VERDAMPERS

De inhoud van deze pagina is vertaald naar het Nederlands met de geautomatiseerde vertaling. De originele versie is in het Engels. Bedankt voor uw begrip.

Â

Soorten vacuÞmverdampers

Verdamping is het proces waarbij een oplosmiddel uit een oplossing wordt verwijderd om het product te concentreren of te verdikken.

VacuÞmverdamping is hetzelfde proces, maar wordt uitgevoerd in een ijle omgeving - in een vacuÞm - en dus bij lagere temperaturen.

VacuÞmverdampers zijn een speciaal type verdamper waarbij het verdampingsproces niet onder atmosferische druk plaatsvindt, maar in een ijle omgeving bij een druk lager dan atmosferische druk.

VacuÞmverdampers worden veel gebruikt in de voedingsmiddelenindustrie, bijvoorbeeld bij de melkverwerking. Met vacuÞmverdampers kunt u warmtegevoelige producten verdikken en concentreren zonder de structuur te beschadigen of te vernietigen en zonder hun eigenschappen te veranderen.

VacuÞmverdampers worden gebruikt voor het verdikken en concentreren van melk, room, zuivelproducten zoals wei, en bij de productie van ingeblikte producten zoals gecondenseerde melk. Bij de verwerking van melk is het noodzakelijk om dergelijke verwerkingsmethoden te kiezen om thermische schade aan het product, namelijk denaturatie van melkeiwitten, te voorkomen.

VacuÞmverdamping wordt ook gebruikt om de karamellisatie van suikers en glucose te verminderen bij het koken van siropen, waardoor de structuur, kleur, smaak, vitaminen en voedingsstoffen in het product behouden blijven. Deze kunnen bij hoge temperaturen verloren gaan.

Er zijn verschillende soorten vacuÞmverdampers, afhankelijk van hun classificatie.

Op basis van het werkingsprincipe worden vacuÞmverdampers onderverdeeld in:

- batchunits en

- continue units.

BatchvacuÞmverdampers zijn klassieke vacuÞmapparaten met ÃĐÃĐn behuizing waarin een bepaald deel van het product wordt gekookt en geconcentreerd.

Continu-vacuÞmverdampers zijn units met meerdere behuizingen die zogenaamde verdampingstrappen hebben voor de productdoorvoer tijdens continu gebruik. Het aantal trappen is afhankelijk van de gewenste kook- en concentratiegraad.

Enkelvoudige units worden op hun beurt ook onderverdeeld in:

- Capacitieve units met een verwarmingsmantel en een condensor

- Circulatie-unit met een externe warmtewisselaar die gebruikmaakt van natuurlijke circulatie

- Circulatie-unit met een externe warmtewisselaar met geforceerde circulatie

- Folieverdamper

- Centrifugaalfilmverdamper

Afhankelijk van de fabrikant en het product worden nieuwe hybride vacuÞmverdampers ontwikkeld die verschillende soorten vacuÞmverdampers combineren.

In klassieke vacuÞmverdampingssystemen wordt stoom gebruikt als warmtedrager, die in de mantel wordt gevoerd, of wordt een warmtewisselaar voor het apparaat gebruikt om het product te verwarmen. Dit komt door de hoge efficiÃŦntie van stoomwarmteoverdracht. In moderne systemen kunnen kleine enkelvoudige capacitieve vacuÞmverdampers ook heet/oververhit water gebruiken als werkvloeistof voor warmteoverdracht.

Nieuwe hybride systemen voor sommige producttypen gebruiken helemaal geen warmtedrager (medium), omdat de verwarming direct in de productstroom plaatsvindt. Dergelijke verdampingssystemen, die rekening houden met het geforceerde circulatiecircuit, behoren tot de meest efficiÃŦnte systemen qua prestaties van verdampt water binnen het kader van capacitieve circulatie-units met ÃĐÃĐn behuizing. Ze combineren ook het principe van flash-pasteurisatie. Het risico op productdegradatie is vrijwel nihil, aangezien het product na verhitting in de stroming in een ijle omgeving terechtkomt, waar het direct wordt afgekoeld door verdamping van de oplossing.

Wij bieden klassieke vacuÞmverdampers voor het koken en concentreren van melk, siropen en wei, maar ook technologische lijnen voor de productie van gecondenseerde melk met en zonder suiker. Ons assortiment omvat ook speciale apparaten â vacuÞmverdampers voor de productie van specifieke producten, zoals pekmez, levensmiddelenadditieven en tincturen, waarmee u het product op lage temperatuur kunt koken en bovendien extracten uit plantaardige materialen kunt produceren vÃģÃģr de daaropvolgende concentratie.

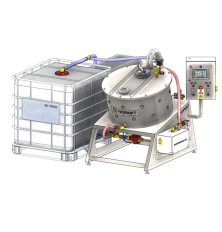

Een vacuÞmverdamper met een externe circulatiewarmtewisselaar is een van de meest efficiÃŦnte verdampingssystemen. Geschikt voor het koken van warmtegevoelige producten zoals melk, room, enz.

- Geen mengapparaat nodig, het product heeft geforceerde circulatie!

- Modulair systeem: keuze uit vacuÞmgenerator, stroom en warmtewisselaar

- Schuin ontwerp en bodemklep voor 100% productafvoer zonder verliezen en blinde hoeken

- GeÃŊsoleerde bovenklep van de unit voor warmtebehoud en veiligheid

- TangentiÃŦle productinlaat in het vacuÞmvat voor gegarandeerde verdamping in een dunne laag

- Materiaal: Roestvrij staal

- Volume: 50l/ 100l/ 300l

Een vacuÞmverdamper is een apparaat dat wordt gebruikt om vloeistoffen bij lagere temperaturen te verdampen door een vacuÞmomgeving te creÃŦren, waardoor het kookpunt van de vloeistof wordt verlaagd en efficiÃŦnte verdamping mogelijk wordt zonder thermische degradatie van gevoelige materialen. Werkvolume tot, l: 1900 l.

- Verwarming: Elektriciteit

- Materiaal: Roestvrij staal

- Verwarmingsvermogen, kW: 30

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Werkvolume: up to 1900 l

Compacte vacuÞmverdampingsmachine met een warmtewisselaar met externe circulatie voor de productie van testbatches van producten, ontwikkeling van nieuwe recepten en technologische kaarten.

- Compacte installatie

- Kan alle verwerkingstechnieken nabootsen die gebruikt worden in industriÃŦle vacuÞmverdampingseenheden met circulatie

- Behoudt de natuurlijke smaak, geur en kleur van het product

- Kan worden gebruikt om kleine batches producten te produceren

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Apparatuursoort: Individuele machine

- Land van herkomst: Slowakije

- Volume: 20l

De prijs wordt aangegeven met een halfautomatisch bedieningspaneel

De vacuÞm kookketel is ontworpen voor gebruik in openbare horecagelegenheden (restaurants, hotels, cateringbedrijven) en kleine productiebedrijven. Met deze apparatuur kunt u koken, blancheren, frituren, verdampen, pasteuriseren, mengen of roeren.

- Een uniek multifunctioneel apparaat

- Mogelijkheid om te koken/bakken onder atmosferische of vacuÞmomstandigheden

- Laboratoriumversie van een vacuÞm friteuse

- Ingebouwd condensatie- en secundair stoomverwijderingssysteem

- Intense elektrische verwarming

- Sectionele mand met deksel

- Ingebouwd systeem om overtollige vloeistof van het product te scheiden en te verwijderen

- Verwarming: Elektriciteit

- Materiaal: Roestvrij staal

- Verwarmingsvermogen, kW: 5

- Volume: 20l

- Olievolume: 8l

- Spanning: 380-400V

- Maximale vacuÞm: -0,8 Bar

De prijs is vastgesteld voor de basisuitvoering van de vacuÞmverdamper met basisbediening (mengmotorschakelaar) en zonder extra opties. De bedieningseenheid wordt individueel aangepast aan de wensen van de klant. De pomp wordt ook apart geselecteerd, afhankelijk van het product.

Een compacte vacuÞmverdampingseenheid waarmee u oplossingen, mengsels en diverse producten kunt concentreren door het oplosmiddel te verdampen. Een modulaire versie gebaseerd op de basis 110/100 vacuÞmreactor.

- Zwaartekrachtmenging - 25% efficiÃŦnter

- Versterkt roerwerkontwerp zonder blinde vlekken

- Bovenste kogelkraan zonder dode zones

- Condensatie en secundair dampverwijderingssysteem

- Eenvoudig te demonteren mengapparaat

- Groot warmtewisselingsoppervlak

- Mogelijkheid om condensaatvolume te meten en te bewaken (optioneel)

- Materiaal: Roestvrij staal

- Motorvermogen, kW: 0,25

- Werkingsprincipe: Continue modus

- Land van herkomst: Slowakije

- Volume: 100l

- Spanning: 220-230V

- Maximale vacuÞm: -0,8 Bar

- Werkvolume: 50-80l

- Condensatiecapaciteit, l/u: 45-55

- Stoomverbruik, kg/u: tot 150

Een vacuÞmdestillatiesysteem wordt gebruikt voor de gecontroleerde scheiding van vloeistoffen door verdamping van de vloeistof en daaropvolgende condensatie van de dampen.

- Materiaal: Roestvrij staal

- Land van herkomst: Slowakije

- Volume: 5l

Een vacuÞmverdamper van het circulatietype verwijst naar een gecombineerde versie van een verdamper die ook gebruik maakt van andere types om de verdampingsefficiÃŦntie te verbeteren, met name door de concentratietijd te verkorten en bij het verwerken van warmtegevoelige producten zoals melk.

- Het externe circulatiecircuit met verwarming versterkt het cyclische verdampingsproces.

- Het geforceerde circulatiesysteem vermindert het risico op plaatselijke oververhitting van het product.

- De condensor maakt een diep vacuÞm mogelijk en handhaaft een lage verdampingstemperatuur.

- Het gebruik van een mengapparaat met een sproeisysteem vergemakkelijkt de verdamping van het product in een dunne laag, waardoor een filmverdamper wordt nagebootst.

- Verwarming: Stoom

- Materiaal: Roestvrij staal

- Bedrijfsmodus: Semi-automatisch

- Land van herkomst: Slowakije

- Totale vermogen, kW: 2,4

- Spanning: 380-400V

De kook en concentratievacuÞmunit is ontworpen voor het concentreren van producten bij lage temperaturen (ongeveer 60 graden) in een reactor met een ontladen omgeving om de kleur, voedingswaarde en nuttige stoffen in producten te behouden. Verdampings- en concentratie-units worden vaak gebruikt bij het koken van jam, sauzen en fruit en groenteconcentraten. Met de vacuÞmconcentrator kunt u hittegevoelige producten koken en concentreren zonder hun structuur of eiwitten, zoals melk, te beschadigen of te vernietigen.

- Hellend ontwerp - maakt zwaartekrachtmenging mogelijk, wat 40% efficiÃŦnter is dan normaal

- Snel en 100% legen van de tank dankzij het hellende ontwerp terwijl de mixer aan staat

- Verwarmings-/koelmantel (duplicator) rond de werktank en de bodem

- Hoge hygiÃŦnestandaard - de uitlaatklep bevindt zich op het laagste hydraulische punt van de reactor

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Volume: 300l/ 500l/ 875l

De vacuÞmverdampingseenheid is speciaal ontworpen voor het indikken van dichte voedingsmiddelen in industriÃŦle hoeveelheden. De verdamper kan gebruikt worden voor de productie van dikke siropen, karamelmassa's, dichte fruitmassa's, maar ook voor de productie van pectine of hittestabiele vullingen met een hoge productiviteit.

- Hoge prestaties

- Roterend sproeisysteem met een krachtige elektrische aandrijving

- Verdamping in een dunne laag met een groot warmteoverdrachtsgebied

- Lage installatiekosten

- TangentiÃŦle invoer voor productwerveling

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Spanning: 380-400V

Installaties voor de productie van alcoholvrije wijn worden geproduceerd in verschillende modellen en configuraties, beginnend bij volumes van 100 liter. De systemen werken volgens het principe van vacuÞmdestillatie, waardoor alcohol bij lage temperaturen kan worden verwijderd, wat resulteert in een gezond product met een minimaal alcoholpercentage.

- Een breed scala aan modellen â geschikt voor zowel kleinschalige productie als grootschalige industriÃŦle processen

- Mogelijkheid om een "gezond product" te produceren met behoud van alle organoleptische eigenschappen van de drank

- Afhankelijk van de productiecapaciteit kunnen de systemen worden ontworpen voor batch- of continubedrijf

- Diep vacuÞm maakt lage verdampingstemperaturen mogelijk, waardoor een bijzonder zachte verdamping mogelijk is zonder thermische degradatie van de smaakprofielen van verschillende soorten wijn

- Materiaal: Roestvrij staal

- Land van herkomst: Slowakije

VacuÞmunit met roerwerk voor de productie van alcoholvrije wijn.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Apparatuursoort: Individuele machine

- Land van herkomst: Slowakije

- Volume: 5l

Dit apparaatmodel is een universeel systeem dat kan worden gebruikt om extracten te produceren uit producten zoals johannesbrood, en om deze onder vacuÞm te koken om een ââdikke siroop te verkrijgen via een sequentieel circulatieproces.

- EÃĐn systeem voor alle opeenvolgende technologische processen voor de productie van pekmez: van het weken en het verkrijgen van een extract, het afkoelen van het eindproduct tot de kookfase in vacuÞm.

- Koken onder vacuÞm maakt het mogelijk om alle nuttige stoffen in het extract te behouden: vitamines van groep A, B en E, micro-elementen zoals calcium, kalium, magnesium, ijzer en zink.

- Zeer efficiÃŦnt kookproces dankzij een speciaal direct-in-de-stroom verwarmingssysteem dat is geÃŊnstalleerd in de circulatie-vacuÞmverdampingsunit.

- Verwarming: Elektriciteit

- Materiaal: Roestvrij staal

- Verwarmingsvermogen, kW: 36

- Volume: 100l

- Condensatiecapaciteit, l/u: 45-55

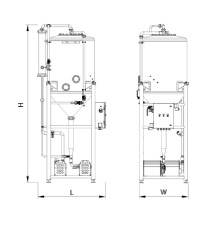

De concentratie- en indikkingslijn is speciaal ontworpen voor industriÃŦle zuivelproductiefaciliteiten met een klein overschot aan melk of kleinere melkverwerkingsbedrijven die hun productassortiment willen uitbreiden. De productiviteit wordt geschat op 50-120 kg/uur bij continue werking.

- Professionele industriÃŦle technologie met compacte afmetingen

- Een groot aantal extra uitrustingen en opties om uit te kiezen

- Materiaal: Roestvrij staal

- Werkingsprincipe: Continue modus

De unieke eigenschap van dit model vacuÞm honingverdamper, dat het onderscheidt van een honingdroger, is de mogelijkheid om een diep vacuÞm te creÃŦren met een restdruk tot 0,08 Bar tijdens de verwerking! Dit innovatieve apparaat zorgt niet alleen voor een snelle en efficiÃŦnte droging van honing, maar maakt ook de onmiddellijke verdamping van water mogelijk, waardoor een halffabrikaat ontstaat dat geschikt is voor de latere productie van "droge honing" of honingpoeder.

- Er is geen groot droogoppervlak nodig - een verdampingsspiegel.

- U hoeft geen mengapparaat te installeren voor dikke en viskeuze producten.

- Lage verdampingstemperatuur van vocht - water uit honing, waarbij de kwaliteit en medicinale eigenschappen niet aangetast worden, en het risico van HMF-groei tot bijna nul gereduceerd wordt.

- Snel en efficiÃŦnt drogen van honing bij een lage verwerkingstemperatuur.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Maximale vacuÞm: -1 Bar

Multifunctionele vacuÞmunit MINI5 - is ideaal voor koken, drogen, concentreren, mengen en nog veel meer. Geschikt voor laboratoria en kleinschalige productie.

- Warmtegevoelige producten bij lagere temperaturen verwerken

- Ideaal voor het maken van honingcrÃĻme

- Mogelijkheid om honing vacuÞm te drogen

- Materiaal: Roestvrij staal

- Motorvermogen, kW: 0,12

- Land van herkomst: Slowakije

- Volume: 5l

Apparatuur voor de productie van gecondenseerde melk uit voorgepasteuriseerde melk. Deze apparatuur kan worden geproduceerd met een capaciteit van 50 tot 500 kg/uur, of op aanvraag. Wij produceren ook gecondenseerde melklijnen volgens TU uit droge melk of genormaliseerde melkconcentratielijnen.

- Materiaal: Roestvrij staal

- Apparatuursoort: Onderdeel van een productielijn

- Land van herkomst: Slowakije

Een vacuÞmontgasser wordt veel gebruikt in de voedingsmiddelenindustrie om gassen te verwijderen uit producten die na het verwerken nog luchtbellen bevatten. Daarnaast wordt een stroomontluchter gebruikt om schuimvorming in producten te minimaliseren, waardoor een dichtere structuur ontstaat, vooral vÃģÃģr het verpakken. VacuÞmontgassers spelen een cruciale rol bij het verwijderen van specifieke geuren uit de producten, zoals bij de productie van sappen, purees en kruidendranken. Dit proces draagt aanzienlijk bij aan de verbetering van de algehele kwaliteit en smaak van het eindproduct.

- Verbetert de kwaliteit, structuur en vorm van het product

- Voorkomt oxidatie door gassen te verwijderen

- Behoudt de organoleptische eigenschappen en verlengt de houdbaarheid

- Geschikt voor dikke en viskeuze producten

- Dankzij het stromingsprincipe kan deze apparatuur in bestaande productielijnen worden geÃŊnstalleerd.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Continue modus

- Land van herkomst: Slowakije

- Spanning: 380-400V

- Maximale vacuÞm: -0,8 Bar

De prijs hangt af van de capaciteit en het product.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Apparatuursoort: Individuele machine

- Land van herkomst: Slowakije

Ontluchter wordt gebruikt om luchtbellen uit de puree te verwijderen. De prijs is afhankelijk van het vereiste volume en de productiecapaciteit.

Stuur ons een verzoek voor meer informatie.

- Productiviteit: 1000 kg/h/ 2000 kg/h

- Materiaal: Roestvrij staal

- Werkingsprincipe: Continue modus

De Atmosferische Verdampingspan concentreert vloeistoffen efficiÃŦnt door ze op een groot oppervlak te verdampen, terwijl hij ook geschikt is voor verschillende kookmethodes zoals smoren, koken en braden.

- Verwarming: Elektriciteit

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

Een verdamper-concentrator-kristalliseerder is een multifunctionele eenheid die vloeistoffen concentreert door water te verdampen en kristallisatie te induceren voor de productie van geconcentreerde oplossingen of kristallijne producten.

- Materiaal: Roestvrij staal

- Werkvolume: up to 6000 L

- Geometric volume: 6500 l

Installatie voor het verdampen, concentreren en kristalliseren van oplossingen. De vacuÞmverdamper zorgt voor een volledige scheiding van de oplossing in een vaste fractie en zuiver water.

Een verdampingseenheid wordt gebruikt om vocht uit zoete stoffen te verwijderen door ze te verhitten, waardoor ze in geconcentreerde siropen of oplossingen worden omgezet.

- Materiaal: Roestvrij staal

- Verwarmingsvermogen, kW: 30

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Spanning: 380-400V

- Geometric volume: 200 l

Wij bieden verschillende soorten vacuÞmverdampingsmachines, dit type is een betaalbare optie voor efficiÃŦnte verdamping in een roestvrijstalen eenheid.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Volume: 100l

Wij bieden een breed scala aan verdampingsapparatuur voor een breed scala aan producten. De prijs is afhankelijk van de capaciteit en het gebruikte product.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

De compacte lijn van dubbel-type vacuÞmkookketels bestaat uit een complex van batch voedselkookeenheden ontworpen voor periodieke thermische verwerking, vacuÞm mengen en ontgassing van diverse producten onder sub-atmosferische druk.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Volume: 2x300l/ 2x600l