PRODUCTS

Explore our extensive selection of innovative food processing equipment tailored to meet the diverse demands of the industry. Our equipment spans various segments, improving productivity, enhancing production efficiency and ensuring high product quality. Invest in innovative solutions that advance your food processing operations.

The electric kettle with a stirring device and manual tilting is suitable for a wide range of applications in food production or professional kitchens. It has an independent frame and built-in intensive electric heating with a wok-shaped, multi-layer ŌĆ£sandwichŌĆØ base, allowing the heating temperature to reach up to 200 ┬░C.

- High processing temperatures of up to 200 ┬░C

- Built-in, powerful 2,6 kW / 6,5 kW electric heating

- Manual tilting and unloading system with three working positions, allowing a maximum tilt angle of 110┬░

- Professional high-temperature thermometer with a probe in the product

- Air insulation of the outer casing

- Stirring device with stainless steel scrapers for high-temperatures

- Material: Stainless steel

- Engine power, kW: 0,06/ 0,25/ 0,37

- Heating power, kW: 2,6 / 6,5

- Volume: 30l/ 50l/ 100l

- Stirrer speed, rpm: 18

Vacuum evaporator with remote circulation using a heat exchanger is one of the most efficient evaporation methods. This evaporation system is suitable for boiling and concentrating heat-sensitive products such as milk, cream, etc.

- No mixing device required, the product has forced circulation!

- Modular system: possibility to choose the vacuum generator, power and heat exchanger type

- Inclined design and bottom valve for 100% product discharge without losses and blind spots

- Insulated upper hatch of the unit for heat retention and safety

- Tangential product inlet into the vacuum vessel for guaranteed evaporation in a thin layer

- Material: Stainless steel

- Volume: 50l/ 100l/ 300l

Electric fat melter (butter melter) ŌĆō is a batch-type machine used for melting solid, frozen blocks of fat, animal fats and vegetable oils, frozen juices, chocolate and glaze, as well as maintaining them in a molten state in the container. It is possible to use it for melting some refractory fats due to the high heating temperature of up to 120┬░C.

- Built-in powerful 2.6 / 6.5 kW electric heating

- Multi-stage switch with 7 heating intensity levels

- Professional, stainless steel thermometer for measuring the temperature in the product

- Compact support structure on height-adjustable legs / optional wheel support

- Three tilt positions of the working container for convenient unloading of the product

- Principle of operation: Batch mode

- Volume: 50l/ 100l

- Total power, kW: 3,5/ 6,5

- Voltage: 380-400V

A compact electric pasteurizer with a heating power of 5 kW is used for long-term batch pasteurization of milk, which includes heating milk to a temperature up to 100 degrees C and maintaining it for a selected period of time. The milk pasteurizer can also be used in the form of a Milk pot to heat milk for feeding calves.

- High heating power (5ŌĆ»kW) on a 220ŌĆ»V single-phase connection

- Stirrer with bottom scrapers that prevents milk from burning when directly heated

- Direct electric heating with a multi-stage power switch

- Hygienic design for simple and easy cleaning

- Simple system for removing and lifting the top hatch with an agitator

- Absence of blind spots where bacteria can grow

- Heating: Electricity

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Heating power, kW: 5

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

The cherry pitting machine is a professional, compact unit for the continuous removal of pits from cherries, sweet cherries, and similar fruits. It is designed specifically for small and medium-sized production facilities, the unit offers high precision and reliability, ensuring high-quality processing of raw materials. The pitting machine is equipped with a 200 mm diameter drum with 10 rows of 6 perforations and an adjustable feed chute.

- Automatic, continuous operation, ideal for small production lines

- Adjustable feed tray angle up to 70┬░ to accommodate various fruit sizes

- Automatic sorting of pits and peeled fruit

- High positioning accuracy maximizes fruit integrity after peeling

- High productivity in a small, compact unit

- Transparent protective cover for visual inspection

- Productivity: 200 kg/h

- Material: Stainless steel

- Engine power, kW: 0,18

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The pasteurization kettle with manual tilting is a modern device designed for gentle heat treatment of milk and dairy products, which allows for their effective pasteurization, extends shelf life and increases safety, while preserving the original taste and nutritional values. The 6-stage heating regulation of the powerful integrated heater, allows the milk to be reliably pasteurized directly in the container with a sandwich bottom, ensuring even heat distribution.

- Ideal solution for small-scale and home production of dairy products

- Removable lid for easy inspection and manual mixing of the product

- Option to equip it with a drain valve for discharging liquid products

- Even heating without burning thanks to the sandwich bottom

- Easy connection to a single-phase 230 V power supply

- Material: Stainless steel

- Heating power, kW: 2,6 / 6,5

- Volume: 30l/ 50l/ 100l

- Voltage: 380-400V

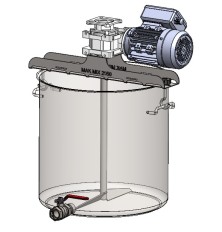

The 50 liter mixer Mak Mix is a universal mixer for mixing, stirring, kneading various solutions and mixtures. Equipped with an easily removable mixing device and a tilting system of the working bowl.

- Gravity mixing which is 40% more efficient, is possible due to the ability to adjust the tilt angle of the working container

- Simple and convenient design for maintenance - compact installation

- Independent stainless steel supporting structure

- Easily removable lid with a mixing device

- Special small elongated protrusion - spout on the edge of the working container for convenient draining and unloading of the product

- Tilt angle for unloading - 110 degrees

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l

- Stirrer speed, rpm: 18

A honey homogenizer is a batch-type device designed to improve the product's structure and organoleptic properties. It ensures a uniform consistency and stable texture of honey.

Homogenization is a processing technology that makes honey flowable and uniform, as well as inhibits crystal growth, thus meeting the needs of producers and consumers. The design, size, and angle of the rotary auger achieve a high level of homogenization, which also reduces raw material processing time.

- High level of homogenization, aimed at increasing stability and improving the honey's structure without altering the product's flavor.

- No dead spots or corners due to the inclined bottom of both the working tank and the auger mixer.

- The working tank is equipped with a jacket and a built-in water heating system.

- Large-diameter outlet valve installed at the lowest hydraulic point.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 4/ 7

- Loading, kg: 500/ 1100

This 800-liter capacity dissolver with a circulation pump is designed for preparing liquid solutions by dissolving substances directly in water or other working fluids. It is used in the food and beverage industries for ensuring uniform dissolution through hydrodynamic mixing in a forced recirculation loop.

Recirculation with a food-grade pump ensures rapid and uniform dissolution without sedimentation or the formation of stagnant zones. The working tank is mounted on a mobile platform with wheels, allowing for easy and quick movement between production areas.

- Fast and uniform dissolution without sediment thanks to hydrodynamic mixing

- Forced recirculation loop with product pump/inline homogenizer (optional)

- Mobile stainless steel platform on wheels

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Geometric volume: 800 l

A universal homogenizing module for mayonnaise production. The special compact atmospheric unit with a bottom homogenizer and a circulation system allows to create stable fat emulsion in just a few minutes!

- Compact design

- No dead zones and corners due to the conical shape of the unit

- Powerful bottom inline homogenizer with circulation

- Hygienic design

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 9

The pistachio paste mill is a colloid type mill. Its operating principle is based on grinding nut kernels between a rotor and stator to achieve colloid-sized particles.

Pistachio paste obtained using this type of mill has a uniform fine texture, natural taste and aroma.

Advantages:

- Easy to operate

- High productivity

- Compact size

- Flexible adjustment settings

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The ghee making machine is a compact, electrically heated tilting unit designed for melting and clarifying butter to produce high-quality ghee. It gently separates milk solids and water from butter, leaving behind pure, aromatic clarified fat. The machine ensures uniform heating, 6 stage heating control, and easy drainage of separated water through the integrated bottom outlet valve.

- Integrated outlet valve for easy separation and drainage of water and residues.

- Tilting design for convenient emptying and cleaning.

- Multi-stage heating control up to 150 ┬░C for effective butter clarification.

- Stainless steel construction ensuring hygiene and durability.

- Compact design with adjustable support or mobile wheel frame.

This industrial hybrid drying cabinet combines two drying principles: heat pump (condensation) and convection (forced circulation of heated air). This dryer is designed for fast, efficient, energy-saving, and "cold" drying of vegetables, fruits, berries, mushrooms, legumes, herbs, meat, fish, and even liquid or semi-liquid products by replacing the shelves with standard GN 2/1 containers. The size of one shelf is 530 x 650 mm.

- Dual technology: condensation drying + hot air convection

- Energy-efficient with optimized consumption (approx. 0.9ŌĆō1.3 kWh depending on mode)

- Drying area expandable up to 14 m┬▓ (optional)

- Uniform drying thanks to forced air flow and controlled moisture removal

- Gentle operation at low temperatures for maximum preservation of nutrients and color

The 300 BIN pressure vessel is a mobile stainless steel unit designed for transferring liquid and semi-liquid products by applying controlled internal pressure. It also serves as a mobile container for moving batches within the production facility. It is suitable for hygienic food processing environments where pumping is not possible or practical.

- Designed for operating pressures up to 0.5 bar, allowing for vertical transfer of liquids without a pump.

- Six hand-tightened lid screws ensure secure sealing during pressurized or vacuum operation.

- Mounted on caster wheels for easy movement within the production area.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

The cream-cooking kettle with manual tilting is designed for controlled heating, concentration, and thermal treatment of cream and cream-based products. Its adjustable temperature control, gentle handling, and uniform heat distribution enable processes such as thickening, reduction, pasteurization, and the preparation of dessert bases.

- 6-stage heating intensity adjustment

- Uniform heat distribution for a consistent product consistency

- Manual tilting system for complete and convenient emptying

- Suitable for cream, dairy desserts, sauces, and similar products

- Smooth stainless steel interior for easy cleaning and maintenance

A single hob cast-iron gas stove designed for heating and cooking in large cooking pots with volumes up to 100 liters. It is equipped with four independently controlled burners, designed for stable, intensive operation in food production.

- Robust cast-iron construction

- Four burners with separate flame control

- Suitable for propaneŌĆōbutane cylinders

- Designed to support heavy 50ŌĆō100 L cooking pots

The stove provides ideal external heating for our 50 L and 100 L cooking kettles with integrated mixing systems.

The rotary drum cooler is designed for efficient pre-cooling, stopping the cooking process, and cooling of boiled, blanched, fried, baked, or thermally processed foods. The rotating perforated drum ensures uniform cooling together with the additional water supply.

- Uniform cooling

- Adjustable drum speed

- Made entirely out of stainless steel

- Suitable for a wide range of food products

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,1

Compact and powerful gas stove with 3 rings designed for the connection to standard LPG cylinders. Ideal for heating large volumes of liquid, cooking soups or sauces in cooking kettles, and maintaining meal temperatures during preparation or service. The sturdy, open-frame design ensures excellent stability and high load capacity for everyday use in catering and food processing.

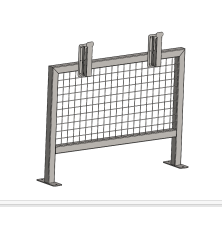

Stainless steel mesh baskets designed for use with our cooking kettles, blanchers, evaporators, fryers and pasteurizers. Ideal for thermal processing, subsequent draining, and unloading of products such as vegetables, fruits, pasta, meat, or jars after cooking, blanching, or pasteurization.

Available in multiple sizes ranging from 30├Ś30 to 40├Ś40 cm.

Compact universal washing and spin-drying unit designed for gentle and effective cleaning of fruits and vegetables. The system combines adjustable whirlpool washing with centrifugal drying, allowing efficient removal of soil, dust, and water in just a few minutes. Constructed entirely from food-grade stainless steel, it ensures hygienic operation and easy cleaning. Ideal for restaurants, hotels, catering kitchens, and small food processors.

- Efficient combined washing and drying process - total cycle under 5 minutes

- Adjustable washing intensity for delicate or firm products

- Stainless steel perforated drum for thorough cleaning and durability

- Integrated spin dryer for quick water removal and extended product shelf life

- Compact, easy-to-clean design with low water and energy consumption

This commercial frying pan with mixing and a tilt function is designed for frying, saut├®ing, searing, and cooking foods in small amounts of oil in large batches. An independent support frame with a tilt mechanism ensures easy unloading. The pan features adjustable heating with 6 intensity levels, making it suitable for professional kitchens and small food production businesses.

- Efficient heat distribution for even cooking.

- High performance for continuous batch processing.

- Rapid heating thanks to bottom electric contact heating.

- Mobile design allows for easy movement across the work area.

- Easy cleaning and maintenance.

This industrial deep fryer, with its independent support structure, is designed for batch deep-frying of various products, such as potatoes, vegetables, meat, prepared and semi-finished foods, snacks, and baked goods.

- Even frying: The basket ensures complete and uniform immersion of the products in oil.

- Increased productivity: By swapping baskets, loading and unloading can occur simultaneously, boosting efficiency.

- Fast cooking: Intensive and even heat transfer from the bottom electric sandwich heating ensures rapid and uniform frying.

- Mobility: The unit is easy to move and position as needed.

- Ease of maintenance and cleaning: Designed for simple upkeep and hygiene.

- Heating: Electricity

- Material: Stainless steel

- Volume: 50l/ 100l

- Voltage: 380-400V

The multifunctional cooking and pasteurization kettle with manual tilting is a simple device designed for the entire jam production process: from cooking the fruit mixture to the subsequent pasteurization of finished products directly in jars. It allows you to prepare the product in a container and then, using an additional basket, pasteurize the filled jars without the need for any additional equipment.

- 6-stage regulation of the built-in heating allows you to set the optimal conditions for cooking the fruits and subsequent pasteurization without the risk of burning or loss of quality.

- The manual tilting mechanism with a three-stage adjustment and a maximum tilt angle of 110┬░ ensures convenient emptying of the container and dosing of the finished product with virtually no losses.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

The Mak Mix tilting mixer is designed for preparing liquid and semi-liquid doughs. It's suitable for mixing dough for waffles, pancakes, cakes, and other baked goods.

- Made entirely out of stainless steel

- Features a tilting system with three working positions (up to 110┬░) for gravity mixing and quick emptying of the mixing bowl

- Frame mixer with a professional industrial motor

- Reinforced high-speed mixer for intensive mixing and kneading

- Safety switch on the top housing for safe operation: the mixer is switched off when the lid is opened

- Simple and easy to clean; the lid and mixer can be quickly and easily removed for cleaning

- Material: Stainless steel

- Engine power, kW: 0,37/ 0,55

- Volume: 50l/ 100l

- Voltage: 220-230V

- Stirrer speed, rpm: 35

The sturdy mobile base for large pots, with a diameter ranging from 405 mm to 625 mm, is designed to support and easily transport our 50L, 100L and 150L cooking kettles.

- Made out of stainless steel

- Features casters with brakes on each wheel for secure handling

- Universal model for pots with diameters from 405 to 625 mm

- High load capacity - up to 200 kg

- Material: Stainless steel

- Type of the equipment: Optional equipment

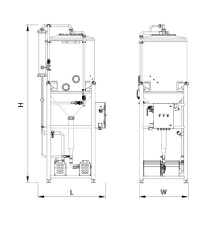

Milk pasteurizer for small and medium-sized enterprises, designed to carry out the pasteurization process of milk and other liquid products.

- Precision and stability of temperature control

- Maintaining the set temperature

- Uniform heating

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 3/

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 100l/ 300l

Universal cooking kettle with a built-in steam generator up to 0.5 bar, frame stirring device and an automatic tilt and unloading system is a convenient and safe solution for processing various liquid products in large volumes.

- Safe design with a jacket (duplicator) and outer casing with insulation

- Intensive steam heating through the jacket using the built-in electric steam generator

- Automatic multi-stage tilt and unloading system

- Frame stirring device for dissolving, mixing, kneading ingredients

- Unloading of the product into rolling carts is possible due to the offset tilted axis

- Heating: Mixed

- Material: Stainless steel

- Country of origin: Slovakia

- Total power, kW: 13,5

The vacuum cooking and mixing tank is used to boil products at low temperatures, which helps preserve the natural color, taste and nutrients in the product.

Vacuum equipment is used for cooking premium-quality jams, sauces, fruit and vegetable concentrates.

- Inclined design

- Efficient emptying

- High hygiene standards

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The Economy series of the cooking kettles comprise a thick-walled stainless steel container with an electric mixer mounted on the quick-release upper housing. The installation allows you to mix and stir products during processing. The thick bottom of the pot allows it to be installed on all types of heating surfaces (gas, induction or electric stove).

The Economy version is recommended for use with low-viscosity liquid products; If processing more thick and viscous products is necessary, we offer the Premium version of the cooking kettle┬Āor the caramel & syrup cooking kettle for extra thick substances.

- Sandwich bottom (multilayer) for use on all types of hobs, including induction

- Quick release lid with an electric stirrer

- Safety grid under the upper hull hatch - safe handling when stirring

- Possibility of visual inspection through the safety grid during processing

- Safe loading of components even during mixing

- Material: Stainless steel

- Engine power, kW: 0,12

- Volume: 30l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

A universal vessel for mixing, whipping and stirring any products using a blade mixing device operating at high speeds.

- Crescent shaped mixing device with three sharpened blades (cutter knives)

- Special high speed drive

- Sandwich bottom for all types of heating surfaces (electricity, gas, induction).

- Productivity: 50l/ 100l

- Material: Stainless steel

- Engine power, kW: 0,18/

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Diameter, mm: 400/ 500/ 600

This pump is a monoblock single-stage liquid ring vacuum pump suitable for low, medium, and high vacuum applications. It is an economical pump with exceptional performance and reliability.

- Productivity: 52 m3/h

- Principle of operation: Continuous mode

The stirrer for mixing and stirring different types of honey comes with a stainless steel container of 50 and 100 liters. It can also be used for mixing honey during blooming, pasteurization, and controlled crystallization (creaming).

- Powerful electric drive and reinforced stirrer for thick products

- Temperature control to ensure that honey does not overheat above 40 degrees during processing

- The mixing device is also equipped with fluoroplastic scrapers

- All materials in contact with the product are made out of stainless steel

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Continuous mode

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

A detachable lid with an automatic food stirrer for stainless steel 40 cm pots, suitable for volumes of 50 and 100 liters. An automatic stirrer allows you to mix and stir various products, including during thermal processing. The type of mixing device can be additionally selected depending on the required process.

- Professional industrial single-phase motor for 220-230 Volts

- The control is located directly on the motor housing or on the drive cable

- Easy and simple installation and fixation of the lid on the pan

- Suitable for standard 40 cm pots with a capacity of 50 or 100 liters

- The lid and stirrer are made entirely out of stainless steel

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Voltage: 220-230V

This is a highly efficient equipment designed for fine grinding and homogenization of solid products. Thanks to its unique design and high speed, the mill provides fine mixing and crushing of particles, which makes it indispensable in a variety of industries.

- Compact design - tabletop installation

- Possibility of using different feeder models

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Voltage: 220-230V

Compact vacuum evaporation machine with an external circulation heat exchanger for the production of test batches of products, development of new recipes and technological maps.

- Compact installation

- Capable of replicating all processing techniques used in industrial vacuum evaporation units with circulation

- Preserves the natural taste, aroma and color of the product

- Can be used to produce small batches of products

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 20l

You don't need professional equipment or special skills to brew beer at home; all you need is to buy a spacious kettle with an automatic stirring device!

- Special mixing device prevents malt from sticking to the bottom.

- The cooking kettle has two side handles for easy manipulation.

- The kettle, lid, and outlet valve are made entirely of stainless steel.

- The beer kettle can be used on any stove or you can purchase an electric base along with the kettle (optional).

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

Steel balls for grinding chocolate are essential components used in ball/bead mills. These 6 mm diameter balls are made out of hardened steel and are considered as consumables required for operating the BALL MILL 5.

- Spherical shape with a diameter of 6 mm

- High hardness steel

- Supplied in 10 kg boxes

- The mill requires 2 boxes (20 kg in total).

- Type of the equipment: Spare parts

The honey creaming machine is produced in various capacities with the possibility of loading from 30 to 225 kg of honey, so every beekeeper can choose the model that suits him. After processing, honey acquires a creamy structure. The creaming process is a method of crystallizing honey using a sample ŌĆō seed (creamed honey), carried out through stirring.

- Compact design

- Easy to operate and maintain

- Connection - 220-230 Volts

- Container and mixing device made out of stainless steel

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Voltage: 220-230V

- Loading, kg: 30/ 75/ 150/ 225

- Diameter, mm: 400/ 500/ 600

Designed for a load of up to 200 kg!

The 5 kW induction cooker is the best alternative to traditional electric and gas stoves. It reduces energy costs, improves safety, and minimizes air pollution, making it suitable for both stationary kitchens and mobile catering setups. Its compact design also makes it a practical choice for small kitchens where space and efficiency matter.

- 10-step power (500ŌĆō5000 W) or 10-step temperature (60ŌĆō280 ┬░C) control

- Connection - 230 Volt

- Compact dimensions: 410x500x200 mm

- Temperature range from 60 to 280 degrees

- Heating power, kW: 5

- Voltage: 220-230V

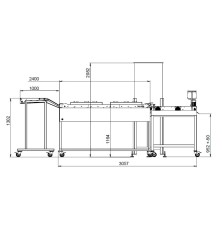

The modular cooling conveyor is produced as a standard tabletop version with a section length of 1000 mm; in addition to it, you can order a stainless table or a frame supporting structure. The air cooling conveyor can be sectionally increased in length by the required number of sections.

- Compact, easy to install on any work surface

- Features a fine-grained stainless steel mesh for high temperatures and small-sized products

- Easily combined in line with a tabletop fryer 400/1100/12

- Easy maintenance and cleaning

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

The home cheese making unit is a simple and compact solution for producing homemade cheeses right in your kitchen or for small-scale food production, it can also be used as a laboratory unit for testing new cheese recipes in industrial factories. The unit is designed for processing milk and producing various cheeses and cheese-based products.

- Options to choose electric or gas heating (additional options)

- Special stirrer for automatic mixing, which prevents possible burning of milk

- Visual control during operation thanks to a special safety grid on the upper sectional opening hatch

- Quick-release lid with a stirrer for easy unloading of the product or cleaning of the unit

You can also choose a version of the cooking kettle with a thermometer and an outlet valve, making it suitable for milk pasteurization as well.

- Material: Stainless steel

- Engine power, kW: 0,12 0,18/ 0,25

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

The burger forming machine is a reliable solution for small to medium-scale food production. Burger formers are designed to automate the patty-making process, they ensure consistency in shape, size, and weight, making them ideal for restaurants, butcher shops, and small food processing businesses.

- Material: Stainless steel

- Principle of operation: Continuous mode

The continuous production line for deep-frying and the subsequent cooling of semi-finished products includes:

- modular deep fryer┬Āwith the option of choosing the conveyor type: a┬Āsecondary conveyor for forced immersion┬Āof the product in oil or a┬Āconveyor with paddles┬Āfor frying light floating products, such as chips;

- stainless steel table┬Āunder the deep fryer with the option of installing an oil container and an┬Āoil filtration system┬Āinside it;

- cooling conveyor for removing excess oil and surface cooling of the product after frying it in the deep fryer.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

This continuous conveyor deep fryer is a reliable and versatile solution suitable for high-performance frying of a wide range of products by immersing them in hot oil.

- Universal application

- Quick transition for frying new types of products

- Possibility of using special frying modes

- Minimal amount of oil in the system

- Trouble-free oil filtration

- High oil exchange ratio

- High efficiency and productivity with compact design

- Manufactured to the highest quality standards using materials and components made in Europe.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

A large stainless steel pot with a drain valve and a temperature sensor can be used on any cooking surface: electric, gas, induction.

- Large 6/4'' drain valve

- Multi-layer sandwich bottom

- Cooking pot wall thickness 1 mm

- Professional, high-temperature temperature sensor

- Material: Stainless steel

- Volume: 50l/ 100l/ 150l

- Diameter, mm: 400/ 500/ 600

The extended version of the modular conveyor fryer with a large number of optional accessories, significantly expands the production capacity for deep-frying various products by increasing both the frying area and heating power.

- Frying time can be adjusted from several minutes up to an hour!

- Overheating safety sensors are installed on each heating element

- Compact support structure on a mobile support

- Fine-mesh conveyor grid allows for frying small and fragile products

- A large number of additional options in the form of automatic oil top-up system, loading conveyor, filtration system, cooling conveyor, etc.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

The simple dryer provides a reliable and cost-effective solution for food producers looking for precise control over the drying process.

- Material: Stainless steel

- Principle of operation: Batch mode

A vacuum distillation system is used for controlled separation of liquids based on the evaporation of the liquid and subsequent condensation of its vapors.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 5l

The high-performance screw pump is used for pumping both thick and viscous food products, as well as various masses containing pieces or solid inclusions such as in the cosmetics, cosmetology, and other industries.

- High performance

- All parts in contact with the product are made out of AISI304

- Does not damage products containing solid pieces

- Additional options: by-pass

- Material: Stainless steel

- Engine power, kW: 1,1/ 1,5 / 3

- Principle of operation: Continuous mode

The electric industrial WOK frying pan with a stirrer and automatic tilting system is suitable for intensive thermal processing, allowing you to stew, fry, boil, and concentrate large quantities of both solid and liquid products.

- Special eccentric working bowl tilting system, up to 90 degrees

- Low working height for loading and operation

- Hydraulic system for tilting and unloading the product

- Direct powerful electric heating of the bottom of the working bowl up to 220 degrees

- Heated walls of the working bowl (optional)

- Unloading of the product into standard 200 L trolleys (optional)

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 70+12

- Principle of operation: Batch mode

- Volume: 450

- Voltage: 380-400V

An automatic forming machine shapes food mixtures such as ground meat or plant-based alternatives into uniform portions. It automates portioning and shaping, and can also add a separation paper for easier handling before transferring the products with a conveyor. These machines reduce manual labor and increase output capacity for food processing facilities, butcher shops, and commercial kitchens.

- Material: Stainless steel

- Principle of operation: Continuous mode

The continuous rotary mixer is a professional solution for mixing, stirring powder and bulk materials.

- Allows precise dosing of components during continuous mixing

- Low energy consumption with high processing volumes

- Made entirely out of stainless steel

- Adjustable working drum tilt

- Special blades for mixing bulk and fragile materials

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A professional cooking boiler with built-in intensive bottom heating and a tilting system for the working container allows you to quickly heat the product to high temperatures (200┬░C). Suitable for blanching, boiling, frying and stewing various products where high-temperatures and efficient processing is required.

- Powerful bottom heating with uniform heat distribution (2600 / 6500 W)

- Professional stainless steel probe in the product with a thermometer for visual control

- Compact standing supporting structure for safe operation

- Three-stage adjustment of the tilt angle of the working container

- The unit is made entirely out of stainless steel

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 3,5/ 6,5

- Volume: 50l/ 100l

- Voltage: 380-400V

Compact digital filling machine for accurate dosing of viscous liquids such as honey, pastes, sauces, and oils. Designed with food-grade materials, easy-to-clean components, and precise digital control, it is ideal for small production, workshops, and laboratories.

- Operation mode: Semi-automatic

A circulation-type vacuum evaporator refers to a combined version of an evaporator that also takes advantage of other types to improve evaporation efficiency particularly by reducing concentration time and when processing heat-sensitive products such as milk.

- The external circulation circuit with heating intensifies the cyclic evaporation process.

- The forced circulation system ensures a decrease in the risk of localized product overheating.

- The condenser enables a deep vacuum and maintains a low evaporation temperature.

- Utilizing a mixing device with a spray system facilitates product evaporation in a thin layer, mimicking a film-type evaporator.

- Heating: Steam

- Material: Stainless steel

- Operation mode: Semi-automatic

- Country of origin: Slovakia

- Total power, kW: 2,4

- Voltage: 380-400V

The vacuum cooking and concentration unit is designed for concentrating products at low temperatures (about 60 degrees) in a reactor with a discharged environment to preserve the color, nutritional value and useful natural substances in present in food products. Evaporation and concentration units are often used when cooking jams, sauces, as well as fruit or vegetable concentrates. The vacuum concentrator allows you to boil and concentrate heat-sensitive products without damaging or destroying their structure or proteins, such as milk.

- Inclined design - allows for gravity mixing, which is 40% more efficient than usual

- Quick and 100% emptying of the tank thanks to the inclined design with the mixer on

- Heating/cooling jacket (duplicator) for the working tank and bottom

- High hygiene standard - the output valve is located at the lowest hydraulic point of the reactor

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 500l/ 875l

The vacuum evaporation unit is specially designed for thickening dense food products in industrial quantities. The evaporator can be used for the production of thick syrups, caramel masses, dense fruit masses, as well as for the production of pectin, or heat-stable fillings with a high productivity.

- High performance

- Rotary spraying system with a powerful electric drive

- Evaporation in a thin layer with a large heat transfer area

- Low investment installation costs

- Tangential entry for product swirling

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

The 3.5 kW induction cooker is a modern alternative to electric and gas stoves, best used with the 50 liter mixing cooking pots. It offers efficient heating, safety, and compact design, making it ideal for small kitchens, catering, and mobile cooking. Lightweight and portable, it is also suitable for outdoor events.

- 13-step power (500ŌĆō3500 W) or 13-step temperature (60ŌĆō280 ┬░C) control

- Built-in timer (up to 120 minutes) and overheating protection

- Connection: 230 V

- Compact dimensions: 326 ├Ś 415 ├Ś 110 mm

- Net weight: 4.6 kg

- Heating: Electricity

- Heating power, kW: 3,5

- Voltage: 220-230V

Installations for the production of non-alcoholic wine are manufactured in various models and configurations starting from volumes of 100 liters. The systems operate on the principle of vacuum distillation, which allows for alcohol removal at low temperatures, resulting in a healthy product with minimal alcohol content.

- A wide range of models ŌĆö suitable both for small-scale production and large-scale industrial operations

- Capability to produce a "healthy product" while preserving all organoleptic properties of the beverage

- Depending on production capacity, the systems can be designed for batch or continuous operation

- Deep vacuum conditions allow for low evaporation temperatures, enabling especially gentle evaporation without thermal degradation of the flavor profiles of different types of wine

- Material: Stainless steel

- Country of origin: Slovakia

Small 3L vacuum unit with a stirring device for the production of non-alcoholic wine.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 5l

Contact pressure gauge with a Bourdon tube, and a bottom connection.

- Type of the equipment: Optional equipment

Rechargeable and portable, ideal for measuring sugar content in fruit juices and beverages, ergonomic design.

A large three-section basket for vacuum fryers, cooking kettles and other batch processing equipment.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Stainless steel baskets for cooking kettles, autoclaves, pasteurizers.

- Material: Stainless steel

- Principle of operation: Batch mode

This system is specifically designed for facilitating the direct transfer of pulp to a press.

- Productivity: 2000 kg/h

- Engine power, kW: 0,37

- Weight: 28

- Type of pump: Volumetric, self-priming

Analogue refractometers offer an efficient, accurate, and easy-to-use solution for measuring Brix levels and ensuring product quality in the food industry.

- Type of the equipment: Optional equipment

The expansion tank is an additional component of the heating system circuit, where flow-through electric heating is used as an independent closed system for heating the hot water, serving as a heat transfer medium circulating in the duplicator of food cooking boilers, reactors, pasteurizers, and other food processing equipment. In heating systems with water heaters operating at temperatures up to 110┬░C, the expansion tank is necessary to accommodate the increased volume of the heat transfer medium as it expands when heated.

- Special high-pressure vessel ŌĆō allows to withstand pressure of up to 5 bar in the system.

- Allows the use of a heat generator with superheated water up to 110┬░C.

- Has different volume options, depending on the volume of the heat transfer medium, selected additionally.

- Type of the equipment: Optional equipment

Within seconds, the device measures the refractive index of the sample and converts it to % of solids using the concentration unit.

The refractometer is ready for use after a simple user calibration with deionized or distilled water.

The circulation pump for the heating system is a mandatory component for the operation of a flow-through heating system used for heating the water serving as a heat transfer medium inside the duplicator of industrial cooking boilers, mixers, reactors, and vacuum evaporators in food production. It is selected based on the required parameters of the heating system (volume). Our specialists will be happy to assist you in selecting the appropriate pump if you provide the technical specification requirements. This pump is an essential additional component for the flow-through water heater┬Āup to 110┬░C.

- It can be used to circulate water at temperatures up to 110┬░ C

- High efficiency with low power consumption

- Also suitable for central heating systems, heated floors and even for solar systems

- Small connections allow the use of flexible pipes with a smaller diameter

- Type of the equipment: Optional equipment

The IBC container insulation cover is designed for use in ice water stations with IBC containers to maintain the cold coolant at a set temperature.

- Allows you to reduce energy costs of the refrigeration machine - chiller

- Protects from short-term fluctuations in ambient temperature, reflects sunlight (up to 97%)

- The cover is easy to install, with valve holes are installed with hook-and-loop fasteners (Velcro)

- Type of the equipment: Optional equipment

Designed for the demanding requirements of the beer and beverage processing industry, this pressure suction food hose offers exceptional safety, durability, and compliance with international food standards. It is ideal for the transportation of high-quality raw, pasteurized, and organic beer, as well as a variety of other beverages, including wine, soft drinks, and alcoholic drinks.

- Type of the equipment: Optional equipment

In the production of condensed milk, a refractometer is used to accurately determine the solids content of the product, which is essential for meeting production standards and ensuring compliance with legal regulations.

- Type of the equipment: Optional equipment

Various installation types are possible: in-line, directly into the product tank or via a bypass connector.

- Type of the equipment: Optional equipment

Industrial refractometers are used to measure the concentration level of liquids in a continuous flow across various industries, applications, and industrial setups. They provide real-time measurement data, ensuring precise process control and maintaining the desired concentration of liquids. This enables industrial automation by eliminating the need for manual sampling and adjustments, allowing for consistent and accurate production.

- Type of the equipment: Optional equipment

A set of additional paddles for transporting and unloading the product from the working area of ŌĆŗŌĆŗthe universal 400/1100/12 fryer.

This rack is typically used as car mat holders at car washes. It can also serve as a universal stand for use in other enterprises.

- Material: Stainless steel

The honey dosing machine is a precise filling machine with a gear pump, it is easy to use and is suitable for filling honey as well as a large number of other different liquids - ranging from thinner ones such as drinking yogurt, to high-viscosity products such as mustard.

- Fast operation

- Easy to use

- Easy to clean

- Accuracy

- Compact design

- Productivity: 200 l

The cheese boiler is used in the dairy industry for the production of cheese grains during the production of natural hard, semi-hard, soft cheeses, and other cheese or curd products. The cheese maker is equipped with a special knife-mixer (lyre) for cutting the cheese curd. Suitable for both small and large scale production. Using this cheese-cooking boiler you can also pasteurize other dairy products, produce yogurt, cottage cheese kefir, fermented baked milk, varenets, sour cream and more.

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 300 l

The vacuum batch dryer is suitable for gentle and high-quality dehydration to obtain a product with low solvent/moisture content.

- Special stirrer for uniform heat distribution and mixing

- Drying of heat-sensitive wet solids

- Suitable for the separation of suspensions and drying extracts

- Low processing temperature due to a deep vacuum

- Material: Stainless steel

- Volume: 300l/ 600l/

Hygienic linear internal stainless steel drainage system for food production, professional kitchens, pharmaceutical enterprises, restaurants and many others. The drain trap has a stainless steel bath and a connection to the sewer.

- Grate with a frame

- The load class of the grate can withstand being runover with a car

- Fixed height drain

- Built-in grease trap (optional)

- Material: Stainless steel

- Country of origin: Slovakia

This equipment model is a universal system, which can be used to produce extracts from products like carobs, as well as to boil them under vacuum conditions to obtain a thick syrup through a sequential circulation process.

- One system for all sequential technological processes of pekmez production: from soaking and obtaining an extract, cooling the finished mixture to its boiling phase in a vacuum.

- Boiling under vacuum allows you to preserve all the useful substances contained in the extract: vitamins of group A, B, E, microelements such as calcium, potassium, magnesium, iron and zinc.

- Highly efficient boiling process due to a special direct in the flow heating system installed in the circulation type vacuum evaporation unit

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 36

- Volume: 100l

- Condensing capacity, l/h: 45-55

Device for tipping barrels with products

- A locking hook under the barrel protects and holds the steel barrel

- Safety drawbar with a single-hand operation and 3 functions (lifting/lowering/moving)

- Foot pedal ensures precise lifting

- Optimum operator protection thanks to the extended handle and protective grid

- Material: Steel

- Operation mode: Manual

- Type of the equipment: Individual machine

Industrial vacuum dryers are designed to remove moisture from sensitive or heat-sensitive food, chemical, or pharmaceutical products under reduced pressure, allowing for lower drying temperatures, minimized thermal degradation, and improved energy efficiency. Vacuum dryers like these are used in various industries - food, chemical, pharmaceutical and others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The peculiarity of this unit is the combination of several functions: homogenization and drying of honey. The vertical vacuum dryer allows you to dry honey weighing up to 3300 kg in a short time while preserving its useful properties, color, taste, and organoleptic qualities. The vacuum honey dryer has a number of significant advantages over classic atmospheric honey dryers due to the reduction of processing time and the preservation of its beneficial properties, which is achieved by drying at a lower temperature.

- The drying process occurs much faster due to the evaporation of moisture under vacuum.

- High degree of homogenization of honey due to the operation of a special mixing device.

- The narrow vertical design does not require large production areas while boasting high productivity.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

A hydraulic crane hoist with a hook is a mechanical device designed to lift and move heavy machinery or engines, commonly used in industrial settings as well as automotive repair for safe and efficient handling of heavy loads.

- Type of the equipment: Optional equipment

The cyclone dust collection system is ideal for food processing facilities looking to prevent contamination by airborne particles, reduce product loss, and maintain a cleaner work environment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

A thermometer is a precision tool used to measure product temperature in food processing, ensuring accurate control during cooking, mixing, and other food production processes. It helps to maintain consistency, optimize processing conditions, and meet safety standards in industrial food processing equipment like cooking kettles, blanchers and fryers.

- Material: Stainless steel

- Type of the equipment: Optional equipment

A hot oil filter for continuous industrial tabletop fryers allows you to quickly and effectively filter oil immediately after the frying process.

- Hot oil filtration - oil temperature up to 200 ┬░C.

- Optional filter material - paper, stainless steel

- Material: Stainless steel

- Country of origin: Slovakia

A frequency converter is an electrical device that adjusts the frequency of an input power source to control the speed and torque of electric motors, commonly used in industrial applications like pumps, fans, and conveyor systems.

- Power: 0.75 kW

- Input Voltage: 1 phase, 230 V, 50/60 Hz

- Rated Output Current: 4.5 A

- Output Frequency: 0 to 999.9 Hz

- Protection Rating: IP65

- Type of the equipment: Optional equipment

- Voltage: 380-400V

A 15-liter pasteurizer with a water bath that has a flat bottom and two canning racks, featuring a large capacity and made out of food grade 304 stainless steel.

- Material: Stainless steel

- Principle of operation: Batch mode

The long-term pasteurization tank is a compact solution for the heat treatment of milk in order to disinfect the microflora and eliminate harmful microorganisms. This unit belongs to the category of long-term pasteurization systems, heating milk between 63 and 95 degrees Celsius, and maintaining it at a specific temperature for a set period of time. The special design allows not only for pasteurization of milk in the flow, but also for sequential cooling, by feeding cold water into the heat exchanger after heating.

- External forced circulation with a heat exchanger

- Highly efficient steam heating via the heat exchanger

- Can also be used as both a pasteurization and cooling unit

- High-performance milk pump

- Compact vertical design

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1000l

The AISI 304 stainless steel oil drain system is suitable for use with most deep fryers. It allows you to filter the oil directly when draining it from the fryer.

- Material: Stainless steel

- Weight: 13,5

The high-performance slicing and dicing machine can function as a standalone unit or be integrated into a production line.

- Can process large products - sweet potato, lettuce, root vegetables

- Large selection of replaceable knives - different sizes of the final product

- Material: Stainless steel

The unique feature of this vacuum honey evaporator model, distinguishing it from a honey dryer, is its ability to create a deep vacuum with a residual pressure of up to 0.08 Bar during processing, and thus lowering the processing temperature! This innovative unit not only allows for quick and efficient drying of honey but also enables the immediate evaporation of water, producing a semi-finished product suitable for the subsequent production of «dry honey» or powdered honey.

- There is no need to have a large drying surface ŌĆō an evaporation mirror.

- There is no need to install a mixing device for thick and viscous products.

- Low evaporation temperature of moisture ŌĆō water from honey, at which its quality and medicinal properties are not compromised, and the risk of HMF growth is reduced to almost zero.

- Fast and efficient dehydration of honey at a low processing temperature.

- Material: Stainless steel

- Principle of operation: Batch mode

- Max vacuum: -1 Bar

A vacuum honey dryer is used to dehydrate (remove moisture from) honey at sub-atmospheric pressure.

- This highly efficient and innovative vacuum drying process guarantees honey drying rates exceeding 1% per hour!

- The vacuum dryer allows for quick and gentle drying of honey at temperatures up to 39┬░C without increasing hydroxymethylfurfural (HMF) levels.

- Any heat source (hot water, steam) can be used to supply thermal energy to the dryer's jacket.

- The specially designed mixing device enhances heat transfer within the product, improving its thermal efficiency and significantly reducing drying energy costs.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Max vacuum: -0,8 Bar

The oil-free four-cylinder piston compressor is the ideal solution for those who value both performance and silence.

- Equipped with two twin-piston units with separate engines

- Four air filters

- Mechanical pressure switch

- Quiet operation (at least 25% quieter than traditional compressors)

- Carrying handle and mobile wheel support

- Principle of operation: Continuous mode

- Total power, kW: 1,5

- Voltage: 220-230V

A drying chamber for vegetables and fruits is a specialized enclosure designed to gently remove moisture from produce, preserving its natural flavors and nutrients while extending its shelf life.

- Type of the equipment: Individual machine

- Weight: 215

- Area, m┬▓: 14

- Number of shelves: 40

The vacuum crystallizer-cooler is specifically designed for sweetened condensed milk. Crystallization with cooling is one of the most important stages in the production of condensed milk according to GOST and is necessary before dosing and packing the finished product.

- After crystallization, condensed milk has a delicate structure with small crystals

- Condensed milk has a homogeneous shape and attractive consumer properties

- The shelf life of condensed milk is extended without changing the quality of the product

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The durable single gas stove serves a versatile purpose, suitable for heating large cooking kettles. 7 kW.

- Heating: Gas

- Heating power, kW: 7