Hydrodynamic extraction line

Our hydrodynamic extraction line is designed for extracting various components from plant materials, including biologically active substances, proteins, fats, carbohydrates, antioxidants, dyes, and flavors.

- Effective ‚Äúsoft‚ÄĚ continuous hydrodynamic extraction ‚Äď percolation from finely crushed raw materials.

- Extraction without the need for pre-drying the product, resulting in savings on labor and energy costs.

- Utilizing raw materials without heat treatment, preserving all of their valuable substances and enzymes.

- Possibility of performing vacuum-pulse extraction (optional).

- Additional income from processing ‚Äúwaste‚ÄĚ products - extracting valuable components from pulp and pomace.

Extractors and extraction lines are widely used in the food, cosmetic, and pharmaceutical industries for the production of medicinal food additives, essential oils, syrups, and other natural bioresources to support immunity and promote health.

The extraction line can be used to process products such as:

|

|

|

|

|

|

|

|

|

|

|

|

Advantages:

- The comprehensive process of ¬ęsoft¬Ľ hydrodynamic natural extraction, without the use of chemical activators, avoids preliminary thermal processing of the product and ensures the preservation of cytolytic enzymes, which would be destroyed if the product were pre-dried.

- The technology of complete liquid vacuum-pulse extraction, based on this production line, enables the production of concentrated extracts using a pulsating vacuum in the extractor, whether on a water or alcohol basis. This technology is particularly useful for heat-sensitive products, preventing their breakdown at elevated temperatures.

- The installations are designed without dead zones or corners, ensuring high hygiene standards during both processing and subsequent cleaning.

- All equipment is manufactured following high standards for treating internal product contact surfaces, meeting the requirements for use in the cosmetics and pharmaceutical industries.

Basic version of the complex

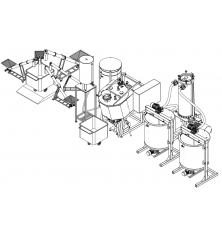

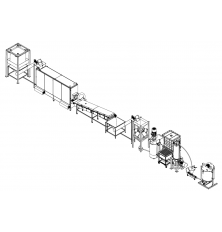

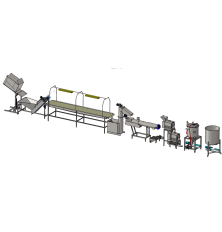

The complex of equipment for hydrodynamic extraction includes:

Raw material grinding Station. When working with raw materials, so-called destoning machines can be utilized to obtain a porridge-like mass for extraction. When processing dry ingredients such as leaves and herbs, a knife mill is usually used for grinding. The grinding process is necessary for any form of extraction, as it allows for a high degree of separation of the raw material.

After grinding, the extraction phase is carried out directly; if the processing recipe requires heating, an atmospheric 2-layer reactor (optional) with an external circulation circuit and flow heating through a heat exchanger (optional) is used. Steam from an external source can be provided as a coolant (optional). The reactor can also be equipped with a frame mixing device (optional). In this case, the heated working fluid (solvent) is supplied into the extractor from an atmospheric reactor using a pump; this process can be carried out cyclically to obtain the required degree of extraction.

In cold extraction, the crushed product is loaded into an extractor, which is already pre-filled with the working fluid.

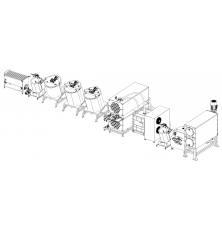

For hydrodynamic extraction, either a separate (independent)¬†flow extractor¬†or a ‚Äúdouble‚ÄĚ system where the extractors can operate in parallel, sequentially, or in circuit mode, depending on production requirements can be installed.

For vacuum-pulse extraction, vacuum reactors with a pulsating vacuum are used, which can also be used to saturate products with various solutions.

After obtaining a saturated solution of the extracted product, it is necessary to boil it to the required concentration of dry substances. For this purpose, a vacuum evaporation unit with a remote forced heating circuit is utilized where a heat exchanger is installed. The vacuum evaporation unit is equipped with a vacuum system, a condensate collection and removal system, which allows the solvent to evaporate at low temperatures.

After obtaining a concentrated extract, it can be fed into a flow pasteurizer.

The flow-through pasteurizer facilitates the heating and subsequent cooling of the dense extract in a continuous flow without air access, allowing the pasteurized mixture to be dispensed directly for the aseptic bottling of the final product.

The level of modification for the complex depends on the product recipe as well as the desired degree of process automation.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia