SIRUP

Der Vakuumverdampfer mit externem UmlaufwÃĪrmetauscher zÃĪhlt zu den effizientesten Verdampfungssystemen. Er eignet sich zum Einkochen hitzeempfindlicher Produkte wie Milch, Sahne usw.

- Kein Mischer erforderlich, das Produkt wird zwangsumgewÃĪlzt!

- Modulares System: AuswahlmÃķglichkeit von Vakuumerzeuger, Leistung und WÃĪrmetauschertyp

- SchrÃĪgbauweise und Bodenventil fÞr 100 % Produktaustrag ohne Verluste und tote Winkel

- Isolierte obere GerÃĪteklappe fÞr WÃĪrmespeicherung und Sicherheit

- Tangentialer Produkteinlass in den VakuumbehÃĪlter fÞr garantierte Verdampfung in einer dÞnnen Schicht

- Material: Edelstahl

- Volumen: 50l/ 100l/ 300l

Professioneller Kochkessel mit RÞhrer fÞr besonders dicke und viskose Produkte. Eine hervorragende technische LÃķsung fÞr die Herstellung von Karamell, Sirup und Zuckerpaste zum Zuckern. Die Heizquelle wird separat ausgewÃĪhlt.

- Der Kessel kann auf allen Arten von KochflÃĪchen verwendet werden, einschlieÃlich Induktion

- Die Basisversion verfÞgt Þber leicht abnehmbare, selbstausrichtende Edelstahlschaber

- Hohes Drehmoment des RÞhrers mit 14-18 Umdrehungen pro Minute

- Professioneller 3-Phasen-Industriemotor

- Der RÞhrer wird mithilfe einer Fernbedienung mit IP66-Schutz selbststÃĪndig eingeschaltet und Þber Schnellverbinder mit dem Kessel verbunden

- Das GerÃĪt kann auch mit einem 3-Phasen-Motor an ein 220-230-Volt-Netz angeschlossen werden!

- Material: Edelstahl

- Motorleistung, kW: 0,25/ 0,37

- Volumen: 20l/ 50l/ 100l/ 150l

- Spannung: 220-230V

- Diameter, mm: 400/ 500/ 600

Der Pasteurisierungskessel mit manueller Kippfunktion ist ein modernes GerÃĪt fÞr die schonende WÃĪrmebehandlung von Milch und Milchprodukten. Er ermÃķglicht eine effektive Pasteurisierung, verlÃĪngert die Haltbarkeit und erhÃķht die Sicherheit, wÃĪhrend der ursprÞngliche Geschmack und die NÃĪhrwerte erhalten bleiben. Dank der 6-stufigen Heizregelung des leistungsstarken integrierten Heizers kann Milch zuverlÃĪssig direkt in einem BehÃĪlter mit Sandwichboden pasteurisiert werden, der eine gleichmÃĪÃige WÃĪrmeverteilung gewÃĪhrleistet.

- Ideale LÃķsung fÞr die Klein und Heimproduktion von Milchprodukten

- Abnehmbarer Deckel fÞr einfache Inspektion und manuelles Mischen des Produkts

- Optional mit Ablassventil zum Entleeren flÞssiger Produkte erhÃĪltlich.

- GleichmÃĪÃiges Erhitzen ohne Anbrennen dank Sandwichboden

- Einfacher Anschluss an ein einphasiges 230-V-Netz

- Material: Edelstahl

- Heizleistung, kW: 2,6 / 6,5

- Volumen: 30l/ 50l/ 100l

- Spannung: 380-400V

Der Preis ist fÞr die Basisversion des Vakuumreaktors ohne zusÃĪtzliche Optionen angegeben, der endgÞltige Preis hÃĪngt von den Modifikationen ab

Der Vakuumhomogenisator ist eine ideale LÃķsung fÞr die Herstellung von Lebensmitteln, z. B. Mayonnaise, er eignet sich auch fÞr die Kosmetikindustrie - die Herstellung von Zahnpasta. Dieses Modell des Homogenisators basiert auf einem Vakuumreaktor mit externem Homogenisator und einem externen Zirkulationskreislauf, dessen Parameter optional gewÃĪhlt werden kÃķnnen.

- Gekipptes Design - 25% effizienteres Mischen

- Leicht zerlegbarer Mischer mit verstÃĪrktem Rahmen, fÞr dicke und zÃĪhflÞssige Produkte

- Mantel fÞr das KÞhlmittel um den Boden und die WÃĪnde des Arbeitsreaktors

- Der Vakuumreaktor kann einem Vakuum von bis zu -0,8 Bar standhalten.

- Eine groÃe Anzahl von Optionen fÞr unterschiedliche Anforderungen

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 300l/ 650l

- Gesamtleistung, kW: 0,55

- Spannung: 380-400V

- Maximaler Vakuum: -0,8 Bar

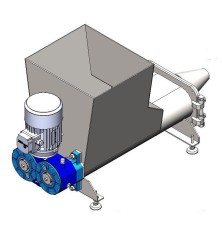

Dieser LÃķsungsbehÃĪlter mit 800 Litern FassungsvermÃķgen und UmwÃĪlzpumpe dient der Herstellung flÞssiger LÃķsungen durch direktes AuflÃķsen von Substanzen in Wasser oder anderen ArbeitsflÞssigkeiten. Er wird in der Lebensmittel und GetrÃĪnkeindustrie eingesetzt, um durch hydrodynamische Mischung in einem Zwangskreislauf eine gleichmÃĪÃige AuflÃķsung zu gewÃĪhrleisten.

Die UmwÃĪlzung mit einer lebensmittelgeeigneten Pumpe sorgt fÞr eine schnelle und gleichmÃĪÃige AuflÃķsung ohne Sedimentation oder die Bildung von Stagnationszonen. Der ArbeitsbehÃĪlter ist auf einer mobilen Plattform mit RÃĪdern montiert und ermÃķglicht so einen einfachen und schnellen Transport zwischen verschiedenen Produktionsbereichen.

- Schnelle und gleichmÃĪÃige AuflÃķsung ohne Sedimentation dank hydrodynamischer Mischung

- Zwangskreislauf mit Produktpumpe/Inline-Homogenisator (optional)

- Mobile Edelstahlplattform auf RÃĪdern

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Geometric volume: 800 l

Das Modell VMG S ist ein effektives und zuverlÃĪssiges VakuumhomogenisiergerÃĪt, das fÞr die Herstellung einer breiten Palette von flÞssigen, pastÃķsen und viskosen Produkten mit unterschiedlichen Anforderungen an die Produktionsbedingungen entwickelt wurde.

Der DruckbehÃĪlter 300 BIN ist eine mobile Edelstahleinheit zum Transfer von flÞssigen und halbfesten Produkten durch kontrollierten Innendruck. Er dient auch als mobiler BehÃĪlter fÞr den Transport von Chargen innerhalb der Produktionsanlage. Er eignet sich fÞr hygienische Lebensmittelverarbeitungsumgebungen, in denen Pumpen nicht mÃķglich oder praktikabel sind.

- Ausgelegt fÞr BetriebsdrÞcke bis zu 0,5 bar, ermÃķglicht er den vertikalen Transfer von FlÞssigkeiten ohne Pumpe.

- Sechs handfest angezogene Deckelschrauben gewÃĪhrleisten eine sichere Abdichtung im Druck und Vakuumbetrieb.

- Dank der Rollen lÃĪsst er sich leicht im Produktionsbereich bewegen.

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 300l

Universeller Kochkessel mit eingebautem RÞhrwerk, zum RÞhren und Kochen von Lebensmitteln aller Art, kosmetischen Emulsionen, Cremes, Zuckerpasten und vielem mehr.

- Leicht abnehmbare, selbsteinstellende Abstreifer

- DeckelÃķffnungssensor fÞr sichere RÞhrwerkswartung

- Hygienischer Temperatursensor fÞr das Produkt

- Auslassventil mit groÃem Durchmesser

- Sicherer Dampfaustritt an der Oberseite des Kesseldeckels

- Material: Edelstahl

- Motorleistung, kW: 0,25

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 50l/ 100l/ 150l

- Spannung: 220-230V

- Auslassventil, Zoll: 6/4

- Diameter, mm: 400/ 500/ 600

Edelstahl Marmelade Kochtopf mit RÞhrwerk 50l und Elektroherd 5kW, ideal und erschwinglich Kochen LÃķsung.

- Heizung: ElektrizitÃĪt

- Material: Edelstahl

- Motorleistung, kW: 0,18/

- Heizleistung, kW: 5

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 50l

- Spannung: 220-230V

- Auslassventil, Zoll: 6/4

- Diameter, mm: 400/ 500/ 600

Der Preis wird mit einem halbautomatischen Bedienfeld angezeigt

Der Vakuumkessel ist fÞr den Einsatz in der Gemeinschaftsverpflegung (Restaurants, Hotels, Catering-Unternehmen) und in kleinen Produktionsbetrieben bestimmt. Dieses GerÃĪt ermÃķglicht das Kochen, Blanchieren, Braten, Verdampfen, Pasteurisieren, Mischen oder RÞhren.

- Ein einzigartiges MultifunktionsgerÃĪt

- MÃķglichkeit, unter atmosphÃĪrischen oder Vakuumbedingungen zu kochen/braten

- Laborversion einer Vakuumfritteuse

- Eingebautes Kondensations- und sekundÃĪres Dampfabfuhrsystem

- Intensive elektrische Heizung

- Sektionaler Korb mit Deckel

- Eingebautes System zur Abtrennung und Entfernung ÞberschÞssiger FlÞssigkeit aus dem Produkt

- Heizung: ElektrizitÃĪt

- Material: Edelstahl

- Heizleistung, kW: 5

- Volumen: 20l

- Ãlvolumen : 8l

- Spannung: 380-400V

- Maximaler Vakuum: -0,8 Bar

Der Preis ist ohne das Bedienfeld angegeben, das separat ausgewÃĪhlt und angeboten werden kann

Ein vielseitiges Kochsystem mit einem geneigten Reaktor und einer Rahmenmischvorrichtung ist fÞr die Verarbeitung einer breiten Palette von Produkten durch Methoden wie Kochen, Sieden und Konzentrieren bei atmosphÃĪrischem Druck konzipiert. Dieses System wird hÃĪufig fÞr die Herstellung von Sirup, Marmelade, KonfitÞre und Honigverarbeitung verwendet.

- SchrÃĪges Design mit Schwerkraftmischung - 25% effizienter!

- ÃuÃeres dekoratives GehÃĪuse aus poliertem Edelstahl mit Isolierung

- Mantel fÞr den Boden und die WÃĪnde des ArbeitsbehÃĪlters Þber die gesamte HÃķhe

- Sensor zum Ãffnen des Deckels fÞr sicheren Betrieb

- Scraper sind bereits in der Basisversion der Installation enthalten

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 100l/ 300l/ 430l/ 600l/ 1000l

- Spannung: 220-230V 380-400V

Der Preis ist ohne Druckluftquelle - Kompressor (optional) - angegeben.

Dies ist ein periodisches GerÃĪt, das dazu bestimmt ist, Feuchtigkeit und ÞberschÞssiges Wasser unter Vakuumbedingungen aus Honig zu entfernen. Dieser Pilot-Vakuumtrockner kann zur Verarbeitung kleiner Mengen Honig direkt in BienenstÃķcken verwendet werden.

- Trocknungsrate bis zu 1 % pro Stunde! (mit allmÃĪhlicher Abnahme bei zunehmender Konzentration)

- GroÃe WÃĪrmeÞbertragungsflÃĪche

- Niedrige Trocknungstemperatur dank des Vakuums

- Einfache Bedienung und Wartung

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 100 - 140 kg

- Gesamtleistung, kW: 6,5

- Spannung: 220-230V 380-400V

- Maximaler Vakuum: -0,8 Bar

FlÞgelzellenpumpen werden zum Pumpen von Produkten mit hoher ViskositÃĪt wie Sirup, Honig, Mayonnaise, SoÃen, Sahne und vielen anderen Produkten verwendet.

- Material: Edelstahl

- Motorleistung, kW: 2,2

- Type of pump: rotary vane

Kompakte Vakuumverdampfungsmaschine mit externem ZirkulationswÃĪrmetauscher fÞr die Herstellung von Testchargen von Produkten, die Entwicklung neuer Rezepte und technologischer PlÃĪne.

- Kompakter Einbau

- Kann alle Verarbeitungstechniken nachbilden, die in industriellen Vakuumverdampfungseinheiten mit Zirkulation verwendet werden

- Bewahrt den natÞrlichen Geschmack, das Aroma und die Farbe des Produkts

- Kann zur Herstellung kleiner Produktchargen verwendet werden

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- GerÃĪtetyp: Einzelmaschine

- Herkunftsland: Slowakei

- Volumen: 20l

Der Preis ist fÞr die Version mit hydraulischem Hub angegeben.

Die industrielle elektrische Bratpfanne mit ThermoÃķl ist eine optimale und wirtschaftliche LÃķsung fÞr die industrielle Lebensmittelproduktion in kleinem MaÃstab. Sie ermÃķglicht niedrige Energie- und Betriebskosten und gewÃĪhrleistet eine gleichmÃĪÃige und intensive ErwÃĪrmung der gesamten Arbeitsschale. Die thermische TrÃĪgheit des Systems trÃĪgt dazu bei, die erforderliche Temperatur Þber einen lÃĪngeren Zeitraum aufrechtzuerhalten, so dass sie sich gut zum Braten von Zwiebeln, Karotten, zum Anbraten von Mehl und GemÞse sowie zur Zubereitung von SoÃen, Suppen, Beilagen, EintÃķpfen und vielem mehr eignet.

- Niedriger Energieverbrauch

- GleichmÃĪÃige ErwÃĪrmung

- Beheizte konische Seiten

- Einstellbare HeizintensitÃĪt

- Controller mit hygienischem GehÃĪuse direkt an der Tragkonstruktion

- Griffe zum Ãffnen des Deckels in der kalten Zone

- Automatisches Hebe- und Kippsystem

- Heizung: ElektrizitÃĪt

- Material: Edelstahl

- Heizleistung, kW: 26

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 300l

- Gesamtleistung, kW: 28

- Spannung: 380-400V

- Duplikatorvolumen: 106l

Der angegebene Preis gilt fÞr die Standardversion der Vakuumverdampferanlage mit grundlegender Steuerung (An/Aus-Schalter fÞr Mischermotor) und ohne zusÃĪtzliche Optionen. Die Steuerungseinheit wird individuell an die Kundenanforderungen angepasst. Auch die Produktpumpe wird je nach Produktart separat ausgewÃĪhlt.

Eine kompakte Vakuumverdampfungsanlage, mit der Sie LÃķsungen, Gemische und verschiedene Produkte durch Verdampfen des LÃķsungsmittels konzentrieren kÃķnnen. Eine modulare Version, die auf dem BasisgerÃĪt 110/100 Vakuumreaktor.

- Schwerkraftmischen â 25 % effizienter

- VerstÃĪrktes RÞhrwerkdesign ohne tote Winkel

- Unteres Kugelventil ohne tote Zonen

- Kondensations- und sekundÃĪres Dampfentfernungssystem

- Einfach zu zerlegendes MischgerÃĪt

- GroÃe WÃĪrmeaustauschflÃĪche

- MÃķglichkeit zur Messung und Ãberwachung des Kondensatvolumens (optional)

- Material: Edelstahl

- Motorleistung, kW: 0,25

- Funktionsprinzip: Kontinuierlicher Betrieb

- Herkunftsland: Slowakei

- Volumen: 100l

- Spannung: 220-230V

- Maximaler Vakuum: -0,8 Bar

- Arbeitsvolumen: 50-80l

- KondensationskapazitÃĪt, l/h: 45-55

- Dampfverbrauch, kg/h: bis zu 150

Die Schraubenspindelpumpe wird zum FÃķrdern von "nicht pumpfÃĪhigen" Produkten verwendet. Eine gute Wahl fÞr alle, die mit schwer zu bewegenden FlÞssigkeiten arbeiten und diese so schnell wie mÃķglich bewegen mÞssen.

- Material: Edelstahl

- Spannung: 380-400V

Die elektrische Industrie-WOK-Bratpfanne mit RÞhrer und automatischem Kippsystem eignet sich fÞr intensive WÃĪrmebehandlungen und ermÃķglicht das Schmoren, Braten, Kochen und Konzentrieren groÃer Mengen fester und flÞssiger Produkte.

- Spezielles exzentrisches Kippsystem der ArbeitsschÞssel bis zu 90 Grad

- Niedrige ArbeitshÃķhe fÞr Beladung und Bedienung

- Hydraulisches System zum Kippen und Entladen des Produkts

- Direkte, leistungsstarke elektrische Heizung des Bodens der ArbeitsschÞssel bis zu 220 Grad

- Beheizte WÃĪnde der ArbeitsschÞssel (optional)

- Entladen des Produkts in Standard-200-Liter-Wagen (optional)

- Heizung: ElektrizitÃĪt

- Material: Edelstahl

- Heizleistung, kW: 70+12

- Funktionsprinzip: Chargenbetrieb

- Volumen: 450

- Spannung: 380-400V

Kochkessel zur Herstellung von Sirup, Karamell, Zuckermasse sowie zur Verarbeitung und Herstellung verschiedener dickflÞssiger Produkte. Wird hÃĪufig zum AuflÃķsen von Zucker und zur Herstellung verschiedener gesÃĪttigter und ÞbersÃĪttigter LÃķsungen verwendet.

- Eingebaute Heizung mit ThermoÃķl bis zu 150 Grad Celsius

- AnkerrahmenrÞhrer fÞr schnelles AuflÃķsen

- Konische Bodengestaltung des ArbeitsbehÃĪlters ohne Totzonen

- Heizung: ElektrizitÃĪt

- Material: Edelstahl

- Herkunftsland: Slowakei

- Volumen: 200l/ 300l

- Gesamtleistung, kW: 19

Ein modernes Koch- und MischgerÃĪt mit einem breiten Anwendungsspektrum in Konditoreien, BÃĪckereien, Gastronomiebetrieben.

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Volumen: 200l/ 300l/ 500l

Die tragbare Vertikalpumpe ist fÞr das Pumpen von flÞssigen oder viskosen FlÞssigkeiten im Bereich von 1-2300 m2/s bei einer Temperatur von ca. 25°C ausgelegt. Die Pumpe kann nicht in explosionsgefÃĪhrdeten Bereichen eingesetzt werden.

- Material: Edelstahl

- Motorleistung, kW: 0,25

- Spannung: 380-400V

Ein Vakuumdestillationssystem dient der kontrollierten Trennung von FlÞssigkeiten durch Verdampfung der FlÞssigkeit und anschlieÃende Kondensation ihrer DÃĪmpfe.

- Material: Edelstahl

- Herkunftsland: Slowakei

- Volumen: 5l

Das FÃķrderband fÞr den Transport von leeren und gefÞllten Flaschen und GlÃĪsern. Weit verbreitet in Verpackungslinien fÞr verschiedene FlÞssigkeiten.

- Material: Edelstahl

- Motorleistung, kW: 0,25

- Funktionsprinzip: Kontinuierlicher Betrieb

- Herkunftsland: EU

Kompakte digitale AbfÞllmaschine fÞr die prÃĪzise Dosierung viskoser FlÞssigkeiten wie Honig, Pasten, SoÃen und Ãle. Dank lebensmittelechter Materialien, leicht zu reinigender Komponenten und prÃĪziser digitaler Steuerung ist sie ideal fÞr kleine Produktionsbetriebe, WerkstÃĪtten und Labore.

- Betriebsmodus: Halbautomatisch

Ein Vakuumumlaufverdampfer ist in der Regel eine kombinierte Version eines Verdampfers, der auch die Vorteile anderer Verdampferarten nutzt, um die Verdampfungseffizienz zu verbessern, insbesondere durch die VerkÞrzung der Konzentrationszeit und bei der Verarbeitung hitzeempfindlicher Produkte wie Milch.

- Der externe Zirkulationskreislauf mit Heizung intensiviert den zyklischen Verdampfungsprozess.

- Das System der ZwangsumwÃĪlzung sorgt dafÞr, dass das Risiko einer lokalen Ãberhitzung des Produkts verringert wird.

- Der Kondensator ermÃķglicht ein tiefes Vakuum und sorgt fÞr eine niedrige Verdampfungstemperatur.

- Die Verwendung einer Mischvorrichtung mit einem SprÞhsystem erleichtert die Produktverdampfung in einer dÞnnen Schicht, die einen Filmverdampfer imitiert.

- Heizung: Dampf

- Material: Edelstahl

- Betriebsmodus: Halbautomatisch

- Herkunftsland: Slowakei

- Gesamtleistung, kW: 2,4

- Spannung: 380-400V

Die Vakuumeindampfanlage ist speziell fÞr die Eindickung von dichten Lebensmitteln in industriellen Mengen konzipiert. Der Verdampfer kann fÞr die Herstellung von dicken Sirupen, Karamellmassen, dichten Fruchtmassen sowie fÞr die Herstellung von Pektin oder hitzestabilen FÞllungen mit hoher ProduktivitÃĪt eingesetzt werden.

- Hohe Leistung

- RotationssprÞhsystem mit einem leistungsstarken elektrischen Antrieb

- Verdampfung in einer dÞnnen Schicht mit einer groÃen WÃĪrmeÞbertragungsflÃĪche

- Niedrige Investitions- und Installationskosten

- Tangentialer Eingang fÞr Produktverwirbelung

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Spannung: 380-400V

Der atmosphÃĪrische Tank mit geneigter Bauweise dient zum Mischen, RÞhren und LÃķsen verschiedener Produkte. Durch die Zufuhr eines WÃĪrmetrÃĪgers zum Mantel (Duplikator) der Einheit von einer externen Quelle kann eine thermische Verarbeitung wie Heizen oder KÞhlen erfolgen (z. B. Heizen oder KÞhlen durch eine externe KÞhlmittelquelle mit einem Eingangsdruck von bis zu 0,5 bar). Diese Einheiten werden hÃĪufig in der Lebensmittel und Kosmetikindustrie eingesetzt.

- Geneigte Bauweise: 50 % effizienteres Mischen

- Durch den Neigungswinkel des Arbeitstanks wird eine schnelle und vollstÃĪndige (100 %) Entleerung erreicht.

- Effiziente WÃĪrmeÞbertragung durch den Heiz/KÞhlmantel

- Keine Totzonen beim Mischen!

- Modulares System mit zahlreichen Zusatzoptionen

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- GerÃĪtetyp: Einzelmaschine

- Herkunftsland: Slowakei

- Arbeitsvolumen: 100l/ 200l/ 300l/ 450 600l/ 900l

Analoge Refraktometer bieten eine effiziente, genaue und einfach zu verwendende LÃķsung zur Messung des Brix-Werts und zur Sicherstellung der ProduktqualitÃĪt in der Lebensmittelindustrie.

- GerÃĪtetyp: Optionale Ausstattung

Der KÞhltank ist fÞr die Lagerung von Milch und anderen GetrÃĪnken vorgesehen.

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: EU

Vertikale RohrbÞndelwÃĪrmetauscher sind fÞr das Erhitzen und KÞhlen von zÃĪhflÞssigen/pastÃķsen Produkten wie Saucen, Mayonnaise, Sahne, Joghurt, Marmelade, Karamell, Babynahrung, Honig usw. konzipiert.

- Material: Edelstahl

- Funktionsprinzip: Kontinuierlicher Betrieb

- Herkunftsland: Slowakei

RohrbÞndelwÃĪrmetauscher oder PlattenwÃĪrmetauscher sind fÞr das Erhitzen und KÞhlen von zÃĪhflÞssigen/pastÃķsen Produkten wie SoÃen, Mayonnaise, Sahne, Joghurt, Marmelade, Karamell, Babynahrung, Honig usw. konzipiert. RohrbÞndelwÃĪrmetauscher gehÃķren aufgrund ihrer robusten Bauweise und einer Vielzahl von Optionen zur Anpassung an unterschiedliche Betriebsbedingungen zu den am hÃĪufigsten verwendeten GerÃĪten.

- Material: Edelstahl

- Funktionsprinzip: Kontinuierlicher Betrieb

- Herkunftsland: Slowakei

Die tensometrische AbfÞllmaschine Normit AP ist ein gewichtsbasiertes System zur AbfÞllung von Honig in FÃĪsser.

- Material: Edelstahl

- Herkunftsland: Slowakei

Die Drehkolbenpumpen sind fÞr das Pumpen von flÞssigen und dickflÞssigen Produkten ausgelegt. Wir bieten Drehkolbenpumpen in 2 Versionen an: 1,5 kW ist der Standard fÞr Milch, Sahne und ÃĪhnliche Produkte, und 3 kW ist fÞr dichte Produkte mit geringem Durchfluss wie Honig, Pasten, HÞttenkÃĪse usw.

- Motorleistung, kW: 1,5 / 3

Der ACM-Mischtank ist fÞr die effiziente KÞhlung, ErwÃĪrmung, Temperierung und Lagerung von Mayonnaise, Sauerrahm, Schokolade, Ãl und ÃĪhnlichen Produkten nach deren Herstellung bestimmt.

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

Wir bieten eine breite Palette von Catering-AusrÞstung fÞr Restaurants, Kantinen und alle Arten von Lebensmitteln servieren Einrichtungen. Der Preis hÃĪngt von der gewÃĪhlten Option ab.

- Heizung: Dampf Gas

- ProduktivitÃĪt: 300 Ðŧ 600 Ðŧ. 1000 Ðŧ.

- Betriebsmodus: Automatisch

- GerÃĪtetyp: Einzelmaschine

Das GerÃĪt ist fÞr die Pasteurisierung einer breiten Palette von Produkten in verschiedenen Verpackungsmaterialien wie Dosen und GlÃĪsern konzipiert.

- Heizung: Gemischt

- ProduktivitÃĪt: 300 Ðŧ 400 Ðŧ 500 l

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- GerÃĪtetyp: Einzelmaschine

Dieses Anlagenmodell ist ein universelles System zur Herstellung von Extrakten aus Produkten wie Johannisbrot und deren Vakuumverdampfung zu einem dickflÞssigen Sirup im sequentiellen Zirkulationsprozess.

- Ein System fÞr alle sequentiellen technologischen Prozesse der Pekmez-Herstellung: vom Einweichen und der Extraktgewinnung Þber das AbkÞhlen der fertigen Mischung bis hin zur Vakuumverdampfung.

- Durch das Vakuumverdampfen bleiben alle im Extrakt enthaltenen wertvollen Inhaltsstoffe erhalten: Vitamine der Gruppen A, B und E sowie Spurenelemente wie Kalzium, Kalium, Magnesium, Eisen und Zink.

- Hocheffizienter Siedeprozess dank eines speziellen Direktdurchlauf-Heizsystems in der Vakuumverdampfungsanlage.

- Heizung: ElektrizitÃĪt

- Material: Edelstahl

- Heizleistung, kW: 36

- Volumen: 100l

- KondensationskapazitÃĪt, l/h: 45-55

Industrielle Vakuumtrockner entfernen Feuchtigkeit aus empfindlichen oder hitzeempfindlichen Lebensmitteln, Chemikalien oder Pharmaprodukten unter reduziertem Druck. Dies ermÃķglicht niedrigere Trocknungstemperaturen, minimiert den thermischen Abbau und verbessert die Energieeffizienz. Vakuumtrockner dieser Art werden in verschiedenen Branchen eingesetzt â der Lebensmittel, Chemie und Pharmaindustrie und weiteren.

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- GerÃĪtetyp: Einzelmaschine

- Herkunftsland: Slowakei

Der Preis ist fÞr die Basisversion des Reaktors ohne zusÃĪtzliche Optionen und das Bedienfeld festgelegt

Der Vakuumkessel mit einem KÞhlmittelverdoppler und einer Mischvorrichtung ist eine universelle LÃķsung fÞr die Verarbeitung verschiedener Produkte bei Unterdruck. Auf der Grundlage dieses einfachen GerÃĪts kÃķnnen Sie es zu komplexen Anlagen wie einem Vakuumverdampfer, einem Vakuum-Kochkessel und einer Anlage zur Herstellung von Cremehonig auswÃĪhlen und modulieren.

- SchrÃĪges Design - Schwerkraftmischen

- Bodenventil DN40 in der Basisversion enthalten

- VervielfÃĪltigungsgerÃĪt fÞr kleine Mengen - niedrige Kosten fÞr die Heizung/KÞhlung des KÞhlmittels

- Modulares System: Individuelle Anpassung der AusrÞstung und ihrer Funktionen durch die Bestellung zusÃĪtzlicher Optionen

- Eine leicht zu demontierende Mischvorrichtung

- Material: Edelstahl

- Motorleistung, kW: 0,25

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 100l

- Spannung: 380-400V

- Maximaler Vakuum: -0,8 Bar

Die Konzentrierungs- und Eindickungslinie wurde speziell fÞr industrielle Molkereibetriebe mit einem geringen MilchÞberschuss oder kleinere milchverarbeitende Betriebe, die ihre Produktpalette erweitern wollen, konzipiert. Sie hat eine geschÃĪtzte ProduktivitÃĪt von bis zu 50-120 kg/Stunde im Dauerbetrieb.

- Professionelle Industrietechnik mit kompakten Abmessungen

- Eine Vielzahl von Zusatzausstattungen und Optionen zur Auswahl

- Material: Edelstahl

- Funktionsprinzip: Kontinuierlicher Betrieb

Unsere hydrodynamische Extraktionsanlage ist fÞr die Extraktion verschiedener Komponenten aus Pflanzenmaterialien konzipiert, darunter biologisch aktive Substanzen, Proteine, Fette, Kohlenhydrate, Antioxidantien, Farbstoffe und Aromen.

- Effektive "weiche" kontinuierliche hydrodynamische Extraktion - Perkolation aus fein zerkleinerten Rohstoffen.

- Extraktion ohne Vortrocknung des Produkts, was zu Einsparungen bei Arbeits- und Energiekosten fÞhrt.

- Verwendung von Rohstoffen ohne WÃĪrmebehandlung, wodurch alle wertvollen Inhaltsstoffe und Enzyme erhalten bleiben.

- MÃķglichkeit zur DurchfÞhrung einer Vakuum-Impulsextraktion (optional).

- ZusÃĪtzliche Einnahmen aus der Verarbeitung von "Abfallprodukten" - Gewinnung wertvoller Bestandteile aus Zellstoff und Trester.

- Material: Edelstahl

- Funktionsprinzip: Kontinuierlicher Betrieb

- Herkunftsland: Slowakei

Der RÃķhrenpasteur ist in der Regel fÞr die Pasteurisierung von Rahm in Butterproduktionslinien vorgesehen. Diese Pasteure werden hÃĪufig in milchverarbeitenden Industrieanlagen eingesetzt, insbesondere in der Butterproduktion und anderen verwandten Bereichen.

- Material: Edelstahl

- Funktionsprinzip: Kontinuierlicher Betrieb

- Herkunftsland: Slowakei

Die AbfÞllmaschine ist fÞr das Pumpen und AbfÞllen von FlÞssigkeiten mit hoher ViskositÃĪt, wie Marmelade, KonfitÞre, SoÃen, Dressings, Sirup und ÃĪhnliche Produkte, konzipiert.

- ProduktivitÃĪt: 200â600 bottles per hour

- Material: Edelstahl

- Funktionsprinzip: Kontinuierlicher Betrieb

Ein vielseitiger atmosphÃĪrischer Wasserkocher, der sich zum Kochen verschiedener Produkte eignet, darunter Marmeladen, Sirup, SoÃen, Obst- und GemÞsesÃĪfte und vieles mehr.

- Material: Edelstahl

- Herkunftsland: Slowakei

- Volumen: 250l/ 300l

- ProduktivitÃĪt: 800 psc/h

- Material: Edelstahl

- Betriebsmodus: Halbautomatisch

Ein Vakuumkocher wird in der lebensmittelverarbeitenden Industrie zum Garen von Zutaten unter vermindertem Druck, in der Regel in einer Vakuumumgebung, verwendet. Diese Methode ermÃķglicht eine prÃĪzise Temperaturkontrolle und kÞrzere Garzeiten, wobei die QualitÃĪt und der Geschmack der Zutaten erhalten bleiben.

Wir bieten verschiedene Vakuumkocher an.

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 2500 l

Ein Vakuumgarer ist ein vielseitiges GerÃĪt, das in der KÞche zum Garen von Lebensmitteln unter Vakuumbedingungen verwendet wird, um Geschmack und Textur zu verbessern und gleichzeitig die Garzeit zu verkÞrzen.

Wir bieten verschiedene Herdarten an.

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Volumen: 100l

- Spannung: 380-400V

Der 5-kW-Hocker-Elektroheizofen mit einem Durchmesser von 40 cm ist fÞr das Erhitzen groÃer TÃķpfe und Pfannen mit einem Volumen von bis zu 100 Litern ausgelegt.

- Heizung: ElektrizitÃĪt

- Material: Edelstahl

- Heizleistung, kW: 5

- GerÃĪtetyp: Optionale Ausstattung

Ein VakuumentlÞfter wird in der Lebensmittelindustrie hÃĪufig eingesetzt, um Gase aus Produkten zu entfernen, in denen sich nach der Verarbeitung noch Blasen bilden kÃķnnen. AuÃerdem wird ein StrÃķmungsentlÞfter eingesetzt, um die Schaumbildung in Produkten zu minimieren und eine dichtere Struktur zu gewÃĪhrleisten, insbesondere vor der Verpackung. VakuumentlÞfter spielen eine entscheidende Rolle bei der Beseitigung bestimmter GerÞche aus den Produkten, z. B. bei der Herstellung von SÃĪften, PÞrees und KrÃĪutergetrÃĪnken. Dieser Prozess trÃĪgt wesentlich zur Verbesserung der GesamtqualitÃĪt und des Geschmacks des Endprodukts bei.

- Verbessert die QualitÃĪt, Struktur und Form des Produkts

- Verhindert Oxidation durch Entfernen von Gasen

- Bewahrt die organoleptischen Eigenschaften und verlÃĪngert die Haltbarkeitsdauer

- Geeignet fÞr dicke und zÃĪhflÞssige Produkte

- Das FlieÃprinzip ermÃķglicht den Einbau dieser Anlage in bestehende Produktionslinien

- Material: Edelstahl

- Funktionsprinzip: Kontinuierlicher Betrieb

- Herkunftsland: Slowakei

- Spannung: 380-400V

- Maximaler Vakuum: -0,8 Bar

DurchfÞhrung verschiedener Produktionsprozesse wie Schneiden, Mischen, Zerkleinern, Raffinieren und Emulgieren verschiedener Produkttypen in einer einzigen Anlage.

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Herkunftsland: Slowakei

- Gewicht: 359 kg

- Volumen: 150l

Der manuelle FlaschenfÞller ist zum AbfÞllen von FlÞssigkeiten in Glasflaschen bestimmt.

- ProduktivitÃĪt: 650 psc/h

- Material: Edelstahl

- Betriebsmodus: Manuell

Halbautomatische Dosiermaschine zum FÞllen und VerschlieÃen von verschiedenen Beuteln mit unterschiedlichen FlÞssigkeiten.

- Material: Edelstahl

- Betriebsmodus: Halbautomatisch

Die 4-Kopf-Vakuum-FlaschenfÞllmaschine dient als professionelle halbautomatische FÞll- und Dosiermaschine zum BefÞllen von Glasflaschen mit verschiedenen FlÞssigkeiten.

- Material: Edelstahl

- Betriebsmodus: Manuell

- GerÃĪtetyp: Einzelmaschine

Der KWS-MischbehÃĪlter ist fÞr den vielseitigen Betrieb, einschlieÃlich Erhitzen, KÞhlen und Mischen von flÞssigen Produkten, mit einer maximalen TemperaturkapazitÃĪt von 60 °C ausgelegt.

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- GerÃĪtetyp: Einzelmaschine

- Herkunftsland: Slowakei

- Geometric volume: 100 l

Die atmosphÃĪrischen Kocher ASC sind fÞr das effiziente Mischen, Erhitzen und Kochen von Produkten fÞr die Lebensmittel- und Kosmetikindustrie konzipiert. Volumen, l: 100 l.

- Heizung: ElektrizitÃĪt

- Material: Edelstahl

- Herkunftsland: Slowakei

- Volumen: 100l

Die atmosphÃĪrischen Kocher AC sind fÞr das effiziente Mischen, Erhitzen und Kochen von Produkten fÞr die Lebensmittel-, Pharma- und Kosmetikindustrie konzipiert. Arbeitsvolumen bis zu, l: 300 l.

- Material: Edelstahl

- Motorleistung, kW: 1,5 KW

- Heizleistung, kW: 13,5

- Funktionsprinzip: Chargenbetrieb

- Arbeitsvolumen: 300 l

- Geometric volume: 350 l

Unser Unternehmen bietet GerÃĪte zum Aufschlagen von Honig mit einem neuen Design an, das eine Schwerkraftmischung beinhaltet. Der Hauptvorteil dieser Technik ist die FÃĪhigkeit, cremigen Honig in 4 Stunden zu produzieren! Das GerÃĪt ist fÞr 450 kg Honig pro Charge ausgelegt.

- Material: Edelstahl

- Herkunftsland: Slowakei

- Volumen: 300l

Der pneumatische VerschlieÃer PTC bringt in Sekundenschnelle Kronkorken auf Bierflaschen, KorkverschlÞsse auf Weinflaschen und SchnappverschlÞsse auf andere BehÃĪlter auf.

- ProduktivitÃĪt: 400 bottles/ h

- Funktionsprinzip: Kontinuierlicher Betrieb

- GerÃĪtetyp: Einzelmaschine

- Herkunftsland: EU

- Gewicht: 25 kg

Diese halbautomatische AbfÞllmaschine wird fÞr die AbfÞllung von Honig und anderen Produkten verwendet. Wir bieten viele verschiedene Arten von AbfÞllmaschinen fÞr unterschiedliche Anwendungen an.

- Material: Edelstahl

- Betriebsmodus: Halbautomatisch

Wir bieten eine groÃe Auswahl an verschiedenen Pumpen fÞr alle Arten von FlÞssigkeiten, halbflÞssigen Produkten in verschiedenen Anwendungen.

- Funktionsprinzip: Kontinuierlicher Betrieb

Wir bieten verschiedene Typen von Vakuumverdampfungsmaschinen an. Dieser Typ ist eine erschwingliche Option fÞr eine effiziente Verdampfung in einer Edelstahleinheit.

- Material: Edelstahl

- Funktionsprinzip: Chargenbetrieb

- Volumen: 100l

Langsamlaufende Kreiselpumpen aus Edelstahl mit flexiblem Laufrad; Wir bieten zwei Versionen an. Auf Sockel oder Wagen.

- Funktionsprinzip: Kontinuierlicher Betrieb

Langsamlaufende Kreiselpumpen aus Edelstahl mit flexiblem Laufrad; besonders geeignet fÞr die FÃķrderung von empfindlichen, zerbrechlichen und viskosen FlÞssigkeiten, auch mit festen Teilen in der Schwebe.

- Funktionsprinzip: Kontinuierlicher Betrieb

Eine Reihe von pneumatischen vertikalen AbfÞllmaschinen fÞr die Dosierung von FlÞssigkeiten mit wasserÃĪhnlicher ViskositÃĪt.

- GerÃĪtetyp: Einzelmaschine