CATALOG

Ta pompa jest monoblokowÄ , jednostopniowÄ pompÄ prÃģÅžniowÄ z pierÅcieniem cieczowym, odpowiedniÄ do zastosowaÅ o niskiej, Åredniej i wysokiej prÃģÅžni. Jest to ekonomiczna pompa charakteryzujÄ ca siÄ wyjÄ tkowÄ wydajnoÅciÄ i niezawodnoÅciÄ .

- Capacity: 52 m3/h

- Capacity: 50l/ 100l

- Material: Stainless steel

- Engine power, kW: 0,18/

- Principle of operation: Batch mode

- Country of origin: Slovakia

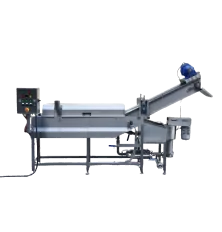

The continuous conveyor deep fryer is a reliable and versatile solution suitable for high-performance frying of a wide range of products by immersing them in hot oil.

- Universal application

- Quick transition for frying new types of products

- Possibility of using special frying modes

- Minimal amount of oil in the system

- Trouble-free oil filtration

- High oil exchange ratio

- High efficiency and productivity with compact design

- Manufactured to the highest quality standards using materials and components made in Europe.

A drying chamber for vegetables and fruits is a specialized enclosure designed to gently remove moisture from produce, preserving its natural flavors and nutrients while extending its shelf life.

- Type of the equipment: Single machine

- Weight: 215

- Area, m2: 14

- Number of shelves: 40

The Economy series of the cooking kettles comprise a thick-walled stainless steel container with an electric mixer mounted on the quick-release upper housing. The installation allows you to mix and stir products during processing. The thick bottom of the pot allows it to be installed on all types of heating surfaces (gas, induction or electric stove).

- Sandwich bottom (multilayer) for use on all types of hobs, including induction

- Quick release lid with an electric stirrer

- Safety grid under the upper hull hatch - safe handling when stirring

- Possibility of visual inspection through the safety grid during processing

- Safe loading of components even during mixing

- Material: Stainless steel

- Engine power, kW: 0,12

- Volume: 20l/ 50l/ 100l

- Voltage: 220-230V

The vacuum crystallizer-cooler is specially designed for sweetened condensed milk. Crystallization with cooling is one of the most important stages in the production of condensed milk according to GOST and is necessary before dosing and packing the finished product.

- After crystallization, condensed milk has a delicate structure with small crystals

- Condensed milk has a homogeneous shape and attractive consumer properties

- The shelf life of condensed milk is extended without changing the quality of the product

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The vacuum evaporation unit is specially designed for thickening dense food products in industrial quantities. It can be used to produce thick syrups, caramel masses, dense fruit masses, as well as in the production of pectin, or heat-stable fillings with a high productivity.

- High performance

- Rotary spraying system with a powerful electric drive

- Evaporation in a thin layer with a large heat transfer area

- Low investment installation costs

- Tangential entry for product swirling

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

Fluid pumping is facilitated by the movement of the stainless steel rotor inside the rubber stator.

System ten zostaÅ specjalnie zaprojektowany, aby uÅatwiÄ bezpoÅrednie przenoszenie pulpy do prasy.

- Capacity: 2000 kg/h

- Weight: 28

Cyrkulacyjna wyparka prÃģÅžniowa zwykle odnosi siÄ do kombinowanej wersji parownika, ktÃģra wykorzystuje rÃģwnieÅž inne typy w celu poprawy wydajnoÅci parowania, szczegÃģlnie poprzez skrÃģcenie czasu zagÄszczania i podczas przetwarzania produktÃģw wraÅžliwych na ciepÅo, takich jak mleko.

- ZewnÄtrzny obieg cyrkulacyjny z ogrzewaniem intensyfikuje cykliczny proces parowania.

- System wymuszonego obiegu zapewnia zmniejszenie ryzyka miejscowego przegrzania produktu.

- Skraplacz umoÅžliwia uzyskanie gÅÄbokiej prÃģÅžni i utrzymuje niskÄ temperaturÄ parowania.

- Zastosowanie urzÄ dzenia mieszajÄ cego z systemem natryskowym uÅatwia odparowanie produktu w cienkiej warstwie, naÅladujÄ c parownik filmowy.

- Heating: Steam

- Material: Stainless steel

- Country of origin: Slovakia

- Total power, kW: 2,4

- Voltage: 380-400V

A durable single gas stove serves a versatile purpose, suitable for heating cooking kettles.

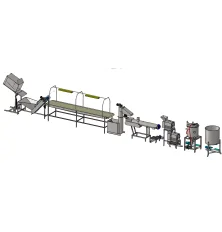

Production line for vegetarian vegetable-based formed or molded products such as falafel. The line is based on the classical method of producing semi-finished products for their subsequent freezing and packaging.

- Compact line suitable for both professional kitchens and industrial production.

- Fully automatic operation with minimal manual labor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

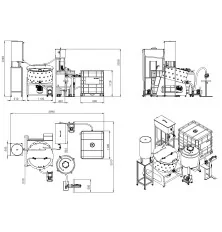

Linia linii do zagÄszczania i zagÄszczania zostaÅa zaprojektowana specjalnie z myÅlÄ o przemysÅowych zakÅadach mleczarskich posiadajÄ cych niewielkie nadwyÅžki mleka lub mniejszych przedsiÄbiorstwach zajmujÄ cych siÄ przetwÃģrstwem mleka, ktÃģre chcÄ poszerzyÄ swÃģj asortyment produktÃģw. Jego szacowana wydajnoÅÄ wynosi do 50-120 kg/h przy pracy ciÄ gÅej.

- Profesjonalna technologia przemysÅowa o kompaktowych wymiarach

- DuÅža iloÅÄ dodatkowego wyposaÅženia i opcji do wyboru

- Material: Stainless steel

- Principle of operation: Continuous mode

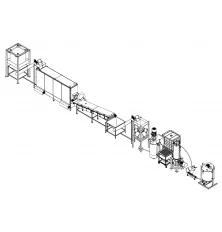

A production line designed for processing core fruits with seeds, such as apples or pears, into puree, with a capacity of up to 2000 kg/hour based on the volume of raw materials processed.

- Capacity: 1000 kg/h/ 2000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Our hydrodynamic extraction line is designed for extracting various components from plant materials, including biologically active substances, proteins, fats, carbohydrates, antioxidants, dyes, and flavors.

- Effective âsoftâ continuous hydrodynamic extraction â percolation from finely crushed raw materials.

- Extraction without the need for pre-drying the product, resulting in savings on labor and energy costs.

- Utilizing raw materials without heat treatment, preserving all of their valuable substances and enzymes.

- Possibility of performing vacuum-pulse extraction (optional).

- Additional income from processing âwasteâ products - extracting valuable components from pulp and pomace.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A production line for thermostable fruit-based fillings, widely used in the production of pastries, baked goods, and various semi-finished products, as well as curd cheeses, creams, and even ice cream.

- Obtaining top-notch thermostable fillings while preserving essential nutrients and vitamins.

- Compact system featuring a unified control panel, ensuring easy and straightforward operation.

- Swift and efficient recycling included as a standard feature.

- Modular design with numerous additional options for customization.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The complex of equipment for the production of mayonnaise consists of several installations for automatic dosing, mixing, and obtaining a stable emulsion.

- Compact design, offering convenient and straightforward operation in a limited space.

- Cost-effective solution for automatic dosing without incurring high automation costs.

- A wide range of additional modular options.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 13,5

- Voltage: 380-400V

Equipment for mixing multi-component mixtures of products, such as vegetable salads with various dressings, including thick and viscous ones like mayonnaise, thick sour cream and other similar sauces.

- Hydraulic tilting system is included in the basic version

- The controls are located directly on the frame supporting structure

- Eccentrically offset working shaft for rotating/tilting the working tank

- Low loading height

- The installation is made entirely out of food grade stainless steel

- Material: Stainless steel

- Operation mode: Mixed

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 600l/ 1000l

The price is indicated for the basic version of the set of equipment with a homogenizer

The equipment for the production of ice cream mixtures is based on a universal vacuum reactor with a coolant jacket and a multi-stage dispersant/homogenizer in an external circulation loop.

- Special type of a stirring device for easy disassembly and cleaning

- Processing with minimal product loss

- The bottom outlet valve is included in the basic version of the installation

- Multi-stage disperser for intensive wetting and homogenization of the flowing mixture

- External circulation circuit with a three-way valve for operation/washing of the equipment

- Reinforced agitator drive for thick and viscous mixtures

- Built-in vacuum pump

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 3

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The FRP hydraulic press is the easiest and fastest solution for pressing various types of crushed fruits. The device is used for pressing crushed fruits with water.

- simple and fast extraction,

- no physical effort required,

- high percentage of juice yield (up to 80%),

- easy cleaning,

- long service life.

The Bag in Box Filler is designed for filling hot and cold liquids into Bags in Boxes and for Stand Up Pouch packaging.

- The machine fills the bags up automatically.

The electric pasteurizer is ideal for the heat treatment of various fruits, including apples, pears, blackberries, strawberries, blueberries, elderberries, currants, carrots, greens, quince, beets, sea buckthorn, rowan berries, and onions.

The VMG S 650P vacuum homogenizing unit can be used for making toothpaste as well as a variety of similar products with complex production requirements.

- The vacuum ensures effective air removal, eliminating the conditions for the development of bacteria and other pathogenic organisms.

- The special shape of the mixing device is tailored for the thickest and most viscous products.Â

- The Ultra Shear submersible homogenizer creates a stable emulsion.

- The cavitation processes aid in activating hydrodynamic mixing.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 29

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 52

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

The price is set for the combination of a basic fryer model and an additional module with rotating paddles.

The universal modular fryer equipped with an additional paddle module is designed for frying thin slices of products that require immersion beneath the oil level.

- Adjustable frying time from a few seconds up to an hour

- Compact, tabletop version

- The paddle conveyor is installed on top of the basic fryer

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

Used for blanching products in water, it is suitable for processing various vegetables, legumes, grains, mushrooms and other products. This versatile machine also functions as a water separator centrifuge which is activated after the blanching processes.

More information: sales@foodtechprocess.com

- Capacity: 30l/ 90l

- Material: Stainless steel

Multifunctional vacuum mixer/homogenizer for grinding, mixing, and homogenizing products to obtain homogeneous masses.

- Built-in jacket for the bottom and walls of the unit.

- Cutter knives with a powerful electric drive

- Slanted design for efficient mixing and chopping

- Forced circulation circuit (optional)

- Wide range of options

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350l/ 650l

- Total power, kW: 13/ 17

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

PoÅÄ czenie kompaktowej frytkownicy model 400/1100/12 z dodatkowym przenoÅnikiem gÃģrno-dociskowym pozwala na poszerzenie asortymentu smaÅžonych produktÃģw. Nadaje siÄ do zapewnienia jednolitego, wysokiej jakoÅci smaÅženia produktÃģw w maÅych zakÅadach przemysÅowych, kuchniach profesjonalnych i zakÅadach gastronomicznych poprzez caÅkowite zanurzenie produktu w oleju podczas caÅego procesu smaÅženia. Kompaktowe wymiary frytownicy uÅatwiajÄ instalacjÄ na blacie roboczym.

- Maksymalna wysokoÅÄ smaÅžonego produktu wynosi - do 50 mm.

- Termometr zanurzeniowy do wizualnego monitorowania temperatury oleju

- Czas smaÅženia moÅžna ustawiÄ od kilku sekund do godziny!

- Wysoka temperatura â do 200C

- PrzenoÅnik taÅmowy wykonany jest z cienkiej siatki ze stali nierdzewnej przeznaczonej do kontaktu z ÅžywnoÅciÄ

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The tubular pasteurizer is typically designed for pasteurizing cream in butter production lines. These pasteurizers are commonly used in dairy processing industrial facilities, especially in butter production and other related sectors.

For additional information, please contact us at sales@foodtechprocess.com

KocioÅ kuchenny do przygotowywania syropÃģw, karmelu, past cukrowych oraz do przetwarzania i wytwarzania rÃģÅžnych produktÃģw gÄstych i lepkich. CzÄsto uÅžywany do rozpuszczania cukru i wytwarzania rÃģÅžnych roztworÃģw nasyconych i przesyconych.

- Wbudowane ogrzewanie olejem termicznym do 150 stopni Celsjusza

- MieszadÅo z ramÄ kotwicznÄ do szybkiego rozpuszczania

- StoÅžkowa konstrukcja dna pojemnika roboczego bez martwych stref

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 300l

- Total power, kW: 19

The working surface is made out of food-grade stainless steel, on top of which the deep fryer can be installed. It is quipped with wheels for ease of movement.

For additional information, please contact us at sales@foodtechprocess.com

Uniwersalny kocioÅ kuchenny z wbudowanym mikserem, sÅuÅžÄ cy do mieszania i gotowania wszelkiego rodzaju potraw, emulsji kosmetycznych, kremÃģw, past cukrowych i wielu innych.

- Åatwo zdejmowalne, samoregulujÄ ce skrobaki teflonowe

- Czujnik otwarcia pokrywy zapewniajÄ cy bezpiecznÄ konserwacjÄ mieszadÅa

- Higieniczny czujnik temperatury produktu

- ZawÃģr wylotowy o duÅžej Årednicy

- Bezpieczny wylot pary na gÃģrze pokrywy kotÅa

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l

- Voltage: 220-230V

- Wylot, cale : 6/4

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

For additional information, please contact us at sales@foodtechprocess.com

Optional module for 400/1100/12 Universal tabletop Modular Fryer - Pressure Conveyor for frying foods that require forced immersion in oil.

This 550 l professional tilting kettle is gas-fired and is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams. With this tilting version, you can make your life even easier.

For a price quote, send us an email to sales@foodtechprocess.com

- Heating: Gas

- Capacity: 500 l

- Material: Stainless steel

This 160L or 220L professional cooking pot is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams.

For a price quote, send us an email to sales@foodtechprocess.com

This gas powered professional cooker is indispensable in professional kitchens. It allows you to easily prepare the most delicious soups, broths, sauces and creams.

Thanks to the indirect heating system, this electric kettle is ideal for cooking liquid foods. It is completely made of stainless steel and equipped with a convenient drain valve.

For more information, please contact us at sales@foodtechprocess.com

This stainless steel cooking pot will always ensure cooking, baking or boiling different foods.

For more information, please, send us an email at sales@foodtechprocess.com

This 265 liter stainless steel cooker is great for boiling or roasting a variety of ingredients. This gas cooker with indirect heating system is ideal for cooking liquid food. It is made of stainless steel and equipped with a convenient drain valve.

Thanks to the indirect heating system, this kettle is ideal for cooking liquid dishes. It is completely made of stainless steel and equipped with a convenient drain valve.

For more information, please, send us an email at sales@foodtechprocess.com

This premium cooking kettle is gas-fired and has a volume of 160 liters. Ideal for preparing a wide variety of dishes in professional kitchens.

For more information, please contact us at sales@foodtechprocess.com

This premium cooking kettle is gas-fired and has a capacity of 120 liters. Ideal for preparing a wide variety of dishes.

For more information, please, send us an email to sales@foodtechprocess.com

This electric cooking pot has a volume of 60 liters and is used to prepare a large number of dishes. It is comfortable to use and easy to clean.

For more information, please, send us an email to sales@foodtechprocess.com

This 60 liter cooking kettle is indispensable for cooking large amounts of food. Runs on gas and handles all basic cooking tasks with ease.

For more information, please, send us an email to sales@foodtechprocess.com

Fat block melter Fastmelter refers to the equipment of periodic action for melting butter and other frozen fats within the food industry.

Cena dotyczy wersji podstawowej bez dodatkowych moduÅÃģw

Uniwersalna moduÅowa frytownica przenoÅnikowa z pojedynczym pasem sÅuÅžy do ciÄ gÅego smaÅženia rÃģÅžnorodnych produktÃģw o niskiej zawartoÅci wody, ktÃģre nie wymagajÄ przymusowego zanurzania pod powierzchniÄ oleju.

- Regulowany czas smaÅženia od kilku sekund do godziny!

- MoÅžliwoÅÄ wykorzystania urzÄ dzenia jako blanszownika ciÄ gÅego lub kotÅa do gotowania produktÃģw o delikatnej strukturze

- System moduÅowy, rozszerzajÄ cy funkcje z kaÅždym nowym moduÅem

- Kompaktowa wersja na komputery stacjonarne

- MoÅžliwoÅÄ okresowego smaÅženia produktÃģw z automatycznym rozÅadunkiem

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

A complete set of equipment for the production of margarine with a capacity of up to 500 kg/hour.

For more information, contact us at: sales@foodtechprocess.com

Cooking tank with a bottom out of stainless steel AISI 316. Capacity of 150 liters.

An ideal solution that greatly facilitates and speeds up the work of the attendants, without having to lift and turn the bowl in order to transfer the dough to another dosing or portioning machine, for example, to another batcher or portioner.

For more information, please contact us at sales@foodtechprocess.com

Chocolate heating pump is the perfect solution to upgrade your production line. You can easily connect the pump to any device (such as a chocolate enrobing machine).

This kettle with a radiator cooling system ranging from 30 to 500 liters is ready to cook according to the principle of a water bath.

A modern cooking and mixing device with a wide range of applications in confectionery, bakeries, catering establishments.

Modern product with a wide range of applications in pastries, bakeries, catering facilities

Universal cooking kettle for thick mixtures: it works on the principle of a water bath and can be used in confectionery shops, bakeries and other catering establishments. Offers a wide variety of models.

- Mechanical tilting system for unloading

- Safety grill for the mixer drive

- Built-in electric heating up to 150 degrees

- Mobile support structure on wheels

- Heating: Electricity

- Principle of operation: Batch mode

- Volume: 30l/ 60l/ 80l/ 120l

Electric steam generator with capacity of 2*24.5 liters - meets PED standards - with double or single resistance.

Electric steam generator with capacity of 57 liters - meets PED standards - with double or single resistance.

Electric steam generator with capacity of 24.5 liters - meets PED standards - with double or single resistance.

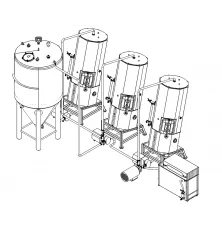

Cleaning-In-Place - Machine for cleaning and disinfection of vessels and pipelines in breweries and other food processing plants with four tanks.

Improve the cleaning process with the CIP-53, a mobile station designed for thorough sterilization and sanitation of vessels and pipelines. Ideal for breweries and the food industry, this comprehensive system with three 50 or 100 liter tanks ensures efficient cleaning of fermentation and storage tanks, offers digital temperature control and neutralization.

CIP-302: Cleaning-In-Place - Machine for cleaning and disinfection of vessels and pipelines in breweries and other food processing plants with two tanks of 300 liters.

CIP-202: Cleaning-In-Place - Machine for cleaning and disinfecting vessels and pipelines in breweries and other food processing plants with two 200 liter tanks.

CIP-102 consists of two main tanks for alkaline and acid solution and one vessel used for neutralization of solutions.

CIP-52: Clean-In-Place - Machine for cleaning and the disinfection vessels and pipelines in breweries and other food processing plants with two 50 liter tanks.

CIP-201 - installation for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 200 liters.

CIP station CIP-101 With a usable capacity of 1Ã100 liters, it is used for cleaning, sanitizing and sterilizing vessels and pipes in a brewery. This type of CIP station is recommended for cleaning and sanitizing tanks from 0 to 4000 liters.

CIP-51: Equipment for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 50 liters

The industrial meat grinder is made out of food-grade stainless steel. The kit includes various accessories such as a sausage attachment and an attachment with two cross blades. The productivity of the meat grinder is around 120 kg of minced meat per hour.

- Compact

- Professional

- With anti-slip rubber feet

- Stainless steel housing

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Total power, kW: 0,75

- Voltage: 220-230V

Additional option to VMG laboratory vacuum homogenizer 20/50.

Additional option to VMG laboratory vacuum homogenizer 20/50.

Fast, sleek, quiet, user-friendly, safe, smooth-running commercial salad dryer, designed to efficiently dry up to 6 Kg.

For more information, send us a request at sales@foodtechprocess.com

The automatic donut frying machine is a high-quality device that is suitable for high productivity and daily usage.

- Tabletop system

- Includes a depositing attachment

- Compact design

- Completely out of stainless steel

- Material: Stainless steel

- Principle of operation: Continuous mode

- Total power, kW: 3

- Voltage: 220-230V

The price is indicated without gastro containers

Use this all-stainless steel water bath for gradual heating or cooking. The device is equipped with a practical drain tap for easy emptying of the container and is suitable for use with gastronorm containers.

- Compact installation

- Simple controls

- Safe operation

- Wide range of applications

- Material: Stainless steel

- Principle of operation: Batch mode

- Voltage: 220-230V

A grain mill made out of stainless steel, it is sturdy and durable grinder, with increased wear resistance.

For more information, contact our sales department at sales@foodtechprocess.com

This powder making machine is made out of stainless steel. All parts that are in contact with food are made out of food grade 304 stainless steel for health and safety reasons.

For additional information, contact us at sales@foodtechprocess.com

The conveyor is made out of strong and highly-resistant stainless steel. It is also additionally reinforced for reliability during operation.

For additional information, please contact us at sales@foodtechprocess.com

The MPP 8 vegetable root peeler is an industrial peeling machine with a stainless steel body.

Designed for pumping hot thermal oil in frying circulation and filtration systems, for oil loading and unloading, in "hot" continuous oil filtration systems with a maximum temperature of up to 200 degrees.

More information: sales@foodtechprocess.com

May include such processes as: honey dissolution, honey drying, honey homogenization, honey pasteurization, honey creaming and honey packaging. The necessary equipment is selected by the customer based on the required processing technology for their manufacturing process.

More information: sales@foodtechprocess.com

This equipment set can be used for the production of a diverse array of sauces, as well as various vegetarian products based on nuts, soy and rice. It is capable of processing around 300/600 liters of product per batch.

For further details, contact us at sales@foodtechprocess.com

A filter designed for continuous fine filtration of conveyor fryers using vegetable oil, and other frying fats.

More information: sales@foodtechprocess.com

For frying foods in oil, deep-frying, suitable for frying onions, seeds, nuts, vegetable snacks and chips, and other products, including breaded or covered in liaison. Can also be used as an oil separating centrifuge for deep fryer.

- Two in one: a deep fryer and a centrifuge to remove excess oil

- Possibility of frying small and fragile products

- Obtaining a âdry productâ after frying

- Low carbonization of oil due to the cleaning feature after frying

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l/ 90l

- Total power, kW: 11

- Voltage: 380-400V

Kompleks urzÄ dzeÅ przeznaczony do przerobu orzeszkÃģw ziemnych surowych, obranych i blanszowanych, oferujÄ cy wydajnoÅÄ produkcyjnÄ do 500 kg/godz.

This equipment complex enables the production of Nutella-type chocolate pastes with a capacity of up to 250 kg/h.

For additional information, please contact us at sales@foodtechprocess.com

Complete set of equipment for processing shelled beans, and the production of a soy base with a capacity of 800-1000 liters per hour.

For additional information, contact us at sales@foodtechprocess.com

This set of equipment for the production of condensed milk from dry components by restoring the milk. This production line can be manufactured with a capacity of up to 500 kg/h or can be customized based on specific requirements.

For more information and detailed inquiries, please contact us at sales@foodtechprocess.com

Designed for "cold" vacuum drying of products sensitive to high temperatures, also suitable for liquid and viscous products.

For more information contact us at: sales@foodtechprocess.com

The set of individual equipment for the production of French fries may differ depending on the initial raw materials. We offer various modifications from washing to frying with subsequent dehumidification starting from 50 kg/h for the final product.

For more information, please contact us at: sales@foodtechprocess.com

This jam production line allows you to get ready-made jam at the exit from whole fruits at the entrance! Equipment options may vary depending on the customer's technology.

For additional information, please contact us at sales@foodtechprocess.com

Equipment for the production of condensed milk from pre-pasteurized milk. This equipment can be manufactured in models with production capacities up to 285 kg/h, it can also be customized based on individual requirements.

For more information, please contact: sales@foodtechprocess.com

The price is indicated without a source of compressed air - compressor (optional).

An atmospheric dryer is a periodic type of equipment designed for removing moisture and excess water from honey under vacuum conditions. This laboratory installation can also be used for processing small volumes of honey directly in apiaries.

- Large heat transfer area

- Low drying temperature thanks to the vacuum

- Easy operation and maintenance

- External forced circulation circuit for intense evaporation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100 - 140 kg

- Total power, kW: 6,5

- Voltage: 220-230V 380-400V

- Max vacuum: -0,8 Bar

The vacuum bread cooler is well-suited for application in small bakeries or as a laboratory unit in industrial enterprises. This enables the post-baking of bread under vacuum conditions, influencing both its shape and structure.

- Built-in deep vacuum system

- Built-in vapor removal and condensation system

- Built-in refrigeration system

- The chamber is designed for 3 gastro containers size GN 1/1, or pallets: 400x600/530x325 mm

- Compact and mobile installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 130l

- Voltage: 380-400V

The vegetable spin dryer has been designed for drying leafy vegetables rapidly and efficiently, both raw and boiled, prepared in medium-large sized professional kitchens and in food industries.

More information: sales@foodtechprocess.com

Set of 4 height adjustable legs+/- 100 mm.

For more information contact: sales@foodtechprocess.com

Supporting structure on wheels with locks (brake), 2 swivel wheels, 2 swivel wheels with a brake.

For more information, contact: sales@foodtechprocess.com

Cena dotyczy wersji podstawowej, bez opcji dodatkowych.

PrzemysÅowa suszarka na podczerwieÅ nadaje siÄ do suszenia szerokiej gamy produktÃģw: orzechÃģw, jabÅek, Åliwek, truskawek, malin, jagÃģd, grzybÃģw, marchwi, cebuli, czosnku, ziÃģÅ, miÄsa, fig, bananÃģw, pianek. W przypadku wybrania opcji dodatkowych moÅžna go rÃģwnieÅž stosowaÄ do peklowania i suszenia caÅych miÄs i ryb.

- Kompaktowa instalacja

- Szybkie i skuteczne suszenie

- MoÅžliwoÅÄ wyboru indywidualnych ustawieÅ suszenia

- Wykonane w caÅoÅci ze stali nierdzewnej

- WewnÄtrzna powierzchnia szafki pokryta jest lustrzanÄ powÅokÄ

- Cicha praca instalacji

- Niskie zuÅžycie energii na cykl suszenia

- Heating: Electricity

- Material: Stainless steel

- Operation mode: Mixed

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 7l/ 10l/ 14l

- Total power, kW: 10/ 15/ 20

- Area, m2: 3,5/ 5,2/ 6,9

- Number of shelves: 10/ 15/ 20

PrzemysÅowa patelnia elektryczna na olej termiczny to optymalne i ekonomiczne rozwiÄ zanie do przemysÅowej produkcji ÅžywnoÅci na maÅÄ skalÄ. Pozwala na niskie koszty energii i eksploatacji, zapewniajÄ c jednoczeÅnie rÃģwnomierne i intensywne ogrzewanie caÅej misy roboczej. BezwÅadnoÅÄ cieplna systemu pomaga utrzymaÄ wymaganÄ temperaturÄ przez dÅuÅžszy czas, dziÄki czemu jest skuteczny podczas smaÅženia cebuli, marchwi, smaÅženia mÄ ki i warzyw oraz przygotowywania sosÃģw, zup, dodatkÃģw, gulaszy i nie tylko.

- Niskie zuÅžycie energii

- Jednolite ogrzewanie

- Podgrzewane boki stoÅžkowe

- Regulowana intensywnoÅÄ ogrzewania

- Sterownik w higienicznej obudowie bezpoÅrednio na konstrukcji noÅnej

- Uchwyty do otwierania pokrywy umieszczone w strefie zimnej

- Automatyczny system podnoszenia/przechylania

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 26

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 28

- Voltage: 380-400V

- Duplicator volume: 106l