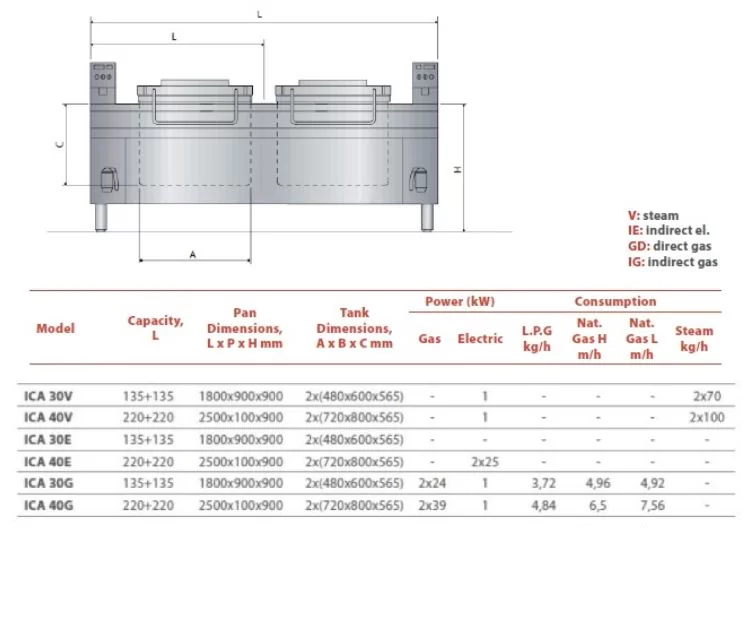

Automatic double cooker

Automatic cooker made for continuous batch production. Different types of food can be boiled, like pasta, rice, vegetables, meat etc. Options: direct gas, indirect steam boiling or direct electric.

Price depends on chosen option.┬Ā

Automatic cooker is made for continuous batch production. Different types of food can be boiled, like pasta, rice (minimum 1.5 mm in size), vegetables, meat etc., thanks to the basketŌĆÖs design.

Setting the cooking parameters is intuitive and easy and with the precise instruments. The cooking results are excellent and cycles can be repeated by simply pressing the start button.

Machine equipped with bright buzzer, timing of cooking cycles, automatic temperature control, automatic replenishing water level in tank and provided with overflow system for auto drain of cooking starch in suspension.┬Ā

TECHNICAL FEATURES:

Cooking tank

- Stainless steel cooking tank in AISI 316/L SB polished

Lid

- Balanced lid in AISI 304 stainless steel with heat resistant handle

- Support frame and panels

Supporting frame in stainless┬Āsteel

- Thermal insulation guaranteed by high density ceramic fiber 64/128

- Panels in AISI 304 stainless steel, fine satin finish

Machine equipped with bright buzzer, timing of cooking cycles, automatic temperature control, automatic replenishing water level in tank and provided with overflow system for auto drain of cooking starch in suspension.┬Ā

HEATING SYSTEM

Direct Gas versions

Heating by means of AISI 304 stainless steel high efficiency tube burners Ignition by means of manual piezo-electric lighter and pilot flame

- Valve-controlled safety tap with a thermocouple

- Safety thermostat against overheating and lack of water

- Venting grid

- Set of jets for different types of gas

Jacket (indirect heated version)

- Jacket with bottom and walls in AISI 304 stainless steel

- Tilting container

- Automatic tilting by electric actuator mechanism with possibility to positioning, by means of selector, to drip product or to drain directly.┬Ā

Direct Electric versions

- Heating with battery of electric heaters

- Safety thermostat to prevent overheating and keeping the equipment from operating without water

- Temperature is controlled by thermostat (50┬░C - 120┬░C)

- Electric supply 400V 3N 50Hz

Indirect Electric versions

┬Ā

- with Jacket Heating by means elements in INCOLOY alloy, separated from the cooking yield

- Safety thermostat to prevent overheating and keeping the equipment from operating without water

- Jacket pressure control by working pressure switch and weight-loaded safety relief valve calibrated 0,5 bar, vacuum valve and pressure gauge

- Jacket water level control taps max/min with the option of automatic filling

- Standard power supply 400V - 3N - 50Hz

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Heating power, kW: 2x25

- Volume: 2x135l/ 2x220l

- Steam consumption, kg/h: 2x70/ 2x100

You might also like

Heating boilers are designed to cook sausages, hams and o’¼Ćal. Technology for superior performance and hygiene.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l/ 400l/ 500l/ 600l/ 800 l / 1000l/ 1200l/

The electric cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, broths, pasta, milk dishes, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. The equipment is not suitable for roasting or baking.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 100l/ 150l/ 200l/ 300l

Tilting pans with mixers cook the product with continuous stirring and subsequently discharge the food into receiving trolleys, ensuring the discharge spout remains at a constant height from the ground. Designed for the catering industry, large kitchens, school cafeterias, restaurants, and other food production businesses.

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Engine power, kW: 0,75

- Heating power, kW: 24/ 36/ 48

- Volume: 200l/ 300l/ 500l

- Steam consumption, kg/h: 85/ 100/ 115

Automatic tilting cooking pots, with lateral support upright designed for cooking solid foods that are transferred by tipping of the container. Options: steam boiling, indirect electric, indirect gas, direct gas. Capacity options: 50, 100, 150, 200, 300, 500l.

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Volume: 50l/ 100l/ 150l/ 200l/ 300l/ 500l

- Voltage: 380-400V

If you need to cook the product at low temperatures, to better preserve the appearance and nutritional properties of the product, or to add components that are sensitive to heat, we recommend using the universal TiltCook boiler.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 250l/ 300l

Industrial kettle for cooking and stewing meat, vegetables, seafood, legumes, cereals under pressure up to 0.5 and temperatures up to 110 ┬░C bar.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 600 l

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

Cooking tank with a bottom out of stainless steel AISI 316. Capacity of 150 liters.

- Heating: Steam

- Material: Stainless steel

- Volume: 150l

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l/ 500l

The universal cooking boiler with an integrated homogenizer and a capacity of 1200 liters is designed for efficient mixing, heating, cooking and homogenizing of products for food, pharmaceutical and cosmetic industries such as jams, marmalades, syrups, fruit juices, nectars, beers, creams, ointments, soaps and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The 1000 L vacuum cooker is used for cooking, concentrating, and evaporating food products under reduced pressure, allowing gentle heat treatment, improved flavor retention, and precise control of moisture content.

For a price quote, send us a request.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 1000l

- Dimensions, mm: 1385x1283x1892

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ŌĆō the double conveyor fryer and the paddle conveyor fryer ŌĆō we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

A Vacuum cooker is a versatile device used in culinary settings to cook food under vacuum conditions, enhancing flavors and textures while also reducing cooking times.

We offer various different cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

A professional cooking boiler with built-in intensive bottom heating and a tilting system for the working container allows you to quickly heat the product to high temperatures (200┬░C). Suitable for blanching, boiling, frying and stewing various products where high-temperatures and efficient processing is required.

- Powerful bottom heating with uniform heat distribution (2600 / 6500 W)

- Professional stainless steel probe in the product with a thermometer for visual control

- Compact standing supporting structure for safe operation

- Three-stage adjustment of the tilt angle of the working container

- The unit is made entirely out of stainless steel

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 3,5/ 6,5

- Volume: 50l/ 100l

- Voltage: 380-400V

Unbeatable price, excellent cooking results, designed to be placed in tight spaces where sharp edges or corners may create problems. We have different capacities boiling cookers.

- Material: Stainless steel

- Heating power, kW: 18

- Volume: 150l

- Voltage: 380-400V

Double-jacket stainless steel cooker for marmalade and jam production.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

- Voltage: 380-400V

Unbeatable price for highest quality material, modern technology, cylinder design. We offer different capacity catering cookers, electric, steam or gas.

- Heating: Steam

- Material: Stainless steel

- Volume: 150l/ 200l

The device is designed for the pasteurization of a wide range of products in various types of packaging material such as cans and jars.

- Heating: Mixed

- Productivity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Chocolate heating pump is the perfect solution to upgrade your production line. You can easily connect the pump to any device (such as a chocolate enrobing machine).

- Principle of operation: Batch mode

- Voltage: 380-400V

The VMG S 650P vacuum homogenizing unit can be used for making toothpaste as well as a variety of similar products with complex production requirements.

- The vacuum ensures effective air removal, eliminating the conditions for the development of bacteria and other pathogenic organisms.

- The special shape of the mixing device is tailored for the thickest and most viscous products.┬Ā

- The Ultra Shear submersible homogenizer creates a stable emulsion.

- The cavitation processes aid in activating hydrodynamic mixing.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 29

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 52

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Stainless steel jam cooking pot with agitator 50l and electric stove 5kW, ideal and affordable cooking solution.

- Heating: Electricity

- Material: Stainless steel

- Engine power, kW: 0,18/

- Heating power, kW: 5

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600