MOLENS, MAALMACHINES

De inhoud van deze pagina is vertaald naar het Nederlands met de geautomatiseerde vertaling. De originele versie is in het Engels. Bedankt voor uw begrip.

Molens en molens worden gebruikt om de deeltjesgrootte van ingrediÃŦnten te verkleinen bij voedselverwerking.

Molens en molens zijn essentieel in de voedselverwerking en worden gebruikt om de deeltjesgrootte van ingrediÃŦnten zoals granen, zaden, specerijen, noten of fruit te verkleinen. Deze apparatuur is cruciaal voor het bereiken van de gewenste textuur, smaak en consistentie in een breed spectrum van voedingsmiddelen.

Wat zijn molens?

Maalmolens zijn ontworpen om grondstoffen te pletten, malen of verpulveren tot kleinere deeltjes. Deze apparaten zijn fundamenteel in de voedingsindustrie voor het produceren van fijne poeders, pasta's en crÃĻmes, en zorgen voor uniformiteit en kwaliteit in het eindproduct.

Hoe werken molens?

Deze machines werken met mechanische krachten zoals impact, compressie of afschuiven. Afhankelijk van het type materiaal en het gewenste eindproduct kunnen molens messen, rollen of andere maalmechanismen gebruiken om de deeltjesgrootte efficiÃŦnt te verkleinen.

Voordelen van het gebruik van molens en slijpmachines

- Deeltjesgroottecontrole: Maalapparatuur biedt nauwkeurige controle over de deeltjesgrootte, wat zorgt voor consistentie in textuur en kwaliteit.

- Verbeterde smaakinfusie: Fijngemalen ingrediÃŦnten zorgen ervoor dat smaken beter vrijkomen, wat de algehele sensorische ervaring verbetert.

- Uniform mengen: Consistent gemalen ingrediÃŦnten bevorderen gelijkmatig mengen, wat cruciaal is voor een evenwichtige smaakverdeling.

- Aanpassing van textuur: Verschillende maaltechnologieÃŦn maken het mogelijk om de textuur en de deeltjesgrootte aan te passen aan specifieke productvereisten.

Toepassingen in voedselverwerking

Frees- en slijpmachines worden veel gebruikt in verschillende sectoren van de voedingsindustrie, waaronder:

- Bakken: Malen van granen tot meel voor brood, gebak en andere gebakken producten om een consistente productie van hoge kwaliteit te garanderen.

- Chocolade en Snoepgoed: Malen van chocolade en soortgelijke pasta's of crÃĻmes voor een gladde textuur en een evenwichtige smaak.

- Verwerking van specerijen: Specerijen malen om de smaak en het aroma te versterken, cruciaal voor culinaire gerechten.

- Fruitverwerking: Het pletten en malen van fruit om purees, sauzen of sappen te maken, essentieel voor verse en geconserveerde producten.

- Notenboterproductie: Het maken van gladde notenboters of notenboters met structuur, die populair zijn in verschillende voedseltoepassingen.

- Productie van dranken: Verwerking van koffiebonen, cacao en andere ingrediÃŦnten om het gewenste smaakprofiel in dranken te krijgen.

Samenwerking met FoodTechProcess voor optimale maaloplossingen

FoodTechProcess biedt een uitgebreid assortiment molens en maalmachines die zijn afgestemd op de specifieke behoeften van de voedingsmiddelenindustrie. Onze apparatuur combineert geavanceerde technologie met robuuste engineering en biedt efficiÃŦnte en nauwkeurige maaloplossingen. Toegewijd aan kwaliteit en innovatie, FoodTechProcess helpt voedselproducenten hun productieprocessen en productkwaliteit te verbeteren.

De pistachepastamolen is een colloÃŊdmolen. Het werkingsprincipe is gebaseerd op het malen van notenpitten tussen een rotor en stator om colloÃŊdale deeltjes te verkrijgen.

Pistachepasta verkregen met dit type molen heeft een uniforme, fijne textuur, natuurlijke smaak en aroma.

Voordelen:

- Eenvoudig te bedienen

- Hoge productiviteit

- Compact formaat

- Flexibele instelmogelijkheden

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Apparatuursoort: Individuele machine

- Land van herkomst: Slowakije

Wij bieden kogelmolens met verschillende capaciteiten, van laboratoriummolens tot industriÃŦle molens tegen een geweldige prijs en de hoogste kwaliteit die uitzonderlijke chocolade produceren.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Continue modus

De bloksnijder is ontworpen voor het fijnhakken van bevroren blokken vlees, vis, gevogelte, vleesbijproducten, sap, boter of margarine zonder deze eerst te ontdooien. Dit is een handige en snelle methode om de producten voor te bereiden voor verdere verwerking, wat tijd bespaart en de kans op productcontaminatie verkleint.

- Snijdt het product efficiÃŦnt in dunne lagen terwijl de textuur behouden blijft

- Veilige pneumatische toevoer van het product naar de maalsectie

- Speciaal bevestigingssysteem voor de productcontainer tijdens het lossen

- Weinig productverlies tijdens de verwerking

- Een krachtige bladaandrijving

- Materiaal: Roestvrij staal

- Werkingsprincipe: Continue modus

- Land van herkomst: Slowakije

- Werkgebiedbreedte: 600 mm

- Totale vermogen, kW: 11

- Spanning: 380-400V

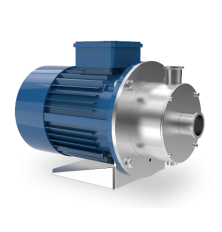

De nieuwe en verbeterde versie van de colloÃŊdmolen wordt gebruikt voor continu malen, om een afgewerkt notenpastaproduct met verschillende viscositeiten te verkrijgen, zonder dat er extra bewerking of voorbereiding nodig is!

- Eenvoudige en gemakkelijke bediening

- Driepunts snij-instelling

- Mogelijkheid om zowel romige als knapperige notenboters te maken

- Compact ontwerp

- Hoge prestaties

- Productiviteit: 180-240 kg/h

- Materiaal: Roestvrij staal

- Werkingsprincipe: Continue modus

- Land van herkomst: Slowakije

- Spanning: 380-400V

Dit is een zeer efficiÃŦnt apparaat dat ontworpen is voor het fijnmalen en homogeniseren van vaste producten. Dankzij het unieke ontwerp en de hoge snelheid zorgt de molen voor het fijn mengen en breken van deeltjes, waardoor hij onmisbaar is in verschillende industrieÃŦn.

- Compact ontwerp - tafelmontage

- Mogelijkheid om verschillende voermodellen te gebruiken

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Apparatuursoort: Individuele machine

- Land van herkomst: Slowakije

- Spanning: 220-230V

De messenmolen wordt gebruikt voor het malen van producten zoals suiker, peper, droge bladeren en andere producten die gebruikt worden bij de productie van specerijen en sauzen.

- Instelbare maalgrootte

- Eenvoudig onderhoud

- Ondersteunende structuur

- Trechter met grote capaciteit

- Materiaal: Roestvrij staal

- Motorvermogen, kW: 5,5

- Werkingsprincipe: Continue modus

- Spanning: 380-400V

- Vultrechtervolume, l: 30

Fruitmolen, volledig gemaakt van AISI 304 roestvrij staal, is geschikt voor fruit, groenten en vele andere producten zoals appels, peren, wortels, citroenen en andere; eenvoudig te gebruiken, hoge productiviteit. Hij kan geleverd worden met ÃĐÃĐn of meer zeven (zeven of raadsels).

- Productiviteit: 800 kg/h/ 1500 kg/h/ 3000 kg/h

- Motorvermogen, kW: 1,35/ 2,1/ 2,6

- Vultrechtervolume, l: 30/ 60/ 100

De industriÃŦle vleesmolen is gemaakt van voedselveilig roestvrij staal. De set bevat verschillende accessoires, zoals een opzetstuk voor worsten en een opzetstuk met twee gekruiste messen. De productiviteit van de vleesmolen is ongeveer 120 kg gehakt per uur.

- Compact

- Professioneel

- Met antislip rubberen voetjes

- Roestvrijstalen behuizing

- Productiviteit: 120 kg/h

- Materiaal: Roestvrij staal

- Bedrijfsmodus: Automatisch

- Werkingsprincipe: Continue modus

- Totale vermogen, kW: 0,75

- Spanning: 220-230V

De prijs is vermeld voor de basisversie van de installatie zonder ballen.

De molen is ontworpen voor het mechanisch malen van grondstoffen voor de productie van chocolade, notenboter en het verkrijgen van een romige, homogene productstructuur met een fractiegrootte tot 20 micron.

- Compacte installatie op een zelfdragende structuur

- Eenvoudig en gemakkelijk onderhoud

- Plexiglas afdekking voor visuele inspectie

- Verwijderbaar roerapparaat

- Materiaal: Roestvrij staal

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Volume: 5l

- Totale vermogen, kW: 1,5

- Spanning: 380-400V

De notenmaalmachine wordt gebruikt voor het verwerken van sesamzaadjes tot een tahini- of sesampasta.

- Materiaal: Roestvrij staal

- Land van herkomst: Slowakije

Deze poedermachine is gemaakt van roestvrij staal. Alle onderdelen die in contact komen met voedsel, zijn om gezondheids- en veiligheidsredenen gemaakt van voedselveilig 304 roestvrij staal.

- Materiaal: Roestvrij staal

- Motorvermogen, kW: 2,2

Deze graanmolen van roestvrij staal is stevig en duurzaam en heeft een verhoogde slijtvastheid.

- Materiaal: Roestvrij staal

- Motorvermogen, kW: 3

Wij bieden verschillende soorten wasapparatuur voor verschillende soorten fruit en groenten.

- Productiviteit: 1500 kg/h

- Materiaal: Roestvrij staal

- Motorvermogen, kW: 3

- Gewicht: 200

Maalmolen voor het continu malen van vlees en ingrediÃŦnten zoals zaden, kleine botjes en kraakbeen die ongewenst zijn in het eindproduct.

- Motorvermogen, kW: 3

- Werkingsprincipe: Continue modus

- Spanning: 380-400V

Onderstel (steunstructuur) voor colloÃŊdmolen - extra optie voor de colloÃŊdmolen 132

- Apparatuursoort: Optionele uitrusting

Kogelmolens worden gebruikt voor de productie van een chocolademassa, verschillende soorten chocoladeglazuur, noten- en chocoladepasta's (zoals Nutella) en soortgelijke producten.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Continue modus

De molen is ontworpen voor het malen van heel fruit of groente vÃģÃģr verdere verwerking. De prijs hangt af van het gekozen fruit en de productiecapaciteit.

Stuur ons een verzoek voor meer informatie.

- Productiviteit: 6000 kg/h

- Materiaal: Roestvrij staal

- Werkingsprincipe: Continue modus

- Materiaal: Roestvrij staal

- Werkingsprincipe: Continue modus

- Land van herkomst: Slowakije

Chocolade schilfermachine voor het automatisch onderscheiden van telkens twee blokken couverture. De schilfers worden verzameld in plastic bakken voor levensmiddelen. De machine wordt geleverd met twee plastic bakken.

- Productiviteit: 30 kg/h

- Materiaal: Roestvrij staal

- Spanning: 220-230V

De wasmachine-auger-molenmachine is ontworpen voor het wassen, transporteren en malen van hele vruchten of groenten vÃģÃģr verdere verwerking. De prijs is afhankelijk van uw product en de productiecapaciteit. Stuur ons een verzoek voor meer informatie.

- Productiviteit: 3000 kg/h

- Materiaal: Roestvrij staal

- Werkingsprincipe: Continue modus

De breker wordt gebruikt voor het pletten van fruit zoals bessen vÃģÃģr het persen. De prijs is afhankelijk van uw productie. Stuur ons een verzoek voor meer informatie.

- Productiviteit: 3000 kg/h

- Materiaal: Roestvrij staal

- Werkingsprincipe: Continue modus

De molen wordt gebruikt voor het malen van zowel vers vlees als voedingsmiddelen, zoals kaas en fruit.

- Materiaal: Roestvrij staal

- Werkingsprincipe: Continue modus

- Spanning: 380-400V