Electric cooker with cooling model MKC

A modern cooking and mixing device with a wide range of applications in confectionery, bakeries, catering establishments.

Cream cookers are a family of very popular food processing machines suitable for cooking, mixing and preparing various products for bakeries, confectionery and other food oriented businesses.

Using the bain-marie concept, excellent results can be achieved in final products such as jam, marmalade, chocolate, various creams, puff pastry marzipan, etc.

- The universal kettle are offered with tank capacities from 30 to 500 liters with various options to customize according to the requirements of each client.

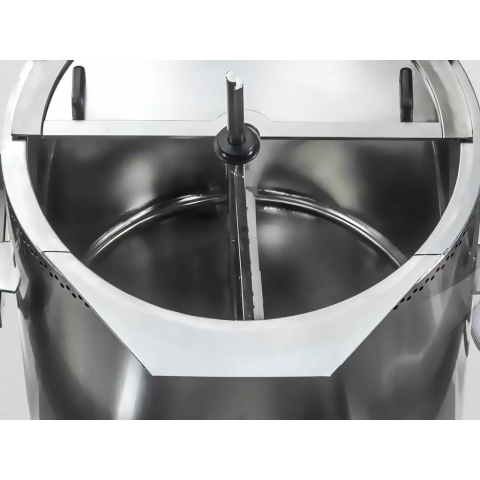

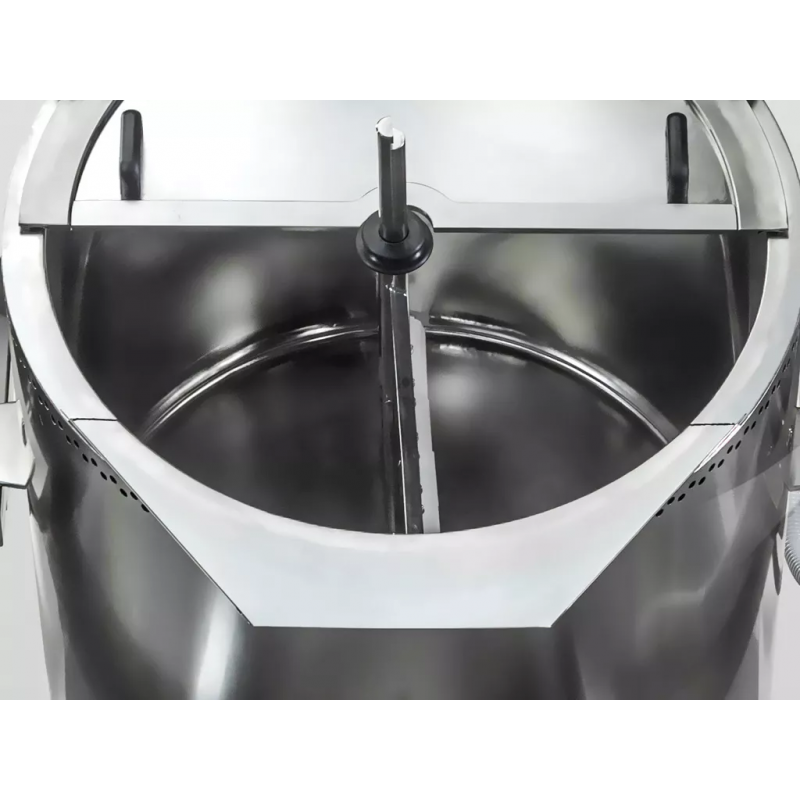

- Special mixing tools with side and bottom scrapers.

- Timer and temperature controller are included as standard.

- Special lid with a small hopper for checking the product or adding ingredients without stopping the machine.

- Easy emptying of the bowl by rotating the wheel to tip the bowl with a stop in any position of the bowl or by using the crane (optional).

- The 200, 300 and 500 liter kettles are fitted as standard with variable speed agitator, motorized bowl tipping system and bowl tap.

- Electric universal kettle from 30 to 500 liters with a cooling system - model MKC.

Special electrical unit that heats and stirs at the same time with the additional option of cooling the finished product. Mass cooling with glycol in a closed circuit, which circulates between the kettle and the cooler as needed. The machine can heat and cool the product. The coolant is glycol. The maximum heating temperature is limited to 90C. Glycol cooling temperature down to 1┬░C. Control panel with heating/cooling switch. Glycol circulation pump, connecting pipes and glycol cooler are supplied with the machine.

It is the most popular and suitable installation for large bakeries, confectionery and food industries.

The bain-marie concept always delivers excellent and expected results. This model has a wide range of standard equipment such as a working timer, temperature controller, adjustable stirrer speed (inverter), motorized and easy-to-use kettle tipping system, and a DN-80 hygienic detachable bowl tap. Depending on actual needs, 33%/66% or 100% heating power can be used. This is a very useful feature that has a great impact on cost reduction. The maximum standard temperature is 90┬░C but can be increased upon request.

The kettle is entirely made of high quality stainless steel, very durable and designed for heavy duty industrial applications.

The lid of the bowl has a small window for adding ingredients or checking the product without stopping the machine. The bowl lid, grate lid and right upright bowl position are protected by sensors so it is not possible to start a machine that is not ready for use. You can choose between standard or special double mix tools. Both tools are equipped with side and bottom scrapers. The electrical system has a phase regulator to always control the correct rotation of the mixing tool. The body of the machine is made for use with a standard pump rack, making it easy to move.

Cooker with cooling system:

MKS series machines are designed for the production and preparation of choux pastry, confectionery creams, chocolate, fondant, jams, pancakes, fillings, various mixtures according to original recipes, as well as for any product that requires uniform heating and smooth mixing. Often used in confectioneries and bakeries.

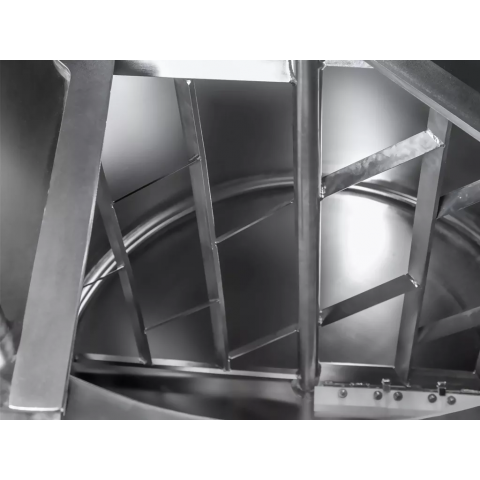

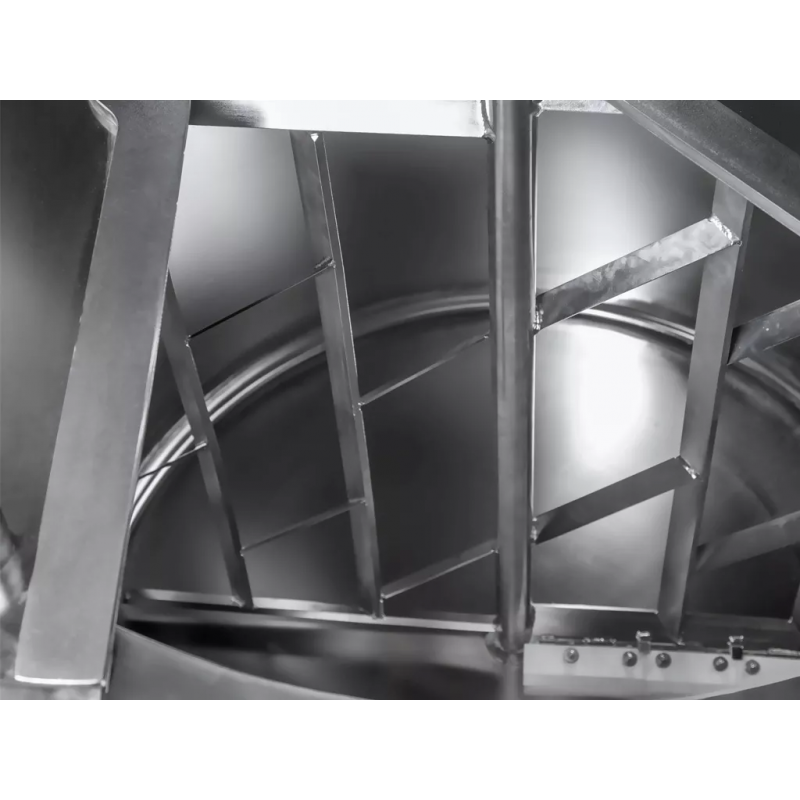

The mixing process is carried out by mixing tools with side and bottom scrapers, which prevent sticking and burning of the mixture. Scrapers are designed to collect layers of mixture from the walls and bottom of the bowl.

- Quick scraper removal system with no tools to clean or replace

- Thermal oil, poured between two layers of the jacket, provides an even distribution of heat, safe for the product during operation.

- The outer, third layer of the bowl prevents heat loss from the machine.

- 2 working speeds (variable on request)

- Maximum temperature up to 90┬░C

- All parts which are in contact with food are made of high quality acid-resistant steel or food-grade materials.

- Tilting bowl with a stop in any position for easy emptying and cleaning - rotating wheel for MK-30,60,80,120 and motorized for MK-200/300/500

- Bowl lid with viewing funnel to monitor the process and add ingredients without having to stop the machine.

- All important electrical components are housed inside the electrical box on the side of the machine to prevent smoke and high temperatures.

- Timer - manual or automatic operation

- Safety thermal switch protects against overheating,

- Ball valve DN-80 - standard for machines of the MK-200/300 and 500 series.

- Each machine can be supplied with a bowl tap

- Heating and cooling with glycol

- Cooling of the finished mixture in a short time

Additional configuration:

- Variable speed (inverter) ŌĆō standard on MK-200/300 and 500

- Fan cooling system - available on all models.

- Lid/bowl grid - available for all models.

- Special double mixer - available for all models.

- LCD - 7' - fully programmable control panel with recipes

- Laser product temperature sensor.