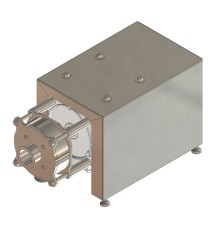

The professional mixer designed for the production of mayonnaise, sauces, cream soups and other homogenized products is made out of high quality AISI 304 stainless steel with a single-piece conical bottom design, a flat ┬Ż opening lid and a special SCRAPER MIXER equipped with Teflon scrapers.

The Teflon scrapers effectively scrub the product from the sides of the container to ensure maximum processing efficiency of the product as well as to make cleaning and maintenance easier.

Homogenization of the product is ensured by a built-in homogenizer (located outside of the vessel) operating on the rotor-stator principle. This model is suitable for the production of emulsions and suspensions with a wide range of viscosities. The homogenizer serves a dual purpose, acting both as a pump and as a means to introduce the product into the container. This enables the simultaneous homogenization of the product during its transfer from the container.

Step 1

The high speed of the rotor induces agitation, the strong vacuum ensures that the liquid, non-homogenized mixture is pumped into the rotor/stator.

Step 2

Centrifugal force drives the product around the circumference of the working head, where the product is mixed.

Step 3

The product is vigorously agitated at high speed, the product enters the pipeline through the holes in the stator. At the same time, the product is pumped into the working head and the mixing cycle is repeated.

The SCRAPER MIXER is driven by a geared motor. The mixer is made out of stainless steel. Push-button control cabinet.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 200l

- Total power, kW: 6

You might also like

The price depends on the selected modifications and specific options

The plow mixer is often used in the food, pharmaceutical, and chemical industries for mixing and saturating powder products with liquid media in order to obtain a high-quality mixture.

- High intensity and quality of mixing, stirring

- Short mixing time and a high productivity

- Guaranteed repeatability and reproducibility of the product batches

- Gentle handling of the product due to the mixing device's special plows

- A large number of options to choose from to fit a specific product type

- Air Purge Seals

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 700l/ 1200l/ 1800l

- Voltage: 380-400V

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

For additional information, please contact us at sales@foodtechprocess.com

Tilting pans with mixers cook the product with continuous stirring and subsequently discharge the food into receiving trolleys, ensuring the discharge spout remains at a constant height from the ground. Designed for the catering industry, large kitchens, school cafeterias, restaurants, and other food production businesses.

The price is set for the basic version of the installation for making plant milk without a steam generator

The Veggie Milk cooking kettle is used as a unit for hydrodynamic thermal extraction of substances from legumes and nuts to create a finished suspension - the basis of plant based drinks.

- Efficient and fast extraction

- Partial pasteurization due to direct steam injection

- High-powered bottom homogenizer

- Hydrodynamic mixing

- Mechanical shaft seal for the homogenizer with an open cooling system

- Safety grid on the hatch cover for safe product loading

- Sectional plexiglass hatch for visual inspection

- Capacity: 600 kg/h for soybeans

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 120l

- Total power, kW: 7,5

- Voltage: 380-400V

Cena z├ívis├ş na po┼żadovan├ę kapacit─Ť. Pro dal┼í├ş informace nebo cenovou nab├şdku n├ím za┼ílete e-mail na adresu sales@foodtechprocess.com

Sm─Ť┼íova─Źe se skl├ídaj├ş z dvoust─Ťnn├ę v├ílcov├ę n├ídoby z nerezov├ę oceli s dutinou, s vypou┼ít─Ťc├şm otvorem a ┼íoup├ítkem o pr┼»m─Ťru 50 cm. Dutina je napln─Ťna vodou, kter├í je oh┼Ö├şv├ína elektrick├Żm odporov├Żm termostatem. Med je m├şch├ín lopatkami s profilem lodn├ş vrtule, v├Ż┼íkov─Ť nastaviteln├Żmi pod├ęl ┼íikm├ę h┼Ö├şdele.

Pro cenovou nab├şdku n├ím po┼ílete e-mail na adresu sales@foodtechprocess.com

Univerz├íln├ş kotel s integrovan├Żm homogeniz├ítorem o objemu 1200 litr┼» je ur─Źen k efektivn├şmu m├şch├ín├ş, oh┼Öevu, va┼Öen├ş a homogenizaci produkt┼» pro potravin├í┼Ösk├Ż, farmaceutick├Ż a kosmetick├Ż pr┼»mysl, jako jsou d┼żemy, marmel├ídy, sirupy, ovocn├ę ┼í┼ą├ívy, nektary, piva, kr├ęmy, masti, m├Żdla a mnoho dal┼í├şch.

Inline homogeniz├ítor je ur─Źen k m├şch├ín├ş, emulgaci, dispergaci a homogenizaci hust├Żch a visk├│zn├şch produkt┼» p┼Öi v├Żrob─Ť majon├ęzy, s├│jov├ęho ml├ęka, zubn├ş pasty, jogurtu a mnoha dal┼í├şch. Lze jej instalovat do vn─Ťj┼í├şho cirkula─Źn├şho okruhu reaktor┼», v├Żrobn├şch linek nebo pou┼ż├şvat samostatn─Ť s nakl├ídac├ş n├ísypkou pro zpracov├ín├ş mal├Żch objem┼» produkt┼».

- Vytv├í┼Ö├ş stabiln├ş emulze a suspenze

- Sni┼żuje velikost ─Ź├ístic

- Rychle rozpou┼ít├ş pevn├ę l├ítky

- Urychluje chemick├ę reakce

- Nevy┼żaduje dal┼í├ş ─Źerpadlo

- Material: Stainless steel

- Engine power, kW: 5,5/ 7,5/ 9/ 11/ 15

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Vakuov├Ż homogeniz├ítor s naklon─Ťnou konstrukc├ş je ur─Źen ke zpracov├ín├ş a v├Żrob─Ť ┼íirok├ę ┼ík├íly kapaln├Żch, pastovit├Żch a visk├│zn├şch produkt┼» s r┼»zn├Żmi po┼żadavky na jejich v├Żrobn├ş podm├şnky a dal┼í├şch produkt┼» v─Źetn─Ť produkt┼» s vysokou viskozitou.

Pro dal┼í├ş informace n├ís pros├şm kontaktujte na adrese sales@foodtechprocess.com

Homogeniz├ítor je ur─Źen k emulgaci hust├Żch tekutin a jin├Żch visk├│zn├şch materi├íl┼» v potravin├í┼Ösk├ęm, chemick├ęm a kosmetick├ęm pr┼»myslu. Jeho pracovn├ş princip je zalo┼żen na principu rotor/stator.

Pro v├şce informac├ş n├ím po┼ílete e-mail na adresu sales@foodtechprocess.com

Cena je uvedena za z├íkladn├ş verzi sady za┼Ö├şzen├ş s homogeniz├ítorem.

Za┼Ö├şzen├ş na v├Żrobu zmrzlinov├Żch sm─Ťs├ş je zalo┼żeno na univerz├íln├şm vakuov├ęm reaktoru s chladic├şm pl├í┼ít─Ťm a v├şcestup┼łov├Żm disperg├ítorem/homogeniz├ítorem ve vn─Ťj┼í├ş cirkula─Źn├ş smy─Źce.

- Speci├íln├ş typ m├şchac├şho za┼Ö├şzen├ş pro snadnou demont├í┼ż a ─Źi┼ít─Ťn├ş

- Zpracov├ín├ş s minim├íln├şmi ztr├ítami produktu

- Spodn├ş vypou┼ít─Ťc├ş ventil je sou─Ź├íst├ş z├íkladn├ş verze instalace.

- V├şcestup┼łov├Ż disperg├ítor pro intenzivn├ş sm├í─Źen├ş a homogenizaci proud├şc├ş sm─Ťsi

- Vn─Ťj┼í├ş cirkula─Źn├ş okruh s trojcestn├Żm ventilem pro provoz/myt├ş za┼Ö├şzen├ş

- Zes├şlen├Ż pohon m├şchadla pro hust├ę a visk├│zn├ş sm─Ťsi

- Vestav─Ťn├ę vakuov├ę ─Źerpadlo

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 3

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

We produce atmospheric honey homogenizers with a batch load ranging from 7500 up to 22 000 kg of honey. The homogenizers HPL are designed for thoroughly mixing, blending, and homogenizing various kinds of honey to improve its qualities.

The price depends on the options you choose.

The price is set for the basic version of the installation for making plant milk without a steam generator

The Veggie Milk cooking kettle is used as a unit for hydrodynamic thermal extraction of substances from legumes and nuts to create a finished suspension - the basis of plant based drinks.

- Efficient and fast extraction

- Partial pasteurization due to direct steam injection

- High-powered bottom homogenizer

- Hydrodynamic mixing

- Mechanical shaft seal for the homogenizer with an open cooling system

- Safety grid on the hatch cover for safe product loading

- Sectional plexiglass hatch for visual inspection

- Capacity: 600 kg/h for soybeans

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 120l

- Total power, kW: 7,5

- Voltage: 380-400V

Tento inline homogeniz├ítor s vysokou smykovou rychlost├ş lze pou┼ż├şt k mlet├ş a v├Żrob─Ť hust├Żch l├ítek, jako jsou om├í─Źky, pasty nebo pomaz├ínky, ─Źokol├ídov├ę kr├ęmy a margar├şnov├ę emulze.

Dvou┼ínekov├Ż mix├ęr s homogeniz├ítorem je ide├íln├şm ┼Öe┼íen├şm pro v├Żrobu kr├ęmov├Żch s├Żr┼», jako je s├Żr feta, s r┼»zn├Żmi p┼Ö├şchut─Ťmi a ko┼Öen├şm. D├şky mechanick├ę homogenizaci z├şsk├í s├Żr jemnou strukturu, ani┼ż by se zm─Ťnily individu├íln├ş chu┼ąov├ę vlastnosti v├Żrobku.

- Objemn├í objemov├í m├şcha─Źka s kapacitou 50 l

- Kompaktn├ş stoln├ş proveden├ş pro pohodlnou ├║dr┼żbu obsluhou

- V├Żkonn├Ż nez├ívisl├Ż pohon pro ka┼żd├Ż ┼íroub s reverzac├ş

- Snadn├í ├║dr┼żba a ─Źi┼ít─Ťn├ş za┼Ö├şzen├ş

- Material: Stainless steel

- Total power, kW: 3,5

- Voltage: 380-400V

Homogenizace m├ísla se prov├íd├ş za ├║─Źelem zlep┼íen├ş jeho konzistence a chu┼ąov├ę stability p┼Öi skladov├ín├ş.

Dal┼í├ş informace o na┼íich homogeniz├ítorech z├şsk├íte na adrese sales@foodtechprocess.com

Inline homogeniz├ítory Yumix Basic maj├ş nejni┼ż┼í├ş cenu v ┼Öad─Ť homogeniz├ítor┼» YUMIX a jejich modely se pohybuj├ş od 1,1 do 3 kW.

Dal┼í├ş informace o za┼Ö├şzen├ş z├şsk├íte od obchodn├şho odd─Ťlen├ş spole─Źnosti na adrese sales@foodtechprocess.com

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

For additional information, please contact us at sales@foodtechprocess.com

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Textur├ítor m├ísla FBHG je ur─Źen k mechanick├ęmu zpracov├ín├ş zmrazen├Żch blok┼» m├ísla, ┼żivo─Źi┼ín├ęho tuku, margar├şnu a dal┼í├şch pl├ínovan├Żch tuk┼» bez p┼Öedchoz├şho rozmrazov├ín├ş.

Dal┼í├ş informace o na┼íich homogeniz├ítorech z├şsk├íte na adrese sales@foodtechprocess.com