Meat patty hamburger former

The machine is suitable for forming minced meat, poultry, fish, potatoe and vegetarian, vegan patties. The price depends on your product specifics and production capacity.

For a price quote, please email us at sales@foodtechprocess.com┬Ā

The meat patty hamburger forming machine is suitable for forming minced meat, poultry, fish, potatoe and vegetarian, vegan patties.

Forming machine Former 600 allows you to produce products in a rectangular, round or triangular shape. It is ideal for producers of all types of patties ŌĆō hamburger patties, poultry patties, sausage patties, fish┬Ā patties and more.┬Ā

Meat fibers are not crushed or destroyed on Former 600 ŌĆō instead they retain their natural alignment so that the finished patty has the superior bite, texture and eating quality. The former poduces formed products with excellent shape retention and weight accuracy using only air to release the products.

Hamburger former - Advantages:

- Meat of almost any shape.

- Simple design.

- Easily produced gourmet patties and burgers.

- Simple changeovers make it easy to produce various size and shape patties.

- Easily replaceable molding plates guarantee a minimum changeover time.

- Molding former machine is suitable for almost all types of products.

- Allows you to make a variety of forms and work with different materials.

- High quality with excellent preservation structure.

- Includes a programmable PLC that optimizes the molding cycle for each individual product.

Efficiency

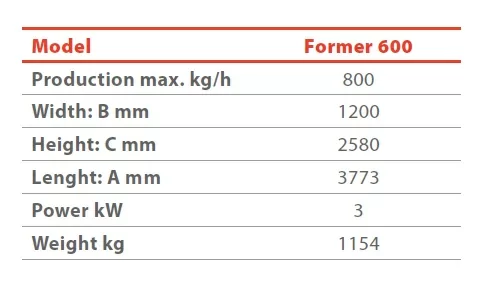

Forming Machine has highly reliable frame and provides production capacity up to 800 kg / h, while low maintenance costs guarantee good value and quality. Hopper design and feeding system provide easy cleaning during the transition to another product material. Bunker rises easily, providing access for cleaning and replacement of equipment.┬Ā

Attachments

You might also like

Heat boilers are designed to produce sausages, hams and o’¼Ćal. Technology for superior performance and hygiene.

For additional information, please contact us at┬Āsales@foodtechprocess.com

Hamburger production line is designed for production of hamburgers, veggie burgers or soy-based burgers. The line produces from 2.000 up to 6.000 hamburgers per hour. Price depends on production.

These meat mixers are characterized by their modern design and strong AISI 304 stainless steel construction.

For more information, send us an email at sales@foodtechprocess.com

12 other products in the same category:

This cookie making machine is designed to produce an unlimited variety of cookies, cakes, and other pastry snacks. We offer five different types of cookie depositing machines, each tailored to various cookie types

For more information, send us an email at sales@foodtechprocess.com

Rotary molding machine for confectionery products: candies from paste-like masses, crushed fruit masses, protein candies and bars. Specially designed for molding candies from food masses.

For a price quote, please send us an email to sales@foodtechprocess.com┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,5

- Voltage: 380-400V

Croquettes production line for making and batter breading croquettes, preparing them for frying. Croquettes from 15 to 55 grams. Produces up to 12,000 pieces/hour. We also offer range of fryers. Price depends on your production capacity.

Fully automatic machine for making kebab and brochettes by skewering meat on a stick with a maximum production capacity of 1500 pieces per hour.

The price depends on the selected option. Please contact us at sales@foodtechprocess.com

This ground-breaking device allows for constant fine tuning of the roundness of the boilies thanks to its PLC control device. It is sold in two versions. The price depends on the options you choose.

We also offer a extruding machine suitable for this boilie machine. For further details, please contact us at sales@foodtechprocess.com

Create natural shapes of nuggets, pieces that have the appearance of a "hand-formed" product.

For more information, contact the company's sales department at sales@foodtechprocess.com

The forming device guarantees precise shaping of a wide range of food mixtures.

For a price quote, send us an email to┬Āsales@foodtechprocess.com┬Ā

Hamburger production line is designed for production of hamburgers, veggie burgers or soy-based burgers. The line produces from 2.000 up to 6.000 hamburgers per hour. Price depends on production.

The forming device guarantees accurate forming of a wide range of food mixtures. The FR 75 is suitable for various mixtures of different textures and consistencies.

For more information, contact our sales department at sales@foodtechprocess.com

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

For more information about the product please contact the sales department at sales@foodtechprocess.com

SIPM pasta mixer is designed for medium size commercial operations, ideal for medium-size restaurants to produce any kind of pasta such as spaghetti, taglia pasta, cannelloni, macaroni, conchiglie, rigatoni, penne and many others. The price includes a pasta cutter.

For more information, send us an email at sales@foodtechprocess.com

Twin-screw extruder is designed for effective extruding, homogenization, pumping over of plastic masses (butter, margarine, honey, curd products, confectionery mixtures), and forming it into bars and rolls.

For a price quote, send us an email to sales@foodtechprocess.com