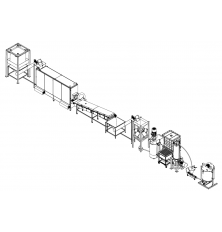

Hydrodynamic extraction line

Our hydrodynamic extraction line is designed for extracting various components from plant materials, including biologically active substances, proteins, fats, carbohydrates, antioxidants, dyes, and flavors.

- Effective ‚Äúsoft‚ÄĚ continuous hydrodynamic extraction ‚Äď percolation from finely crushed raw materials.

- Extraction without the need for pre-drying the product, resulting in savings on labor and energy costs.

- Utilizing raw materials without heat treatment, preserving all of their valuable substances and enzymes.

- Possibility of performing vacuum-pulse extraction (optional).

- Additional income from processing ‚Äúwaste‚ÄĚ products - extracting valuable components from pulp and pomace.

Extractors and extraction lines are widely used in the food, cosmetic, and pharmaceutical industries for the production of medicinal food additives, essential oils, syrups, and other natural bioresources to support immunity and promote health.

The extraction line can be used to process products such as:

|

|

|

|

|

|

|

|

|

|

|

|

Advantages:

- The comprehensive process of ¬ęsoft¬Ľ hydrodynamic natural extraction, without the use of chemical activators, avoids preliminary thermal processing of the product and ensures the preservation of cytolytic enzymes, which would be destroyed if the product were pre-dried.

- The technology of complete liquid vacuum-pulse extraction, based on this production line, enables the production of concentrated extracts using a pulsating vacuum in the extractor, whether on a water or alcohol basis. This technology is particularly useful for heat-sensitive products, preventing their breakdown at elevated temperatures.

- The installations are designed without dead zones or corners, ensuring high hygiene standards during both processing and subsequent cleaning.

- All equipment is manufactured following high standards for treating internal product contact surfaces, meeting the requirements for use in the cosmetics and pharmaceutical industries.

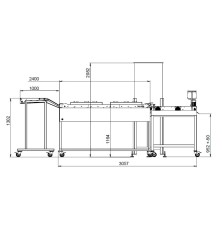

Basic version of the complex

The complex of equipment for hydrodynamic extraction includes:

Raw material grinding Station. When working with raw materials, so-called destoning machines can be utilized to obtain a porridge-like mass for extraction. When processing dry ingredients such as leaves and herbs, a knife mill is usually used for grinding. The grinding process is necessary for any form of extraction, as it allows for a high degree of separation of the raw material.

After grinding, the extraction phase is carried out directly; if the processing recipe requires heating, an atmospheric 2-layer reactor (optional) with an external circulation circuit and flow heating through a heat exchanger (optional) is used. Steam from an external source can be provided as a coolant (optional). The reactor can also be equipped with a frame mixing device (optional). In this case, the heated working fluid (solvent) is supplied into the extractor from an atmospheric reactor using a pump; this process can be carried out cyclically to obtain the required degree of extraction.

In cold extraction, the crushed product is loaded into an extractor, which is already pre-filled with the working fluid.

For hydrodynamic extraction, either a separate (independent)¬†flow extractor¬†or a ‚Äúdouble‚ÄĚ system where the extractors can operate in parallel, sequentially, or in circuit mode, depending on production requirements can be installed.

For vacuum-pulse extraction, vacuum reactors with a pulsating vacuum are used, which can also be used to saturate products with various solutions.

After obtaining a saturated solution of the extracted product, it is necessary to boil it to the required concentration of dry substances. For this purpose, a vacuum evaporation unit with a remote forced heating circuit is utilized where a heat exchanger is installed. The vacuum evaporation unit is equipped with a vacuum system, a condensate collection and removal system, which allows the solvent to evaporate at low temperatures.

After obtaining a concentrated extract, it can be fed into a flow pasteurizer.

The flow-through pasteurizer facilitates the heating and subsequent cooling of the dense extract in a continuous flow without air access, allowing the pasteurized mixture to be dispensed directly for the aseptic bottling of the final product.

The level of modification for the complex depends on the product recipe as well as the desired degree of process automation.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

You might also like

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The price is set for the basic version of the vacuum evaporation unit with basic controls (mixer motor switch) and without additional options. The control unit is customized based on individual customer requirements. The pump is also selected separately depending on the product.

A compact vacuum evaporation unit that allows you to concentrate solutions, mixtures, and various products by evaporating the solvent. A modular version based on the basic version of the 110/100 vacuum reactor.

- Gravity mixing - 25% more efficient

- Reinforced agitator design with no blind spots

- Bottom ball valve with no dead zones

- Condensation and secondary vapor removal system

- Easy to disassemble mixing device

- Large heat exchange area

- Ability to measure and monitor condensate volume (optional)

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

- Condensing capacity, l/h: 45-55

- Steam consumption, kg/h: up to 150

Used for blanching products in water, it is suitable for processing various vegetables, legumes, grains, mushrooms and other products. This versatile machine also functions as a water separator centrifuge which is activated after the blanching processes.

- Productivity: 30l/ 90l

- Material: Stainless steel

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

An equipment complex designed for processing raw, peeled, and blanched peanuts, offering a production capacity of up to 500 kg/hour.

- Productivity: 500 kg/h/

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The set of individual equipment for the production of French fries may differ depending on the initial raw materials. We offer various modifications from washing to frying with subsequent dehumidification starting from 50 kg/h for the final product.

- Principle of operation: Continuous mode

- Country of origin: Slovakia

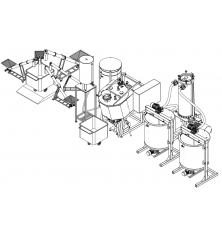

This equipment complex enables the production of Nutella-type chocolate pastes with a capacity of up to 250 kg/h.

- Material: Stainless steel

- Country of origin: Slovakia

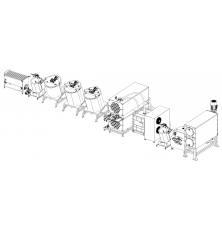

The continuous production line for deep-frying and the subsequent cooling of semi-finished products includes:

- modular deep fryer with the option of choosing the conveyor type: a secondary conveyor for forced immersion of the product in oil or a conveyor with paddles for frying light floating products, such as chips;

- stainless steel table under the deep fryer with the option of installing an oil container and an oil filtration system inside it;

- cooling conveyor for removing excess oil and surface cooling of the product after frying it in the deep fryer.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

Production line for vegetarian vegetable-based formed or molded products such as falafel. The line is based on the classical method of producing semi-finished products for their subsequent freezing and packaging.

- Compact line suitable for both professional kitchens and industrial production.

- Fully automatic operation with minimal manual labor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

The concentration and thickening line line has been especially designed for industrial dairy production facilities with a small surplus of milk or smaller milk processing businesses that want to expand their product range. It has an estimated productivity of up to 50-120 kg/hour during continuous operation.

- Professional industrial technology with compact dimensions

- A large number of additional equipment and options to choose from

- Material: Stainless steel

- Principle of operation: Continuous mode

Complete set of equipment for processing shelled beans, and the production of a soy base with a capacity of 800-1000 liters per hour.

- Productivity: 800 l/h

- Material: Stainless steel

- Country of origin: Slovakia

The hamburger production line is designed for the production of hamburgers, veggie burgers or soy-based burgers. The line produces from 2.000 up to 6.000 hamburgers per hour. Price depends on the production requirements.

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Voltage: 220-230V

Equipment for the production of condensed milk from pre-pasteurized milk. This equipment can be manufactured with a capacity of 50 to 500 kg/hour, or on request. We also manufacture condensed milk lines according to TU from dry milk or normalized milk concentration lines.

- Material: Stainless steel

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

A production line for thermostable fruit-based fillings, widely used in the production of pastries, baked goods, and various semi-finished products, as well as curd cheeses, creams, and even ice cream.

- Obtaining top-notch thermostable fillings while preserving essential nutrients and vitamins.

- Compact system featuring a unified control panel, ensuring easy and straightforward operation.

- Swift and efficient recycling included as a standard feature.

- Modular design with numerous additional options for customization.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

A complete set of equipment for the production of margarine with a capacity of up to 500 kg/hour.

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

We offer equipment for processes such as: honey dissolution, honey drying, honey homogenization, honey pasteurization, honey creaming and honey packaging. The necessary equipment is selected by the customer based on the required processing technology for their manufacturing process.

- Material: Stainless steel

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

The extended version of the modular conveyor fryer with a large number of optional accessories, significantly expands the production capacity for deep-frying various products by increasing both the frying area and heating power.

- Frying time can be adjusted from several minutes up to an hour!

- Overheating safety sensors are installed on each heating element

- Compact support structure on a mobile support

- Fine-mesh conveyor grid allows for frying small and fragile products

- A large number of additional options in the form of automatic oil top-up system, loading conveyor, filtration system, cooling conveyor, etc.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

Meatball production line comprises of a filler, automatic machine for making meatballs and batter-breading machine. Price depends on your production capacity.

- Productivity: 15 000

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

This set of equipment for the production of condensed milk from dry components by restoring the milk. This production line can be manufactured with a capacity of up to 500 kg/h or can be customized based on specific requirements.

- Material: Stainless steel

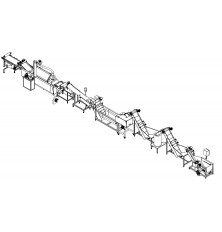

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode