. This device is available in various belt width configurations of 200, 300, 400 and 600 mm. For more information, please contact our sales department at sales@foodtechprocess.com

Excellent blancher and cooker for efficient handling of vegetables and other food products.

For a price quote or more information, email us at sales@foodtechprocess.com

A donut fryer is special designed for small confectionery shops, industries and catering establishments. It┬Āis capable of frying of various products similar to donuts.

For more information, please contact us at┬Āsales@foodtechprocess.com

The device is designed for the pasteurization of a wide range of products in various types of packaging material such as cans and jars. For more information, contact our sales department at sales@foodtechprocess.com

- Heating: Mixed

- Capacity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Single machine

SnackPro blancher will prepare different types of products making it a great solution for blanching large volumes of fruits and vegetables in a short time.┬Ā

For more information and price quote email us at sales@foodtechprocess.com

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

For a price quote, send us an email at sales@foodtechprocess.com

This multifunctional cooking machine is designed for different ways of use and is suitable for a lot of variety of businesses - any small enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

For a price quote, send us an email at sales@foodtechprocess.com

We offer wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments. Price depends on the chosen option. Please email┬Āsales@foodtechprocess.com

- Heating: Gas Steam

- Capacity: 300 l 600 l 1000 l

- Type of the equipment: Single machine

The screw elevator is intended for transporting grape marc / bagasse. It also suitable for processing olives. This type of an elevator is great for food production facilities focusing on fruit processing as well as wine and olive oil production. The machine is made in two models with 3000 and 4000 mm length.┬Ā

For more information, send us an email to┬Āsales@foodtechprocess.com

The fruit pitting machine is intended for removing cores or pits from plums and apricots. Besides the fruits mentioned above, this device can be used for nectarines, peaches, etc. It can simultaneously cut fruits into several parts (two, four). The machine is perfect for use by small and medium-sized enterprises, and in farms.

For more information, send us an email to sales@foodtechprocess.com

The cherry seeds separation machine has a high processing capacity ranging - from 200 to 300 kg of raw materials that can be loaded per hour (depending on the size of the cherries). It roughly equals to 720 processed berries per minute. This machine is perfect for small and medium-sized food enterprises and farms.

For more information, send us an email at sales@foodtechprocess.com

ProfiCut is an ideal solution for efficient and economical processing of dressings, sauces, baby food as well as spreads, pat├® and processed cheese with advanced processing techniques.

For more information, please, contact our sales department at sales@foodtechprocess.com

Highly efficient production of a high viscosity pharmaceutical and cosmetic products.

For a price quote, send us an email to sales@foodtechprocess.com

We offer professional infrared dryers from 8 to 56 trays with a capacity of 200 to 3000 kg/day for vegetables, fruits, tea, herbs, mushrooms, medicinal herbs and other products. The dryers of this type is a turnkey solution based on two technologies - direct infrared and air convection drying.

For more information about the dryer, contact our sales department at sales@foodtechprocess.com

The cost is indicated without the price of the baskets

A batch blancher with indirect electric or steam heating is used for blanching vegetables, mushrooms, meat, fish, and seafood. This type of blancher is ideal for use in catering kitchens and hospitals.

- Simple controls

- Built-in electric heating

- Large outlet valve

- Safe operation

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l

The price is set for the basic version of the evaporation unit without additional options.

A compact vacuum evaporation unit that allows you to concentrate solutions, mixtures, and various products by evaporating the solvent. A modular version based on the basic 110/100 vacuum reactor.

- Gravity mixing - 25% more efficient

- Reinforced agitator design with no blind spots

- Condensation and vapor removal system

- Easily disassembled mixing device

- Large heat exchange area: jacket over the entire height of the reactor

- Ability to measure and monitor condensate volume (optional)

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 100l

- Max vacuum: -0,8 Bar

- Duplicator volume: 3l

- Heat transfer area, m2: 1,05

The innovative cooking device combines the advantages of cooking with automatic mixing and compact dimensions.

Contact sales@foodtechprocess.com for more information.

The forming device guarantees accurate forming of a wide range of food mixtures. The FR 75 is suitable for various mixtures of different textures and consistencies.

For more information, contact our sales department at sales@foodtechprocess.com

The forming device guarantees precise shaping of a wide range of food mixtures.

For a price quote, send us an email to┬Āsales@foodtechprocess.com┬Ā

The new design of the universal cutter with gravity mixing is used for the production of thick and pasty products. The cutter is designed to carry out production processes such as cutting, mixing, crushing and emulsifying various types of products in liquid form in a single installation. Thanks to the built-in duplicator, it can also be used as a device for the production of cream honey or cream honey souffl├®.

- Cutting knives with a powerful 11 kW electric drive

- Frame mixing device with fluoroplastic scrapers

- Hatch opening sensor for safe maintenance

- Plexiglass hatch for visual inspection

- Duplicator for the thermal liquid around the bottom as well as the walls of the installation

- Inclined design for efficient grinding, homogenization and discharge of thick and viscous products

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 12

- Voltage: 380-400V

Atmospheric processing machine with a stainless steel design with and a 60 L processing bowl with a cutter (grinding knife)

For a price quote, send us an email to sales@foodtechprocess.com

The box tipper VK is designed for semi-automatic emptying of boxes/containers/crates with all kinds of root, tuber vegetables, and fruits.

For more information, send us an email to sales@foodtechprocess.com

We sell many different types of cooking equipment, with a mixer or without, tilting, electric/steam/gas heating system, and many different modifications. For more information, send us an email to┬Āsales@foodtechprocess.com┬Ā

Designed for cooking or blanching vegetables, fruits, legumes, pasta, seafood and other products in a continuous manner.

For a free consultation, email us at sales@foodtechprocess.com┬Ā

We offer different types of washing equipment for various different food products. For a price quote or a free consultation, email us at sales@foodtechprocess.com

The washer with external loading conveyor UNI M is specifically designed for the efficient and high-performance washing of vegetables, potatoes, and fruits, using gentle exposure to water to ensure thorough cleaning without harming the product.

Price on request. E-mail sales@foodtechprocess.com

The drum washer is designed for washing potatoes and other roots as well as for seeds, nuts and grains.

Price on request. E-mail sales@foodtechprocess.com

A rotary defroster is a device used to thaw or defrost frozen food products by rotating them gently in a heated chamber, allowing for even and efficient thawing without damaging the food's texture or integrity.

Price depends on the chosen option. Please email sales@foodtechprocess.com

The screw conveyor with heating is a device designed for the transportation of material using a screw mechanism, while heat is applied to the product to facilitate easier transfer. This type of conveyor is often used to simplify the transfer of various bulk materials.

For more information, send us an email to sales@foodtechprocess.com

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

For more information, send us an email to sales@foodtechprocess.com

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor. For more information, send us an email to sales@foodtechprocess.com

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

For more information, send us an email to sales@foodtechprocess.com

A universal conveyor with a PVC belt with horizontal sections, a volumetric storage, adjustable in height and angle of inclination, which can easily be adapted to existing installations for lifting the product to a certain height. The conveyor has its own independent drive, the speed of which can be adjusted using an inverter (optional).

- Lightweight: the supporting structure of the conveyor is made out of aluminum profiles

- Hopper made out of food grade stainless steel

- Bearing frame on wheeled supports with position locks

- High sidewalls made out of stainless steel

- White PVC tape for transporting products with temperatures of up to 80 degrees

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Volume: 50l/

The tank is designed for heating and mixing chocolate, butter, margarine, honey and similar products.

For more information or a price quote, send us an email at: sales@foodtechprocess.com

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. The price depends on the product as well as the size of the conveyor.

For more information, send us an email at sales@foodtechprocess.com

The price is indicated with a semi-automatic control panel

The vacuum kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing, or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 10l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

An air cooling conveyor is used to rapidly cool products in food processing industries by circulating cool air over them as they move along a conveyor belt. This efficient cooling process helps preserve product quality and reduce the time between processing stages, facilitating smoother production workflows.

For a price quote or a free consultation, send us an email to sales@foodtechprocess.com

Grinding mill for continuous grinding of meat and ingredients such as seeds, small bones and cartilages that are unwanted in the final product.

For more information, send us an email at sales@foodtechprocess.com

EcoFry is designed for frying onion rings, seafood, dumplings, spring rolls, pies, vegetables, nuggets and hamburgers with the help of pouring hot oil. A smaller capacity, efficient frying equipment intended for small to medium sized┬Āproduction facilities.

For a quote, please send us an email at┬Āsales@foodtechprocess.com

The series of Continuous Fryers Pour Oil is the boom in the market of frying and roasting equipment. The new construction designed by our engineers, based on existing practical experience in the production and use of conveyor fryers, provides the best example of environmental friendliness.┬Ā

For more information please email┬Āsales@foodtechprocess.com

The continuous pouring fryer is designed to fry meat, fish, vegetables and pasta products as well as chicken drumsticks, cutlets, nuggets, croutons, sliced zucchini or eggplant, and etc. using immersion frying and hot oil pouring methods.

For more information please send us an email at┬Āsales@foodtechprocess.com

It's┬Ācompact cooking equipment for catering and gastronomic sphere:┬Ācafes, bars, canteens. The cooking equipment is designed for boiling, stewing, frying and mixing products of different viscosity.

Price depends on the chosen option. Please email us at sales@foodtechprocess.com

A pouring fryer is a specialized equipment used in commercial kitchens for frying foods using a continuous pouring method. It offers precise control over the frying process by continuously pouring oil over the food, ensuring even cooking and consistent results.

Price depends on the chosen option. Please email sales@foodtechprocess.com

┬ĀFor more information, send us an email at sales@foodtechprocess.com┬Ā

┬ĀFor more information, send us an email to sales@foodtechprocess.com┬Ā

┬ĀFor a price quote, send us an email to sales@foodtechprocess.com

Blanchers are used to quickly heat or steam vegetables or fruits, often for the purpose of softening, preserving color, or removing skins before further processing. Geometrical volume 400 l.

Price depends on the chosen option. Please email sales@foodtechprocess.com

The KWS mixing vessel is engineered for versatile operations, including heating, cooling, and mixing of liquid products, with a maximum temperature capability of 60 ┬░C.

For a price quote, send us an email at┬Āsales@foodtechprocess.com┬Ā

Atmospheric cookers ASC are designed for efficient mixing, heating and cooking products for food and cosmetic industries. Volume, l: 100 l.

For a price quote, send us an email at sales@foodtechprocess.com

Atmospheric cookers AC are designed for efficient mixing, heating and cooking products for the food, pharmaceutical and cosmetic industries. Working volume up to, l: 300 l.

For a price quote, send us an email to sales@foodtechprocess.com┬Ā

Vacuum diffusion - the process in which the air inside the product is removed by vacuum and the released pores are filled with flavor, vitamins or other ingredients.

For a price quote, send us an email to sales@foodtechprocess.com┬Ā

Our company offers equipment for whipping honey with a new design which includes gravity mixing. The main advantage of the technique is the ability to produce creamy honey in 4 hours! The device is designed for 450 kg of honey per batch.

For additional information or a quote, please email us at sales@foodtechprocess.com

Running of various production processes such as cutting, mixing, crushing, refining and emulsifying different types of product in a single unit.

Price depends on the chosen option. Please email sales@foodtechprocess.com

A rotating drum unit designed for continuous coating operations and product saturation with seasonings and flavor additives, utilized in production lines for chips, snacks, and various semi-finished products.

- Adjustment of the Drum Tilt Angle

- Hygienic design and execution: mirror-polished inner surface of the drum

- Various blade options for gently turning the product (optional)

- Dispensers for dry and wet flavorings (optional)

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 0,25

- Voltage: 380-400V