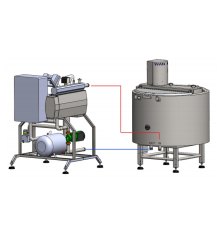

Vacu├╝m mantel-agitaatvat - reactor 110/100

De prijs is vastgesteld voor de basisversie van de reactor zonder extra opties en het bedieningspaneel

De vacu├╝mketel met een koelvloeistofduplicator en een menginrichting is een universele oplossing voor het verwerken van verschillende producten onder subatmosferische druk. Op basis van dit eenvoudige apparaat kunt u het selecteren en moduleren tot complexe installaties zoals een┬Āvacu├╝mverdamper, een vacu├╝mkookketel┬Āeen┬Āinstallatie voor de productie van roomhoning.

- Schuin ontwerp - Mengen op zwaartekracht

- Bodemventiel DN40 inbegrepen in de basisversie

- Duplicator voor kleine volumes - lage kosten voor het verwarmen/koelen van koelmiddel

- Modulair systeem: aanpassing van de apparatuur en de functionaliteiten door extra opties te bestellen

- Een gemakkelijk te demonteren mengapparaat

De inhoud van deze pagina is vertaald naar het Nederlands met de geautomatiseerde vertaling. De originele versie is in het Engels. Bedankt voor uw begrip.

Het optimale volume van de vacu├╝mreactor maakt hem geschikt voor kleine en middelgrote voedselverwerkingsbedrijven, maar ook voor cateringorganisaties, donkere keukens in het HoReąĪa-segment en laboratoriumtoepassingen voor grote voedselverwerkingsbedrijven.

Vacu├╝mreactoren zijn ontworpen om verschillende producten te kunnen verwerken bij subatmosferische druk.

Sommige producten zijn gevoelig voor hoge temperaturen, dus worden ze verwerkt bij lagere temperaturen, temperaturen onder het kookpunt van water onder atmosferische druk. Hierdoor blijven de meeste heilzame stoffen, sporenelementen en vitaminen in de producten behouden, evenals hun oorspronkelijke smaak en kleur.

Dergelijke reactoren worden gebruikt om te produceren:

|

|

|

|

|

|

|

|

|

|

Voordelen:

- Productmenging op basis van zwaartekracht, die 20-25% effectiever is dan de klassieke mengmethode.

- Geen dode hoeken tijdens het mengen: het product stroomt vanzelf langs de wanden naar beneden, en het mengapparaat neemt het op en kneedt het in de hoofdmassa.

- Zeer efficiënt voor het mengen van mengsels met meerdere componenten.

- Het bodemventiel zorgt voor een grondige verwerking zonder dode hoeken - dit is een essentiële vereiste voor professionele installaties, vooral in industrieën zoals de farmaceutische industrie, waar een nauwkeurige dosering van stoffen van cruciaal belang is tijdens batchverwerking. De aanwezigheid ervan zorgt ervoor dat alle componenten en mengsels, ook die met een zwakke of langzame oplosbaarheid, grondig gemengd en opgelost worden in het hele volume van het product. De bodemklep bevindt zich op de bodem van de werktank, zodat er geen componenten in vallen en onverwerkt in de afvoerleidingen achterblijven.

- Een "koelmantel" met een klein volume (tot 0,5 bar) wordt over de gehele hoogte van de werktank geïnstalleerd, inclusief de bodem, waardoor een groot warmteoverdrachtsgebied ontstaat. Dit vermindert het energieverlies aanzienlijk bij het vervangen van de koelvloeistof (verwarmen/koelen), afhankelijk van de vereiste verwerkingsmethode.

- Dit model maakt deel uit van een serie modulaire eenheden die, met extra apparatuur, kunnen worden omgevormd tot een vacu├╝mhomogenisatiemodule, een vacu├╝mverdampingseenheid of een creame-eenheid.

- De basisversie is uitgerust met een professionele industriële tandwielmotor met een driefasige aansluiting.

Technologische processen:

|

|

|

|

|

|

|

|

Opties:

Controle

- Frequentieomvormer in de vorm van een standalone bedieningspaneel met IP66 elektrische bescherming wordt gebruikt om de tandwielmotor van het mengapparaat te regelen.

- Eenfasige motorreductor met de mogelijkheid om aangesloten te worden op een 220-240 Volt netwerk; als extra optie kunt u een regelaar kiezen om de snelheid van de motorreductor te regelen, waardoor de snelheid soepel aangepast kan worden en het motorvermogen behouden blijft wanneer er een belasting optreedt.

- Driefasige motorreductor voor dikke en viskeuze producten met een hoger koppel.

- Bimetaalthermometer in de mantel om de huidige temperatuur bij de koelmiddelinlaat weer te geven.

- Extra thermostaat met een sonde om de temperatuur van het product in de container te meten.

- Onderste temperatuursensor in het product (PT100) met een thermostaat. Deze optie is alleen beschikbaar als u kiest voor de schakelkast met de installatie van een thermische regelaar.

- Elektromagnetische klep voor het toevoeren van de koelvloeistof in de mantel met een elektrische regeling.

- Regelkleppen voor de toevoer van de koelvloeistof naar de mantel voor een nauwkeurigere afstelling van de koelvloeistofstroom. Deze optie kan alleen worden geselecteerd als u kiest voor de elektrische kast waarin de installatie van een klepregeling is inbegrepen.

- Een schakelkast van koolstofstaal met IP54-beschermingslaag, waarin de signaal, veiligheids en regelelektrische componenten (relais, contacten, enz.) zijn ondergebracht. Als extra optie kunt u kiezen voor een schakelkast die volledig van AISI304 roestvrij staal is gemaakt. De bovenste wijziging van de schakelkast is de hygiënische versie die ontworpen is voor voedselproductie.

Extra systemen:

- U kunt kiezen uit vacu├╝m genererende systemen afhankelijk van het type energie: ejector voor perslucht, water of vloeistofringpomp; deze omvat: een vacu├╝mgenerator en een vacu├╝mmeter; als extra optie kan een vacu├╝mmeter in een roestvrijstalen behuizing gevuld met glycerine worden gekozen.

- Het systeem voor het vasthouden en aanpassen van het vacu├╝m met behulp van een speciale elektrisch gestuurde vacu├╝mmeter (deze optie is beschikbaar als u een elektrische schakelkast kiest) stelt u in staat om de vacu├╝mdiepte en de grenzen van de retentie direct op de vacu├╝mmeter aan te passen.

- Een vacu├╝mregelsysteem met een elektrisch gestuurde magneetklep (deze functie is toegankelijk als u de configuratie met een elektrische schakelkast selecteert).

Optionele uitrusting:

- Ondersteuning in de vorm van verstelbare en stelpoten van versterkt polyamide, met of zonder scharnier.

- Zwenkwielsteunen, bestand tegen belasting en fysieke slijtage, met een remmechanisme en een speciale coating voor voedselproductie.

- Sel verstelbare zijschrapers met veren gemaakt van AISI304 roestvrij staal, gebruikt om de wanden van de werkcontainer schoon te maken.

- De schrapers zijn gemaakt van voedselveilig polytetrafluorethyleen (fluoroplastic-4/merk Teflon), dat zeer duurzaam, goed vervormbaar en met een lage wrijvingscoëfficiënt is! Heeft certificaten voor gebruik in de voedingsmiddelenindustrie.

- Bodemschrapers voor het reinigen van de bodem van het vat. De schrapers zijn gemaakt van voedselveilig polytetrafluorethyleen (fluoroplastic-4, merk Teflon), dat zeer duurzaam, goed vervormbaar en met een lage wrijvingscoëfficiënt is! Heeft certificaten voor gebruik in de voedingsmiddelenindustrie. Deze optie kan alleen worden geselecteerd als u een speciale bodemtemperatuursensor voor het product kiest;

- CIP-koppen (sproeikoppen) voor het wassen zijn gemaakt van voedselveilig roestvrij staal; als extra optie kunnen roterende sproeikoppen worden besteld, zodat u alle oppervlakken van de containers kunt bedekken, inclusief het openingsluik van de apparatuur.

- Externe decoratieve hygiënische behuizing van gepolijst roestvrij staal AISI304.

- Thermische isolatie. Afhankelijk van de temperatuurcondities die voor de verwerking gebruikt worden, kan gekozen worden voor lage temperatuur isolatie van thermisch isolatieschuim met folie, of een hoge temperatuur type thermische isolatie van minerale wol.

- Een elektrisch doorstroomwaterverwarmingssysteem (koelvloeistof - water) met verschillende verwarmingsvermogens beschikbaar, zoals 12, 24, 48 kW.

- Voor het comprimeren van de lucht wordt een speciale luchtcompressor met lage snelheid gebruikt, die werkt bij een druk van 6-10 bar. Deze optie is essentieel als u kiest voor een ejector die perslucht gebruikt als vacu├╝mgenerator.

- Watertoevoerpomp voor het creëren van een vacuüm bij gebruik van de waterejector als vacuümgenerator.

- Een speciale pijp met een slang maakt het mogelijk om de container vacu├╝m te vullen via de bodemklep tot het niveau van de werkvloeistof. Deze optie is alleen beschikbaar als u de optie voor vacu├╝mopwekking kiest.

- Een inline Ultra Shear-homogenisator die via flexibele leidingen op het recirculatiesysteem kan worden aangesloten.

- Materiaal: Roestvrij staal

- Motorvermogen, kW: 0,25

- Werkingsprincipe: Batchmodus

- Land van herkomst: Slowakije

- Volume: 100l

- Spanning: 380-400V

- Maximale vacu├╝m: -0,8 Bar