Flow Deaerator DEAS

A vacuum deaerator is extensively used in the food industry to remove gases from products that may retain some bubbles post-processing. Additionally, a flow deaerator is utilized to minimize foaming in products, ensuring a denser structure, especially prior to packaging. Vacuum deaerators play a crucial role in eliminating specific odors from the products, such as in the production of juices, purees, and herbal drinks. This process significantly contributes to enhancing the overall quality and taste of the final product.

- Enhances product quality, structure, and shape

- Prevents oxidation by removing gases

- Preserves organoleptic properties and extends the shelf life

- Suitable for thick and viscous products

- The flow principle allows for the installation of this equipment in existing production lines

Deaeration is widely employed not only in the food industry but also in the pharmaceutical, cosmetic, chemical, and other manufacturing sectors. Air dissolved in the product may contain bacteria, viruses, and various odors. The presence of gases in products can adversely affect the product's properties, consumer qualities, and shelf life, especially when processing products sensitive to oxidation. Deaerators enable the improvement of products, maintenance of high production standards, assurance of mass stability, and extension of shelf life.

Deaerators are used in the production of various products, including:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Advantages:

- Can be used for various types of liquid or paste products, including those with small solid inclusions. The special pump ensures that even products with solid pieces can be processed without compromising their structure. The installed product pump is designed to handle such materials delicately, preventing any damage to their composition.

- The basic version includes a frequency converter to control the pump's speed and to extract the product from the deaerator's vacuum chamber, allowing for adjustments based on the specific product being processed in real-time.

- The continuous deaeration equipment significantly expands the evaporation surface area by processing the product in a thin layer. This approach substantially improves the efficiency of the degassing process.

- Flow-through deaerators stand out as the most cost-effective solution due to their compact size and ability to efficiently handle large volumes, ensuring improved productivity.

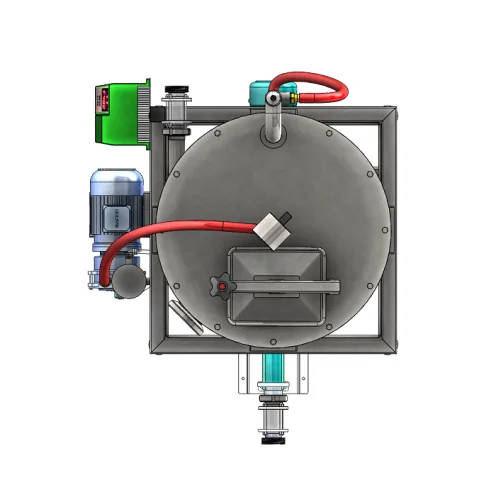

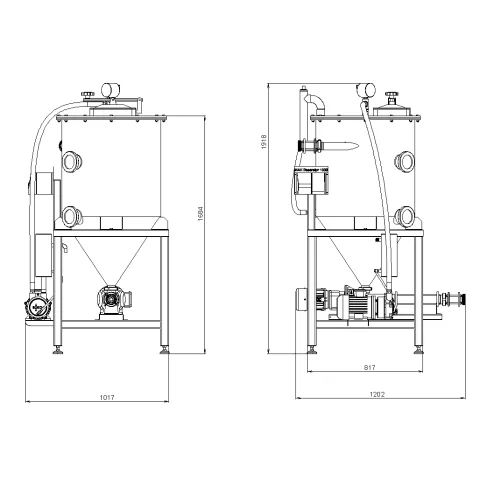

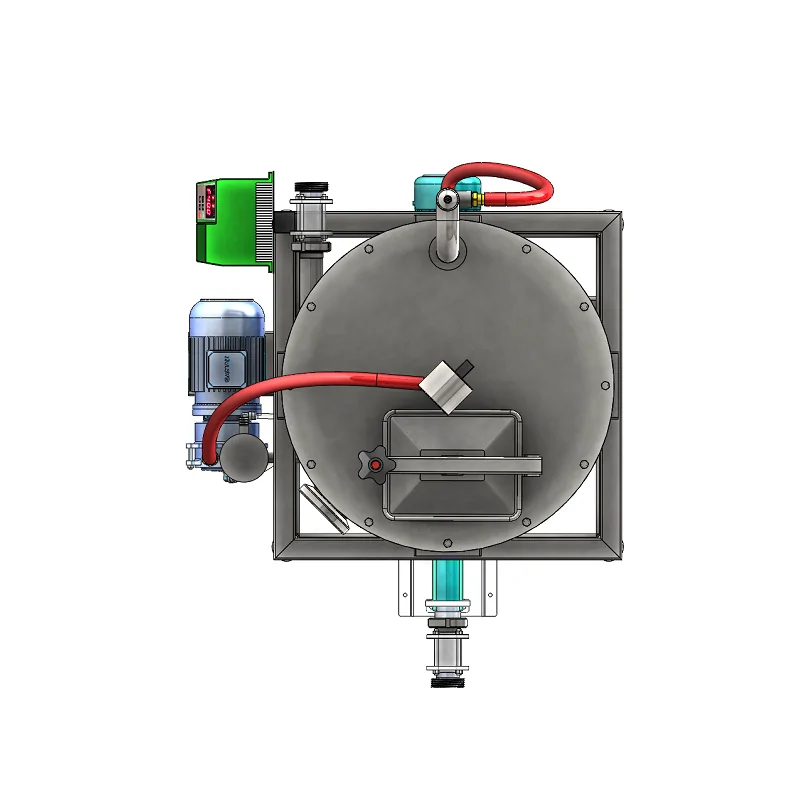

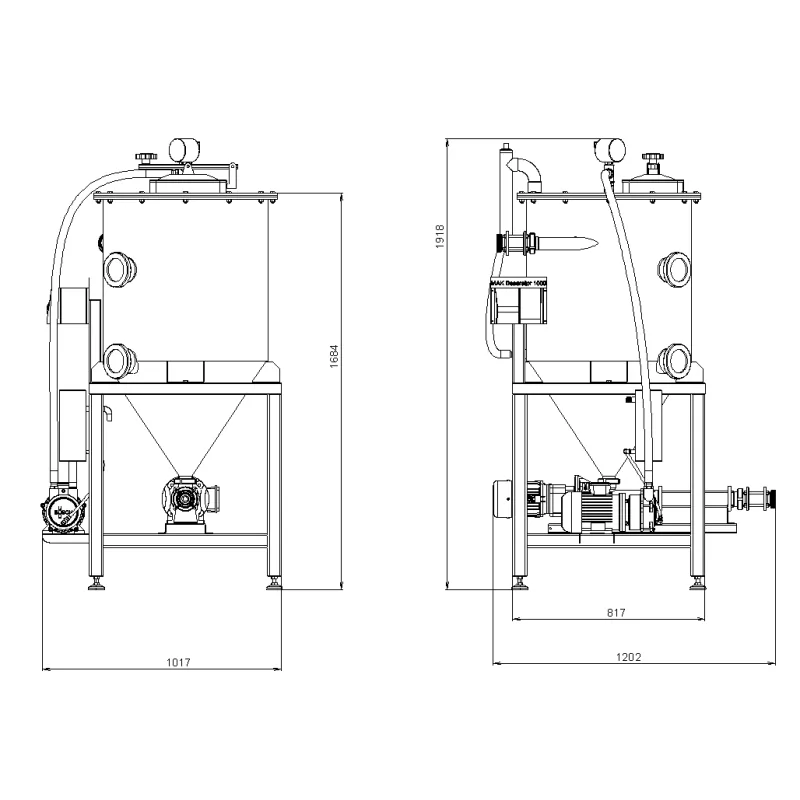

Basic version

The basic equipment package comprises a conical vacuum chamber on a supporting structure, equipped with a specialized vacuum pump for compressed air (a vacuum ejector) and a special screw pump. Two small windows are installed on the vacuum chamber for visual monitoring of the deaeration process, while the upper housing features a service vacuum hatch. Control is managed by a pump-product frequency converter.

Operation principle

The primary benefit of the deaerator is its capacity for the thermal treatment of hot raw materials under reduced pressure conditions (vacuum). The product is introduced into the evaporation chamber, where it spreads evenly in a thin layer along the walls, due to a special tangential feeding system. When moisture and bubbles of air and gases within the product's cavities enter a vacuum, they rapidly disappear and are drawn out of the installation. This process effectively removes odors, foam, excess moisture, and air pockets from the product.

Options

- Liquid ring pump for the rapid creation of a high vacuum

- Vacuum depth adjustment

- Product spray system in a vacuum chamber

- Transparent flow-through inspection section at the product inlet and outlet of the vacuum chamber

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Max vacuum: -0,8 Bar