TOFFEEMASSE, KARAMELL

Professioneller Kochkessel mit R├╝hrer f├╝r besonders dicke und viskose Produkte. Eine hervorragende technische L├Čsung f├╝r die Herstellung von Karamell, Sirup und Zuckerpaste zum Zuckern. Die Heizquelle wird separat ausgew├żhlt.

- Der Kessel kann auf allen Arten von Kochfl├żchen verwendet werden, einschlie├¤lich Induktion

- Die Basisversion verf├╝gt ├╝ber leicht abnehmbare, selbstausrichtende Edelstahlschaber

- Hohes Drehmoment des R├╝hrers mit 14-18 Umdrehungen pro Minute

- Professioneller 3-Phasen-Industriemotor

- Der R├╝hrer wird mithilfe einer Fernbedienung mit IP66-Schutz selbstst├żndig eingeschaltet und ├╝ber Schnellverbinder mit dem Kessel verbunden

- Das Ger├żt kann auch mit einem 3-Phasen-Motor an ein 220-230-Volt-Netz angeschlossen werden!

- Material: Edelstahl

- Motorleistung, kW: 0,25/ 0,37

- Volumen: 20l/ 50l/ 100l/ 150l

- Spannung: 220-230V

- Diameter, mm: 400/ 500/ 600

Das Modell VMG S ist ein effektives und zuverl├żssiges Vakuumhomogenisierger├żt, das f├╝r die Herstellung einer breiten Palette von fl├╝ssigen, past├Čsen und viskosen Produkten mit unterschiedlichen Anforderungen an die Produktionsbedingungen entwickelt wurde.

Der Preis ist ohne das Steuerger├żt angegeben

Der W├żrmetauscher ist f├╝r eine effiziente und schonende W├żrmebehandlung konzipiert: Erhitzen und K├╝hlen von fl├╝ssigen und past├Čsen Produkten, auch solchen mit hoher Viskosit├żt, wie Marmelade, Schokolade, Karamell, Glasuren, Cremes, Marinaden, Babynahrung, Honig, Fisch- oder Fleischf├╝llungen und viele ├żhnliche Produkte.

- Gleichm├ż├¤ige thermische Verarbeitung von dicken und z├żhfl├╝ssigen Produkten dank der Zufuhr des K├╝hlmittels in den Duplikator

- Effiziente W├żrme├╝bertragung durch speziell geformte Schaufeln

- Kontinuierlicher Betrieb, der keine lokale ├£berhitzung oder Unterk├╝hlung des Produkts zul├żsst

- Intensive W├żrme├╝bertragung durch die innere Durchmischung des Produktes mit Abstreifern

- Material: Edelstahl

- Funktionsprinzip: Kontinuierlicher Betrieb

- Herkunftsland: Slowakei

- Volumen: 250l/ 500l

- Spannung: 380-400V

- W├żrme├╝bertragungsfl├żche, m┬▓: 2,7 5,4

Der 1000-l-Vakuumkocher dient zum Garen, Konzentrieren und Verdampfen von Lebensmitteln unter reduziertem Druck. Er erm├Čglicht eine schonende W├żrmebehandlung, verbessert den Geschmack und l├żsst sich pr├żzise regulieren.

F├╝r ein Preisangebot fordern Sie bitte eine Anfrage an.

- Heizung: Dampf

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Ger├żtetyp: Einzelmaschine

- Volumen: 1000l

- Dimensions, mm: 1385x1283x1892

Universeller Kochkessel mit eingebautem R├╝hrwerk, zum R├╝hren und Kochen von Lebensmitteln aller Art, kosmetischen Emulsionen, Cremes, Zuckerpasten und vielem mehr.

- Leicht abnehmbare, selbsteinstellende Abstreifer

- Deckel├Čffnungssensor f├╝r sichere R├╝hrwerkswartung

- Hygienischer Temperatursensor f├╝r das Produkt

- Auslassventil mit gro├¤em Durchmesser

- Sicherer Dampfaustritt an der Oberseite des Kesseldeckels

- Material: Edelstahl

- Motorleistung, kW: 0,25

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 50l/ 100l/ 150l

- Spannung: 220-230V

- Auslassventil, Zoll: 6/4

- Diameter, mm: 400/ 500/ 600

Ein Vakuumverdampfer ist ein Ger├żt, das zum Verdampfen von Fl├╝ssigkeiten bei niedrigeren Temperaturen verwendet wird, indem eine Vakuumumgebung geschaffen wird, die den Siedepunkt der Fl├╝ssigkeit herabsetzt und eine effiziente Verdampfung ohne thermische Sch├żdigung empfindlicher Materialien erm├Čglicht. Arbeitsvolumen bis zu, l: 1900 l.

- Heizung: Elektrizit├żt

- Material: Edelstahl

- Heizleistung, kW: 30

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Arbeitsvolumen: up to 1900 l

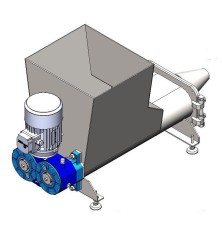

Der Z-Sigma-Arm-Paddelmischer ist f├╝r intensives Mischen, R├╝hren, Kneten und Plastifizieren von Produkten mit hoher und sehr hoher Viskosit├żt wie Kaugummibasis, fester Teig mit geringem Wassergehalt, Toffeemasse, Seifenbasis, Klebstoffe konzipiert.

- Doppelte Z-f├Črmige Klinge

- Sehr hohe Scherkraft

- Minimaler Abstand zwischen Z-Klingen und Arbeitsbeh├żlter

- Unabh├żngiger elektrischer Antrieb f├╝r jede Klinge

- Elektrisches Kippen zum automatischen Entladen um bis zu 180 Grad

- Der Mischer ist vollst├żndig aus lebensmittelechtem Edelstahl AISI304 gefertigt

- M├Čglichkeit, die Seite zum Kippen und Entladen zu w├żhlen

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 70l/ 140/ 300l/ 460/ 700l/

- Spannung: 380-400V

Edelstahl Marmelade Kochtopf mit R├╝hrwerk 50l und Elektroherd 5kW, ideal und erschwinglich Kochen L├Čsung.

- Heizung: Elektrizit├żt

- Material: Edelstahl

- Motorleistung, kW: 0,18/

- Heizleistung, kW: 5

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 50l

- Spannung: 220-230V

- Auslassventil, Zoll: 6/4

- Diameter, mm: 400/ 500/ 600

Der angegebene Preis gilt f├╝r die Standardversion der Vakuumverdampferanlage mit grundlegender Steuerung (An/Aus-Schalter f├╝r Mischermotor) und ohne zus├żtzliche Optionen. Die Steuerungseinheit wird individuell an die Kundenanforderungen angepasst. Auch die Produktpumpe wird je nach Produktart separat ausgew├żhlt.

Eine kompakte Vakuumverdampfungsanlage, mit der Sie L├Čsungen, Gemische und verschiedene Produkte durch Verdampfen des L├Čsungsmittels konzentrieren k├Čnnen. Eine modulare Version, die auf dem Basisger├żt 110/100 Vakuumreaktor.

- Schwerkraftmischen ŌĆō 25 % effizienter

- Verst├żrktes R├╝hrwerkdesign ohne tote Winkel

- Unteres Kugelventil ohne tote Zonen

- Kondensations- und sekund├żres Dampfentfernungssystem

- Einfach zu zerlegendes Mischger├żt

- Gro├¤e W├żrmeaustauschfl├żche

- M├Čglichkeit zur Messung und ├£berwachung des Kondensatvolumens (optional)

- Material: Edelstahl

- Motorleistung, kW: 0,25

- Funktionsprinzip: Kontinuierlicher Betrieb

- Herkunftsland: Slowakei

- Volumen: 100l

- Spannung: 220-230V

- Maximaler Vakuum: -0,8 Bar

- Arbeitsvolumen: 50-80l

- Kondensationskapazit├żt, l/h: 45-55

- Dampfverbrauch, kg/h: bis zu 150

Kochkessel zur Herstellung von Sirup, Karamell, Zuckermasse sowie zur Verarbeitung und Herstellung verschiedener dickfl├╝ssiger Produkte. Wird h├żufig zum Aufl├Čsen von Zucker und zur Herstellung verschiedener ges├żttigter und ├╝bers├żttigter L├Čsungen verwendet.

- Eingebaute Heizung mit Thermo├Čl bis zu 150 Grad Celsius

- Ankerrahmenr├╝hrer f├╝r schnelles Aufl├Čsen

- Konische Bodengestaltung des Arbeitsbeh├żlters ohne Totzonen

- Heizung: Elektrizit├żt

- Material: Edelstahl

- Herkunftsland: Slowakei

- Volumen: 200l/ 300l

- Gesamtleistung, kW: 19

Ein modernes Koch- und Mischger├żt mit einem breiten Anwendungsspektrum in Konditoreien, B├żckereien, Gastronomiebetrieben.

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Volumen: 200l/ 300l/ 500l

Die Schraubenspindelpumpe wird zum F├Črdern von "nicht pumpf├żhigen" Produkten verwendet. Eine gute Wahl f├╝r alle, die mit schwer zu bewegenden Fl├╝ssigkeiten arbeiten und diese so schnell wie m├Čglich bewegen m├╝ssen.

- Material: Edelstahl

- Spannung: 380-400V

Ein Vakuumumlaufverdampfer ist in der Regel eine kombinierte Version eines Verdampfers, der auch die Vorteile anderer Verdampferarten nutzt, um die Verdampfungseffizienz zu verbessern, insbesondere durch die Verk├╝rzung der Konzentrationszeit und bei der Verarbeitung hitzeempfindlicher Produkte wie Milch.

- Der externe Zirkulationskreislauf mit Heizung intensiviert den zyklischen Verdampfungsprozess.

- Das System der Zwangsumw├żlzung sorgt daf├╝r, dass das Risiko einer lokalen ├£berhitzung des Produkts verringert wird.

- Der Kondensator erm├Čglicht ein tiefes Vakuum und sorgt f├╝r eine niedrige Verdampfungstemperatur.

- Die Verwendung einer Mischvorrichtung mit einem Spr├╝hsystem erleichtert die Produktverdampfung in einer d├╝nnen Schicht, die einen Filmverdampfer imitiert.

- Heizung: Dampf

- Material: Edelstahl

- Betriebsmodus: Halbautomatisch

- Herkunftsland: Slowakei

- Gesamtleistung, kW: 2,4

- Spannung: 380-400V

Die Vakuumeindampfanlage ist speziell f├╝r die Eindickung von dichten Lebensmitteln in industriellen Mengen konzipiert. Der Verdampfer kann f├╝r die Herstellung von dicken Sirupen, Karamellmassen, dichten Fruchtmassen sowie f├╝r die Herstellung von Pektin oder hitzestabilen F├╝llungen mit hoher Produktivit├żt eingesetzt werden.

- Hohe Leistung

- Rotationsspr├╝hsystem mit einem leistungsstarken elektrischen Antrieb

- Verdampfung in einer d├╝nnen Schicht mit einer gro├¤en W├żrme├╝bertragungsfl├żche

- Niedrige Investitions- und Installationskosten

- Tangentialer Eingang f├╝r Produktverwirbelung

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Spannung: 380-400V

Der atmosph├żrische Tank mit geneigter Bauweise dient zum Mischen, R├╝hren und L├Čsen verschiedener Produkte. Durch die Zufuhr eines W├żrmetr├żgers zum Mantel (Duplikator) der Einheit von einer externen Quelle kann eine thermische Verarbeitung wie Heizen oder K├╝hlen erfolgen (z. B. Heizen oder K├╝hlen durch eine externe K├╝hlmittelquelle mit einem Eingangsdruck von bis zu 0,5 bar). Diese Einheiten werden h├żufig in der Lebensmittel und Kosmetikindustrie eingesetzt.

- Geneigte Bauweise: 50 % effizienteres Mischen

- Durch den Neigungswinkel des Arbeitstanks wird eine schnelle und vollst├żndige (100 %) Entleerung erreicht.

- Effiziente W├żrme├╝bertragung durch den Heiz/K├╝hlmantel

- Keine Totzonen beim Mischen!

- Modulares System mit zahlreichen Zusatzoptionen

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Ger├żtetyp: Einzelmaschine

- Herkunftsland: Slowakei

- Arbeitsvolumen: 100l/ 200l/ 300l/ 450 600l/ 900l

Vertikale Rohrb├╝ndelw├żrmetauscher sind f├╝r das Erhitzen und K├╝hlen von z├żhfl├╝ssigen/past├Čsen Produkten wie Saucen, Mayonnaise, Sahne, Joghurt, Marmelade, Karamell, Babynahrung, Honig usw. konzipiert.

- Material: Edelstahl

- Funktionsprinzip: Kontinuierlicher Betrieb

- Herkunftsland: Slowakei

Rohrb├╝ndelw├żrmetauscher oder Plattenw├żrmetauscher sind f├╝r das Erhitzen und K├╝hlen von z├żhfl├╝ssigen/past├Čsen Produkten wie So├¤en, Mayonnaise, Sahne, Joghurt, Marmelade, Karamell, Babynahrung, Honig usw. konzipiert. Rohrb├╝ndelw├żrmetauscher geh├Čren aufgrund ihrer robusten Bauweise und einer Vielzahl von Optionen zur Anpassung an unterschiedliche Betriebsbedingungen zu den am h├żufigsten verwendeten Ger├żten.

- Material: Edelstahl

- Funktionsprinzip: Kontinuierlicher Betrieb

- Herkunftsland: Slowakei

Der ACM-Mischtank ist f├╝r die effiziente K├╝hlung, Erw├żrmung, Temperierung und Lagerung von Mayonnaise, Sauerrahm, Schokolade, ├¢l und ├żhnlichen Produkten nach deren Herstellung bestimmt.

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

Die Abf├╝llmaschine ist f├╝r das Pumpen und Abf├╝llen von Fl├╝ssigkeiten mit hoher Viskosit├żt, wie Marmelade, Konfit├╝re, So├¤en, Dressings, Sirup und ├żhnliche Produkte, konzipiert.

- Produktivit├żt: 200ŌĆō600 bottles per hour

- Material: Edelstahl

- Funktionsprinzip: Kontinuierlicher Betrieb

Ein Vakuumkocher wird in der lebensmittelverarbeitenden Industrie zum Garen von Zutaten unter vermindertem Druck, in der Regel in einer Vakuumumgebung, verwendet. Diese Methode erm├Čglicht eine pr├żzise Temperaturkontrolle und k├╝rzere Garzeiten, wobei die Qualit├żt und der Geschmack der Zutaten erhalten bleiben.

Wir bieten verschiedene Vakuumkocher an.

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 2500 l

Ein Vakuumgarer ist ein vielseitiges Ger├żt, das in der K├╝che zum Garen von Lebensmitteln unter Vakuumbedingungen verwendet wird, um Geschmack und Textur zu verbessern und gleichzeitig die Garzeit zu verk├╝rzen.

Wir bieten verschiedene Herdarten an.

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 100l

- Spannung: 380-400V

Der Doppelschneckenextruder ist zum effektiven Extrudieren, Homogenisieren, Umpumpen von plastischen Massen (Butter, Margarine, Honig, Quarkprodukte, S├╝├¤warenmischungen) und zum Formen von Stangen und Rollen bestimmt.

- Produktivit├żt: 400 kg/h

- Material: Edelstahl

- Funktionsprinzip: Kontinuierlicher Betrieb

- Herkunftsland: Slowakei

- Gewicht: 115 kg

F├╝r einen Kostenvoranschlag senden Sie uns bitte eine Anfrage.

- Heizung: Elektrizit├żt

- Material: Edelstahl

- Heizleistung, kW: 30

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 200l

- Dimensions, mm: 2055x1800x1980

Er ist ideal zum Kochen von Konfit├╝ren, Marmeladen, Sirup, So├¤en, Cremes und anderen Produkten.

Der Preis h├żngt von der gew├żhlten Option ab.

- Heizung: Elektrizit├żt

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Volumen: 300l

- Geometric volume: 350 l

Die Atmosph├żrische Verdampfungspfanne konzentriert Fl├╝ssigkeiten effizient, indem sie sie auf einer gro├¤en Oberfl├żche verdampft, und eignet sich gleichzeitig f├╝r verschiedene Garmethoden wie Schmoren, Kochen und Braten.

- Heizung: Elektrizit├żt

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

Ein Verdampfer-Konzentrator-Kristallisator ist ein multifunktionales Ger├żt, das Fl├╝ssigkeiten durch Verdampfen von Wasser und Auskristallisieren konzentriert, um konzentrierte L├Čsungen oder kristalline Produkte herzustellen.

- Material: Edelstahl

- Arbeitsvolumen: up to 6000 L

- Geometric volume: 6500 l

Eine Verdampfungsanlage wird eingesetzt, um s├╝├¤en Substanzen durch Erhitzen die Feuchtigkeit zu entziehen und sie in konzentrierte Sirupe oder L├Čsungen zu verwandeln.

- Material: Edelstahl

- Heizleistung, kW: 30

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Spannung: 380-400V

- Geometric volume: 200 l

Diese halbautomatische Abf├╝llmaschine wird f├╝r die Abf├╝llung von Honig und anderen Produkten verwendet. Wir bieten viele verschiedene Arten von Abf├╝llmaschinen f├╝r unterschiedliche Anwendungen an.

- Material: Edelstahl

- Betriebsmodus: Halbautomatisch

Ein Kochkessel mit Vakuummischer f├╝r die periodische Entl├╝ftung von Produkten wie Mayonnaise, Ketchup, verschiedenen Saucen, Cremes, Gelen und Pasten. Er ist eine Variante eines Vakuumreaktors und eines Vakuumverdampfers. Das Vakuumsystem erm├Čglicht die Erzeugung eines Vakuums nach dem Kochvorgang und die anschlie├¤ende Entl├╝ftung (Vakuumierung), um Luftblasen mit potenziellen Verunreinigungen zu entfernen und ein Produkt mit dichterer Struktur zu erhalten. Durch das Vakuumieren ist das Produkt l├żnger haltbar, da enthaltene Krankheitserreger und Mikroben zusammen mit der Luft entfernt werden.

- Geneigte Konstruktion mit Schwerkraftmischung, die 30 % effizienter ist als herk├Čmmliche L├Čsungen.

- 100 %ige Entleerung des Produkts nach der Verarbeitung dank Bodenventil.

- Leicht demontierbares, abnehmbares Mischger├żt.

- Anschlussm├Čglichkeit an eine CIP-Station zur Reinigung und Reinigung.

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Volumen: 100l

- Gesamtleistung, kW: 0,12

- Maximaler Vakuum: -0,8 Bar