M├Īquina semi-autom├Ītica de enchimento de sacos em caixa

A m├Īquina de enchimento de sacos em caixas foi concebida para encher l├Łquidos quentes e frios em sacos em caixas e para embalagens Stand Up Pouch.

- A m├Īquina enche os sacos automaticamente.

O conte├║do desta p├Īgina foi traduzido para o portugu├¬s com tradu├¦├Żo autom├Ītica. A vers├Żo original est├Ī em ingl├¬s. Obrigado pela compreens├Żo.

A m├Īquina de enchimento Bag in Box ├® ideal para encher v├Īrios l├Łquidos, incluindo:

|

|

|

|

|

|

A m├Īquina enche os sacos automaticamente. Basta inserir o saco ou a embalagem na m├Īquina de enchimento Bag in Box e puxar a pega. Depois de encher o saco com o produto, volte a colocar a pega de enchimento na sua posi├¦├Żo original e feche a embalagem.

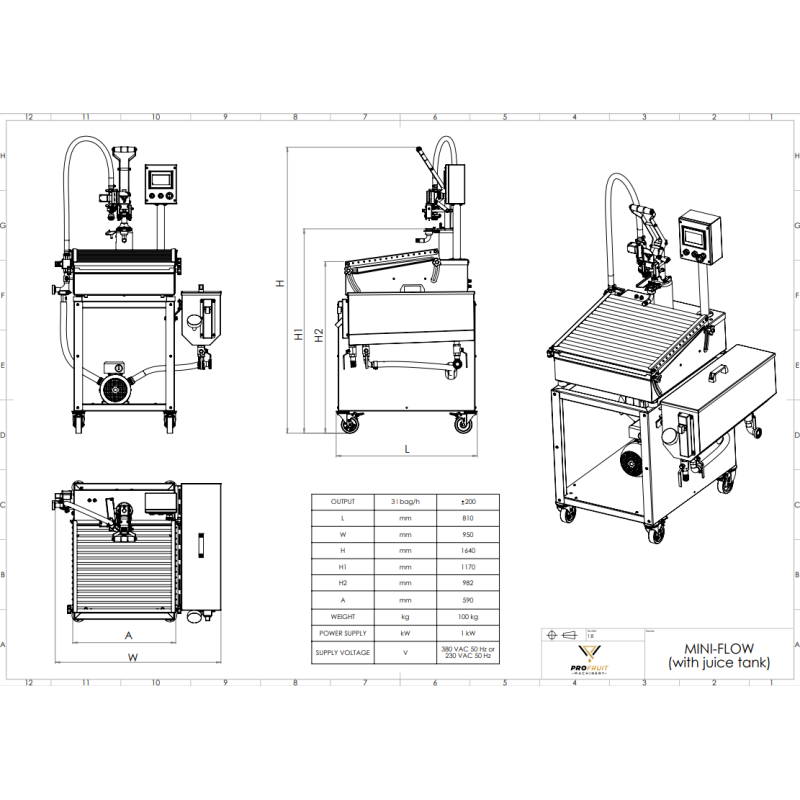

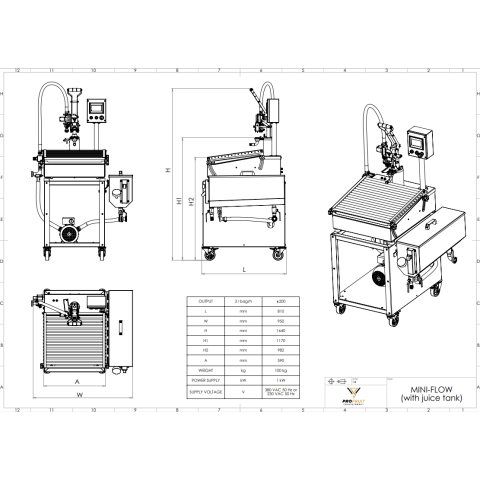

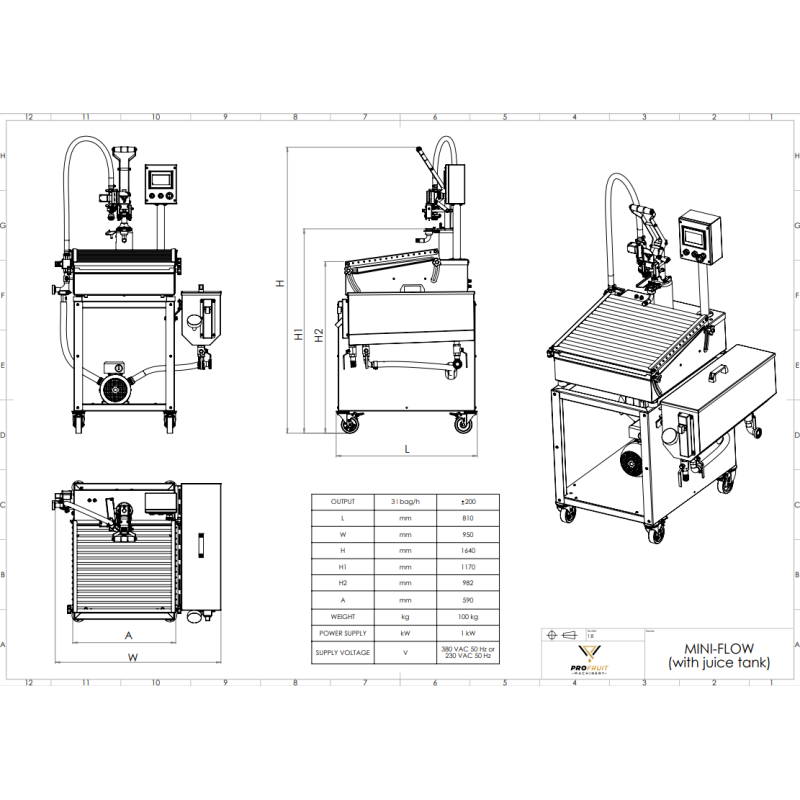

Capacidade - 250 sacos unit├Īrios 3 L/hora

- Enche sacos Bag in Box com um volume de 1-30 l, sacos Stand up Pouch com um volume de 0,75-5 l.

- Adequado para enchimento quente e frio.

- A m├Īquina enche embalagens Bag in Box e Stand up Pouch utilizando uma torneira.

- A enchedora pode ter um dep├│sito tamp├Żo adicional amov├Łvel para enchimento a quente. ├ē convenientemente fixado na parte lateral da m├Īquina para uma melhor inspe├¦├Żo e uma limpeza mais f├Īcil. O dep├│sito tamp├Żo tamb├®m reduz a forma├¦├Żo de espuma durante o processo de enchimento a quente.

- Existe um regulador de n├Łvel de l├Łquido incorporado no interior do tanque-tamp├Żo para regular o transbordo e o n├Łvel de l├Łquido no tanque. O tanque tamp├Żo tamb├®m est├Ī ligado ao nosso pasteurizador.

- O erro de repetibilidade do volume ├® de apenas ┬▒0,5%.

- A m├Īquina de enchimento faz uma pr├®-vacua├¦├Żo dos sacos e bolsas antes do enchimento.

- Inclui um painel t├Ītil e um menu multilingue.

- A mesa de enchimento facilmente ajust├Īvel permite-lhe encher facilmente sacos Bag in Box e Stand up Pouch de v├Īrios tamanhos.

- A superf├Łcie de trabalho da mesa ├® constitu├Łda por rolos de transporte, f├Īceis de limpar e que facilitam o deslizamento suave de sacos e embalagens.

- A enchedora pode ser facilmente limpa ap├│s a utiliza├¦├Żo com a ajuda de lavagem externa e CIP.

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo cont├Łnuo

You might also like

M├Īquina doseadora semi-autom├Ītica, concebida para encher e tapar diferentes bolsas com v├Īrios l├Łquidos.

- Material: A├¦o inoxid├Īvel

- Modo de opera├¦├Żo: Semiautom├Ītico

A m├Īquina de enchimento ├® concebida para bombear e encher l├Łquidos de alta viscosidade, tais como compotas, confeitos, molhos, temperos, xaropes e produtos semelhantes.

- Produtividade: 200ŌĆō600 bottles per hour

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo cont├Łnuo

O dispositivo foi concebido para encher sacos em caixas. Adequado para encher produtos quentes n├Żo viscosos. O dispositivo pode ser adquirido separadamente ou com op├¦├Ąes adicionais - carrinho e carregador.

- Material: A├¦o inoxid├Īvel

- Modo de opera├¦├Żo: Autom├Ītico

A TEPF ├® um doseador pneum├Ītico para dosear v├Īrios tipos de produtos. A m├Īquina permite o enchimento de produtos alimentares, qu├Łmicos, cosm├®ticos ou farmac├¬uticos em diversos tipos de garrafas e frascos.

O pre├¦o depende do produto utilizado.

- Material: A├¦o inoxid├Īvel

- Modo de opera├¦├Żo: Autom├Ītico Manual

- Tipo de equipamento: M├Īquina individual

O dispositivo foi concebido para encher sacos em caixas. Adequado para encher produtos quentes n├Żo viscosos. O dispositivo pode ser adquirido separadamente ou com op├¦├Ąes adicionais - carrinho e carregador.

- Material: A├¦o inoxid├Īvel

- Modo de opera├¦├Żo: Autom├Ītico

A VBF ├® uma m├Īquina de enchimento de garrafas a v├Īcuo r├Īpida, robusta e vers├Ītil. Esta ├® a m├Īquina de enchimento que procura se deseja aumentar o volume de produ├¦├Żo dos seus produtos caseiros e profissionalizar o engarrafamento de vinho, azeite, cerveja, sumos de fruta ou outros produtos.

- Modo de opera├¦├Żo: Semiautom├Ītico

- Princ├Łpio de opera├¦├Żo: Modo cont├Łnuo

Envasadora digital compacta para uma dosagem precisa de l├Łquidos viscosos, como mel, pastas, molhos e ├│leos. Concebida com materiais de qualidade alimentar, componentes f├Īceis de limpar e controlo digital preciso, ├® ideal para pequenas produ├¦├Ąes, oficinas e laborat├│rios.

- Modo de opera├¦├Żo: Semiautom├Ītico

A m├Īquina de enchimento tensom├®trico Normit AP ├® um sistema baseado no peso para o enchimento de mel em barris.

- Material: A├¦o inoxid├Īvel

- Pa├Łs de origem: Eslov├Īquia

Concebida para uma alimenta├¦├Żo e embalagem precisas de l├Łquidos sob press├Żo.

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo em lotes

- Pa├Łs de origem: Eslov├Īquia

- Volume: 80l/

M├Īquina de enchimento e capsulagem concebida para o enchimento e capsulagem de produtos l├Łquidos ou semi-l├Łquidos em sacos flex├Łveis doypack com bico.

- Material: A├¦o inoxid├Īvel

- Voltagem: 220-230V

A enchedora ├® um dispositivo concebido para dosear e bombear o mel. Garante um tratamento c├│modo e profissional do mel.

- Material: A├¦o inoxid├Īvel

- Potência do motor, kW: 0,18

- Voltagem: 220-230V

A enchedora de pist├Żo foi concebida para a dosagem de diferentes tipos de produtos l├Łquidos nas ind├║strias alimentar, qu├Łmica, farmac├¬utica e cosm├®tica.

- Material: A├¦o inoxid├Īvel

- Modo de opera├¦├Żo: Manual

- Tipo de equipamento: M├Īquina individual

Transportadores vibrat├│rios adequados para organizar o produto antes do processamento posterior.

- Largura da ├Īrea de trabalho: 720 mm

- Voltagem: 380-400V

Esta m├Īquina de enchimento semi-autom├Ītica ├® utilizada para o enchimento de mel, bem como de outros produtos. Oferecemos muitos tipos diferentes de m├Īquinas de enchimento para diferentes aplica├¦├Ąes.

- Material: A├¦o inoxid├Īvel

- Modo de opera├¦├Żo: Semiautom├Ītico

A bomba de parafuso ├® utilizada para a transfer├¬ncia de produtos "n├Żo bombe├Īveis". Uma ├│ptima escolha para quem trabalha com l├Łquidos dif├Łceis de mover e precisa de os mover o mais rapidamente poss├Łvel.

- Material: A├¦o inoxid├Īvel

- Voltagem: 380-400V

Enchedoras de pist├Żo hidr├Īulicas para a ind├║stria de transforma├¦├Żo de alimentos, m├Īquinas de enchimento para carne e salsichas, equipamento ideal para produtores e talhantes da ind├║stria da carne.

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo cont├Łnuo

- Volume: 20l/ 30l/ 50l

Sistema econ├│mico de enchimento de barris com base em balan├¦as para enchimento do produto com bomba.

A m├Īquina de enchimento e filtragem serve como uma fonte fi├Īvel para o fornecimento do produto l├Łquido, mantendo-o tamb├®m no estado l├Łquido.

- Produtividade: 1000 kg/h/