FORMING MACHINES

Forming machines designed for precisely forming materials into desired shapes

Forming machines offer the ability to accurately and consistently shape a wide range of food mixtures. These machines create uniform shapes, sizes, and textures, contributing to efficient production and visually appealing end products. This guide explores the functions of gorming machines, their types, and applications across the food industry.

What are forming machines used for?

Forming machines are designed to transform raw ingredients into uniform shapes and portions. They work by applying controlled pressure to the material, guiding it through shaping molds or dies. This process ensures the creation of consistently shaped products like patties, nuggets, meatballs, sweets, protein bars, desserts, and more, while maintaining uniformity and adherence to portion control standards.

Types of forming and molding machines

- Patty Formers: These machines shape ground meat or plant-based mixtures into patties of consistent size and thickness.

- Nugget Formers: Ideal for producing chicken or vegetable nuggets, these machines shape mixtures into bite-sized pieces.

- Bar Forming Machines: These machines are designed to shape various food mixtures, such as cereal or protein bars, into uniform bars of consistent size and shape.

- Dough Depositors: Depositors are versatile machines that deposit consistent amounts of dough or batter onto trays or molds, creating products like cookies, muffins, and more.

Benefits of using formers in food production

- Consistency: Forming machines ensure uniformity in shape, size, and weight, resulting in visually appealing and evenly cooked products.

- Efficiency: Automated processes speed up production, reducing the need for manual labor and increasing output.

- Portion Control: Forming machines help maintain portion sizes, aiding in cost control and nutritional consistency.

- Versatility: These machines can adapt to various recipes and ingredients, offering flexibility in product offerings.

Applications of forming machines

Forming machines find extensive applications in the food industry:

- Meat Processing: Forming machines create consistent patties, cutlets, meatballs and other meat products for further processing or retail.

- Bakery: Depositors are used to shape dough for various baked goods, ensuring uniformity in size and texture.

- Sweets and Bars: Forming machines shape confections, protein bars, and other snack bars with precise portioning and consistency.

- Plant-Based Foods: As the demand for plant-based products grows, forming machines play a role in shaping mixtures into vegan alternatives.

- Snack Production: Nuggets, cutlets, and similar products are efficiently created using forming machines.

Partnering with FoodTechProcess for forming equipment solutions

FoodTechProcess offers forming machines tailored to different food processing needs. Our formers are designed to streamline the production of protein bars, cookies, burgers, and more while increasing production efficiency and ensuring consistency in shaping. Collaborate with FoodTechProcess to select a forming machine that meets your production requirements.

This ground-breaking device allows for constant fine tuning of the roundness of the boilies thanks to its PLC control device. It is sold in two versions. The price depends on the options you choose.

We also offer a extruding machine suitable for this boilie machine.

- Material: Stainless steel

- Principle of operation: Continuous mode

An automatic forming machine shapes food mixtures such as ground meat or plant-based alternatives into uniform portions. It automates portioning and shaping, and can also add a separation paper for easier handling before transferring the products with a conveyor. These machines reduce manual labor and increase output capacity for food processing facilities, butcher shops, and commercial kitchens.

- Material: Stainless steel

- Principle of operation: Continuous mode

The burger forming machine is a reliable solution for small to medium-scale food production. Burger formers are designed to automate the patty-making process, they ensure consistency in shape, size, and weight, making them ideal for restaurants, butcher shops, and small food processing businesses.

- Material: Stainless steel

- Principle of operation: Continuous mode

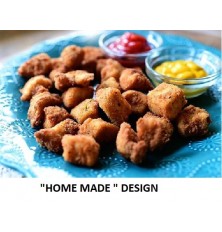

Create natural shapes of nuggets, pieces that have the appearance of a "hand-formed" product.

- Material: Stainless steel

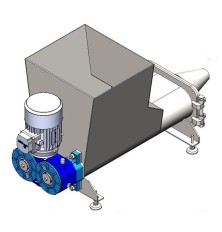

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V

The forming device guarantees accurate forming of a wide range of food mixtures. The FR 75 is suitable for various mixtures of different textures and consistencies.

The forming device guarantees precise shaping of a wide range of food mixtures.

- Material: Stainless steel

- Principle of operation: Continuous mode

Twin-screw extruder is designed for effective extruding, homogenization, pumping over of plastic masses (butter, margarine, honey, curd products, confectionery mixtures), and forming it into bars and rolls.

- Productivity: 400 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Weight: 115 kg

Rotary molding machine for confectionery products: candies from paste-like masses, crushed fruit masses, protein candies and bars. Specially designed for molding candies from food masses.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,5

- Voltage: 380-400V

Semi-automatic tying machines are designed for tying sausages and other meat products. Suitable for meat producers or small butchers.┬Ā

- Material: Stainless steel

- Weight: 42

Fully automatic machine for making kebab and brochettes by skewering meat on a stick with a maximum production capacity of 1500 pieces per hour.

- Productivity: 1500 psc/h

- Principle of operation: Continuous mode

- Weight: 120

- Voltage: 220-230V

This cookie making machine is designed to produce an unlimited variety of cookies, cakes, and other pastry snacks. We offer five different types of cookie depositing machines, each tailored to various cookie types

- Engine power, kW: 2,4/ 2,5/ 3,3 3/

- Principle of operation: Continuous mode

- Voltage: 220-230V

The machine is suitable for forming minced meat, poultry, fish, potato and vegetarian, vegan patties. The price depends on your product specifics and production capacity.

- Productivity: 800 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 600 mm

- Voltage: 380-400V

SIPM 10 liter pasta mixer is designed for medium size commercial operations, ideal for medium-size restaurants to produce any kind of pasta such as spaghetti, taglia pasta, cannelloni, macaroni, conchiglie, rigatoni, penne and many others. The price includes a pasta cutter.

- Productivity: 8,4 kg/h

- Material: Stainless steel

- Engine power, kW: 0,75

Croquettes production line for making and batter breading croquettes, preparing them for frying. Croquettes from 15 to 55 grams. Produces up to 12,000 pieces/hour. We also offer a range of fryers.

Price depends on your production capacity.

- Productivity: 12 000

- Material: Stainless steel

- Principle of operation: Continuous mode

The hamburger production line is designed for the production of hamburgers, veggie burgers or soy-based burgers. The line produces from 2.000 up to 6.000 hamburgers per hour. Price depends on the production requirements.

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Voltage: 220-230V