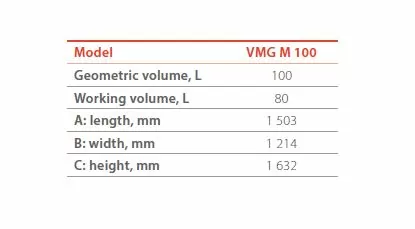

Vacuum homogenizer VMG M 100

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

For additional information, please contact us at sales@foodtechprocess.com

Thanks to its favorable price and versatility in the produced types of products, it is an optimal solution for start-ups and production of pilot batches of production, preparation of recipes and testing of new types of production.

PROCESSES:

- heating

- cooling

- mixing

- deaeration

- dispersion

- emulsification

- homogenization

- deaeration

APPLICATIONS IN VARIOUS INDUSTRIES:

- Milk - soft curd, kefir, condensed milk, reconstituted (restored) milk powder, cream.

- Fats - blend of oils, margarines, mayonnaise, pastes.

- Fruits and vegetables - jams, ketchup, ketchup, sauces, overcoats, puree, pastes, baby food.

- Confectionery - creams, filling, chocolate-nut paste, chocolate glaze, honey.

- Non-alcoholic beverages - juices, nectars, beverages.

- Cosmetics - creams, shampoos, balms, gels, ointments, toothpastes.

- Pharmaceuticals - ointments, emulsions, gels.

- Chemicals - detergents, adhesives, varnishes, polishes, disinfectants.

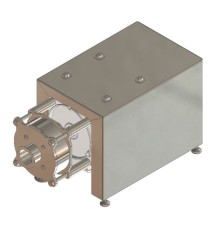

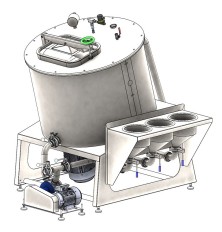

The structure of the device consists of a working container equipped with an insulating layer and a heating / cooling jacket. The slow-moving agitator with scraper has a top drive. On the day of the working vessel is an integrated homogenizer with the rotor-stator principle. Vessel mounted on rotatable supports with fixator, product unloading is secured by tilting the container (with manual or mechanical drive depending on vessel volume). The lid is easily disengaged (manually or with the help of gas-filled silencers installed at the rear) and sealed in its closed position by four clamps.

Depending on the customer's needs, different levels of automation can be selected: weighing and dosing of raw materials, control of heating and cooling temperatures, melting, emulsification, homogenization, agitator speed control and vacuum.

Vacuum - the air removal process allows you to lower the product processing temperature, maximally maintaining its performance properties.

Mixing - a special shape stirrer and worktop geometry ensure a uniform mixing of the product without dead zones. Thanks to special "floating" scrapers, the product does not blend into the walls of the container and also helps to maximize heat or cold heat exchange from the walls to the thin film product.

Homogenization - The integrated rotor-stator homogenizer at the bottom of the vessel ensures fast and efficient dispersion, emulsification and homogenization with a particle size of up to 3 microns (even smaller on demand). The product obtained has an appealing external appearance, a stable and homogeneous structure, does not separate and has a long shelf life. By means of the homogenizer, recirculation and discharging of the product are also ensured, it is not necessary to use additional pumps, which increases the hygiene and ease of maintenance of the device.

Heating and cooling - the heating and cooling jacket allows heating, melting, cooling to be carried out in one installation. Optionally, "direct injection of steam into the product" allows significant reduction of the heating time and shorter product processing time. The automated management system eliminates the human factor and guarantees a consistently high quality finished product from batch to batch.

ADVANTAGES OF VACUUM MIXERS - HOMOGENIZERS

- Low purchasing costs for equipment purchases, suitable for novice entrepreneurs, for processing new prescriptions and for production of pilot production batches.

- Minimum filling of 15% of container volume

- High performance

- Reliable construction and long trouble-free operation

- Fast transition to new product type

- Simple operation, maintenance and sanitation

- Low operating costs

- Low noise

Options

- Inserting additional ingredients into the homogenizer vacuum chamber

- The funnel for inserting components into the container during the working cycle

- Tilting the container

- Lid fitted with gas-filled silencers

- Various types of stirrers

- Adjustable rotational speed of the agitator

- Sharp steam into the product

- Different levels of automation GMP version

- A set of validation dossiers for use in the pharmaceutical industry

You might also like

A professional mixer for the production of mayonnaise, sauces, soups and other homogenized products. The price depends on your production capacity, as well as the technological requirements.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 200l

- Total power, kW: 6

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

We produce atmospheric honey homogenizers with a batch load ranging from 7500 up to 22 000 kg of honey. The homogenizers HPL are designed for thoroughly mixing, blending, and homogenizing various kinds of honey to improve its qualities.

The price depends on the options you choose.┬Ā

The butter texturizer FBHG is intended for mechanical processing of frozen blocks of butter, animal fat, margarine and other plan fats, without prior defrosting.

For more information about our homogenizers, please email us at┬Āsales@foodtechprocess.com

The homogenizer is designed to homogenize, mix and disintegrate / grind different fluids and components into small particles.

For a price quote, send us an email at sales@foodtechprocess.com

The homogenization of butter is carried out in order to improve the butter's consistency and taste stability under storage conditions.

For more information regarding our homogenizers, please email us at sales@foodtechprocess.com

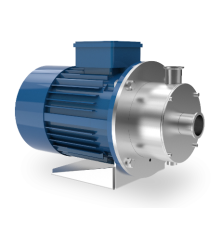

The inline homogenizer is designed for mixing, emulsifying, dispersing, and homogenizing thick and viscous products in the production of mayonnaise, soy milk, toothpaste, yogurt, and much more. It can be installed in an external circulation circuit of reactors, production lines, or used independently with a loading hopper for processing small volumes of products.

- Creates stable emulsions and suspensions

- Reduces particle size

- Quickly dissolves solids

- Accelerates chemical reactions

- Does not require an additional pump

- Material: Stainless steel

- Engine power, kW: 5,5/ 7,5/ 9/ 11/ 15

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The VMG S 650P vacuum homogenizing unit can be used for making toothpaste as well as a variety of similar products with complex production requirements.

- The vacuum ensures effective air removal, eliminating the conditions for the development of bacteria and other pathogenic organisms.

- The special shape of the mixing device is tailored for the thickest and most viscous products.┬Ā

- The Ultra Shear submersible homogenizer creates a stable emulsion.

- The cavitation processes aid in activating hydrodynamic mixing.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 29

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 52

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Inline Yumix Basic homogenizers have the lowest price in the range of YUMIX homogenizers and models range from 1.1 to 3 kW.

For more information on the device, contact the company's sales department at sales@foodtechprocess.com

Multifunctional vacuum mixer/homogenizer for grinding, mixing, and homogenizing products to obtain homogeneous masses.

- Built-in jacket for the bottom and walls of the unit.

- Cutter knives with a powerful electric drive

- Slanted design for efficient mixing and chopping

- Forced circulation circuit (optional)

- Wide range of options

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350l/ 650l

- Total power, kW: 13/ 17

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Vacuum mixer processing plant for viscous products is an ideal solution for the production of pilot batches and the industrial manufacturing of a wide range of products from small to medium capacity.

The mixers are made up of a double-walled cylindrical stainless steel vessel with cavity, with drain hole and 50 cm diameter butterfly valve. The cavity is filled with water which is heated by an electric resistance thermostat. The honey is mixed by blades with a marine propeller profile, adjustable in height along an oblique shaft.┬Ā

For a price quote, send us an email to┬Āsales@foodtechprocess.com┬Ā

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

For a price quote, send us an email to sales@foodtechprocess.com

Homogenizer for the production of whipped cream, ice cream, and much more. It allows you to obtain stable liquid emulsions of food mixtures.

- The homogenizer can be installed directly into the container with the product

- High productivity - in just 8 minutes, it is possible to whip up to 60 liters of milk mixture

- The peripheral speed of the knives is 16 m/s

- Engine power, kW: 0,37/ 2,2

- Voltage: 380-400V

A professional mixer for the production of mayonnaise, sauces, soups and other homogenized products. The price depends on your production capacity, as well as the technological requirements.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 200l

- Total power, kW: 6

The price is indicated for the basic version of the vacuum reactor without additional options, the final cost depends on the modifications

The vacuum homogenizer is an ideal solution for the production of food, for example mayonnaise, it is also suitable for the cosmetics industry - the production of toothpaste. This model of the homogenizer is based on a vacuum reactor with an external homogenizer and an external circulation circuit, the parameters of which are selected as options.

- Tilted design - 25% more efficient mixing

- Easily disassembled reinforced frame mixer, for thick and viscous products

- Jacket for the coolant around the bottom and walls of the working reactor

- The vacuum reactor can withstand a vacuum up to -0.8 Bar

- A large number of options to choose from to suit various requirements

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 650l

- Total power, kW: 0,55

- Voltage: 380-400V

- Max vacuum: -0,8 Bar