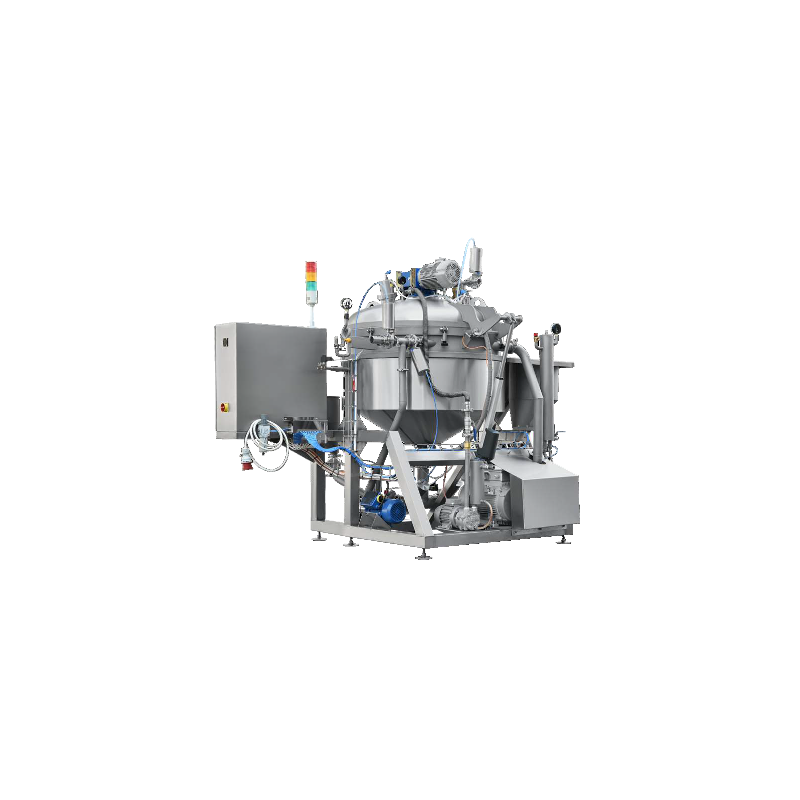

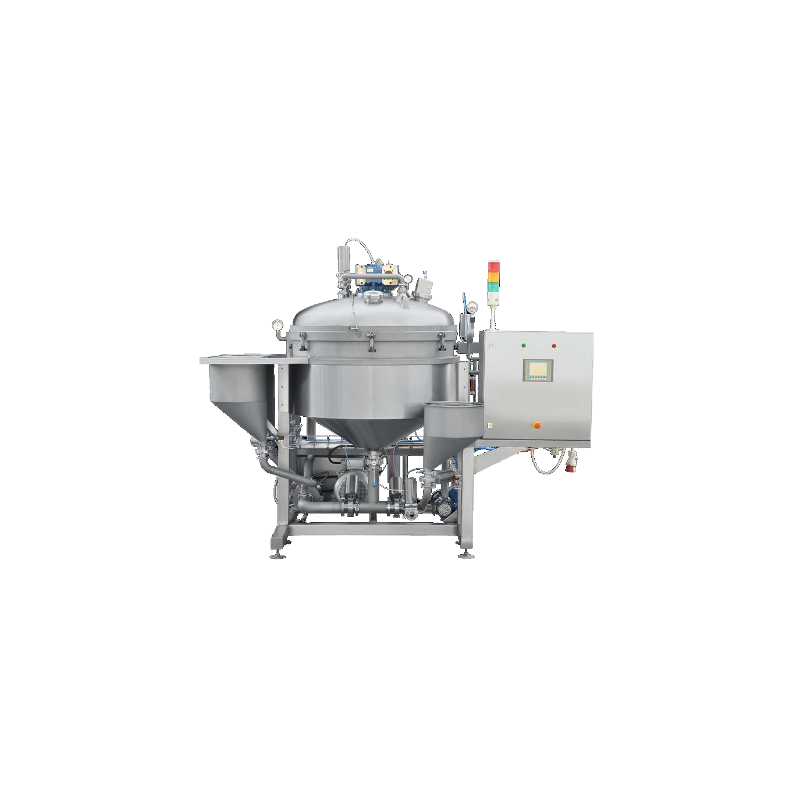

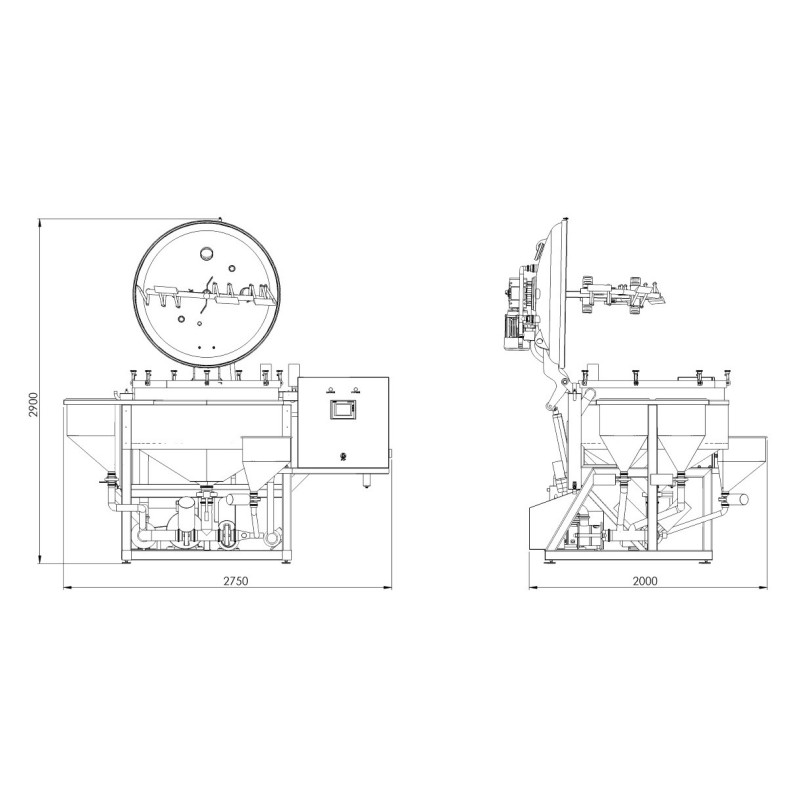

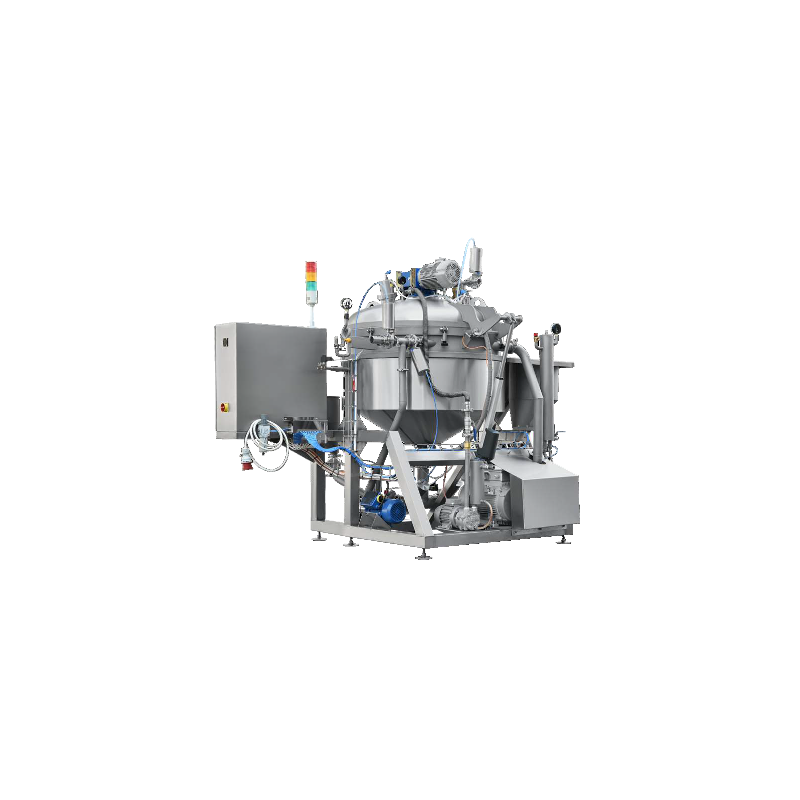

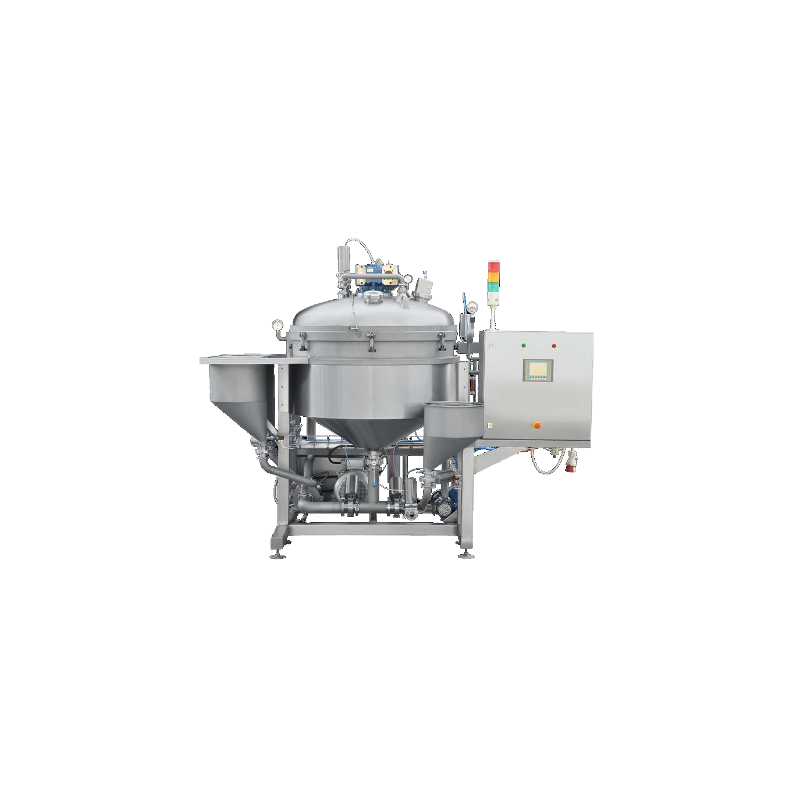

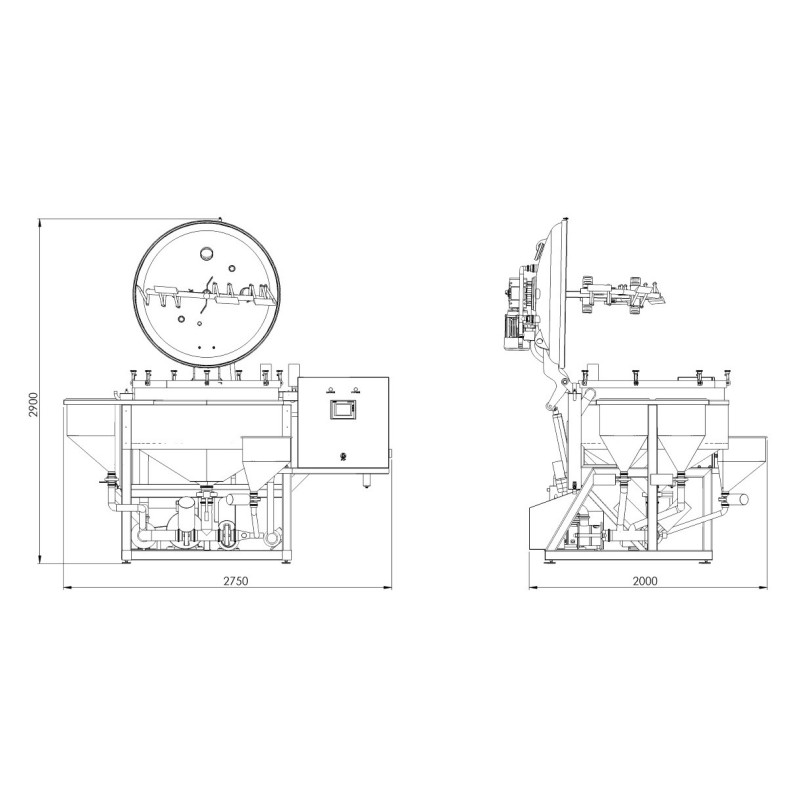

Vacu├╝mhomogenisator VMG S 650 M

De vacu├╝mhomogenisator is ontworpen voor het opkloppen van mayonaise, ketchup, diverse sauzen, banketbakkerspasta's en -vullingen, gecondenseerde melk, jam en marmelade, conserven, evenals soortgelijke vloeibare of pasteuze producten met een homogene structuur.

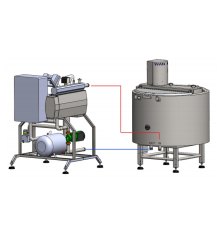

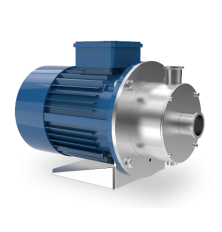

- Homogenisator in een externe circulatielus

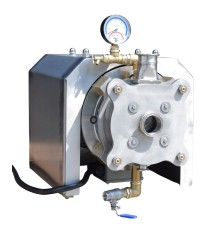

- Ingebouwd vacu├╝mopwekkings- en retentiesysteem

- Modulair ontwerp met talloze opties

- Mogelijkheid tot automatische dosering van ingrediënten (optioneel)

- Geen extra pomp nodig voor laden/lossen

- Automatisch hefsysteem voor bovenklep

De inhoud van deze pagina is vertaald naar het Nederlands met de geautomatiseerde vertaling. De originele versie is in het Engels. Bedankt voor uw begrip.

Modulair ontwerp, zodat u voor elk type productie de optimale aanpassing kunt kiezen. De vacuümhomogenisator is een zeer efficiënte en betrouwbare oplossing voor de productie van een breed scala aan voedingsmiddelen en produceert stabiele, homogene emulsies en dispersies.

De vacu├╝mhomogenisatiemodule kan worden gebruikt in de voedingsmiddelen-, cosmetica-, farmaceutische of chemische industrie voor de productie en verwerking van producten zoals:

|

|

|

|

|

|

|

|

|

|

Voordelen:

- Veelzijdig en flexibel in gebruik. Het is geschikt voor de productie van de meeste vloeibare, pasta-achtige en zeer viskeuze producten.

- Modern ontwerp, gemakkelijke toegang tot alle interne oppervlakken, zonder moeilijk bereikbare plaatsen waar het product zich kan ophopen.

- Er is geen extra pomp nodig om het product te lossen.

- Eenvoudige reiniging indien aangesloten op een CIP-systeem.

- Kan zelfstandig worden gebruikt of gemakkelijk in een bestaand productieproces worden geïntegreerd.

- De minimale verwerkingstijd voor elke batch wordt bereikt door de hoge efficiëntie van opwarm-/koelprocessen via de mantel (duplicator) met een koelmiddel dat van een externe bron wordt geleverd, evenals malen, mengen en homogeniseren.

- De hoge efficiëntie van het homogenisatieproces wordt bereikt door de kern van het apparaat - een robuuste en betrouwbare rotor-stator homogenisator met verschillende tandvormen, waardoor producten met verschillende eigenschappen geproduceerd kunnen worden.

- Het optimale ontwerp van de conische werkkamer zorgt voor een gelijkmatige menging van het product.

- De mixer met lage snelheid en boveninvoer is uitgerust met schrapers die de wanden van het vat efficiënt reinigen voor maximale warmte-uitwisseling. Het product wordt gelijkmatig verhit, zonder risico op oververhitting of verbranding.

- Een effectief vacu├╝msysteem garandeert een hoogwaardige ontluchting van het product, wat de smaak, consistentie en duurzaamheid aanzienlijk verbetert.

- Als er strenge eisen worden gesteld aan de homogenisatiegraad en de minimale deeltjesgrootte, is het apparaat uitgerust met een homogenisator met een zwakkere pompfunctie, maar met verbeterde maal- en homogenisatiecapaciteiten. In dit geval wordt het product vervolgens gelost met een extra pomp.

- De werkcapaciteit hangt af van de eigenschappen van het product - van 20 tot 80% van het totale volume. Het apparaat garandeert een constant hoge kwaliteit van eindproducten en reproduceerbaarheid van batches.

Basisversie

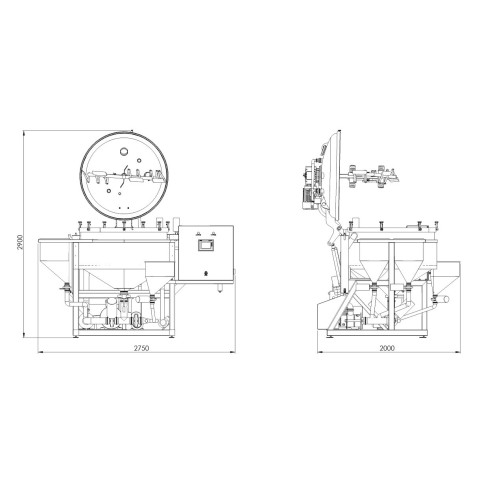

Hij bestaat uit een vacuümreactor met een conische bodem en een mantel voor het koelmiddel tot 0,5 bar, die op een ondersteunende frameconstructie is geïnstalleerd. Uitgerust met een mengapparaat met schrapers, een systeem voor het optillen van het bovendeksel, een extern circulatiecircuit met een homogenisator, een vulsysteem en een leidingsysteem met regel- en afsluitfittingen.

Processen

|

|

|

|

|

|

*- van een externe bron

Opties:

- Thermische isolatie van de mantel en een externe decoratieve behuizing

- Elke verwarmingsbron (stoomgenerator, warmwaterbron)

- Een willekeurig aantal extra trechters en ingrediëntlaadblokken

- Mogelijkheid tot automatische dosering van ingrediënten

- Directe stoominjectie in het product

- Fabricage van het systeem uit AISI 316L of AISI 316Ti (in direct contact met het product)

- Automatisch, halfautomatisch of handmatig besturingssysteem (op aanvraag)

- CIP-koppen voor wassen (roterend)

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Volume: 650l

- Totale vermogen, kW: 13,5

- Spanning: 380-400V

- Maximale vacu├╝m: -0,8 Bar

You might also like

De prijs is vastgesteld voor de basisversie van de installatie zonder extra apparatuur.

De vacu├╝mhomogenisator is ontworpen voor een groot aantal processen, zoals voor de productie van mayonaise, ketchup, diverse sauzen, banketbakkerspasta's en -vullingen, vloeibare of pasta-achtige producten met een homogene structuur. Het is ook geschikt voor de productie van diverse cr├©mes, gels, shampoos en andere producten in de cosmetische industrie.

- Ingebouwde Ultra Shear bodemhomogenisator

- Mengapparaat met beweegbare schrapers

- Kantelbare versie voor gemakkelijk lossen

- Breed scala aan toepassingen

- Volledig gemaakt van voedselveilig roestvrij staal AISI304/ AISI316 - optie

- Compact ontwerp

- Veel extra opties om uit te kiezen

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Volume: 20l/ 50l

- Totale vermogen, kW: 2,3/ 2,4

- Spanning: 220-230V

- Maximale vacu├╝m: -0,8 Bar

Vacuümhomogenisator VMG M is de ideale oplossing voor de productie van proefcharges en de industriële productie van een breed scala aan producten van kleine en middelgrote productie. De prijs is afhankelijk van de productiecapaciteit.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Volume: 100l

- Maximale vacu├╝m: -0,8 Bar

- Werkvolume: 50-80l

Elektrisch verwarmingspaneel met drie verschillende vermogensmogelijkheden: 12, 24 en 48 KW - uitstekend product vervaardigd door mensen die het geheim van productopslag, -onderhoud en -verwerking perfect kennen.

- Verwarmingsvermogen, kW: 12/ 24/ 48

- Land van herkomst: EU

De generator is gemonteerd op een roestvaststalen platformsteun, bekleed met roestvaststaal AISI 304 met de juiste vorm en met reeds gemaakte elektrische en wateraansluitingen. Roestvrijstalen kranen AISI 316, pijpfittingen van smeedbaar ijzer, voedingswaterpomp (mod. TP78A CALPEDA) met 1 roestvrijstalen terugslagklep, met VITON afdichting.

- Verwarmingsvermogen, kW: 24/ 32/ 48

De prijs is vastgesteld voor de basisversie van de installatie voor het maken van plantaardige melk zonder stoomgenerator

De Veggie Milk kookketel wordt gebruikt als een eenheid voor hydrodynamische thermische extractie van stoffen uit peulvruchten en noten om een afgewerkte suspensie te creëren - de basis van plantaardige dranken.

- Efficiënte en snelle extractie

- Gedeeltelijke pasteurisatie door directe stoominjectie

- Krachtige bodemhomogenisator

- Hydrodynamisch mengen

- Mechanische asafdichting voor de homogenisator met een open koelsysteem

- Veiligheidsrooster op het luikdeksel voor het veilig laden van producten

- Sectioneel plexiglas luik voor visuele inspectie

- Productiviteit: 600 kg/h voor sojabonen

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Volume: 120l

- Totale vermogen, kW: 7,5

- Spanning: 380-400V

Inline Yumix Basic homogenisatoren hebben de laagste prijs in het assortiment YUMIX homogenisatoren en de modellen variëren van 1,1 tot 3 kW.

- Materiaal: Roestvrij staal

- Motorvermogen, kW: 1,1/ 1,5 / 2,2/ 3

- Werkingsprincipe: Continue modus

De prijs is vastgesteld voor de basisversie van de installatie zonder extra apparatuur.

De vacu├╝mhomogenisator is ontworpen voor een groot aantal processen, zoals voor de productie van mayonaise, ketchup, diverse sauzen, banketbakkerspasta's en -vullingen, vloeibare of pasta-achtige producten met een homogene structuur. Het is ook geschikt voor de productie van diverse cr├©mes, gels, shampoos en andere producten in de cosmetische industrie.

- Ingebouwde Ultra Shear bodemhomogenisator

- Mengapparaat met beweegbare schrapers

- Kantelbare versie voor gemakkelijk lossen

- Breed scala aan toepassingen

- Volledig gemaakt van voedselveilig roestvrij staal AISI304/ AISI316 - optie

- Compact ontwerp

- Veel extra opties om uit te kiezen

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Volume: 20l/ 50l

- Totale vermogen, kW: 2,3/ 2,4

- Spanning: 220-230V

- Maximale vacu├╝m: -0,8 Bar

De dubbelschroefmenger met homogenisator is een ideale oplossing voor de productie van romige kaas, zoals fetakaas, met verschillende smaken en kruiden. Dankzij mechanische homogenisatie krijgt de kaas een delicate structuur zonder de individuele smaakeigenschappen van het product te veranderen. Het wordt gebruikt voor het plastificeren, opkloppen en verzachten van boter, margarine en andere vetten.

- Een ruime volumetrische menger met een capaciteit van 50 l

- Compact tafelontwerp voor handig onderhoud door de operator

- Een krachtige onafhankelijke aandrijving voor elke schroef met omkeermechanisme

- Eenvoudig onderhoud en reiniging van de apparatuur

- Productiviteit: 250 kg/h/ 1500 kg/h

- Materiaal: Roestvrij staal

- Werkingsprincipe: Continue modus

- Land van herkomst: Slowakije

- Totale vermogen, kW: 3,5

- Spanning: 380-400V

De VMG S 650P vacu├╝mhomogenisatietoestel kan gebruikt worden voor het maken van tandpasta en een verscheidenheid aan vergelijkbare producten met complexe productievereisten.

- Het vacuüm zorgt voor een effectieve luchtverwijdering, waardoor de omstandigheden voor de ontwikkeling van bacteriën en andere pathogene organismen worden geëlimineerd.

- De speciale vorm van het mengapparaat is op maat gemaakt voor de dikste en meest viskeuze producten.

- De Ultra Shear dompelhomogenisator creëert een stabiele emulsie.

- De cavitatieprocessen helpen bij het activeren van het hydrodynamisch mengen.

- Verwarming: Elektriciteit

- Materiaal: Roestvrij staal

- Verwarmingsvermogen, kW: 29

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Volume: 650l

- Totale vermogen, kW: 52

- Spanning: 380-400V

- Maximale vacu├╝m: -0,8 Bar

Een professionele mixer voor de productie van mayonaise, sauzen, soepen en andere gehomogeniseerde producten. De prijs is afhankelijk van uw productiecapaciteit en van de technologische vereisten.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Volume: 100l/ 200l

- Totale vermogen, kW: 6

De homogenisator is ontworpen om verschillende vloeistoffen en componenten te homogeniseren, mengen en desintegreren / vermalen tot kleine deeltjes.

- Werkingsprincipe: Continue modus

- Land van herkomst: Slowakije

- Spanning: 380-400V

De prijs is aangegeven voor de basisversie van de uitrustingsset met een homogenisator

De apparatuur voor de productie van ijsmengsels is gebaseerd op een universele vacu├╝mreactor met een koelmantel en een meertraps dispergeer-/homogenisator in een externe circulatielus.

- Speciaal type roerinrichting voor eenvoudige demontage en reiniging

- Verwerking met minimaal productverlies

- De onderste uitlaatklep is inbegrepen in de basisversie van de installatie

- Meertrapsdispergeerder voor intensieve bevochtiging en homogenisering van het stromende mengsel

- Extern circulatiecircuit met een driewegklep voor het bedienen/spoelen van de apparatuur

- Versterkte roerwerkaandrijving voor dikke en viskeuze mengsels

- Ingebouwde vacu├╝mpomp

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Volume: 100l

- Totale vermogen, kW: 3

- Spanning: 380-400V

- Maximale vacu├╝m: -0,8 Bar

De boterstexturizer FBHG is bedoeld voor mechanische verwerking van bevroren blokken boter, dierlijk vet, margarine en andere plantaardige vetten, zonder voorafgaande ontdooiing.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Continue modus

Een honinghomogenisator is een batch-apparaat dat is ontworpen om de structuur en organoleptische eigenschappen van het product te verbeteren. Het zorgt voor een uniforme consistentie en stabiele textuur van honing.

Homogenisatie is een verwerkingstechnologie die honing vloeibaar en uniform maakt en kristalgroei remt, waardoor wordt voldaan aan de behoeften van producenten en consumenten. Het ontwerp, de grootte en de hoek van de roterende schroef zorgen voor een hoge mate van homogenisatie, wat ook de verwerkingstijd van de grondstoffen verkort.

- Hoge mate van homogenisatie, gericht op het verhogen van de stabiliteit en het verbeteren van de honingstructuur zonder de smaak van het product te veranderen.

- Geen dode hoeken of hoeken dankzij de schuine bodem van zowel de werktank als de schroefmixer.

- De werktank is voorzien van een mantel en een ingebouwd waterverwarmingssysteem.

- Uitlaatklep met grote diameter geïnstalleerd op het laagste hydraulische punt.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Totale vermogen, kW: 4/ 7

- Belading, kg: 500/ 1100

Model VMG S is een effectieve en betrouwbare vacu├╝mhomogenisatietoestel dat ontworpen is voor de productie van een breed assortiment vloeibare, pasteuze en viskeuze producten met verschillende vereisten voor de productieomstandigheden.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Continue modus

- Land van herkomst: Slowakije

Wij produceren atmosferische honinghomogenisatoren met een batchbelasting van 7500 tot 22 000 kg honing. De homogenisatoren HPL zijn ontworpen voor het grondig mengen, mengen en homogeniseren van verschillende soorten honing om de kwaliteit ervan te verbeteren.

De prijs hangt af van de opties die u kiest.

- Productiviteit: do 12000 kg

- Materiaal: Roestvrij staal

- Volume: 8000 l

De mengers bestaan uit een dubbelwandig cilindrisch roestvrijstalen vat met holte, met afvoergat en vlinderklep met een diameter van 50 cm. De holte is gevuld met water dat verwarmd wordt door een elektrische weerstandsthermostaat. De honing wordt gemengd door bladen met een scheepsschroefprofiel, die langs een schuine as in hoogte verstelbaar zijn.

- Materiaal: Roestvrij staal

- Motorvermogen, kW: 0,37/ 0,55/ 1,1

- Werkingsprincipe: Batchmodus

- Volume: 100 kg / 250 kg/ 600 kg/ 1000 kg/ 2000 kg

Vacuümhomogenisator VMG M is de ideale oplossing voor de productie van proefcharges en de industriële productie van een breed scala aan producten van kleine en middelgrote productie. De prijs is afhankelijk van de productiecapaciteit.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Volume: 100l

- Maximale vacu├╝m: -0,8 Bar

- Werkvolume: 50-80l

De inline homogenisator is ontworpen voor het mengen, emulgeren, dispergeren en homogeniseren van dikke en viskeuze producten bij de productie van mayonaise, sojamelk, tandpasta, yoghurt en nog veel meer. Het kan geïnstalleerd worden in een extern circulatiecircuit van reactoren, productielijnen of onafhankelijk gebruikt worden met een vultrechter voor het verwerken van kleine hoeveelheden producten.

- Creëert stabiele emulsies en suspensies

- Vermindert de deeltjesgrootte

- Lost vaste stoffen snel op

- Versnelt chemische reacties

- Vereist geen extra pomp

- Materiaal: Roestvrij staal

- Motorvermogen, kW: 5,5/ 7,5/ 9/ 11/ 15

- Werkingsprincipe: Continue modus

- Land van herkomst: Slowakije

- Spanning: 380-400V