HEAT GENERATORS

Generators provide a reliable heat supply to ensure consistent heating and temperature control

Generators and heaters in the food processing industry provide the necessary heat for various production processes that transform raw ingredients into finished products, including cooking, frying, concentration, pasteurization and more. This comprehensive guide explores the functions of heat and steam generators, their types, and the role they play in food production.

The principle of heat and steam generation

The process of food production often involves heating and precise temperature control. Generators and heaters are designed to supply the necessary heat or steam for indirect cooking, evaporation, pasteurization, and other thermal processing stages. Steam generators and hot air heaters are used for heating and maintaining optimal temperatures in diverse food processing applications.

Key functions of heaters and generators

- Steam Generation: Steam generators provide controlled and consistent steam for cooking, sterilization, and blanching.

- Hot Air Heating: Hot air heaters ensure uniform heat distribution in dryers, roasting ovens and other chambers.

- Water Heating: Water heaters are used to provide consistently hot water for washing, blanching, or cooking.

- Indirect Heating: Indirect heating is used in applications where direct contact could compromise the product, such as using steam or oil as a heat transfer medium.

Types of┬Āheaters and generators

- Steam Generators: Offer energy efficient steam production, vital for indirect heating as well as processes like steam blanching and sterilization.

- Hot Air Heaters: Utilized in equipment for drying, roasting, and baking, they ensure uniform heat distribution for even thermal processing.

- Water Heaters: Essential for heating and maintaining water temperatures through circulation during various processing stages.

- Hot Oil Heaters: Indirect heat transfer systems using hot oil are suitable for applications requiring higher temperatures like frying and saut├®ing.

Applications across the food industry

Generators and heaters are used in various food processing applications:

- Cooking and Pasteurization:┬ĀWater and steam generators provide the thermal energy for cooking, pasteurization, and blanching operations.

- Drying Processes:┬ĀHot air heaters efficiently circulate hot air and remove moisture from food products, extending shelf life.

- Baking Industry: Hot air heaters contribute to consistent baking results, ensuring products are uniformly browned and cooked through.

- Canning and Bottling: Steam generators allow for sterilization and maintaining aseptic conditions during canning and bottling.

Partner with FoodTechProcess for a reliable heat generator

FoodTechProcess offers heaters and generators with a range of different production capacities. Heat generators provide precise temperature control, energy efficiency, and a consistent supply of heat. Contact us at FoodTechProcess to select the right steam generator for your production process.

A single hob cast-iron gas stove designed for heating and cooking in large cooking pots with volumes up to 100 liters. It is equipped with four independently controlled burners, designed for stable, intensive operation in food production.

- Robust cast-iron construction

- Four burners with separate flame control

- Suitable for propaneŌĆōbutane cylinders

- Designed to support heavy 50ŌĆō100 L cooking pots

The stove provides ideal external heating for our 50 L and 100 L cooking kettles with integrated mixing systems.

Compact and powerful gas stove with 3 rings designed for the connection to standard LPG cylinders. Ideal for heating large volumes of liquid, cooking soups or sauces in cooking kettles, and maintaining meal temperatures during preparation or service. The sturdy, open-frame design ensures excellent stability and high load capacity for everyday use in catering and food processing.

Designed for a load of up to 200 kg!

The 5 kW induction cooker is the best alternative to traditional electric and gas stoves. It reduces energy costs, improves safety, and minimizes air pollution, making it suitable for both stationary kitchens and mobile catering setups. Its compact design also makes it a practical choice for small kitchens where space and efficiency matter.

- 10-step power (500ŌĆō5000 W) or 10-step temperature (60ŌĆō280 ┬░C) control

- Connection - 230 Volt

- Compact dimensions: 410x500x200 mm

- Temperature range from 60 to 280 degrees

- Heating power, kW: 5

- Voltage: 220-230V

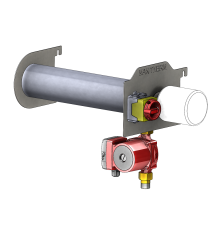

A flow-through water heater is a device for flow-through electric heating of water in heating systems for cooking boilers, evaporators and other units where it is necessary to supply a hot heat transfer medium - superheated water - to the heating jacket (duplicator). When choosing a flow-through heater, it is necessary to select a circulation pump based on the volume of the jacket or heat transfer vessel.

- The heater allows you to heat water up to 110 degrees

- Easily integrated into heating systems

- Has heating temperature regulation

- 2 stages of heating power adjustment

- Independent control panel with protection against overheating and "dry" running

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 2/ 3/ 6/ 9/ 10/ 12

- Principle of operation: Continuous mode

Electric continuous flow heaters in different designs and performance parameters.

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Type of pump: sealless pump

The 3.5 kW induction cooker is a modern alternative to electric and gas stoves, best used with the 50 liter mixing cooking pots. It offers efficient heating, safety, and compact design, making it ideal for small kitchens, catering, and mobile cooking. Lightweight and portable, it is also suitable for outdoor events.

- 13-step power (500ŌĆō3500 W) or 13-step temperature (60ŌĆō280 ┬░C) control

- Built-in timer (up to 120 minutes) and overheating protection

- Connection: 230 V

- Compact dimensions: 326 ├Ś 415 ├Ś 110 mm

- Net weight: 4.6 kg

- Heating: Electricity

- Heating power, kW: 3,5

- Voltage: 220-230V

Electric heating panel with three different power possibilities: 12, 24 and 48 KW ŌĆō excellent product manufactured by people who perfectly know the secret of product storage, maintenance and processing.

- Heating power, kW: 12/ 24/ 48

- Country of origin: EU

The durable single gas stove serves a versatile purpose, suitable for heating large cooking kettles. 7 kW.

- Heating: Gas

- Heating power, kW: 7

Electric steam generator with capacity of 2*24.5 liters - meets PED standards - with double or single resistance.

- Type of the equipment: Individual machine

Electric steam generator equipped with two boilers.

- Type of the equipment: Individual machine

Electric steam generator with capacity of 57 liters - meets PED standards - with double or single resistance.

- Material: Stainless steel

- Type of the equipment: Individual machine

Electric steam generator with capacity of 24.5 liters - meets PED standards - with double or single resistance.

- Type of the equipment: Individual machine

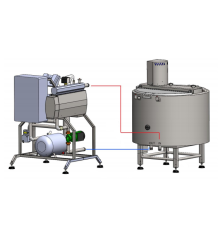

The generator is mounted on a stainless steel platform support, covered with stainless steel AISI 304 properly shaped with electrical and water connections already made. Stainless steel cocks AISI 316, malleable iron pipe fittings, feed water pump (mod. TP78A CALPEDA) with 1 stainless steel non-return valve, with VITON seal.

- Heating power, kW: 24/ 32/ 48

The 5 kw stool-type electric heating stove with a diameter of 40 cm is designed to heat large pots and pans with a volume of up to 100 liters.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Type of the equipment: Optional equipment

This air cooler and heater is multifunctional. It can be used as air cooler, heater. The compact and lightweight air cooler / heater contains. 4 caster wheels make it easy to move the unit.

The device is designed for generating hot air by burning wood as well as other flammable materials.

- Type of the equipment: Individual machine

Vertical steam generators with horizontal pipes that take up a compact area. Price on request.┬Ā

- Material: Stainless steel