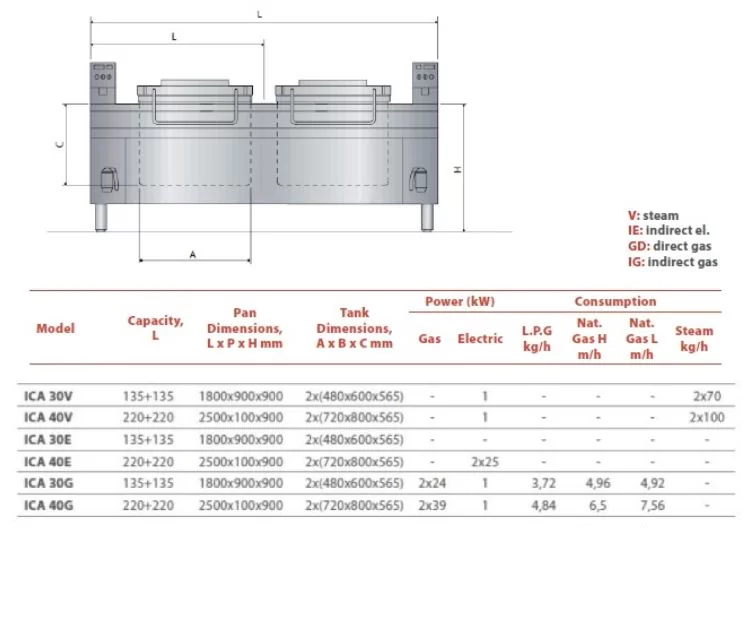

Automatic double cooker

Automatic cooker made for continuous batch production. Different types of food can be boiled, like pasta, rice, vegetables, meat etc. Options: direct gas, indirect steam boiling or direct electric.

Price depends on chosen option.Â

Automatic cooker is made for continuous batch production. Different types of food can be boiled, like pasta, rice (minimum 1.5 mm in size), vegetables, meat etc., thanks to the basketâs design.

Setting the cooking parameters is intuitive and easy and with the precise instruments. The cooking results are excellent and cycles can be repeated by simply pressing the start button.

Machine equipped with bright buzzer, timing of cooking cycles, automatic temperature control, automatic replenishing water level in tank and provided with overflow system for auto drain of cooking starch in suspension.Â

TECHNICAL FEATURES:

Cooking tank

- Stainless steel cooking tank in AISI 316/L SB polished

Lid

- Balanced lid in AISI 304 stainless steel with heat resistant handle

- Support frame and panels

Supporting frame in stainless steel

- Thermal insulation guaranteed by high density ceramic fiber 64/128

- Panels in AISI 304 stainless steel, fine satin finish

Machine equipped with bright buzzer, timing of cooking cycles, automatic temperature control, automatic replenishing water level in tank and provided with overflow system for auto drain of cooking starch in suspension.Â

HEATING SYSTEM

Direct Gas versions

Heating by means of AISI 304 stainless steel high efficiency tube burners Ignition by means of manual piezo-electric lighter and pilot flame

- Valve-controlled safety tap with a thermocouple

- Safety thermostat against overheating and lack of water

- Venting grid

- Set of jets for different types of gas

Jacket (indirect heated version)

- Jacket with bottom and walls in AISI 304 stainless steel

- Tilting container

- Automatic tilting by electric actuator mechanism with possibility to positioning, by means of selector, to drip product or to drain directly.Â

Direct Electric versions

- Heating with battery of electric heaters

- Safety thermostat to prevent overheating and keeping the equipment from operating without water

- Temperature is controlled by thermostat (50°C - 120°C)

- Electric supply 400V 3N 50Hz

Indirect Electric versions

Â

- with Jacket Heating by means elements in INCOLOY alloy, separated from the cooking yield

- Safety thermostat to prevent overheating and keeping the equipment from operating without water

- Jacket pressure control by working pressure switch and weight-loaded safety relief valve calibrated 0,5 bar, vacuum valve and pressure gauge

- Jacket water level control taps max/min with the option of automatic filling

- Standard power supply 400V - 3N - 50Hz

You might also like

Heating boilers are designed to cook sausages, hams and oďŹal. Technology for superior performance and hygiene.

For additional information, please contact us at sales@foodtechprocess.com

The electric cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, broths, pasta, milk dishes, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. The equipment is not suitable for roasting or baking.

For additional information, please contact us at sales@foodtechprocess.com

Tilting pans with mixers cook the product with continuous stirring and subsequently discharge the food into receiving trolleys, ensuring the discharge spout remains at a constant height from the ground. Designed for the catering industry, large kitchens, school cafeterias, restaurants, and other food production businesses.

Automatic tilting cooking pots, with lateral support upright designed for cooking solid foods that are transferred by tipping of the container. Options: steam boiling, indirect electric, indirect gas, direct gas. Capacity options: 50, 100, 150, 200, 300, 500l.

Pokud potĹebujete vĂ˝robek vaĹit pĹi nĂzkĂ˝ch teplotĂĄch, abyste lĂŠpe zachovali jeho vzhled a výŞivovĂŠ vlastnosti, nebo pokud chcete pĹidat sloĹžky citlivĂŠ na teplo, doporuÄujeme pouĹžĂt univerzĂĄlnĂ kotel TiltCook.

Pro cenovou nabĂdku nĂĄm zaĹĄlete Şådost na adresu sales@foodtechprocess.com

VarnĂŠ zaĹĂzenĂ je vybaveno plĂĄĹĄtÄm pro ohĹev a topnĂ˝m systĂŠmem, elektricky pohĂĄnÄnĂ˝m mĂchadlem (s pĹevodovĂ˝m motorem) a teflonovĂ˝mi ĹĄkrabkami, kterĂŠ umoĹžĹujĂ zpracovĂĄnĂ produktĹŻ s nĂzkou aĹž stĹednĂ viskozitou. VarnĂŠ zaĹĂzenĂ je rovnÄĹž vybaveno vakuovĂ˝m systĂŠmem.

Pro vĂce informacĂ kontaktujte naĹĄe obchodnĂ oddÄlenĂ na adrese sales@foodtechprocess.com

- Capacity: 100l

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Type of the equipment: Single machine

JednĂĄ se o kompaktnĂ varnĂŠ zaĹĂzenĂ pro gastronomii: kavĂĄrny, bary, jĂdelny. ZaĹĂzenĂ je urÄeno k vaĹenĂ, duĹĄenĂ, smaĹženĂ a mĂchĂĄnĂ produktĹŻ rĹŻznĂŠ viskozity.

Cena zĂĄvisĂ na zvolenĂŠ variantÄ. NapiĹĄte nĂĄm prosĂm na adresu sales@foodtechprocess.com

BlanĹĄĂrovaÄ SnackPro pĹipravĂ rĹŻznĂŠ typy produktĹŻ, takĹže je skvÄlĂ˝m ĹeĹĄenĂm pro blanĹĄĂrovĂĄnĂ velkĂŠho mnoĹžstvĂ ovoce a zeleniny v krĂĄtkĂŠm Äase.

Pro vĂce informacĂ a cenovou nabĂdku nĂĄm napiĹĄte na sales@foodtechprocess.com

KompaktnĂ Ĺada vakuovĂ˝ch varnĂ˝ch kotlĹŻ dvojitĂŠho typu zahrnuje komplex dĂĄvkovĂ˝ch varnĂ˝ch jednotek urÄenĂ˝ch k periodickĂŠmu tepelnĂŠmu zpracovĂĄnĂ, vakuovĂŠmu mĂchĂĄnĂ a odvzduĹĄĹovĂĄnĂ rĹŻznĂ˝ch produktĹŻ za subatmosfĂŠrickĂŠho tlaku.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2x300l/ 2x600l

AtmosfĂŠrickĂŠ vaĹiÄe AC jsou urÄeny k ĂşÄinnĂŠmu mĂchĂĄnĂ, ohĹevu a vaĹenĂ produktĹŻ pro potravinĂĄĹskĂ˝, farmaceutickĂ˝ a kosmetickĂ˝ prĹŻmysl. PracovnĂ objem do 300 l.

Pro cenovou nabĂdku nĂĄm zaĹĄlete e-mail na adresu sales@foodtechprocess.com

ZaĹĂzenĂ je urÄeno k pasterizaci ĹĄirokĂŠ ĹĄkĂĄly vĂ˝robkĹŻ v rĹŻznĂ˝ch typech obalovĂ˝ch materiĂĄlĹŻ, jako jsou plechovky a sklenice.

Pro vĂce informacĂ kontaktujte naĹĄe obchodnĂ oddÄlenĂ na adrese sales@foodtechprocess.com

- Heating: Mixed

- Capacity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Single machine

JednĂĄ se o topnĂ˝ kotel o objemu 400 l, nabĂzĂme komerÄnĂ vaĹiÄe o rĹŻznĂ˝ch objemech, pro vĂce informacĂ nĂĄm zaĹĄlete e-mail na adresu sales@foodtechprocess.com

Tento nerezovĂ˝ hrnec vĹždy zajistĂ vaĹenĂ, peÄenĂ nebo vaĹenĂ rĹŻznĂ˝ch potravin.

Pro vĂce informacĂ nĂĄm prosĂm poĹĄlete e-mail na adresu sales@foodtechprocess.com

KompletnĂ sada zaĹĂzenĂ pro zpracovĂĄnĂ loupanĂ˝ch fazolĂ a vĂ˝robu sĂłjovĂŠho zĂĄkladu o kapacitÄ 800-1000 litrĹŻ za hodinu.

DalĹĄĂ informace zĂskĂĄte na adrese sales@foodtechprocess.com

Cena je stanovena pro zĂĄkladnĂ verzi reaktoru bez dalĹĄĂch moĹžnostĂ a ovlĂĄdacĂho panelu.

VakuovĂĄ konvice s duplikĂĄtorem chladicĂ kapaliny a mĂchacĂm zaĹĂzenĂm je univerzĂĄlnĂm ĹeĹĄenĂm pro zpracovĂĄnĂ rĹŻznĂ˝ch produktĹŻ pĹi subatmosfĂŠrickĂŠm tlaku. Na zĂĄkladÄ tohoto jednoduchĂŠho zaĹĂzenĂ lze zvolit a modulovat do komplexnĂch zaĹĂzenĂ, jako je napĹ. vakuovĂĄ vĂ˝parnĂk, vakuovĂĄ konvicea zaĹĂzenĂ na vĂ˝robu smetanovĂŠho medu.

- Ĺ ikmĂĄ konstrukce - gravitaÄnĂ mĂsenĂ

- SpodnĂ ventil DN40 v zĂĄkladnĂ verzi

- DuplikĂĄtor s malĂ˝m objemem - nĂzkĂŠ nĂĄklady na ohĹev/chlazenĂ chladicĂ kapaliny

- ModulĂĄrnĂ systĂŠm: pĹizpĹŻsobenĂ zaĹĂzenĂ a jeho funkcĂ objednĂĄnĂm dalĹĄĂch moĹžnostĂ.

- Snadno rozebĂratelnĂŠ mĂchacĂ zaĹĂzenĂ

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

- Duplicator volume: 3l

Äerpadlo na ohĹev ÄokolĂĄdy je dokonalĂ˝m ĹeĹĄenĂm pro modernizaci vaĹĄĂ vĂ˝robnĂ linky. Äerpadlo mĹŻĹžete snadno pĹipojit k jakĂŠmukoli zaĹĂzenĂ (napĹ. k zaĹĂzenĂ na vĂ˝robu ÄokolĂĄdy).

Tyto plynovĂŠ vaĹiÄe se vyrĂĄbÄjĂ pro profesionĂĄlnĂ kuchynÄ a takĂŠ pro dalĹĄĂ potravinĂĄĹskĂŠ zĂĄvody. JednĂĄ se o kapacitu 150 l.

NabĂzĂme vĂce kapacit. Pro vĂce informacĂ nĂĄm prosĂm napiĹĄte na sales@foodtechprocess.com

Pokud potĹebujete vĂ˝robek vaĹit pĹi nĂzkĂ˝ch teplotĂĄch, abyste lĂŠpe zachovali jeho vzhled a výŞivovĂŠ vlastnosti, nebo pokud chcete pĹidat sloĹžky citlivĂŠ na teplo, doporuÄujeme pouĹžĂt univerzĂĄlnĂ kotel TiltCook.

Pro cenovou nabĂdku nĂĄm zaĹĄlete Şådost na adresu sales@foodtechprocess.com

DvouplĂĄĹĄĹĽovĂ˝ vaĹiÄ z nerezovĂŠ oceli pro vĂ˝robu marmelĂĄd a dĹžemĹŻ.

PrĹŻmyslovĂ˝ kotel pro vaĹenĂ a duĹĄenĂ masa, zeleniny, moĹskĂ˝ch plodĹŻ, luĹĄtÄnin a obilovin pod tlakem do 0,5 a teplotou do 110 °C bar.

Pro cenovou nabĂdku nĂĄm poĹĄlete e-mail na adresu sales@foodtechprocess.com