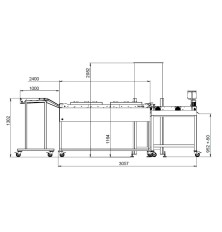

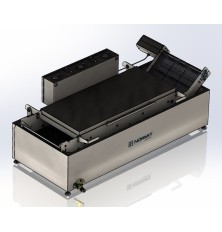

Fritadeira cont├Łnua para cebolas, nozes ODF 50

Esta fritadeira de tapete cont├Łnuo ├® uma solu├¦├Żo fi├Īvel e vers├Ītil adequada para a fritura de alto desempenho de uma vasta gama de produtos por imers├Żo em ├│leo quente.

- Aplica├¦├Żo universal

- Transi├¦├Żo r├Īpida para fritar novos tipos de produtos

- Possibilidade de utilizar modos de fritura especiais

- Quantidade m├Łnima de ├│leo no sistema

- Filtragem de ├│leo sem problemas

- Elevado r├Īcio de troca de ├│leo

- Elevada eficiência e produtividade com um design compacto

- Fabricado de acordo com os mais elevados padr├Ąes de qualidade, utilizando materiais e componentes fabricados na Europa.

O conte├║do desta p├Īgina foi traduzido para o portugu├¬s com tradu├¦├Żo autom├Ītica. A vers├Żo original est├Ī em ingl├¬s. Obrigado pela compreens├Żo.

As fritadeiras cont├Łnuas utilizam o m├®todo de imers├Żo dos produtos alimentares em ├│leo a uma profundidade ajust├Īvel, tornando-as ideais para fritar carne, peixe e produtos vegetais, bem como produtos de pastelaria e snacks processados, incluindo produtos com uma estrutura dura ou fr├Īgil, com ou sem panado.

Com esta fritadeira cont├Łnua, pode fritar facilmente alimentos como..:

|

|

|

|

|

|

|

|

|

|

|

|

Vantagens

- Equipamento de fritura universal, transi├¦├Żo r├Īpida entre a mudan├¦a para a fritura de novos tipos de produtos, a capacidade de utilizar modos de fritura especiais.

- Quantidade m├Łnima de ├│leo no sistema, filtragem ininterrupta do ├│leo, elevada taxa de troca de ├│leo - na maioria dos casos, n├Żo h├Ī necessidade de trocar o ├│leo devido ao seu ran├¦o, sendo apenas necess├Īrio encher o sistema com ├│leo novo.

- Elevada efici├¬ncia e produtividade numa ├Īrea reduzida.

- Fabricado de acordo com os mais elevados padr├Ąes de qualidade, utilizando materiais e componentes fabricados na Europa.

Princ├Łpio de funcionamento

As fritadeiras cont├Łnuas utilizam um m├®todo de imers├Żo de alimentos em ├│leo a uma profundidade ajust├Īvel que ├® ideal para fritar carne, peixe e produtos vegetais, bem como aperitivos de massa e v├Īrios alimentos transformados com uma estrutura dura ou fr├Īgil, com ou sem panado.

Os produtos s├Żo fritos por imers├Żo em ├│leo quente e movem-se atrav├®s do banho de trabalho num ├║nico tapete transportador. Uma carater├Łstica distintiva das fritadeiras de tapete rolante ├® a capacidade de ajustar facilmente o n├Łvel de imers├Żo do tapete rolante em ├│leo. A precis├Żo do ajuste ├® de 0,1 mm, o que permite fritar produtos de diferentes alturas utilizando esta fritadeira. O produto que se desloca ao longo do tapete rolante n├Żo flutua enquanto estiver completamente imerso em ├│leo a um n├Łvel pr├®-determinado. O ajuste da profundidade de imers├Żo ocorre suavemente e demora apenas alguns minutos, o que lhe permite passar ├Ā fritura de outros tipos de alimentos sem perda de tempo.

O ├│leo quente circula vigorosamente entre o sistema de aquecimento e o produto, com o ├│leo a fluir na dire├¦├Żo do produto. O ├│leo liberta a sua energia t├®rmica muito rapidamente no produto, fornecendo assim uma carga t├®rmica semelhante ├Ā que o produto estaria sujeito se fosse constantemente agitado em ├│leo quente. O ├│leo ├® filtrado continuamente por meio de filtros de a├¦o inoxid├Īvel com cartuchos inoxid├Īveis substitu├Łveis. As fritadeiras podem ser equipadas com um sistema de aquecimento el├®trico.

- Aquecimento: Eletricidade

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo cont├Łnuo

You might also like

Os contentores IBC s├Żo fabricados com uma capacidade de at├® 3500 litros. A unidade de armazenamento de l├Łquidos em destaque foi concebida para armazenar ├│leo e tem uma capacidade de 1000 litros. Para mais informa├¦├Ąes, envie-nos um pedido.

- Material: A├¦o inoxid├Īvel

- Volume: 500l/ 750 1000l/ 1250l/ 1500l

O pre├¦o ├® fixado para a vers├Żo b├Īsica sem m├│dulos adicionais. Se adquirir a fritadeira juntamente com os dois m├│dulos transportadores adicionais ŌĆō o transportador duplo e o transportador de p├Īs ŌĆō oferecemos um desconto de 300 EUR.

Uma fritadeira de tapete transportador modular vers├Ītil com um ├║nico tapete ├® utilizada para fritar continuamente uma variedade de produtos com baixo teor de ├Īgua que n├Żo requerem imers├Żo for├¦ada sob a superf├Łcie do ├│leo.

- Tempo de fritura regul├Īvel de alguns segundos a uma hora!

- Possibilidade de utilizar a unidade como um branqueador cont├Łnuo ou caldeira para cozinhar produtos com uma estrutura delicada

- Sistema modular, que aumenta as fun├¦├Ąes com cada novo m├│dulo

- Vers├Żo compacta para computador

- Possibilidade de fritura peri├│dica de produtos com descarga autom├Ītica

- Aquecimento: Eletricidade

- Material: A├¦o inoxid├Īvel

- Potência de aquecimento, kW: 12

- Princ├Łpio de opera├¦├Żo: Modo cont├Łnuo

- Pa├Łs de origem: Eslov├Īquia

- Comprimento da ├Īrea de trabalho: 1100 mm

- Largura da ├Īrea de trabalho: 400 mm

- Volume de ├│leo: 60l

- Voltagem: 380-400V

O sistema de drenagem de ├│leo em a├¦o inoxid├Īvel AISI 304 ├® adequado para utiliza├¦├Żo com a maioria das fritadeiras. Permite filtrar o ├│leo diretamente ao dren├Ī-lo da fritadeira.

- Material: A├¦o inoxid├Īvel

- Peso: 13,5

Dispomos de v├Īrios tipos de fritadeiras cont├Łnuas ou por lotes. Basta dizer-nos qual o tipo de produto que pretende fritar e n├│s ajudamo-lo a escolher a fritadeira certa.

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo cont├Łnuo

- Pa├Łs de origem: Eslov├Īquia

Esta frigideira comercial com fun├¦├Żo de misturar e inclinar foi concebida para fritar, estufar, selar e cozinhar alimentos em pequenas quantidades de ├│leo, mesmo em grandes lotes. Uma estrutura de suporte independente com mecanismo de inclina├¦├Żo facilita o descarregamento. A frigideira possui um aquecimento ajust├Īvel com 6 n├Łveis de intensidade, sendo adequada para cozinhas profissionais e pequenas empresas de produ├¦├Żo alimentar.

- Distribui├¦├Żo de calor eficiente para uma cozedura uniforme.

- Alto desempenho para processamento cont├Łnuo em lotes.

- Aquecimento r├Īpido gra├¦as ao aquecimento el├®ctrico por contacto na base.

- Design m├│vel que permite uma f├Īcil movimenta├¦├Żo pela ├Īrea de trabalho.

- F├Īcil limpeza e manuten├¦├Żo.

A EcoFry foi concebida para fritar an├®is de cebola, marisco, bolinhos de massa, rolinhos primavera, empadas, legumes, nuggets e hamb├║rgueres com a ajuda de ├│leo quente. Um equipamento de fritura eficiente e de menor capacidade destinado a instala├¦├Ąes de produ├¦├Żo de pequena e m├®dia dimens├Żo.

- Aquecimento: Eletricidade

- Material: A├¦o inoxid├Īvel

- Potência de aquecimento, kW: 36

- Princ├Łpio de opera├¦├Żo: Modo cont├Łnuo

- Pa├Łs de origem: Eslov├Īquia

M├│dulo opcional para a Fritadeira Modular de mesa universal 400/1100/12 - Transportador de press├Żo para fritar alimentos que requerem imers├Żo for├¦ada em ├│leo.

- Material: A├¦o inoxid├Īvel

As panelas multifuncionais funcionam como um dispositivo para fritar, cozinhar e misturar numa s├│ instala├¦├Żo.

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo em lotes

A vers├Żo alargada da fritadeira modular com tapete transportador, com um grande n├║mero de acess├│rios opcionais, expande significativamente a capacidade de produ├¦├Żo para a fritura de v├Īrios produtos, aumentando tanto a ├Īrea de fritura como a pot├¬ncia de aquecimento.

- O tempo de fritura pode ser ajustado desde alguns minutos at├® uma hora!

- Os sensores de seguran├¦a contra sobreaquecimento s├Żo instalados em cada elemento de aquecimento

- Estrutura de suporte compacta sobre suporte m├│vel

- A grelha transportadora de malha fina permite fritar produtos pequenos e fr├Īgeis

- Um grande n├║mero de op├¦├Ąes adicionais sob a forma de sistema autom├Ītico de abastecimento de ├│leo, transportador de carga, sistema de filtragem, transportador de refrigera├¦├Żo, etc.

- Aquecimento: Eletricidade

- Material: A├¦o inoxid├Īvel

- Potência de aquecimento, kW: 24

- Pa├Łs de origem: Eslov├Īquia

- Largura da ├Īrea de trabalho: 400 mm

- Voltagem: 380-400V

As fritadeiras autom├Īticas de donuts s├Żo m├Īquinas extremamente eficazes concebidas para facilitar a produ├¦├Żo de donuts.

- Material: A├¦o inoxid├Īvel

- Modo de opera├¦├Żo: Autom├Ītico

- Tipo de equipamento: M├Īquina individual

A fritadeira de vazamento cont├Łnuo foi concebida para fritar carne, peixe, legumes e produtos de massa, bem como coxinhas de frango, costeletas, nuggets, croutons, courgettes ou beringelas fatiadas, etc., utilizando os m├®todos de fritura por imers├Żo e de vazamento de ├│leo quente.

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo cont├Łnuo

- Pa├Łs de origem: Eslov├Īquia

- Voltagem: 380-400V

PRODUTO USADO - 1 DISPON├ŹVEL EM STOCK

A fritadeira cont├Łnua OIL MINI foi concebida para a gastronomia e a restaura├¦├Żo. ├ē ideal para a fritura de carne, ravioli, alm├┤ndegas, marisco, aves e legumes. Garante uma fritura cont├Łnua e resultados de fritura est├Īveis. Os elementos de aquecimento est├Żo situados num fundo de alum├Łnio de espessura dupla, o chamado "fundo de sandu├Łche", que evita que o produto se cole aos elementos de aquecimento e se queime, pelo que pode utilizar o ├│leo muitas vezes mais!

Pre├¦o de base - 5960 euros. Possibilidade de acrescentar um m├│dulo de pulveriza├¦├Żo de ├│leo (combifry), por um custo adicional de 3980 Ōé¼ (OP├ć├āO RECOMENDADA)

O pre├¦o ├® fixado para a combina├¦├Żo de um modelo b├Īsico de fritadeira e um m├│dulo adicional com p├Īs rotativas.

A fritadeira modular universal equipada com um m├│dulo de p├Ī adicional foi concebida para fritar fatias finas de produtos que requerem imers├Żo abaixo do n├Łvel do ├│leo.

- Tempo de fritura ajust├Īvel de alguns segundos a uma hora

- Vers├Żo compacta, de mesa

- O transportador de p├Īs ├® instalado no topo da fritadeira b├Īsica

- Aquecimento: Eletricidade

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo cont├Łnuo

- Pa├Łs de origem: Eslov├Īquia

- Comprimento da ├Īrea de trabalho: 1100 mm

- Largura da ├Īrea de trabalho: 400 mm

- Potência total, kW: 12

- Volume de ├│leo: 60l

- Voltagem: 380-400V

O m├│dulo de p├Īs para a Fritadeira Modular de Mesa Universal 400/1100/12 ├® um transportador com p├Īs especialmente curvadas para fritar suavemente alimentos fr├Īgeis e leves.

- Material: A├¦o inoxid├Īvel

- Tipo de equipamento: Equipamento opcional

Para fritar alimentos em ├│leo, fritar em profundidade, adequado para fritar cebolas, sementes, frutos secos, snacks de vegetais e batatas fritas, e outros produtos, incluindo panados ou cobertos de liga├¦├Żo. Tamb├®m pode ser utilizada como centr├Łfuga de separa├¦├Żo de ├│leo para fritadeiras.

- Dois em um: uma fritadeira e uma centrifugadora para retirar o excesso de ├│leo

- Possibilidade de fritar produtos pequenos e fr├Īgeis

- Obten├¦├Żo de um "produto seco" ap├│s a fritura

- Baixa carboniza├¦├Żo do ├│leo devido ├Ā fun├¦├Żo de limpeza ap├│s a fritura

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo em lotes

- Pa├Łs de origem: Eslov├Īquia

- Volume: 30l/ 90l

- Potência total, kW: 11

- Voltagem: 380-400V

A s├®rie de fritadeiras cont├Łnuas Pour Oil ├® o boom no mercado de equipamentos para fritar e assar. A nova constru├¦├Żo concebida pelos nossos engenheiros, com base na experi├¬ncia pr├Ītica existente na produ├¦├Żo e utiliza├¦├Żo de fritadeiras de tapete, fornece o melhor exemplo de respeito pelo ambiente.

- Material: A├¦o inoxid├Īvel

- Princ├Łpio de opera├¦├Żo: Modo cont├Łnuo

- Tipo de equipamento: M├Īquina individual

- Pa├Łs de origem: Eslov├Īquia

O sistema de transporte cont├Łnuo controlado digitalmente assegura a fritura de uma vasta gama de produtos a um n├Łvel consistente. Gra├¦as ├Ās possibilidades de fritura em profundidade, este modelo ├® adequado para uma vasta gama de produtos, desde rolinhos primavera, bhajis de cebola e falafel a douradinhos de peixe, hamb├║rgueres e nuggets de frango. A fritadeira est├Ī dispon├Łvel em larguras de 200, 300, 400 e 600 mm.

- Material: A├¦o inoxid├Īvel

- Voltagem: 380-400V

A superf├Łcie de trabalho ├® feita de a├¦o inoxid├Īvel de qualidade alimentar, em cima da qual a fritadeira pode ser instalada. Est├Ī equipada com rodas para facilitar a desloca├¦├Żo.

- Material: A├¦o inoxid├Īvel

Uma fritadeira de donuts ├® especialmente concebida para pequenas confeitarias, ind├║strias e estabelecimentos de restaura├¦├Żo. ├ē capaz de fritar v├Īrios produtos semelhantes a donuts.

- Material: A├¦o inoxid├Īvel

- Potência de aquecimento, kW: 12

- Pa├Łs de origem: Eslov├Īquia