MILLS, GRINDERS

Mills and grinders are utilized to reduce the particle size of ingredients in food processing

Mills and grinders in food processing are used to reduce the particle size of ingredients such as grains, seeds, spices, nuts, and fruits. They are crucial for achieving the desired texture and consistency of food products like flours, pastes, and powders.

What are mills and grinders?

Grinding mills are designed to crush, grind, or pulverize raw materials into smaller particles. These devices are used in the food industry for producing fine powders, nut pastes, chocolate creams, fruits and much more, ensuring uniform consistency of the final product.

How do mills work?

These machines operate using mechanical forces such as impact, compression, or shearing. Depending on the type of material and the desired final product, mills may utilize blades, rollers, or other grinding mechanisms to efficiently reduce particle size.

Advantages of using mills and grinders

- Particle Size Control: Grinding equipment provides precise control over particle size, ensuring consistency in mixture texture.

- Enhanced Flavor Infusion: Finely ground ingredients facilitate better flavor release, enhancing the overall sensory experience.

- Uniform Mixing: Consistently ground ingredients promote even mixing, crucial for balanced flavor distribution.

- Customization of Texture: Different grinding mills allow for the adjustment of texture and particle size according to specific product requirements.

Applications in food processing

Mills and grinding machines are widely used in various sectors of the food industry, including:

- Baking: Grinding grains into flour for breads, pastries, and other baked goods to ensure a consistently high-quality output.

- Chocolate and Confectionery: Grinding chocolate and similar pastes and creams to ensure a smooth texture and balanced flavor.

- Spice Processing: Grinding spices to enhance their flavor and aroma, crucial for all culinary dishes.

- Fruit Processing: Crushing and grinding fruits to produce purees, smoothies, sauces, or juices, processing both fresh and preserved products.

- Nut Butter Production: Creating smooth or crunchy nut butters, which are popular in various food applications.

- Beverage Production: Processing coffee beans, cocoa, and other ingredients to achieve the desired flavor profile and texture in beverages.

Partner with FoodTechProcess for optimal grinding solutions

FoodTechProcess offers a range of mills and grinders, each tailored to the specific needs of the food industry. Commercial mills offer an efficient solution for grinding various food products to the desired particle size. Contact FoodTechProcess to help you select the right grinder for your production process.

The pistachio paste mill is a colloid type mill. Its operating principle is based on grinding nut kernels between a rotor and stator to achieve colloid-sized particles.

Pistachio paste obtained using this type of mill has a uniform fine texture, natural taste and aroma.

Advantages:

- Easy to operate

- High productivity

- Compact size

- Flexible adjustment settings

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

We offer different capacity ball mills, from laboratory mills to industrial mills at great price and highest quality which produce exceptional chocolate.

- Material: Stainless steel

- Principle of operation: Continuous mode

The block cutter is designed for chopping frozen blocks of meat, fish, poultry, meat by-products, juice, butter or margarine without prior defrosting. This is a convenient and quick method of preparing the products for further processing, which saves time and reduces the likelihood of product contamination.

- Efficiently slices the product into thin layers while preserving its texture

- Safe pneumatic feeding of the product into the grinding section

- Special fixation system for the product container during unloading

- Low product losses during processing

- A powerful blade drive

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 600 mm

- Total power, kW: 11

- Voltage: 380-400V

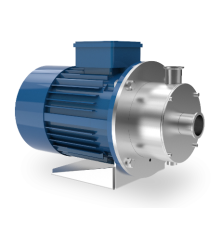

The colloid mill is used for continuous grinding of nuts, to obtain a finished nut paste of various viscosities with one pass through, without requiring additional processing or preparation!

- Simple and easy operation

- Three-point grinding adjustment

- Possibility of producing both creamy and crunch-type nut butters

- Compact design

- High performance

- Productivity: 180-240 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

This is a highly efficient equipment designed for fine grinding and homogenization of solid products. Thanks to its unique design and high speed, the mill provides fine mixing and crushing of particles, which makes it indispensable in a variety of industries.

- Compact design - tabletop installation

- Possibility of using different feeder models

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Voltage: 220-230V

The knife mill is used for grinding products such as sugar, pepper, dry leaves and other products that are used during the production of spices and sauces.

- Adjustable grinding size

- Easy maintenance

- Support structure

- Large capacity hopper

- Material: Stainless steel

- Engine power, kW: 5,5

- Principle of operation: Continuous mode

- Voltage: 380-400V

- Hopper volume, l: 30

Fruit crushing mill, entirely made of AISI 304 stainless steel is suitable for fruit, vegetables and for many other products such as apples, pears, carrots, lemons and others; easy to use, high productivity. It can be supplied with one or more sieves (screens or riddles).

- Productivity: 800 kg/h/ 1500 kg/h/ 3000 kg/h

- Engine power, kW: 1,35/ 2,1/ 2,6

- Hopper volume, l: 30/ 60/ 100

The industrial meat grinder is made out of food-grade stainless steel. The kit includes various accessories such as a sausage attachment and an attachment with two cross blades. The productivity of the meat grinder is around 120 kg of minced meat per hour.

- Compact

- Professional

- With anti-slip rubber feet

- Stainless steel housing

- Productivity: 120 kg/h

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Total power, kW: 0,75

- Voltage: 220-230V

The price is stated for the basic version of the installation without balls.

The mill is designed for mechanical grinding of raw materials for the production of chocolate, nut butters and obtaining a creamy, homogeneous product structure with a fraction size of up to 20 microns.

- Compact installation on a self-supporting structure

- Simple and convenient maintenance

- Plexiglas cover for visual inspection

- Removable stirring device

- Jacket for the heat transfer medium

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 5l

- Total power, kW: 1,5

- Voltage: 380-400V

The nut grinding machine is used for processing sesame seeds to produce a tahini or a sesame paste.

- Material: Stainless steel

- Country of origin: Slovakia

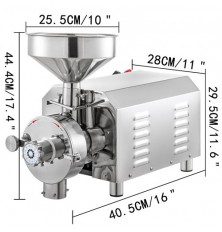

This powder making machine is made out of stainless steel. All parts that are in contact with food are made out of food grade 304 stainless steel for health and safety reasons.

- Material: Stainless steel

- Engine power, kW: 2,2

A grain mill made out of stainless steel, it is sturdy and durable grinder, with increased wear resistance.

- Material: Stainless steel

- Engine power, kW: 3

We offer different types of washing equipment for various different fruits and vegetables.

- Productivity: 1500 kg/h

- Material: Stainless steel

- Engine power, kW: 3

- Weight: 200

Grinding mill for continuous grinding of meat and ingredients such as seeds, small bones and cartilages that are unwanted in the final product.

- Engine power, kW: 3

- Principle of operation: Continuous mode

- Voltage: 380-400V

Stand (support structure) for colloid mill machine - additional option for the colloid mill 132

- Type of the equipment: Optional equipment

Ball mills are used for the production of a chocolate mass, various types of chocolate glazes, nut and chocolate pastes (such as Nutella) and similar products.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

The mill is designed for milling whole fruit or vegetable before further processing. Price depends on the chosen fruit and production capacity.

For more information, send us a request.┬Ā

- Productivity: 6000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Chocolate flaking machine for automatically differentiating two blocks of couverture each time. The flakes are collected in plastic baking for food. The machine comes with two plastic bins.

- Productivity: 30 kg/h

- Material: Stainless steel

- Voltage: 220-230V

The washer-auger-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

Price depends on your product and the production capacity. For more information, send us a request.

- Productivity: 3000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

The crusher is used for crushing fruits such as berries before pressing. The price depends on your production.┬ĀFor more information, send us a request.┬Ā

- Productivity: 3000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

Grinder is used for grinding both fresh meat and food products, such as cheese, fruits.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V