CHOCOLATE, SWEETS

The cost is specified for the basic modification without a heating system

Fat block melters are designed for melting frozen, solid blocks of animal or vegetable fat, as well as maintaining them in a molten state at a specified temperature. We produce models with the option to connect steam as a coolant to the melting grid, separate electric heating systems, or configurations with built-in electric heating for supply into the jacket and melting grid.

- Large area of the melting grid where the coolant circulates

- Special shape of the melting grid, cutting blocks during melting

- Greater versatility in terms of the coolant and its source

- Mirror surface of the melting grid, ensuring high hygiene

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 200l/ 300l/ 500l/ 1000l

The fat melter refers to periodic equipment designed for the preliminary melting and mixing of both crystallized honey and frozen blocks of fat or oil. This installation combines thermal and mechanical effects on the product and can also function as a feeding device for loading and feeding dense products for further processing.

- Highly Efficient Combined Processing of Products: Thermal and Mechanical Effects

- Universal heat carrier source (steam/water).

- No pump required; the mixing device functions as a screw pump.

- Large area for laying out the product blocks ŌĆō ensuring high productivity.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 400l/ 1000l

- Total power, kW: 1,1/ 2,2

- Voltage: 380-400V

We offer different capacity ball mills, from laboratory mills to industrial mills at great price and highest quality which produce exceptional chocolate.

- Material: Stainless steel

- Principle of operation: Continuous mode

The 1000 L vacuum cooker is used for cooking, concentrating, and evaporating food products under reduced pressure, allowing gentle heat treatment, improved flavor retention, and precise control of moisture content.

For a price quote, send us a request.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 1000l

- Dimensions, mm: 1385x1283x1892

A sturdy extruder machine, with a tank made from AISI 304 stainless steel, ideal for extruding and mixing, and the production of protein bars. For a mini line for making boilie, you can purchase our boilie rolling machine.

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

This ground-breaking device allows for constant fine tuning of the roundness of the boilies thanks to its PLC control device. It is sold in two versions. The price depends on the options you choose.

We also offer a extruding machine suitable for this boilie machine.

- Material: Stainless steel

- Principle of operation: Continuous mode

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l

Universal cooking kettle for thick mixtures: it works on the principle of a water bath and can be used in confectionery shops, bakeries and other catering establishments. Offers a wide variety of models.

- Mechanical tilting system for unloading

- Safety grill for the mixer drive

- Built-in electric heating up to 150 degrees

- Mobile support structure on wheels

- Heating: Electricity

- Principle of operation: Batch mode

- Volume: 30l/ 60l/ 80l/ 120l

The laboratory vacuum cutter mixer is designed for uniform grinding, emulsifying and mixing of food, cosmetic and pharmaceutical products, chemical mixtures with the addition of oil, dyes, concentrates or liquid flavors.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The price is stated for the basic version of the installation without balls.

The mill is designed for mechanical grinding of raw materials for the production of chocolate, nut butters and obtaining a creamy, homogeneous product structure with a fraction size of up to 20 microns.

- Compact installation on a self-supporting structure

- Simple and convenient maintenance

- Plexiglas cover for visual inspection

- Removable stirring device

- Jacket for the heat transfer medium

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 5l

- Total power, kW: 1,5

- Voltage: 380-400V

Homogenizer for the production of whipped cream, ice cream, and much more. It allows you to obtain stable liquid emulsions of food mixtures.

- The homogenizer can be installed directly into the container with the product

- High productivity - in just 8 minutes, it is possible to whip up to 60 liters of milk mixture

- The peripheral speed of the knives is 16 m/s

- Material: Stainless steel

- Engine power, kW: 0,37/ 2,2

- Country of origin: EU

- Voltage: 380-400V

Steel balls for grinding chocolate are essential components used in ball/bead mills. These 6 mm diameter balls are made out of hardened steel and are considered as consumables required for operating the BALL MILL 5.

- Spherical shape with a diameter of 6 mm

- High hardness steel

- Supplied in 10 kg boxes

- The mill requires 2 boxes (20 kg in total).

- Type of the equipment: Spare parts

A modern cooking and mixing device with a wide range of applications in confectionery, bakeries, catering establishments.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

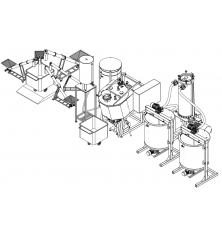

This equipment complex enables the production of Nutella-type chocolate pastes with a capacity of up to 250 kg/h.

- Material: Stainless steel

- Country of origin: Slovakia

The atmospheric tank with an inclined design is used for mixing, stirring, and dissolving various products. By supplying a thermal carrier to the unitŌĆÖs jacket (duplicator) from an external source, thermal processing such as heating or cooling can occur (i.e. heating or cooling from an external coolant source with an inlet pressure of up to 0.5 bar). These units are widely utilized in the food and cosmetic industries.

- Inclined design: 50% more efficient mixing

- Due to the inclination angle of the working tank, rapid and complete (100%) emptying is achieved.

- Efficient heat transfer through the heating/cooling jacket

- No dead zones during mixing!

- Modular system with a wide range of additional options

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Working volume: 100l/ 200l/ 300l/ 450l/ 600l/ 900l

Vertical shell and tube heat exchanger is designed to heat and cool such viscous/pasty products as sauces, mayonnaise, creams yogurts, jams, caramel, baby food, honey etc.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Shell-and-tube or tabular heat exchanger is designed to heat and cool viscous/pasty products such as sauces, mayonnaise, creams yogurts, jams, caramel, baby food, honey etc. Shell-and-tube heat exchangers are one of the most widely used units due to their robust design and a variety of options to suit different operating conditions.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

Normelt C is a compact machine for efficient industrial melting of solid fats of vegetable and animal origin.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Geometric volume: 100 l

Planetary mixers are primarily used in the confectionary industry. Offered in three different capacities.

- Material: Stainless steel

- Engine power, kW: 1,5 / 2,2

- Principle of operation: Batch mode

The industrial planetary mixer is mainly used in the confectionary industry. Available in three different sizes: 120, 140 and 170 L.

- Engine power, kW: 5,5

- Voltage: 380-400V

A spiral mixer with a fixed bowl and an electronic control panel. Available in various different capacities.

- Principle of operation: Batch mode

- Volume: 60l/ 80l/ 120 l/ 160 l/ 200l/ 250 l

- Voltage: 380-400V

The cyclone dust collection system is ideal for food processing facilities looking to prevent contamination by airborne particles, reduce product loss, and maintain a cleaner work environment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

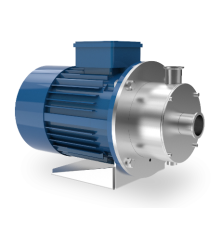

Chocolate heating pump is the perfect solution to upgrade your production line. You can easily connect the pump to any device (such as a chocolate enrobing machine).

- Principle of operation: Batch mode

- Voltage: 380-400V

Atmospheric cutter mixer with capacity of 150l for medium size production of confectionery, chocolate, ice cream, ready meals, cheese, cream smoothie, vegetable puree.

For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 150l

The conveyor is made out of strong and highly-resistant stainless steel. It is also additionally reinforced for reliability during operation.

- Material: Stainless steel

- Principle of operation: Continuous mode

The tempering machine ensures a shiny, smooth finish and stable structure for chocolate, significantly reducing the possibility of fat bloom. This equipment is essential in the production of various sweets, confections, chocolate-coated dragees, and other applications requiring chocolate coatings.

- 4-zone tempering system

- Automatic control system

- Temperature measurement in each zone at the inlet and outlet

- High productivity from 150-300 kg/hour

- Heating: Electricity

- Productivity: 150-300 kg/h

- Heating power, kW: 10-18

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

This set of equipment for the production of condensed milk from dry components by restoring the milk. This production line can be manufactured with a capacity of up to 500 kg/h or can be customized based on specific requirements.

- Material: Stainless steel

The tank is designed for heating and mixing chocolate, butter, margarine, honey and similar products.

- Material: Stainless steel

A vacuum cooker is used in the food processing industry to cook ingredients under reduced pressure, typically in a vacuum environment. This method allows for precise temperature control and faster cooking times while preserving the quality and flavor of the ingredients.

We offer different vacuum cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2500 l

A Vacuum cooker is a versatile device used in culinary settings to cook food under vacuum conditions, enhancing flavors and textures while also reducing cooking times.

We offer various different cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

Intense fat melting machines MixMelters are designed for melting frozen, solid blocks of animal and vegetable fat such as butter and margarine as well as to maintain them in a melted state at a given temperature. Working volume up to, l: 200 l.

- Material: Stainless steel

- Heating power, kW: 12/ 24/ 48

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 200 l

The industrial mixing and homogenizing equipment is well-suited for small and medium-sized production enterprises engaged in the processing of food, cosmetics, and various chemicals.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 300 l

This air cooler and heater is multifunctional. It can be used as air cooler, heater. The compact and lightweight air cooler / heater contains. 4 caster wheels make it easy to move the unit.

The conical bottom mixer with a 400-liter capacity is designed for efficient mixing and smooth product discharge. Its conical shape directs contents toward the lower outlet, making it ideal for processing thicker or denser materials in an atmospheric-pressure environment.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 400l

- Voltage: 380-400V

Used in chemical, construction, cosmetic or food industries.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 85

- Volume: 50l

- Voltage: 380-400V

This machine is used to produce sweets coated with chocolate.┬ĀFor more information, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 7l/ 16

- Voltage: 220-230V

Rotary molding machine for confectionery products: candies from paste-like masses, crushed fruit masses, protein candies and bars. Specially designed for molding candies from food masses.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,5

- Voltage: 380-400V

Chocolate tempering machine provides fluidity in the chocolate at all times and a perfect union of crystals.

- Engine power, kW: 1,5 /

- Weight: 80 / 120

- Volume: 12 kg / 24 kg

TEPF is a pneumatic dispenser for dosing several kind of products. The machine allows the filling of food, chemical, cosmetic, or pharmaceutical products into diverse type of bottles and jars.

Price depends on the product used.

- Material: Stainless steel

- Operation mode: Automatic Manual

- Type of the equipment: Individual machine

Specialized vacuum cooking kettle for sweet masses, ideal for commercial applications and medium to large scale food production.

For a price quote, send us a request.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 200l

- Dimensions, mm: 2055x1800x1980

Tilting atmospheric cooking kettle is designed for homogeneous cooking and mixing of sauces, smoothies, jams, spreads, soups, pasta, yoghurts, ice cream, curd desserts, mousse, air confectionery masses, pastry cream, fillings for sweets, waffles, rolls, chocolate, gingerbread, cookies, muffins, rolls, pastilla, marshmallows, meringues, marshmallows, brewed dough, sponge cake.

For a price quote, send us a request.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Voltage: 380-400V

- Geometric volume: 330

- Dimensions, mm: 1700x1030x1500

Ball mills are used for the production of a chocolate mass, various types of chocolate glazes, nut and chocolate pastes (such as Nutella) and similar products.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

The universal cooking boiler with an integrated homogenizer and a capacity of 1200 liters is designed for efficient mixing, heating, cooking and homogenizing of products for food, pharmaceutical and cosmetic industries such as jams, marmalades, syrups, fruit juices, nectars, beers, creams, ointments, soaps and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

Semi automatic packaging machine for filling and capping jars.

- Material: Stainless steel

The Atmospheric Evaporating Pan efficiently concentrates liquids by evaporating them on a large surface area, while also being suitable for various cooking methods including braising, cooking, and roasting.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

An evaporator concentrator-crystallizer is a multifunctional unit that concentrates liquids by evaporating water and inducing crystallization for the production of concentrated solutions or crystalline products.

- Material: Stainless steel

- Working volume: up to 6000 L

- Geometric volume: 6500 l

An evaporating unit is utilized to remove moisture from sweet substances through heating, transforming them into concentrated syrups or solutions.

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 200 l

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The twinscrew mixer with two horizontal shafts is designed for intensive mixing and kneading dough as well as chocolate, pralines and other similar products with medium or high viscosity.

- Material: Stainless steel

- Engine power, kW: 2,2

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

This cookie making machine is designed to produce an unlimited variety of cookies, cakes, and other pastry snacks. We offer five different types of cookie depositing machines, each tailored to various cookie types

- Engine power, kW: 2,4/ 2,5/ 3,3 3/

- Principle of operation: Continuous mode

- Voltage: 220-230V

Chocolate fountain attracts the attention of customers thanks to its stylish design, and can be used to top ice cream cones, to fill cups with hot chocolate drinks etc. Price is for the machine only. You can purchase additional mobile counter, covering rings or various nozzles.

- Material: Stainless steel

- Voltage: 220-230V

Chocolate flaking machine for automatically differentiating two blocks of couverture each time. The flakes are collected in plastic baking for food. The machine comes with two plastic bins.

- Productivity: 30 kg/h

- Material: Stainless steel

- Voltage: 220-230V

The tempering machine for chocolate is manufactured in 3 different volumes, 100l, 200 and 300l.

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

- Voltage: 380-400V

For the price quote or more information regarding this equipment complex for the production of chocolate, please send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

This machine is made for the production of coated sweets. This can include roasted sugar around almond nuts.

For more information, send us a request.

- Material: Stainless steel

- Engine power, kW: 0,17/ 0,37

- Principle of operation: Batch mode

- Voltage: 220-230V

Vacuum mixer processing plant for viscous products is an ideal solution for the production of pilot batches and the industrial manufacturing of a wide range of products from small to medium capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l

Cooling tunnel with a length of 15.2 meters. The standard design consists of 13 sections with removable top. For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

Automatic enrobing unit for the production of chocolate truffles.┬ĀFor more information, send us a request.

- Productivity: 50 kg/h

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Working Area Width: 180 mm

- Voltage: 220-230V

A cooking kettle and a vacuum mixer for periodic deaeration of products such as mayonnaise, ketchup, various sauces, creams, gels and pastes. It is one of the modifications of a vacuum reactor and a vacuum evaporator. The presence of a vacuum system allows you to create a vacuum after the cooking process and perform vacuuming (deaeration) to remove air bubbles with potential contaminants and obtain a product with a denser structure. Thanks to vacuuming, the product has an extended shelf life, since pathogens and microbes contained within are removed together with the air.

- Inclined design with gravity mixing, which is 30% more efficient than usual

- 100% emptying of the product after processing due to the bottom valve

- Easy to disassemble removable mixing device

- Possibility of connecting it to a CIP station for cleaning and washing

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Total power, kW: 0,12

- Max vacuum: -0,8 Bar

Double-jacket stainless steel cooker for marmalade and jam production.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

- Voltage: 380-400V

Price depends on the chosen option. Please send us a request.┬Ā

- Heating: Electricity Steam

- Material: Stainless steel

- Engine power, kW: 2,2

- Volume: 300l

- Dimensions, mm: 1070x1120x1040

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

Vertical steam generators with horizontal pipes that take up a compact area. Price on request.┬Ā

- Material: Stainless steel