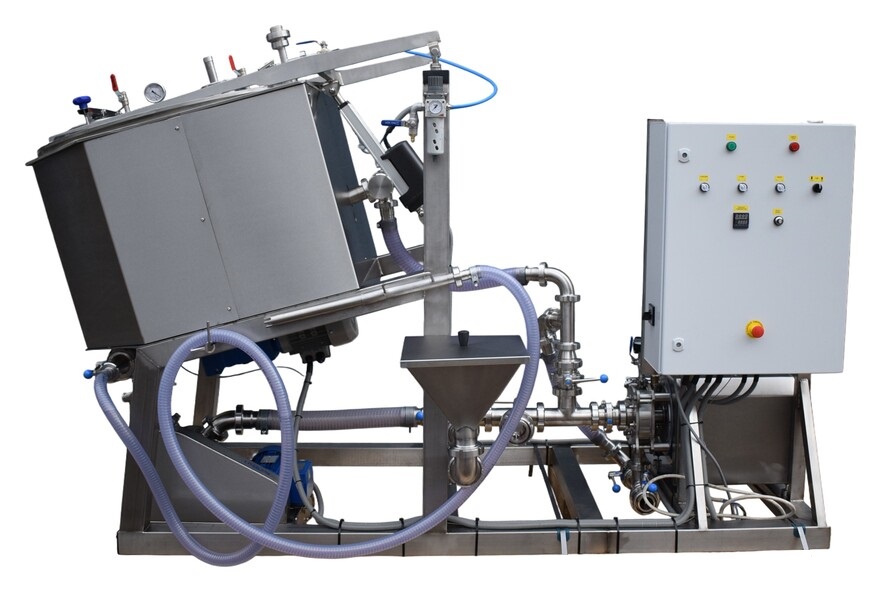

We have recently completed production of our 300 liter vacuum homogenizer with gravity mixing, designed for food and cosmetics manufacturers working with sauces, emulsions, and other liquid or semi-liquid products. This unit combines several processing functions in one system, allowing producers to heat, mix, homogenize, and deaerate the product without the need of transferring it between vessels.

The working tank is equipped with a double jacket (duplicator) that allows circulation of hot or cold water for accurate indirect thermal control. This makes the unit ideal for cooking sauces such as mayonnaise, ketchup, dressings, cheese sauces, and cream-based mixtures, but can also be used for controlled cooling when needed.

A high-shear homogenizer is integrated into the system to ensure stable and smooth emulsions without lumps or phase separation. The vacuum system removes air bubbles and dissolved gases from the product, eliminating potential contaminants and significantly extending shelf life.

This configuration makes the 300L vacuum homogenizer perfect for small and medium-scale producers looking to improve product quality and consistency, hygiene, and the overall efficiency of the process.