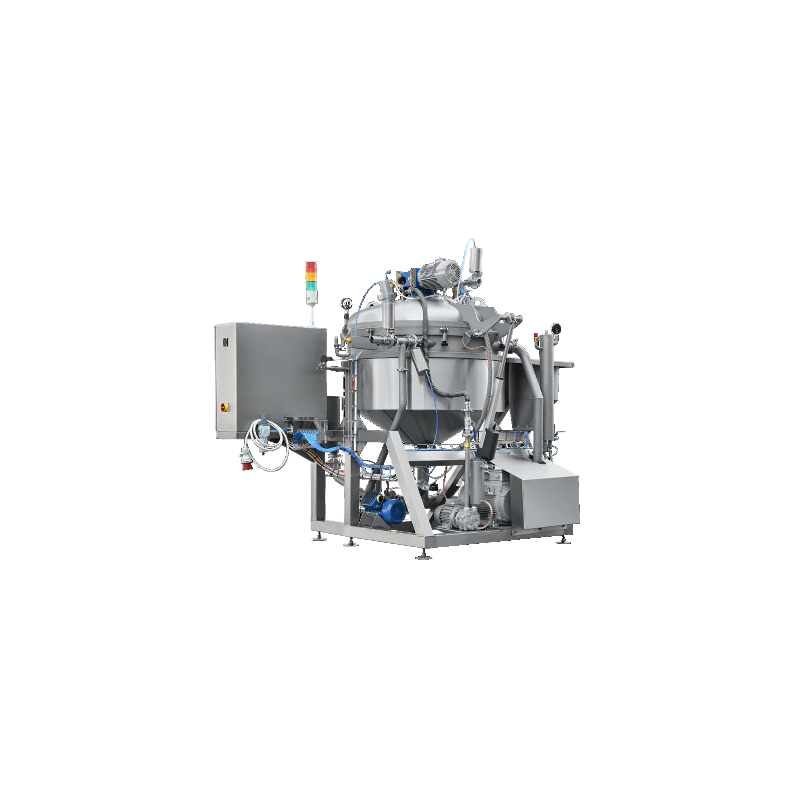

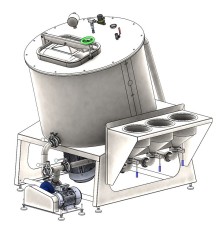

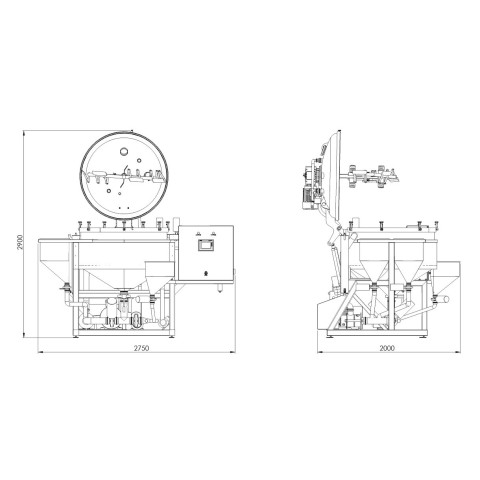

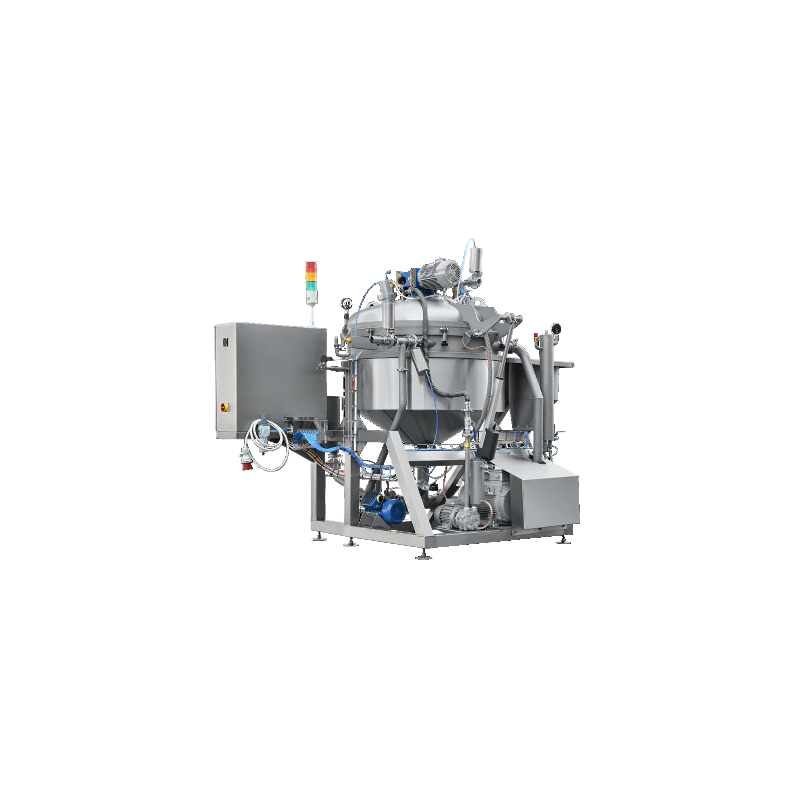

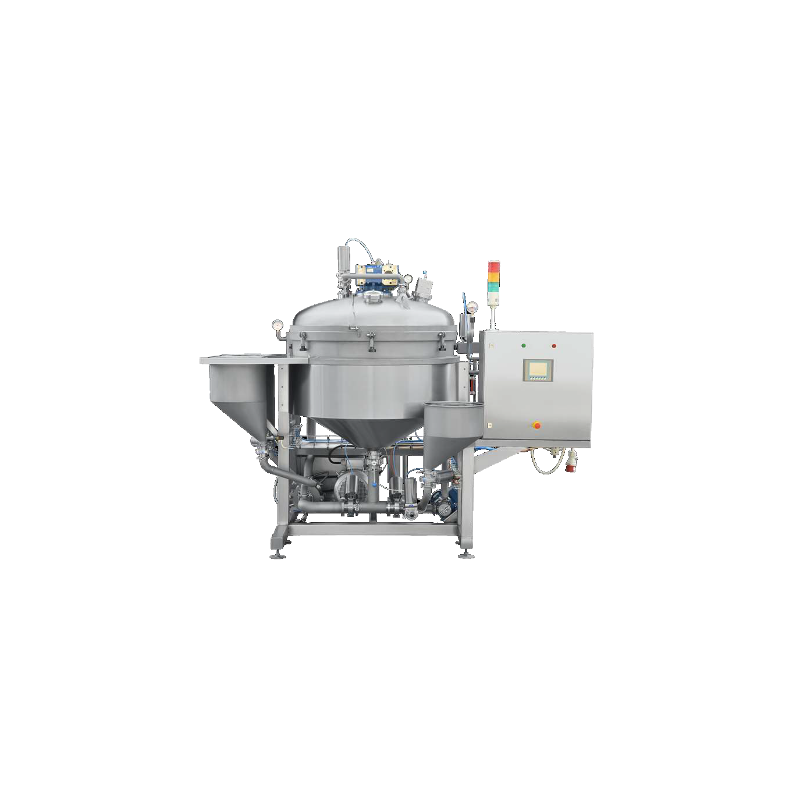

Vacuum homogenizer VMG S 650 M

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

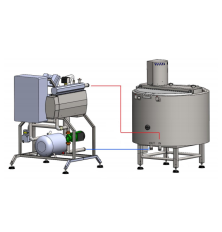

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

Modular design, allowing you to choose the optimal modification for any type of production. The vacuum homogenizer is a highly efficient and reliable solution for the production of a wide range of food products, producing stable, homogeneous emulsions and dispersions.

The vacuum homogenizing module can be used in both the food, cosmetics, pharmaceutical, or chemical industries for the production and processing of products such as:

|

|

|

|

|

|

|

|

|

|

Advantages:

- Versatility and flexibility in use. It is suitable for the production of most liquid, paste-like, and highly viscous products.

- Modern design, easy access to all internal surfaces, without hard-to-reach places where the product can accumulate.

- No need for an additional pump to unload the product.

- Easy sanitization when connected to a CIP system.

- Can be used independently or easily integrated into an existing production process.

- Minimum processing time for each batch is achieved through the high efficiency of heating/cooling processes via the jacket (duplicator) with a coolant supplied from an external source, as well as grinding, mixing, and homogenization.

- The high efficiency of the homogenization process is achieved through the device's core ÔÇô a robust and reliable rotor-stator type homogenizer with various different tooth shapes, enabling the production of products with distinct properties.

- The optimal design of the conical working chamber ensures uniform mixing of the product.

- The low-speed mixer with top feeding is equipped with scrapers that efficiently clean the vessel walls for maximum heat exchange. The product is heated evenly, without the risk of overheating or burning.

- An effective vacuum system guarantees high-quality deaeration of the product, which significantly improves taste, consistency, and durability.

- In case of strict requirements for the degree of homogenization and minimum particle size, the device is equipped with a homogenizer with a weaker pump function, but with enhanced grinding and homogenization capabilities. In this case, the product is subsequently unloaded using an additional pump.

- The working capacity depends on the properties of the product - from 20 to 80% of the total volume. The device guarantees consistently high quality of finished products and batch reproducibility.

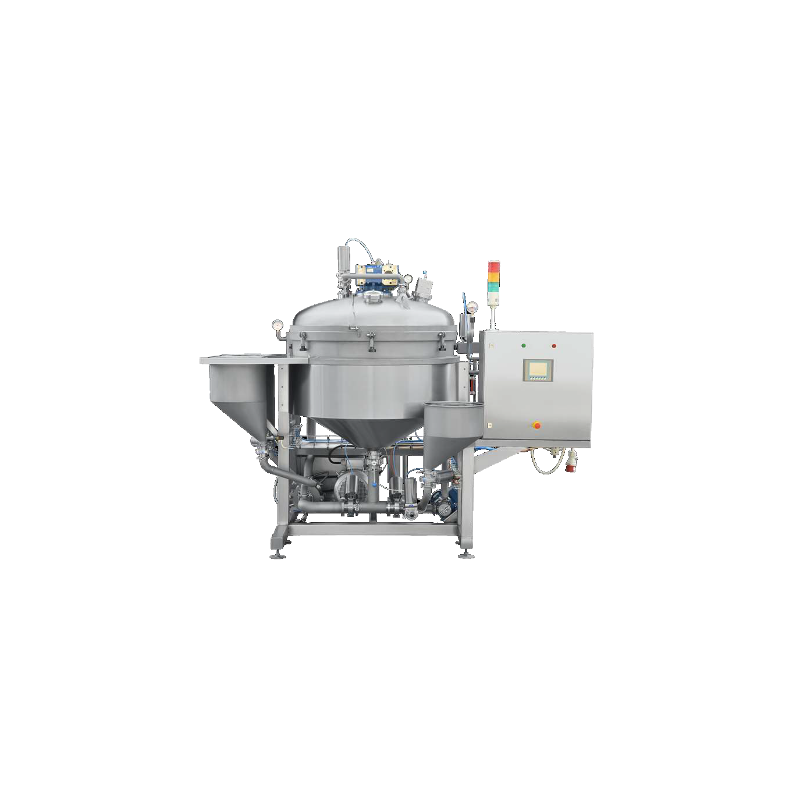

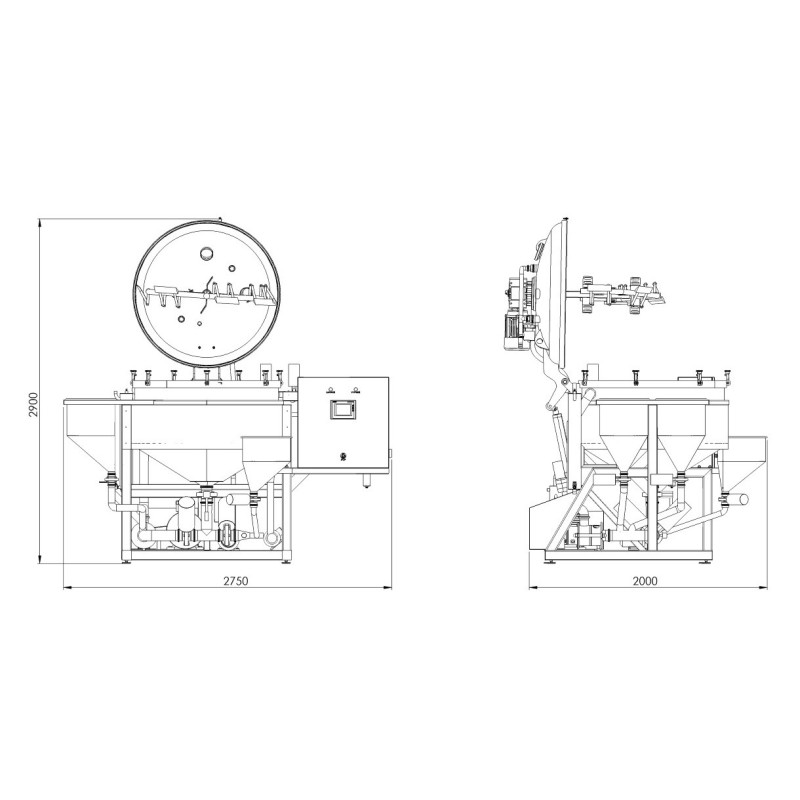

Basic version

It includes a vacuum reactor with a conical bottom and a jacket for the coolant up to 0.5 bar, which is installed on a supporting frame structure. Equipped with a mixing device featuring scrapers, a system for lifting the top cover, an external circulation circuit with a homogenizer, a filling system, and a piping system with regulation and shut-off fittings.

Processes

|

|

|

|

|

|

*- from an external source

Options:

- Thermal insulation of the jacket and an external decorative casing

- Any heating source (steam generator, hot water source)

- Any number of additional funnels and ingredient loading blocks

- Possibility of automatic dosing of ingredients

- Direct steam injection into the product

- Manufacturing the system from AISI 316L or AISI 316Ti (in direct contact with the product)

- Automatic, semi-automatic or manual control system (on request)

- CIP heads for washing (rotary)

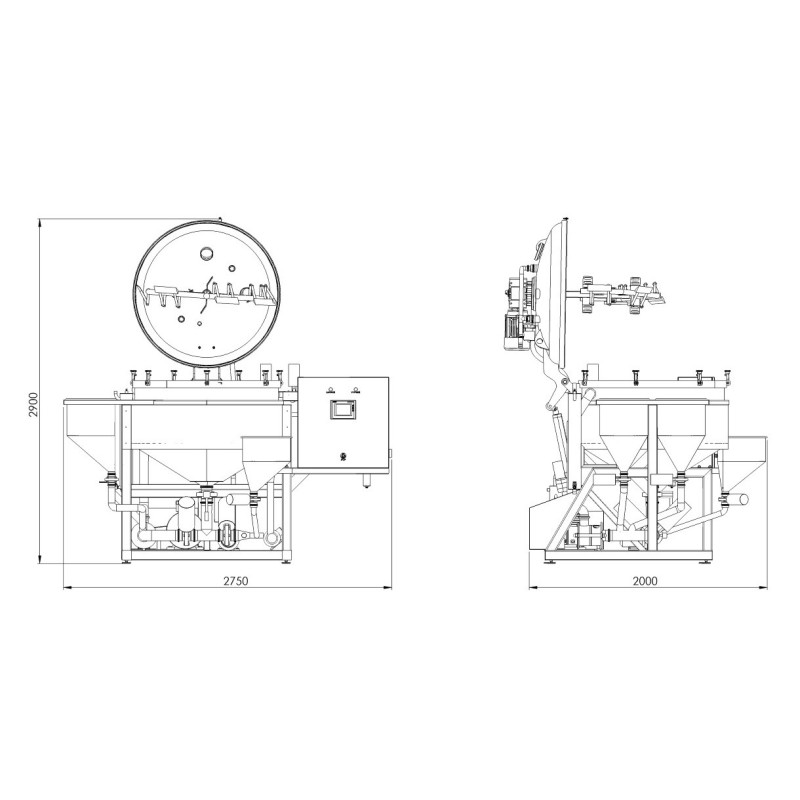

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

You might also like

Elektrick├Ż topn├Ż panel se t┼Öemi r┼»zn├Żmi mo┼żnostmi v├Żkonu: Vynikaj├şc├ş v├Żrobek vyroben├Ż lidmi, kte┼Ö├ş dokonale znaj├ş tajemstv├ş skladov├ín├ş, ├║dr┼żby a zpracov├ín├ş v├Żrobk┼».

Dal┼í├ş informace z├şsk├íte e-mailem sales@foodtechprocess.com

Gener├ítor je namontov├ín na podp─Ť┼Öe z nerezov├ę oceli, pokryt├ę nerezovou ocel├ş AISI 304, ┼Ö├ídn─Ť tvarovanou s ji┼ż proveden├Żmi elektrick├Żmi a vodovodn├şmi p┼Ö├şpojkami. Kohouty z nerezov├ę oceli AISI 316, tvarovky z kujn├ę litiny, ─Źerpadlo nap├íjec├ş vody (mod. TP78A CALPEDA) s 1 zp─Ťtn├Żm ventilem z nerezov├ę oceli, s t─Ťsn─Ťn├şm VITON.

Dal┼í├ş informace z├şsk├íte na e-mailov├ę adrese sales@foodtechprocess.com

Cena je uvedena pro z├íkladn├ş verzi vakuov├ęho reaktoru bez dal┼í├şch mo┼żnost├ş, kone─Źn├í cena z├ívis├ş na ├║prav├ích.

Vakuov├Ż homogeniz├ítor je ide├íln├şm ┼Öe┼íen├şm pro v├Żrobu potravin, nap┼Ö├şklad majon├ęzy, je vhodn├Ż i pro kosmetick├Ż pr┼»mysl - v├Żrobu zubn├ş pasty. Tento model homogeniz├ítoru je zalo┼żen na vakuov├ęm reaktoru s extern├şm homogeniz├ítorem a extern├şm cirkula─Źn├şm okruhem, jeho┼ż parametry se vol├ş jako voliteln├ę.

- Naklon─Ťn├í konstrukce - o 25 % ├║─Źinn─Ťj┼í├ş m├şch├ín├ş

- Snadno rozeb├şrateln├Ż m├şcha─Ź se zes├şlen├Żm r├ímem, pro hust├ę a visk├│zn├ş produkty

- pl├í┼í┼ą pro chladic├ş kapalinu kolem dna a st─Ťn pracovn├şho reaktoru.

- Vakuov├Ż reaktor vydr┼ż├ş vakuum a┼ż -0,8 baru.

- Velk├Ż v├Żb─Ťr mo┼żnost├ş, kter├ę vyhovuj├ş r┼»zn├Żm po┼żadavk┼»m.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 650l

- Total power, kW: 0,55

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Homogeniz├ítor pro v├Żrobu ┼íleha─Źky, zmrzliny a dal┼í├şch produkt┼». Umo┼ż┼łuje z├şskat stabiln├ş tekut├ę emulze potravinov├Żch sm─Ťs├ş.

- Homogeniz├ítor lze instalovat p┼Ö├şmo do n├ídoby s produktem.

- Vysok├í produktivita - za pouh├Żch 8 minut je mo┼żn├ę na┼ílehat a┼ż 60 litr┼» ml├ę─Źn├ę sm─Ťsi.

- Obvodov├í rychlost no┼ż┼» je 16 m/s.

- Engine power, kW: 0,37/ 2,2

- Voltage: 380-400V

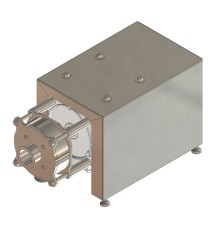

Inline homogeniz├ítor je ur─Źen k m├şch├ín├ş, emulgaci, dispergaci a homogenizaci hust├Żch a visk├│zn├şch produkt┼» p┼Öi v├Żrob─Ť majon├ęzy, s├│jov├ęho ml├ęka, zubn├ş pasty, jogurtu a mnoha dal┼í├şch. Lze jej instalovat do vn─Ťj┼í├şho cirkula─Źn├şho okruhu reaktor┼», v├Żrobn├şch linek nebo pou┼ż├şvat samostatn─Ť s nakl├ídac├ş n├ísypkou pro zpracov├ín├ş mal├Żch objem┼» produkt┼».

- Vytv├í┼Ö├ş stabiln├ş emulze a suspenze

- Sni┼żuje velikost ─Ź├ístic

- Rychle rozpou┼ít├ş pevn├ę l├ítky

- Urychluje chemick├ę reakce

- Nevy┼żaduje dal┼í├ş ─Źerpadlo

- Material: Stainless steel

- Engine power, kW: 5,5/ 7,5/ 9/ 11/ 15

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Model VMG S je ├║─Źinn├í a spolehliv├í vakuov├í homogeniza─Źn├ş jednotka ur─Źen├í k v├Żrob─Ť ┼íirok├ę ┼ík├íly tekut├Żch, cukr├í┼Ösk├Żch a visk├│zn├şch v├Żrobk┼» s r┼»zn├Żmi po┼żadavky na v├Żrobn├ş podm├şnky.

Pro cenovou nab├şdku n├ím po┼ílete e-mail na adresu sales@foodtechprocess.com

Zvl├í┼ítnost├ş t├ęto jednotky je kombinace n─Ťkolika funkc├ş: homogenizace a su┼íen├ş medu. Vertik├íln├ş vakuov├í su┼íi─Źka umo┼ż┼łuje su┼íit med o hmotnosti a┼ż 3300 kg v kr├ítk├ęm ─Źase p┼Öi zachov├ín├ş jeho u┼żitn├Żch vlastnost├ş, barvy, chuti a organoleptick├Żch vlastnost├ş. Vakuov├í su┼íi─Źka medu m├í oproti klasick├Żm atmosf├ęrick├Żm su┼íi─Źk├ím medu ┼Öadu v├Żznamn├Żch v├Żhod d├şky zkr├ícen├ş doby zpracov├ín├ş a zachov├ín├ş jeho prosp─Ť┼ín├Żch vlastnost├ş, ─Źeho┼ż je dosa┼żeno su┼íen├şm p┼Öi ni┼ż┼í├ş teplot─Ť.

- Proces su┼íen├ş prob├şh├í mnohem rychleji d├şky odpa┼Öov├ín├ş vlhkosti ve vakuu.

- Vysok├Ż stupe┼ł homogenizace medu d├şky provozu speci├íln├şho m├şchac├şho za┼Ö├şzen├ş.

- ├Üzk├í vertik├íln├ş konstrukce nevy┼żaduje velk├ę v├Żrobn├ş plochy a z├írove┼ł se vyzna─Źuje vysokou produktivitou.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Homogeniz├ítor je ur─Źen k emulgaci hust├Żch tekutin a jin├Żch visk├│zn├şch materi├íl┼» v potravin├í┼Ösk├ęm, chemick├ęm a kosmetick├ęm pr┼»myslu. Jeho pracovn├ş princip je zalo┼żen na principu rotor/stator.

Pro v├şce informac├ş n├ím po┼ílete e-mail na adresu sales@foodtechprocess.com

Univerz├íln├ş kotel s integrovan├Żm homogeniz├ítorem o objemu 1200 litr┼» je ur─Źen k efektivn├şmu m├şch├ín├ş, oh┼Öevu, va┼Öen├ş a homogenizaci produkt┼» pro potravin├í┼Ösk├Ż, farmaceutick├Ż a kosmetick├Ż pr┼»mysl, jako jsou d┼żemy, marmel├ídy, sirupy, ovocn├ę ┼í┼ą├ívy, nektary, piva, kr├ęmy, masti, m├Żdla a mnoho dal┼í├şch.

Homogeniz├ítor je ur─Źen k homogenizaci, m├şch├ín├ş a dezintegraci/rozm─Ťln─Ťn├ş r┼»zn├Żch kapalin a komponent na mal├ę ─Ź├ístice.

Pro cenovou nab├şdku n├ím za┼ílete e-mail na adresu sales@foodtechprocess.com

Homogenizace m├ísla se prov├íd├ş za ├║─Źelem zlep┼íen├ş jeho konzistence a chu┼ąov├ę stability p┼Öi skladov├ín├ş.

Dal┼í├ş informace o na┼íich homogeniz├ítorech z├şsk├íte na adrese sales@foodtechprocess.com

Multifunk─Źn├ş vakuov├Ż mix├ęr/homogeniz├ítor pro mlet├ş, m├şch├ín├ş a homogenizaci produkt┼» za ├║─Źelem z├şsk├ín├ş homogenn├ş hmoty.

- Vestav─Ťn├Ż pl├í┼í┼ą pro dno a st─Ťny jednotky.

- ┼śezac├ş no┼że s v├Żkonn├Żm elektrick├Żm pohonem

- ┼áikm├í konstrukce pro efektivn├ş m├şch├ín├ş a sek├ín├ş

- Okruh nucen├ęho ob─Ťhu (voliteln├Ż)

- ┼áirok├í nab├şdka mo┼żnost├ş

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350l/ 650l

- Total power, kW: 13/ 17

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Textur├ítor m├ísla FBHG je ur─Źen k mechanick├ęmu zpracov├ín├ş zmrazen├Żch blok┼» m├ísla, ┼żivo─Źi┼ín├ęho tuku, margar├şnu a dal┼í├şch pl├ínovan├Żch tuk┼» bez p┼Öedchoz├şho rozmrazov├ín├ş.

Dal┼í├ş informace o na┼íich homogeniz├ítorech z├şsk├íte na adrese sales@foodtechprocess.com

Dvou┼ínekov├Ż mix├ęr s homogeniz├ítorem je ide├íln├şm ┼Öe┼íen├şm pro v├Żrobu kr├ęmov├Żch s├Żr┼», jako je s├Żr feta, s r┼»zn├Żmi p┼Ö├şchut─Ťmi a ko┼Öen├şm. D├şky mechanick├ę homogenizaci z├şsk├í s├Żr jemnou strukturu, ani┼ż by se zm─Ťnily individu├íln├ş chu┼ąov├ę vlastnosti v├Żrobku.

- Objemn├í objemov├í m├şcha─Źka s kapacitou 50 l

- Kompaktn├ş stoln├ş proveden├ş pro pohodlnou ├║dr┼żbu obsluhou

- V├Żkonn├Ż nez├ívisl├Ż pohon pro ka┼żd├Ż ┼íroub s reverzac├ş

- Snadn├í ├║dr┼żba a ─Źi┼ít─Ťn├ş za┼Ö├şzen├ş

- Material: Stainless steel

- Total power, kW: 3,5

- Voltage: 380-400V

The price is set for the basic version of the installation for making plant milk without a steam generator

The Veggie Milk cooking kettle is used as a unit for hydrodynamic thermal extraction of substances from legumes and nuts to create a finished suspension - the basis of plant based drinks.

- Efficient and fast extraction

- Partial pasteurization due to direct steam injection

- High-powered bottom homogenizer

- Hydrodynamic mixing

- Mechanical shaft seal for the homogenizer with an open cooling system

- Safety grid on the hatch cover for safe product loading

- Sectional plexiglass hatch for visual inspection

- Capacity: 600 kg/h for soybeans

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 120l

- Total power, kW: 7,5

- Voltage: 380-400V

Cena z├ívis├ş na po┼żadovan├ę kapacit─Ť. Pro dal┼í├ş informace nebo cenovou nab├şdku n├ím za┼ílete e-mail na adresu sales@foodtechprocess.com

We produce atmospheric honey homogenizers with a batch load ranging from 7500 up to 22 000 kg of honey. The homogenizers HPL are designed for thoroughly mixing, blending, and homogenizing various kinds of honey to improve its qualities.

The price depends on the options you choose.

Sm─Ť┼íova─Źe se skl├ídaj├ş z dvoust─Ťnn├ę v├ílcov├ę n├ídoby z nerezov├ę oceli s dutinou, s vypou┼ít─Ťc├şm otvorem a ┼íoup├ítkem o pr┼»m─Ťru 50 cm. Dutina je napln─Ťna vodou, kter├í je oh┼Ö├şv├ína elektrick├Żm odporov├Żm termostatem. Med je m├şch├ín lopatkami s profilem lodn├ş vrtule, v├Ż┼íkov─Ť nastaviteln├Żmi pod├ęl ┼íikm├ę h┼Ö├şdele.

Pro cenovou nab├şdku n├ím po┼ílete e-mail na adresu sales@foodtechprocess.com