JUICE, NECTAR

Vacuum evaporator with remote circulation using a heat exchanger is one of the most efficient evaporation methods. This evaporation system is suitable for boiling and concentrating heat-sensitive products such as milk, cream, etc.

- No mixing device required, the product has forced circulation!

- Modular system: possibility to choose the vacuum generator, power and heat exchanger type

- Inclined design and bottom valve for 100% product discharge without losses and blind spots

- Insulated upper hatch of the unit for heat retention and safety

- Tangential product inlet into the vacuum vessel for guaranteed evaporation in a thin layer

- Material: Stainless steel

- Volume: 50l/ 100l/ 300l

Electric fat melter (butter melter) ŌĆō is a batch-type machine used for melting solid, frozen blocks of fat, animal fats and vegetable oils, frozen juices, chocolate and glaze, as well as maintaining them in a molten state in the container. It is possible to use it for melting some refractory fats due to the high heating temperature of up to 120┬░C.

- Built-in powerful 2.6 / 6.5 kW electric heating

- Multi-stage switch with 7 heating intensity levels

- Professional, stainless steel thermometer for measuring the temperature in the product

- Compact support structure on height-adjustable legs / optional wheel support

- Three tilt positions of the working container for convenient unloading of the product

- Principle of operation: Batch mode

- Volume: 50l/ 100l

- Total power, kW: 3,5/ 6,5

- Voltage: 380-400V

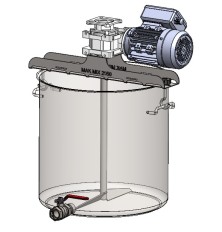

Professional cooking boiler with a stirrer for particularly thick and viscous products. An excellent technical solution for the production of caramel, syrups and sugar paste for sugaring. The heating source is selected separately.

- The kettle can be used on all types of cooking surfaces, including induction

- The basic version has easily removable, self-aligning stainless steel scrapers

- High torque of the stirrer with 14-18 revolutions per minute

- Professional 3-phase industrial motor

- The stirrer is turned on independently using a remote control with IP66 protection, connected to the boiler using quick-release connectors

- The unit can be connected to a 220-230 volt network even with a 3-phase motor!

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Volume: 20l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

The fat melter refers to periodic equipment designed for the preliminary melting and mixing of both crystallized honey and frozen blocks of fat or oil. This installation combines thermal and mechanical effects on the product and can also function as a feeding device for loading and feeding dense products for further processing.

- Highly Efficient Combined Processing of Products: Thermal and Mechanical Effects

- Universal heat carrier source (steam/water).

- No pump required; the mixing device functions as a screw pump.

- Large area for laying out the product blocks ŌĆō ensuring high productivity.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 400l/ 1000l

- Total power, kW: 1,1/ 2,2

- Voltage: 380-400V

The price is indicated for the basic version of the vacuum reactor without additional options, the final cost depends on the modifications

The vacuum homogenizer is an ideal solution for the production of food, for example mayonnaise, it is also suitable for the cosmetics industry - the production of toothpaste. This model of the homogenizer is based on a vacuum reactor with an external homogenizer and an external circulation circuit, the parameters of which are selected as options.

- Tilted design - 25% more efficient mixing

- Easily disassembled reinforced frame mixer, for thick and viscous products

- Jacket for the coolant around the bottom and walls of the working reactor

- The vacuum reactor can withstand a vacuum up to -0.8 Bar

- A large number of options to choose from to suit various requirements

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 650l

- Total power, kW: 0,55

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

This 800-liter capacity dissolver with a circulation pump is designed for preparing liquid solutions by dissolving substances directly in water or other working fluids. It is used in the food and beverage industries for ensuring uniform dissolution through hydrodynamic mixing in a forced recirculation loop.

Recirculation with a food-grade pump ensures rapid and uniform dissolution without sedimentation or the formation of stagnant zones. The working tank is mounted on a mobile platform with wheels, allowing for easy and quick movement between production areas.

- Fast and uniform dissolution without sediment thanks to hydrodynamic mixing

- Forced recirculation loop with product pump/inline homogenizer (optional)

- Mobile stainless steel platform on wheels

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Geometric volume: 800 l

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

The 300 BIN pressure vessel is a mobile stainless steel unit designed for transferring liquid and semi-liquid products by applying controlled internal pressure. It also serves as a mobile container for moving batches within the production facility. It is suitable for hygienic food processing environments where pumping is not possible or practical.

- Designed for operating pressures up to 0.5 bar, allowing for vertical transfer of liquids without a pump.

- Six hand-tightened lid screws ensure secure sealing during pressurized or vacuum operation.

- Mounted on caster wheels for easy movement within the production area.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

The Economy series of the cooking kettles comprise a thick-walled stainless steel container with an electric mixer mounted on the quick-release upper housing. The installation allows you to mix and stir products during processing. The thick bottom of the pot allows it to be installed on all types of heating surfaces (gas, induction or electric stove).

The Economy version is recommended for use with low-viscosity liquid products; If processing more thick and viscous products is necessary, we offer the Premium version of the cooking kettle┬Āor the caramel & syrup cooking kettle for extra thick substances.

- Sandwich bottom (multilayer) for use on all types of hobs, including induction

- Quick release lid with an electric stirrer

- Safety grid under the upper hull hatch - safe handling when stirring

- Possibility of visual inspection through the safety grid during processing

- Safe loading of components even during mixing

- Material: Stainless steel

- Engine power, kW: 0,12

- Volume: 30l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

The vacuum cooking and mixing tank is used to boil products at low temperatures, which helps preserve the natural color, taste and nutrients in the product.

Vacuum equipment is used for cooking premium-quality jams, sauces, fruit and vegetable concentrates.

- Inclined design

- Efficient emptying

- High hygiene standards

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

Universal cooking kettle with a built-in steam generator up to 0.5 bar, frame stirring device and an automatic tilt and unloading system is a convenient and safe solution for processing various liquid products in large volumes.

- Safe design with a jacket (duplicator) and outer casing with insulation

- Intensive steam heating through the jacket using the built-in electric steam generator

- Automatic multi-stage tilt and unloading system

- Frame stirring device for dissolving, mixing, kneading ingredients

- Unloading of the product into rolling carts is possible due to the offset tilted axis

- Heating: Mixed

- Material: Stainless steel

- Country of origin: Slovakia

- Total power, kW: 13,5

The cost is indicated without the control panel, which can be selected and offered separately

A versatile cooking system, featuring an inclined reactor, a duplicator for heating and a frame mixing device, it is designed for processing a diverse range of products through methods such as cooking, boiling, and concentrating at atmospheric pressure. This system is commonly used for the production of syrups, jams, confiture, and honey processing.

- Slanted design with gravity mixing - 25% more efficient!

- External decorative casing made out of polished stainless steel with insulation

- Jacket for the bottom and the walls of the working container along the entire height

- Lid opening sensor for safe operation

- Scrapers are already included in the basic version of the installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l/ 430l/ 600l/ 1000l

- Voltage: 220-230V 380-400V

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Stainless steel jam cooking pot with agitator 50l and electric stove 5kW, ideal and affordable cooking solution.

- Heating: Electricity

- Material: Stainless steel

- Engine power, kW: 0,18/

- Heating power, kW: 5

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

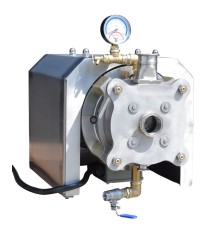

The circulation type homogenizer is designed for emulsifying thick fluids and other viscous materials within the food, chemical and cosmetic industries. Its working principle is based on the rotor/stator principle.┬Ā

- Material: Stainless steel

- Engine power, kW: 1,1/ 7,5 kW

- Country of origin: Slovakia

A detachable lid with an automatic food stirrer for stainless steel 40 cm pots, suitable for volumes of 50 and 100 liters. An automatic stirrer allows you to mix and stir various products, including during thermal processing. The type of mixing device can be additionally selected depending on the required process.

- Professional industrial single-phase motor for 220-230 Volts

- The control is located directly on the motor housing or on the drive cable

- Easy and simple installation and fixation of the lid on the pan

- Suitable for standard 40 cm pots with a capacity of 50 or 100 liters

- The lid and stirrer are made entirely out of stainless steel

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Voltage: 220-230V

Compact vacuum evaporation machine with an external circulation heat exchanger for the production of test batches of products, development of new recipes and technological maps.

- Compact installation

- Capable of replicating all processing techniques used in industrial vacuum evaporation units with circulation

- Preserves the natural taste, aroma and color of the product

- Can be used to produce small batches of products

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 20l

A universal vessel for mixing, whipping and stirring any products using a blade mixing device operating at high speeds.

- Crescent shaped mixing device with three sharpened blades (cutter knives)

- Special high speed drive

- Sandwich bottom for all types of heating surfaces (electricity, gas, induction).

- Productivity: 50l/ 100l

- Material: Stainless steel

- Engine power, kW: 0,18/

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Diameter, mm: 400/ 500/ 600

The inline homogenizer is designed for mixing, emulsifying, dispersing, and homogenizing thick and viscous products in the production of mayonnaise, soy milk, toothpaste, yogurt, and much more. It can be installed in an external circulation circuit of reactors, production lines, or used independently with a loading hopper for processing small volumes of products.

- Creates stable emulsions and suspensions

- Reduces particle size

- Quickly dissolves solids

- Accelerates chemical reactions

- Does not require an additional pump

- Material: Stainless steel

- Engine power, kW: 5,5/ 7,5/ 9/ 11/ 15

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The price is set for the basic version of the vacuum evaporation unit with basic controls (mixer motor switch) and without additional options. The control unit is customized based on individual customer requirements. The pump is also selected separately depending on the product.

A compact vacuum evaporation unit that allows you to concentrate solutions, mixtures, and various products by evaporating the solvent. A modular version based on the basic version of the 110/100 vacuum reactor.

- Gravity mixing - 25% more efficient

- Reinforced agitator design with no blind spots

- Bottom ball valve with no dead zones

- Condensation and secondary vapor removal system

- Easy to disassemble mixing device

- Large heat exchange area

- Ability to measure and monitor condensate volume (optional)

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

- Condensing capacity, l/h: 45-55

- Steam consumption, kg/h: up to 150

The portable vertical pump is designed for pumping fluent or viscous liquids in the range from 1-2300 m2/s at a temperature of around 25┬░C. The pump cannot be used in potentially explosive atmospheres.

- Material: Stainless steel

- Engine power, kW: 0,25

- Voltage: 380-400V

Fat block melter Fastmelter refers to the equipment of periodic action for melting butter and other frozen fats within the food industry.

- Material: Stainless steel

- Principle of operation: Batch mode

The pump provides a delicate straight-streaming┬Āpumping of a wide range of liquids with or without solid fragments with viscosity up to 150 Pa.s.┬Ā

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

The high-performance screw pump is used for pumping both thick and viscous food products, as well as various masses containing pieces or solid inclusions such as in the cosmetics, cosmetology, and other industries.

- High performance

- All parts in contact with the product are made out of AISI304

- Does not damage products containing solid pieces

- Additional options: by-pass

- Material: Stainless steel

- Engine power, kW: 1,1/ 1,5 / 3

- Principle of operation: Continuous mode

A vacuum distillation system is used for controlled separation of liquids based on the evaporation of the liquid and subsequent condensation of its vapors.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 5l

The conveyor for transferring empty as well as filled bottles and jars. Widely used within packaging lines for various liquids.

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: EU

A professional cooking boiler with built-in intensive bottom heating and a tilting system for the working container allows you to quickly heat the product to high temperatures (200┬░C). Suitable for blanching, boiling, frying and stewing various products where high-temperatures and efficient processing is required.

- Powerful bottom heating with uniform heat distribution (2600 / 6500 W)

- Professional stainless steel probe in the product with a thermometer for visual control

- Compact standing supporting structure for safe operation

- Three-stage adjustment of the tilt angle of the working container

- The unit is made entirely out of stainless steel

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 3,5/ 6,5

- Volume: 50l/ 100l

- Voltage: 380-400V

Compact digital filling machine for accurate dosing of viscous liquids such as honey, pastes, sauces, and oils. Designed with food-grade materials, easy-to-clean components, and precise digital control, it is ideal for small production, workshops, and laboratories.

- Operation mode: Semi-automatic

A circulation-type vacuum evaporator refers to a combined version of an evaporator that also takes advantage of other types to improve evaporation efficiency particularly by reducing concentration time and when processing heat-sensitive products such as milk.

- The external circulation circuit with heating intensifies the cyclic evaporation process.

- The forced circulation system ensures a decrease in the risk of localized product overheating.

- The condenser enables a deep vacuum and maintains a low evaporation temperature.

- Utilizing a mixing device with a spray system facilitates product evaporation in a thin layer, mimicking a film-type evaporator.

- Heating: Steam

- Material: Stainless steel

- Operation mode: Semi-automatic

- Country of origin: Slovakia

- Total power, kW: 2,4

- Voltage: 380-400V

The vacuum cooking and concentration unit is designed for concentrating products at low temperatures (about 60 degrees) in a reactor with a discharged environment to preserve the color, nutritional value and useful natural substances in present in food products. Evaporation and concentration units are often used when cooking jams, sauces, as well as fruit or vegetable concentrates. The vacuum concentrator allows you to boil and concentrate heat-sensitive products without damaging or destroying their structure or proteins, such as milk.

- Inclined design - allows for gravity mixing, which is 40% more efficient than usual

- Quick and 100% emptying of the tank thanks to the inclined design with the mixer on

- Heating/cooling jacket (duplicator) for the working tank and bottom

- High hygiene standard - the output valve is located at the lowest hydraulic point of the reactor

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 500l/ 875l

The vacuum evaporation unit is specially designed for thickening dense food products in industrial quantities. The evaporator can be used for the production of thick syrups, caramel masses, dense fruit masses, as well as for the production of pectin, or heat-stable fillings with a high productivity.

- High performance

- Rotary spraying system with a powerful electric drive

- Evaporation in a thin layer with a large heat transfer area

- Low investment installation costs

- Tangential entry for product swirling

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

The atmospheric tank with an inclined design is used for mixing, stirring, and dissolving various products. By supplying a thermal carrier to the unitŌĆÖs jacket (duplicator) from an external source, thermal processing such as heating or cooling can occur (i.e. heating or cooling from an external coolant source with an inlet pressure of up to 0.5 bar). These units are widely utilized in the food and cosmetic industries.

- Inclined design: 50% more efficient mixing

- Due to the inclination angle of the working tank, rapid and complete (100%) emptying is achieved.

- Efficient heat transfer through the heating/cooling jacket

- No dead zones during mixing!

- Modular system with a wide range of additional options

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Working volume: 100l/ 200l/ 300l/ 450l/ 600l/ 900l

Rechargeable and portable, ideal for measuring sugar content in fruit juices and beverages, ergonomic design.

Analogue refractometers offer an efficient, accurate, and easy-to-use solution for measuring Brix levels and ensuring product quality in the food industry.

- Type of the equipment: Optional equipment

MP cooker is a reliable and extremely functional solution for cooking, pasteurizing in the same tank thus saving equipment cost, space. All material are most reliable in European market so guarantee a long and trouble free operation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

The cooling tank is designed for storing milk and other beverages.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

Pasteurizers are used for the heat treatment (pasteurization) of juice before it is filled into bottles, containers or other types of packaging. Its compact, space-saving design and simple operation make it suitable for various production facilities.

- Productivity: 400 l

- Material: Stainless steel

- Heating power, kW: 36

- Country of origin: EU

- Voltage: 380-400V

The plate heat exchanger is designed for cooling/heating and transfer liquid products such as milk, water, juices, syrups etc.

- Type of the equipment: Individual machine

- Country of origin: EU

Shell-and-tube or tabular heat exchanger is designed to heat and cool viscous/pasty products such as sauces, mayonnaise, creams yogurts, jams, caramel, baby food, honey etc. Shell-and-tube heat exchangers are one of the most widely used units due to their robust design and a variety of options to suit different operating conditions.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The new line of TCAEY compact cooling units is suitable as a cooling source for industrial applications. It's a reliable chilling device for cooling┬Ādifferent kinds of liquids.┬Ā

- Principle of operation: Continuous mode

- Country of origin: EU

The appropriate mixing equipment for drum processing depends upon the properties of the products and with the available drum opening.

- Type of the equipment: Individual machine

- Voltage: 230 V/ 380-400V

The lobe rotary pumps are designed for pumping both liquid and thick products. We offer┬Ālobe pumps in 2 versions with┬Ā1.5 kW is a standard for milk, cream and similar products,┬Āand 3 kW is for dense low-flow products such as honey, pastes, cottage cheese etc.┬Ā

- Engine power, kW: 1,5 / 3

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

The screw elevator is intended for transporting grape marc / bagasse. It also suitable for processing olives. This type of an elevator is great for food production facilities focusing on fruit processing as well as wine and olive oil production. The machine is made in two models with 3000 and 4000 mm length.┬Ā

- Productivity: 2-10 ton/h

- Engine power, kW: 1,5 KW

- Principle of operation: Continuous mode

We offer wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments. Price depends on the chosen option.

- Heating: Gas Steam

- Productivity: 300 l 600 l 1000 l

- Operation mode: Automatic

- Type of the equipment: Individual machine

The device is designed for the pasteurization of a wide range of products in various types of packaging material such as cans and jars.

- Heating: Mixed

- Productivity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

This equipment model is a universal system, which can be used to produce extracts from products like carobs, as well as to boil them under vacuum conditions to obtain a thick syrup through a sequential circulation process.

- One system for all sequential technological processes of pekmez production: from soaking and obtaining an extract, cooling the finished mixture to its boiling phase in a vacuum.

- Boiling under vacuum allows you to preserve all the useful substances contained in the extract: vitamins of group A, B, E, microelements such as calcium, potassium, magnesium, iron and zinc.

- Highly efficient boiling process due to a special direct in the flow heating system installed in the circulation type vacuum evaporation unit

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 36

- Volume: 100l

- Condensing capacity, l/h: 45-55

Device for tipping barrels with products

- A locking hook under the barrel protects and holds the steel barrel

- Safety drawbar with a single-hand operation and 3 functions (lifting/lowering/moving)

- Foot pedal ensures precise lifting

- Optimum operator protection thanks to the extended handle and protective grid

- Material: Steel

- Operation mode: Manual

- Type of the equipment: Individual machine

Industrial vacuum dryers are designed to remove moisture from sensitive or heat-sensitive food, chemical, or pharmaceutical products under reduced pressure, allowing for lower drying temperatures, minimized thermal degradation, and improved energy efficiency. Vacuum dryers like these are used in various industries - food, chemical, pharmaceutical and others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

A 15-liter pasteurizer with a water bath that has a flat bottom and two canning racks, featuring a large capacity and made out of food grade 304 stainless steel.

- Material: Stainless steel

- Principle of operation: Batch mode

The tubular pasteurizer is typically designed for pasteurizing cream in butter production lines. These pasteurizers are commonly used in dairy processing industrial facilities, especially in butter production and other related sectors.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A chiller is a cooling machine that removes heat from a liquid through vapor compression and absorption in a cyclic manner.

- Principle of operation: Continuous mode

- Cooling performance l/h: 100 / 200 l/ 300

- Productivity: 800 psc/h

- Material: Stainless steel

- Operation mode: Semi-automatic

Intense fat melting machines MixMelters are designed for melting frozen, solid blocks of animal and vegetable fat such as butter and margarine as well as to maintain them in a melted state at a given temperature. Working volume up to, l: 200 l.

- Material: Stainless steel

- Heating power, kW: 12/ 24/ 48

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 200 l

A vacuum deaerator is extensively used in the food industry to remove gases from products that may retain some bubbles post-processing. Additionally, a flow deaerator is utilized to minimize foaming in products, ensuring a denser structure, especially prior to packaging. Vacuum deaerators play a crucial role in eliminating specific odors from the products, such as in the production of juices, purees, and herbal drinks. This process significantly contributes to enhancing the overall quality and taste of the final product.

- Enhances product quality, structure, and shape

- Prevents oxidation by removing gases

- Preserves organoleptic properties and extends the shelf life

- Suitable for thick and viscous products

- The flow principle allows for the installation of this equipment in existing production lines

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The device is designed for filling Bags In Boxes. Suitable for filling hot non-viscous products. The device can be purchased separately or with additional options - trolley and magazine.

- Material: Stainless steel

- Operation mode: Automatic

Beverage Pasteurizer SB 750 refers to chamber types of pasteurizers used to pasteurize bottled beverages.

- Material: Stainless steel

- Principle of operation: Batch mode

VBF is a fast, robust, and versatile vacuum bottle filler.┬ĀThis is the filling machine you are looking for if you desire to increase the production volume of your homemade products, and professionalize the bottling of wine, oil, beer, fruit juices, or other products.

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

Running of various production processes such as cutting, mixing, crushing, refining and emulsifying different types of product in a single unit.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 359 kg

- Volume: 150l

The pasteurization equipment MGGP is suitable for the heat treatment of low viscosity foods as well as drinking water.

- Productivity: 500 l

- Material: Stainless steel

- Principle of operation: Continuous mode

A milk pasteurizer is designed for quick and effective pasteurization of milk, where the heating of the product in the working container is achieved by supplying hot water into the jacket.

- Special mixing device

- Large outlet valve at the lowest point of the pasteurizer

- Insulation of the working container to reduce heat loss during pasteurization

- Compact installation

- The control panel is located directly on the unit's body

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 300l

Pasteurizer, cheese boiler is designed for processing milk, yogurt, fruit juice or other liquids.┬Ā

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Volume: 200l/ 300l/ 500l

The manual bottle filler is designed to fill liquids in glass bottles.┬Ā

- Productivity: 650 psc/h

- Material: Stainless steel

- Operation mode: Manual

The fruit mash pump is designed for efficiently transporting mashed fruits from a crusher to a press for extracting juice.

- Productivity: 6000 kg/h

- Material: Stainless steel

- Engine power, kW: 1,85

- Voltage: 380-400V

Semi-automatic dosing machine, designed for filling and capping different spouted pouches with various liquids.

- Material: Stainless steel

- Operation mode: Semi-automatic

4 Heads vacuum bottle filling machine serves as a professional semi-automatic filling and dosing machine for filling glass bottles with various fluids.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

The KWS mixing vessel is engineered for versatile operations, including heating, cooling, and mixing of liquid products, with a maximum heating temperature of 60 ┬░C.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Geometric volume: 100 l

Atmospheric cookers ASC are designed for efficient mixing, heating and cooking products for food and cosmetic industries. Volume, l: 100 l.

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 100l

Atmospheric cookers AC are designed for efficient mixing, heating and cooking products for the food, pharmaceutical and cosmetic industries. Working volume up to, l: 300 l.

- Material: Stainless steel

- Engine power, kW: 1,5 KW

- Heating power, kW: 13,5

- Principle of operation: Batch mode

- Working volume: 300 l

- Geometric volume: 350 l

Our company offers equipment for whipping honey with a new design which includes gravity mixing. The main advantage of the technique is the ability to produce creamy honey in 4 hours! The device is designed for 450 kg of honey per batch.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 300l

Pneumatic capper PTC applies crown caps to beer bottles, cork caps on wine bottles, snap-on caps on other containers in just a matter of seconds.

- Productivity: 400 bottles/ h

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Country of origin: EU

- Weight: 25 kg

This semi-automatic filling machine is used for filling honey as well as other products. We offer many different kinds of filling machines for different applications.

- Material: Stainless steel

- Operation mode: Semi-automatic

We offer different pasteurizers for different applications.

- Heating: Gas

- Productivity: 300 l

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Country of origin: EU

- Voltage: 220-230V

We offer different types of pumps for different processes.

- Engine power, kW: 0,37

- Dimensions, mm: 230x190x120

Centrifugal impeller pumps are ideal for various industrial applications such as food processing, manufacturing, washing and surface treatment of metal pieces, boxes, containers, glass jars and vessels. These pumps are also suitable for dishwashers, bottle washing lines, painting processes, and pumping liquids into various chambers.

- Principle of operation: Continuous mode

Stainless steel low-speed rotary pumps with flexible impeller; particularly suitable for transfer of delicate, fragile and viscous fluids, also with solid parts in suspension.

- Principle of operation: Continuous mode

We offer fruit belt presses for squeezing out juice of various capacities.

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

The pasteurizer equipment MGGP is suitable for the heat treatment of low viscosity liquids as well as drinking water.

- Productivity: 500 l/h/ 800 l/h

- Material: Stainless steel

- Principle of operation: Continuous mode

These storage tanks are intended for fruit and vegetable juice storage and treatment. Price depends on your production process and the product.

For more information, send us a request.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 750 1000l/ 1500l 2000 2600 l/ 3000 4000 l/ 5000 l

The belt press is designed for pressing fruit or vegetable mass. Price depends on your production and product.

- Productivity: 700 kg/h 1500 kg/h/ 3000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

Pneumatic fruit presses are intended for smaller winemakers who want to produce high quality wine. Price depends on your production parameters.

- Material: Stainless steel

- Principle of operation: Continuous mode

For a price quote or for a free consultation, send us a request.

- Productivity: 90l

- Material: Stainless steel

- Heating power, kW: 6/

- Principle of operation: Continuous mode

- Voltage: 380-400V

A range of pneumatic vertical filling machines for dosing liquids with viscosity is similar to water.

- Type of the equipment: Individual machine