Melters for fat and butter blocks NorMelter 200-1000

The cost is specified for the basic modification without a heating system

Fat block melters are designed for melting frozen, solid blocks of animal or vegetable fat, as well as maintaining them in a molten state at a specified temperature. We produce models with the option to connect steam as a coolant to the melting grid, separate electric heating systems, or configurations with built-in electric heating for supply into the jacket and melting grid.

- Large area of the melting grid where the coolant circulates

- Special shape of the melting grid, cutting blocks during melting

- Greater versatility in terms of the coolant and its source

- Mirror surface of the melting grid, ensuring high hygiene

The fat melting machine is used in the industry for processing margarine, oil mixtures for the production of ice cream, condensed milk, fillings, creams, cookies, ointments, oils, and much more.

Fat melting machines (melting lard, fats, oil) are designed for frozen blocks of solid or melted fat of animal and vegetable origin as well as maintaining them in a molten state at a certain temperature, for example:

|

|

|

|

|

|

|

|

Advantages:

- Maximum heating intensity due to a very short energy transfer path between the heating surfaces and the coolant.

- Simple design, variability in using different types of coolants and their sources.

- High reliability, hygienic design and execution and a mirror surface of the melting grid.

- Large layout area, designed for 20 kg blocks measuring 380x253mm.

- Components exclusively from European manufacturers are used, ensuring a high level of safety.

Basic version

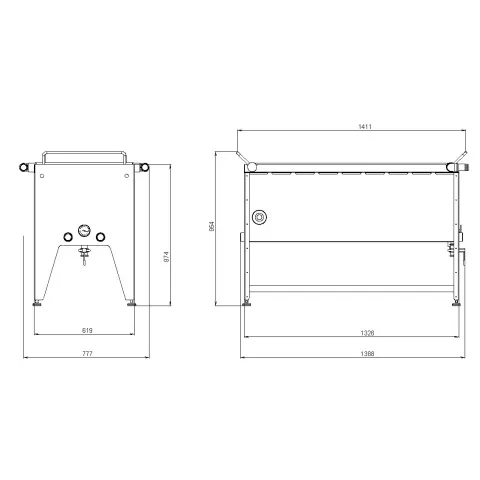

The fat melter comprises a two-layer vertical tank with a heating jacket and an upper grid made out of specially shaped melting pipes. Heating is carried out with the help of a coolant through the heating jacket due to its supply to the melting grid. The heating source is selected additionally: external electric heater for water (hot water supply), built-in electric heating. Control is determined depending on the modification and heating source.

A version with built-in electrical heating

It includes a heating system with a heat exchanger positioned beneath the working vessel, integrating built-in heating elements (power dependent on the grease chamber volume). The utilized coolant is heated water circulating through the melting grid.

Principle of operation

The upper melting grid is heated by a thermal medium that circulates continuously in the heating system, transferring heat intensively to the product. The loading of blocks is carried out manually directly onto the upper grid made out of melting pipes. The temperature of the blocks must be above -20┬░C. The molten product is discharged through an outlet valve located at the bottom of the melting machine.

Options:

- Built-in electric heating 24/48 kW

- Removable cover

- Self-priming pump (for product discharge or circulation)

- Heating for the pump and pipelines of the circulation system

- Submersible mixing device

- Thermal insulation of the walls of the installation with an external decorative casing made out of polished stainless steel

- In-line reusable stainless steel filter

Optional equipment

- Hot water source

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 200l/ 300l/ 500l/ 1000l