BURGERS

Production line for vegetarian vegetable-based formed or molded products such as falafel. The line is based on the classical method of producing semi-finished products for their subsequent freezing and packaging.

- Compact line suitable for both professional kitchens and industrial production.

- Fully automatic operation with minimal manual labor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

The price is set for the combination of a basic fryer model and an additional module with rotating paddles.

The universal modular fryer equipped with an additional paddle module is designed for frying thin slices of products that require immersion beneath the oil level.

- Adjustable frying time from a few seconds up to an hour

- Compact, tabletop version

- The paddle conveyor is installed on top of the basic fryer

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

For additional information, please contact us at sales@foodtechprocess.com

Fast, sleek, quiet, user-friendly, safe, smooth-running commercial salad dryer, designed to efficiently dry up to 6 Kg.

For more information, send us a request at sales@foodtechprocess.com

The price is indicated without the frequency converter

A twin-screw mixer for fast and intensive mixing, stirring of bulk solid products, such as granules, muesli with various powder additives.

- The mixing blades carefully move while thoroughly mixing the product

- The mixing mode allows you to move the product cyclically in a circle

- High mixing efficiency due to the counter-movement of the 2 shafts

- Compact design

- Possibility to install scrapers on each blade (optional)

- Reinforced drive, can be used for products saturated with moisture as well

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 500l

- Total power, kW: 3

The forming device guarantees precise shaping of a wide range of food mixtures.

For a price quote, send us an email to┬Āsales@foodtechprocess.com┬Ā

Batter breading machines are designed for batter breading products such as meatball, hamburgers, soya, vegetarian burgers, croquettes, vegetables and other products. The machine is suitable for catering companies as well as big productions.

For more information, write to us at┬Āsales@foodtechprocess.com

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. The price depends on the product as well as the size of the conveyor.

For more information, send us an email at sales@foodtechprocess.com

An air cooling conveyor is used to rapidly cool products in food processing industries by circulating cool air over them as they move along a conveyor belt. This efficient cooling process helps preserve product quality and reduce the time between processing stages, facilitating smoother production workflows.

For a price quote or a free consultation, send us an email to sales@foodtechprocess.com

Grinding mill for continuous grinding of meat and ingredients such as seeds, small bones and cartilages that are unwanted in the final product.

For more information, send us an email at sales@foodtechprocess.com

EcoFry is designed for frying onion rings, seafood, dumplings, spring rolls, pies, vegetables, nuggets and hamburgers with the help of pouring hot oil. A smaller capacity, efficient frying equipment intended for small to medium sized┬Āproduction facilities.

For a quote, please send us an email at┬Āsales@foodtechprocess.com

The series of Continuous Fryers Pour Oil is the boom in the market of frying and roasting equipment. The new construction designed by our engineers, based on existing practical experience in the production and use of conveyor fryers, provides the best example of environmental friendliness.┬Ā

For more information please email┬Āsales@foodtechprocess.com

The continuous pouring fryer is designed to fry meat, fish, vegetables and pasta products as well as chicken drumsticks, cutlets, nuggets, croutons, sliced zucchini or eggplant, and etc. using immersion frying and hot oil pouring methods.

For more information please send us an email at┬Āsales@foodtechprocess.com

Our continuous fryer is designed for frying cutlets, potatoes, meatballs, croquettes, fish, vegetables and many other products. Working volume up to l: 300 l.

For a price quote, send us an email to sales@foodtechprocess.com

A pouring fryer is a specialized equipment used in commercial kitchens for frying foods using a continuous pouring method. It offers precise control over the frying process by continuously pouring oil over the food, ensuring even cooking and consistent results.

Price depends on the chosen option. Please email sales@foodtechprocess.com

Vacuum diffusion - the process in which the air inside the product is removed by vacuum and the released pores are filled with flavor, vitamins or other ingredients.

For a price quote, send us an email to sales@foodtechprocess.com┬Ā

We offer different types of meat stuffing machine for domestic and commercial use. For more information, send us an email to sales@foodtechprocess.com

This is a filling machine for stuffing meat. We offer many different dosing machines for different applications. For more information, send us an email to sales@foodtechprocess.com┬Ā

Mechanical vacuum filler, regulated by electronic system, with frequency converter.

We offer different hopper capacities, for a price quote or a free consultation, send us an email to sales@foodtechprocess.com┬Ā

We can help you choose the┬Āright continuous fryer suited for your needs. For a free consultation or a quote, please send us an email at┬Āsales@foodtechprocess.com

We sell different types of deep fryers, for a price quote or for a free consultation, send us an email to sales@foodtechprocess.com┬Ā

USED PRODUCT - 1 LEFT IN STOCK

Continuous deep fryer OIL MINI is designed for gastronomy and catering. It is ideal for deep frying of meat, ravioli, meatballs, seafood, poultry and vegetables. It ensures continuous frying and stable frying results. The heating elements are located in a double thick aluminum bottom, the so-called "sandwich bottom", which prevents the product from sticking to the heating elements and burning, thus you can use the oil many times more!

Basic price - 5960Ōé¼. The possibility of adding an oil spraying module (combifry), for an additional cost of 3980 Ōé¼ (RECOMMENDED OPTION)

For more information please email us at sales@foodtechprocess.com

We have various types of continuous or batch fryers. Just tell us what kind of product you wish to fry and we will help you choose the right deep fryer.

For a quote or additional information, send us an email at sales@foodtechprocess.com

Hydraulic sausage filling machine is the ideal equipment to fill sausage of various specifications and is suitable for filling in different kinds of casings. We offer different meat processing machines, for more information, send us an email to sales@foodtechprocess.com

It is possible to order tubs with four perforated walls and bottom, with or without outlet drain or with a tap. For more information, email us at sales@foodtechprocess.com┬Ā┬Ā

Vacuum tumblers are designed to remove air and draw moisture and marinade into the meat.┬Ā

Vacuum tumblers are designed to remove air and draw moisture and marinade into the meat.┬Ā

Vacuum paddle mixers are designed for fast and precise mixing meat-mass in a vacuum. Used in meat production in meat processing factories.┬Ā

Grinder is used for grinding both fresh meat and food products, such as cheese, fruits.┬Ā

Paddle Mixer type is designed for fast and precise mixing for meat-mass production in meat processing factories. Can also be used for mixing products such as spices or tea.

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product as well as size of the conveyor.

The VFB vacuum fryer with a built-in blancher is intended for drying and frying a wide range of products as well as for the production of chips and crisps from potatoes, carrots, onions, celery, parsley, beetroot and many other types of fruits, vegetables, and different snacks made out of meat, pork skin and fish.

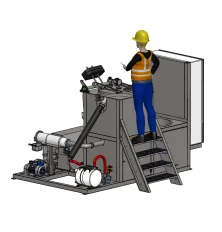

Hamburger production line is designed for production of hamburgers, veggie burgers or soy-based burgers. The line produces from 2.000 up to 6.000 hamburgers per hour. Price depends on production.

Batter breading machines are designed for breading products such as meatball, hamburgers, soya, vegetarian burgers, croquettes, vegetables and other products in batter and breadcrumbs. Whether you are a small kitchen or have bigger production capacity, we are able to offer complete solution.

Batter breading machines are designed for batter breading products such as meatball, hamburgers, soya, vegetarian burgers, croquettes, vegetables and other products. Whether you are a small kitchen or have bigger production capacity, we are able to offer complete solution.

The price depends on your production capacity.┬Ā

Air cooling conveyor with MULTI AIR KNIFE is a system for┬Ā intensive┬Āremoving excess water or oil and preliminary cooling.┬Ā

Suitable for mixing a small amount of dough or meat as well as other thick media.