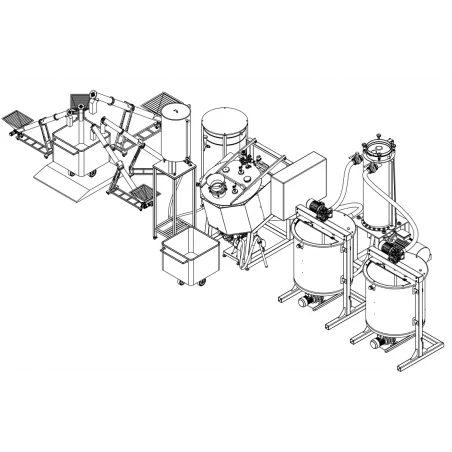

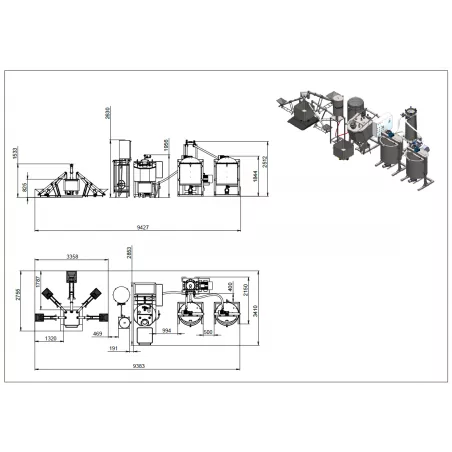

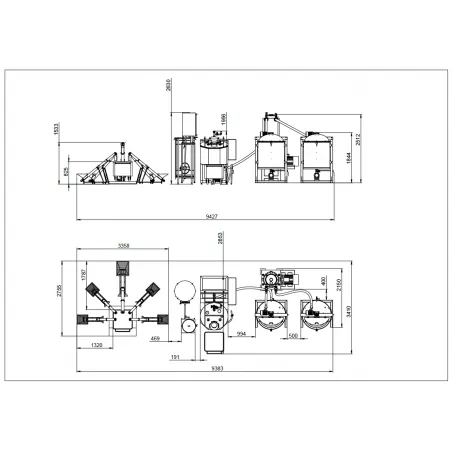

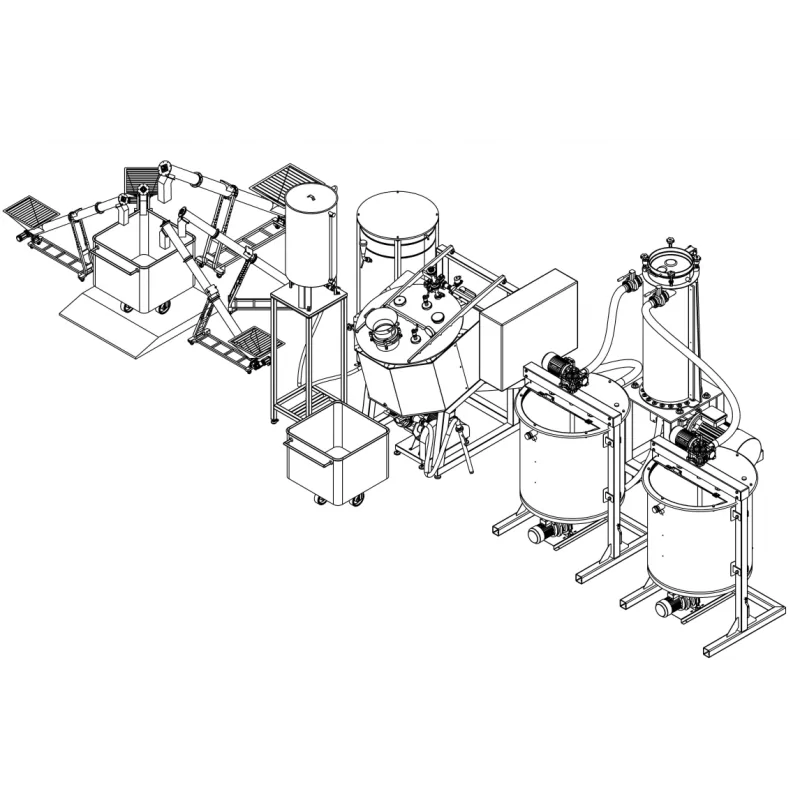

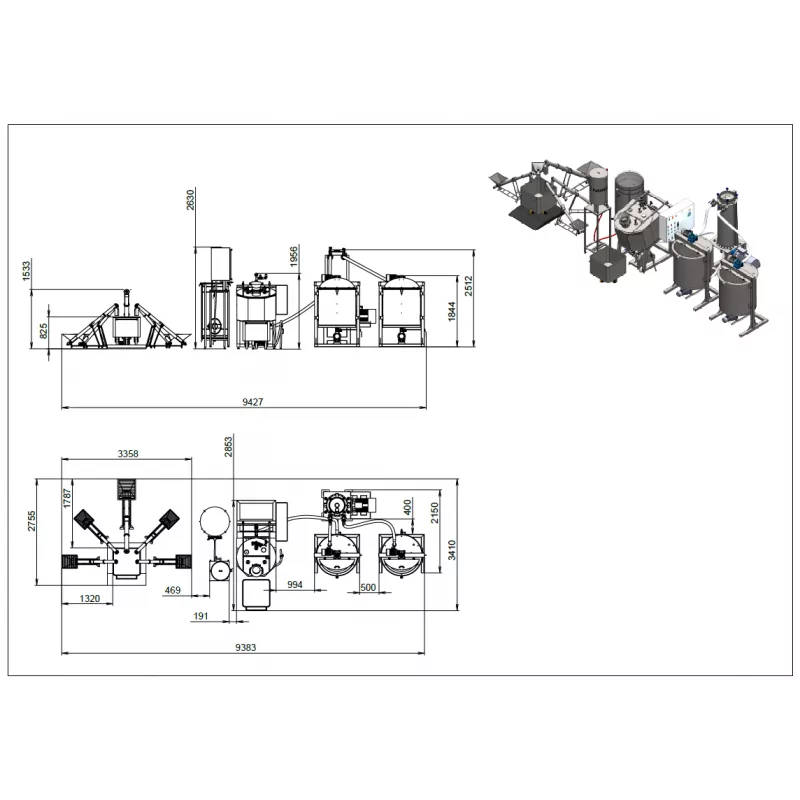

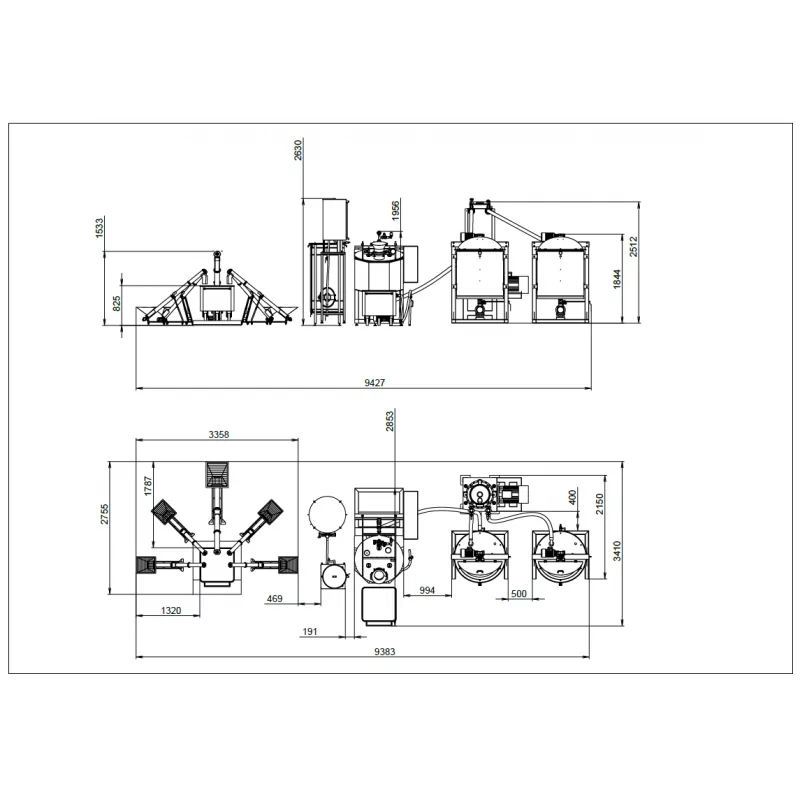

Chocolate spread production line

This equipment complex enables the production of Nutella-type chocolate pastes with a capacity of up to 250 kg/h.

For additional information, please contact us at sales@foodtechprocess.com

The complex of equipment is based on a recipe that uses melted fats; when using refractory fats, they must first be melted in a fat melter.

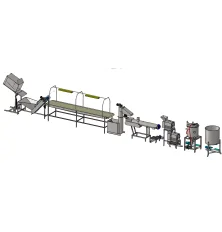

The preliminary part includes the process of preparation and dosing of loose components:

- in the basic version, scales with a display are used to measure bulk powdered/granular components, this option involves a lot of mechanical work, but is also the most economical;

- an automated alternative to dosing ingredients is a weighing station - a terminal with tensometric gauges and a controller for automatic operation in accordance with the recipe;

- for safe and convenient loading of sugar and other bulk components, it is recommended to use bag tipper

- feeding conveyors with receiving hoppers and rolling carts are also part of the dosing process.

Since sugar is practically the main ingredient in terms of percentage, a special XL screw conveyor is provided for it, which is equipped with an above-standard hopper and an extended screw with a pipe. On the receiving hopper, a grate is set up for unloading bags. Dosing is carried out according to weight parameters in manual or automatic mode (depending on the type of weighing equipment selected). As an additional option, it is recommended to choose a frequency converter to adjust the speed of the conveyor and, accordingly, the speed of the raw materials being fed into the trolley for a single portion of the product.

For dosing the remaining loose bulk components, a standard-sized conveyor is provided. The number of conveyor belts depends on the recipe, with the classic recipe up to 5 of them can be used. The sequence of dosing ingredients is recommended to be done from the most to the least dusty.

All bulk components are dosed into "Euro tub" trolleys with a standard volume of 200 liters, equipped with wheels and handles for easy transportation. It is recommended to use at least 2 for continuous operation.

For storage and subsequent dosing of liquid components, the following is used:

A closed container made of stainless steel with a "duplicator" for a coolant* up to 0.5 bar with the possibility of visual control of the level with a volume of 3000 liters. This unit is designed to store pre-melted, molten fats and keep them in a liquid state. To do this, it is recommended to supply warm water into the "jacket".

Fat is fed into the hopper from below by means of a liquid component dispenser pump. The dispenser of liquid components consists of a stainless steel vessel mounted on a supporting structure raised to the top. The unit is equipped with a filling level indicator that automatically turns off the pump when the required volume is reached.

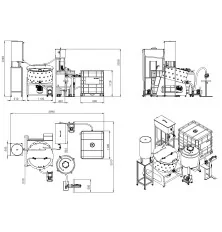

The main process of mixing up the components is carried out in a vacuum homogenizer.

The vacuum homogenizer with a volume of 300 liters is designed for intensive mixing of ingredients, equipped with a "duplicator" for a heat carrier * with a pressure of up to 0.5 bar, a frame mixer with an electric drive, a circulation system (external circulation circuit), an inline homogenizer with a pump, a vacuum system with a special hose for loading bulk Vacuum homogenizer with a volume of 300 liters is designed for intensive mixing of ingredients, equipped with a "jacket" for a heat carrier * with a pressure of up to 0.5 bar, a frame mixer with an electric drive, a circulation system (external circulation circuit), an inline homogenizer with a pump, a vacuum system with a special hose for loading loose components and deaeration of the product during circulation and movement. In the basic version, a hatch is located on the upper body for the possibility of loading additional components in accordance with the recipe.

It is recommended to feed liquid components into the working chamber of the homogenizer first. The supply of bulk components is carried out after adding liquid ones first, it can be done in two ways: into the working container below the liquid level with stirring for their effective trapping and wetting by the liquid, or for poorly wetted components such as milk powder, it is recommended to serve it "into the stream". By introducing powdered ingredients directly into the vacuum created in the zone of highest shear rate, the product is immediately wetted and dispersed. This achieves complete wetting, deagglomeration and uniform distribution of solid particles in the liquid.

The advantage of this method is the reduction of dust formation and loss of powder components in the production process. Powder ingredients do not settle on the walls, lid and shaft of the agitator and do not impair the quality of the finished product.

Optionally, for this equipment, an opening lifting top cover with electric actuators can be selected.

After mixing, the finished mass is fed into a ball mill.

The ball mill 200 VBM is designed for grinding, pulverizing, crushing, (rolling) chocolate and nut masses. It is a vertical cylindrical container with a ŌĆ£jacketŌĆØ for a coolant* with a pressure of up to 0.5 bar, inside which a specially shaped mixer is installed on the shaft. Equipped with a recirculation circuit: ball mill - accumulator - ball mill. During the circulation of the product, a high level of homogenization of the mixture is achieved. It is possible to process the components to the level of dispersion down to the mass of 25 microns.

Special steel grinding balls are used as a grinding element. Different levels of mixing elements move in the same direction, but at different speeds. The speed of their movement at the ends of the rods (fingers) of the agitator is the highest and tends down to almost zero near the shaft, thereby significantly reducing wear. Balls with a diameter of 9.5 mm, 900 kg (not included in the scope of delivery).

After reaching the required degree of dispersion, the product is fed into the accumulator/accumulators.

The forced circulation circuit includes a special pump for thick and viscous products.

Accumulator for the finished┬Āchocolate mass

- The complex includes two storage tanks. One is used in the recirculation circuit of the ball mill, the second as a buffer tank for subsequent dosing and packaging.

- The accumulator with a volume of 500 l is equipped with a "duplicator" for a heat carrier * with a pressure of up to 0.5 bar g, and a mixing device with a drive.

- The entire equipment piping system has heated piping*.

- The control system depends on the requested degree of automation and is agreed upon additionally after selecting the equipment.

*- coolant source is not included in the basic set. But it can be ordered additionally depending on the technical requirements of the customer.