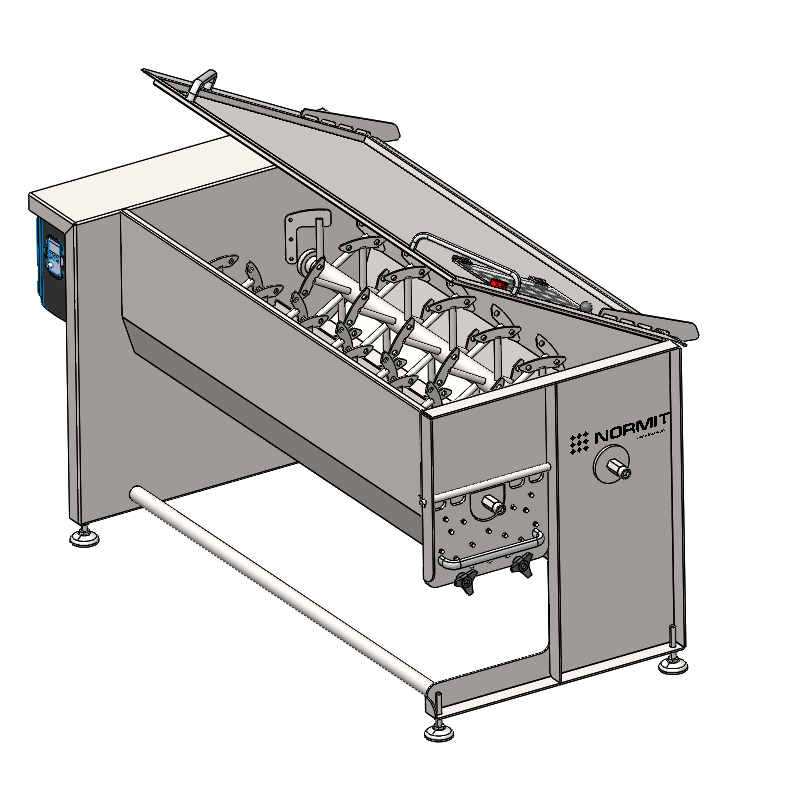

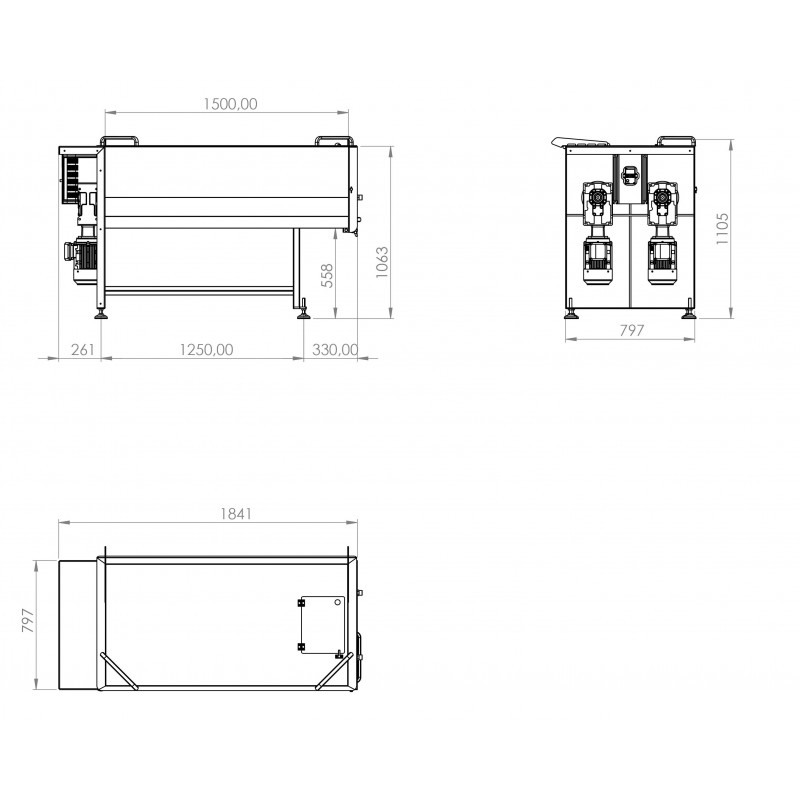

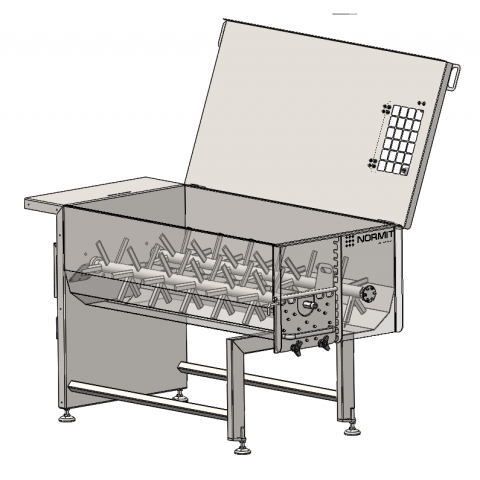

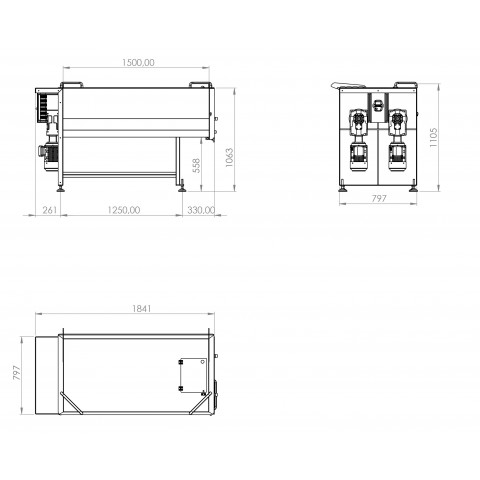

Misturador de p├Īs de veio duplo MSH 540

O pre├¦o ├® indicado sem o conversor de frequ├¬ncia

Um misturador de parafuso duplo para mistura r├Īpida e intensiva, agita├¦├Żo de produtos s├│lidos a granel, tais como gr├ónulos, muesli com v├Īrios aditivos em p├│.

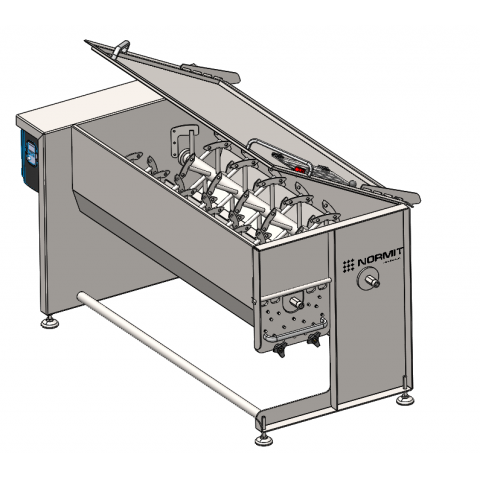

- As lâminas misturadoras movem-se cuidadosamente enquanto misturam bem o produto

- O modo de mistura permite-lhe mover o produto ciclicamente num c├Łrculo

- Elevada efic├Īcia de mistura devido ao movimento contr├Īrio dos 2 eixos

- Design compacto

- Possibilidade de instalar raspadores em cada lâmina (opcional)

- Acionamento refor├¦ado, tamb├®m pode ser utilizado para produtos saturados de humidade

O conte├║do desta p├Īgina foi traduzido para o portugu├¬s com tradu├¦├Żo autom├Ītica. A vers├Żo original est├Ī em ingl├¬s. Obrigado pela compreens├Żo.

Um misturador de p├Īs de eixo duplo ├® utilizado para preparar misturas homog├®neas, independentemente do tamanho, forma e densidade das part├Łculas da mat├®ria-prima misturada. ├ē capaz de misturar e agitar com elevado desempenho, de forma completa e eficaz, tanto materiais secos a granel como s├│lidos com uma certa quantidade de l├Łquido. Os nossos misturadores s├Żo concebidos, fabricados e testados profissionalmente para utiliza├¦├Żo numa variedade de aplica├¦├Ąes industriais que requerem mistura, mistura dispersiva e mistura distributiva.

O misturador de eixo duplo ├® utilizado no fabrico de produtos como:

|

|

|

|

|

|

|

|

Vantagens:

- Fabricado inteiramente em a├¦o inoxid├Īvel de qualidade alimentar

- Possibilidade de alterar o tipo de dispositivo de mistura (opcional)

- Estrutura de suporte de carga est├Īvel e maci├¦a

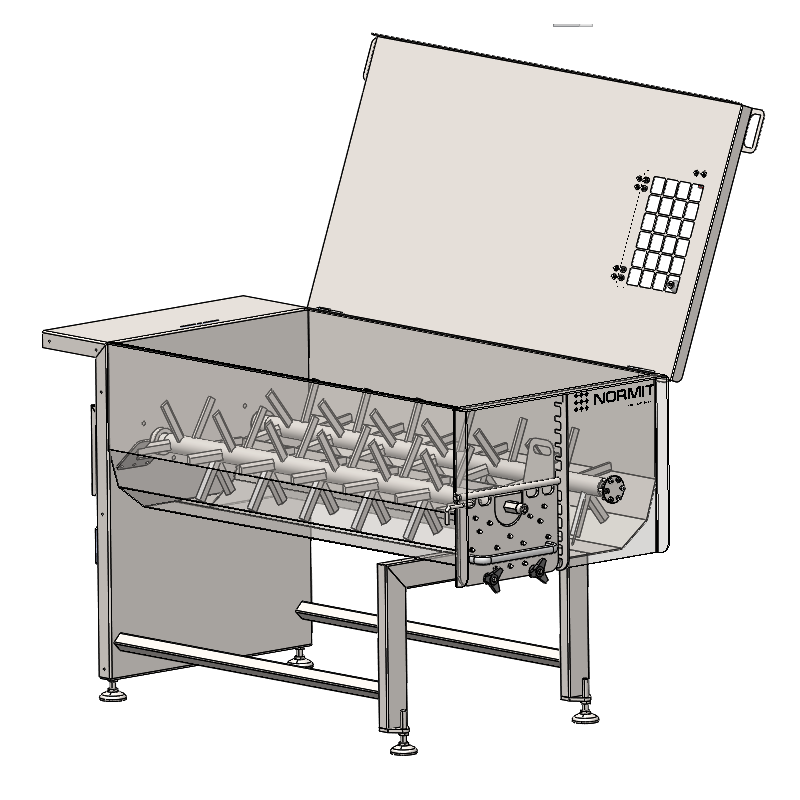

- Escotilha com fecho na posi├¦├Żo aberta para descarga de produtos

- Grelha de seguran├¦a na tampa superior para inspe├¦├Żo visual e carregamento seguro de ingredientes/componentes

- A tampa superior fecha-se para um manuseamento, manuten├¦├Żo e limpeza seguros

- Sensor de abertura da tampa

- Vedantes higi├®nicos para os po├¦os e a escotilha de descarga

- Possibilidade de regular a velocidade de rota├¦├Żo dos veios com a ajuda de um inversor (opcional)

Vers├Żo b├Īsica

├ē composto por um banho de trabalho e 2 dispositivos misturadores com l├óminas de forma especial instaladas no interior, equipados com uma escotilha lateral para descarga e uma tampa superior com uma grelha de seguran├¦a. O dispositivo de mistura tem um acionamento el├®trico refor├¦ado em cada eixo.

Princ├Łpio de funcionamento

O misturador de l├ómina dupla foi concebido para a dosagem consistente e uniforme ou para a mistura cont├Łnua de p├│s e gr├ónulos. O seu desempenho pode variar entre uma mistura suave e uma mistura de alta intensidade. A mistura intensiva ocorre na intersec├¦├Żo das l├óminas misturadoras. A mistura circula de um lado para o outro e de uma extremidade ├Ā outra do misturador. O misturador, consoante o tipo de modelo, pode funcionar em modo cont├Łnuo ou peri├│dico.

Op├¦├Ąes:

- Conversores de frequ├¬ncia para a regula├¦├Żo da velocidade de rota├¦├Żo dos veios: mistura e desloca├¦├Żo do produto para a descarga

- Sistema de dosagem incorporado para misturas l├Łquidas

- Raspadores de lâminas para a misturadora

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo cont├Łnuo

- Pa├Łs de origem: Eslov├Īquia

- Volume: 500l

- Potência total, kW: 3

You might also like

Os misturadores s├Żo cuidadosamente concebidos, constru├Łdos e testados para lidar com uma variedade de aplica├¦├Ąes industriais que requerem mistura, mistura dispersiva, mistura distributiva e muito mais.

- Material: A├¦o inoxid├Īvel

- Pa├Łs de origem: Eslov├Īquia

- Voltagem: 380-400V

- Geometric volume: 500 l

O conversor de frequ├¬ncia ├® utilizado e instalado diretamente no equipamento sem necessidade de instalar arm├Īrios el├®ctricos.

- Tipo de equipamento: Equipamento opcional

A batedeira basculante Mak Mix foi concebida para preparar massas l├Łquidas e semil├Łquidas. ├ē adequada para misturar massas para waffles, panquecas, bolos e outros produtos de pastelaria.

- Feita inteiramente em a├¦o inoxid├Īvel

- Possui um sistema de inclina├¦├Żo com tr├¬s posi├¦├Ąes de trabalho (at├® 110┬░) para mistura por gravidade e esvaziamento r├Īpido da ta├¦a

- Amassadeira de estrutura com motor industrial profissional

- Amassadeira de alta velocidade refor├¦ada para mistura e amassamento intensivos

- Interruptor de seguran├¦a na parte superior para um funcionamento seguro: a batedeira ├® desligada quando a tampa ├® aberta

- Simples e f├Īcil de limpar; a tampa e a batedeira podem ser removidas de forma r├Īpida e f├Īcil para a limpeza

- Material: A├¦o inoxid├Īvel

- Potência do motor, kW: 0,37/ 0,55

- Volume: 50l/ 100l

- Voltagem: 220-230V

- Stirrer speed, rpm: 35

Um difusor de v├Īcuo ├® um dispositivo utilizado na ind├║stria alimentar para remover o oxig├®nio de um produto em condi├¦├Ąes de v├Īcuo, utilizado principalmente para melhorar a conserva├¦├Żo dos alimentos, reduzindo a oxida├¦├Żo e prolongando o prazo de validade.

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo em lotes

- Tipo de equipamento: M├Īquina individual

- Pa├Łs de origem: Eslov├Īquia

- Volume: 200l/ 1000l

- Voltagem: 380-400V

- V├Īcuo m├Īximo: -0,8 Bar

O homogeneizador de v├Īcuo com um design inclinado foi concebido para processar e fabricar uma vasta gama de produtos l├Łquidos, pastosos e viscosos com diferentes requisitos para as suas condi├¦├Ąes de produ├¦├Żo e outros produtos, incluindo os de elevada viscosidade.

- Material: A├¦o inoxid├Īvel

- Potência do motor, kW: 1,5 KW

- Princ├Łpio de opera├¦├Żo: Modo em lotes

- Pa├Łs de origem: Eslov├Īquia

O misturador de massa ├® um equipamento de mistura do tipo batch, que trabalha na dire├¦├Żo oposta, para produzir uma vasta gama de dispers├Ąes e emuls├Ąes de viscosidade vari├Īvel.

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo em lotes

- Pa├Łs de origem: Eslov├Īquia

- Volume: 100l/ 200l

O misturador industrial ajust├Īvel AA50 foi concebido para uma mistura eficiente e de elevado desempenho de produtos l├Łquidos, viscosos e pastosos, bem como para dispersar ingredientes secos (pigmentos, corantes e outros materiais) num meio l├Łquido para obter suspens├Ąes, emuls├Ąes e pastas altamente dispersas.

- Material: A├¦o inoxid├Īvel

Uma misturadora profissional para a produ├¦├Żo de maionese, molhos, sopas e outros produtos homogeneizados. O pre├¦o depende da sua capacidade de produ├¦├Żo, bem como dos requisitos tecnol├│gicos.

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo em lotes

- Pa├Łs de origem: Eslov├Īquia

- Volume: 100l/ 200l

- Potência total, kW: 6

O misturador de fundo c├│nico com capacidade de 400 litros foi concebido para uma mistura eficiente e uma descarga suave do produto. O seu formato c├│nico direciona o conte├║do para a sa├Łda inferior, tornando-o ideal para processar materiais mais espessos ou densos num ambiente de press├Żo atmosf├®rica.

- Aquecimento: Eletricidade

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo em lotes

- Volume: 400l

- Voltagem: 380-400V

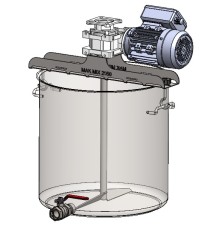

Um homogeneizador de mel ├® um equipamento de lote concebido para melhorar a estrutura e as propriedades organol├®ticas do produto. Garante uma consist├¬ncia uniforme e uma textura est├Īvel do mel.

A homogeneiza├¦├Żo ├® uma tecnologia de processamento que torna o mel fluido e uniforme, al├®m de inibir o crescimento de cristais, atendendo assim ├Ās necessidades dos produtores e consumidores. O design, o tamanho e o ├óngulo do misturador helicoidal proporcionam um elevado n├Łvel de homogeneiza├¦├Żo, o que tamb├®m reduz o tempo de processamento da mat├®ria-prima.

- Elevado n├Łvel de homogeneiza├¦├Żo, visando aumentar a estabilidade e melhorar a estrutura do mel sem alterar o sabor do produto.

- Sem pontos mortos ou cantos devido ao fundo inclinado tanto do tanque de trabalho como do misturador helicoidal.

- O dep├│sito de trabalho est├Ī equipado com camisa de aquecimento e sistema de aquecimento de ├Īgua integrado.

- V├Īlvula de sa├Łda de grande di├ómetro instalada no ponto hidr├Īulico mais baixo.

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo em lotes

- Pa├Łs de origem: Eslov├Īquia

- Potência total, kW: 4/ 7

- Carga, kg: 500/ 1100

O homogeneizador a v├Īcuo VMG M ├® a solu├¦├Żo ideal para a produ├¦├Żo de lotes piloto e para a produ├¦├Żo industrial de uma vasta gama de produtos de pequena e m├®dia produ├¦├Żo. O pre├¦o depende da capacidade de produ├¦├Żo.

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo em lotes

- Pa├Łs de origem: Eslov├Īquia

- Volume: 100l

- V├Īcuo m├Īximo: -0,8 Bar

- Volume de trabalho: 50-80l

A unidade de processamento de misturadores a v├Īcuo para produtos viscosos ├® uma solu├¦├Żo ideal para a produ├¦├Żo de lotes piloto e para o fabrico industrial de uma vasta gama de produtos de pequena a m├®dia capacidade.

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo em lotes

- Pa├Łs de origem: Eslov├Īquia

- Volume: 50l

Homogeneizador para a produ├¦├Żo de chantilly, gelados e muito mais. Permite-lhe obter emuls├Ąes l├Łquidas est├Īveis de misturas alimentares.

- O homogeneizador pode ser instalado diretamente no recipiente com o produto

- Elevada produtividade - em apenas 8 minutos, ├® poss├Łvel bater at├® 60 litros de mistura de leite

- A velocidade perif├®rica das facas ├® de 16 m/s

- Material: A├¦o inoxid├Īvel

- Potência do motor, kW: 0,37/ 2,2

- Pa├Łs de origem: EU

- Voltagem: 380-400V

Caldeira de cozedura profissional com agitador para produtos particularmente espessos e viscosos. Uma excelente solu├¦├Żo t├®cnica para a produ├¦├Żo de caramelos, xaropes e pastas de a├¦├║car para ado├¦ar. A fonte de aquecimento ├® selecionada em separado.

- A chaleira pode ser utilizada em todos os tipos de superf├Łcies de cozedura, incluindo indu├¦├Żo

- A vers├Żo b├Īsica possui raspadores de a├¦o inoxid├Īvel autocompensadores e facilmente remov├Łveis

- Elevado bin├Īrio do agitador com 14-18 rota├¦├Ąes por minuto

- Motor industrial trif├Īsico profissional

- O agitador ├® ligado de forma independente atrav├®s de um comando ├Ā dist├óncia com prote├¦├Żo IP66, ligado ├Ā caldeira atrav├®s de conectores de aperto r├Īpido

- A unidade pode ser ligada a uma rede de 220-230 volts mesmo com um motor trif├Īsico!

- Material: A├¦o inoxid├Īvel

- Potência do motor, kW: 0,25/ 0,37

- Volume: 20l/ 50l/ 100l/ 150l

- Voltagem: 220-230V

- Diameter, mm: 400/ 500/ 600

Tampa com agitador autom├Ītico para tachos de a├¦o inoxid├Īvel de 40 cm, adequados para volumes de 50 e 100 litros. Um agitador autom├Ītico permite-lhe misturar e agitar v├Īrios produtos, incluindo durante o processamento t├®rmico. O tipo de dispositivo de mistura pode ser selecionado adicionalmente, dependendo do processo necess├Īrio.

- Motor industrial profissional monof├Īsico para 220-230 Volts

- O controlo est├Ī localizado diretamente na caixa do motor ou no cabo de acionamento

- Instala├¦├Żo e fixa├¦├Żo f├Īceis e simples da tampa no tabuleiro

- Adequado para recipientes normais de 40 cm com uma capacidade de 50 ou 100 litros

- A tampa e o agitador s├Żo feitos inteiramente de a├¦o inoxid├Īvel

- Material: A├¦o inoxid├Īvel

- Potência do motor, kW: 0,18/ 0,25

- Princ├Łpio de opera├¦├Żo: Modo em lotes

- Voltagem: 220-230V

As batedeiras planet├Īrias s├Żo utilizadas principalmente na ind├║stria de confeitaria. Oferecidas em tr├¬s capacidades diferentes.

- Material: A├¦o inoxid├Īvel

- Potência do motor, kW: 1,5 / 2,2

- Princ├Łpio de opera├¦├Żo: Modo em lotes

Esta ├® uma caldeira de aquecimento com capacidade de 400 l, oferecemos caldeiras de cozedura comercial com diferentes capacidades.

- Aquecimento: Eletricidade

- Material: A├¦o inoxid├Īvel

- Potência de aquecimento, kW: 25

- Princ├Łpio de opera├¦├Żo: Modo em lotes

- Tipo de equipamento: M├Īquina individual

- Volume: 400l

- Voltagem: 380-400V