Vacuum

The price is set based on the basic built-in heating option of 24 kW.

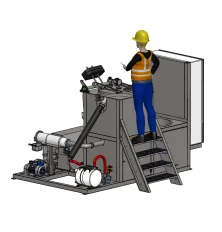

The vacuum fryer is designed for frying foods in oil at low temperatures, allowing for the production of healthy snacks such as vegetable and fruit chips. The vacuum feature enables you to reduce the frying temperature of oil down to 110-120 degrees!

- «Cold roast» is a tasty and healthy method of processing the product

- Drying and frying without caramelizing the sugars contained in the product

- Large frying tank - for processing foods with a higher water content

- Modular heating system which allows you to increase the heating power up to 108 kW (optional)

- Circulating heating of oil through a heat exchanger minimizes oil spoilage and prevents localized overheating

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l

- Oil volume: 200l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The price is indicated with a semi-automatic control panel

The vacuum kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing, or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 10l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The VFB vacuum fryer with a built-in blancher is intended for drying and frying a wide range of products as well as for the production of chips and crisps from potatoes, carrots, onions, celery, parsley, beetroot and many other types of fruits, vegetables, and different snacks made out of meat, pork skin and fish.

A vacuum frying unit designed for frying vegetables and other snacks at low temperatures, thus making them healthier and less saturated with oil.