EXTRUDERS

Extruders are used for shaping materials by forcing them through a die under pressure

Extruders in modern food processing are used to transform raw materials into a diverse array of forms, shapes, and textures. They utilize the principle of extrusion to produce a wide range of food products, from cereal or protein bars to complex sweets and even meat products like burgers, meatballs or cutlets. This guide explores the mechanisms of extruders, their advantages, and their extensive applications in food processing.

Understanding extruders

Extruders allow to shape various ingredients and mixtures before further processing by forcing them through a die under controlled temperature and pressure conditions. This process, known as extrusion, involves the transformation of raw materials into finished products with distinct shapes and size characteristics. Extruders often utilize a feeding hopper and a twin-screw system to continuously push the product forward.

Advantages of extruders in the food industry

- Versatility in Product Range: Extruders enable the production of a wide variety of food products, including burgers, bars, crisps, chips, and other snacks.

- Texture Customization: Extrusion allows precise control over size and texture, enabling the creation of diverse consistencies while also improving digestibility and bioavailability.

- Efficiency and Continuous Production: Extruders ensure a highly efficient, continuous production process, maintaining consistent product size and minimizing downtime.

Applications in the food industry

Extruders are used in various segments of the food industry:

- Bars: Extruders are used to produce cereal bars and protein bars, ensuring consistent shape and texture.

- Snacks: Used for making crisps, chips, and other snack products with uniform quality.

- Burgers and Cutlets: Extruders shape meat mixtures and plant-based alternatives into consistent forms and shapes.

- Sweets and Confectionery: Used to create various candy mixtures that can later be coated in chocolate or other coverings.

- Pet Food: The pet food industry uses extruders to produce kibble and specialty pet foods that meet nutritional and textural requirements.

- Pasta: Extruders are used in pasta production to ensure uniform shape, texture, and quality.

Partnering with FoodTechProcess for extrusion equipment solutions

FoodTechProcess offers a comprehensive range of extruders designed for different requirements of the food industry. Extruders are used for feeding and shaping various mixtures into products like protein or cereal bars, sweets, extruded chips, and other snacks. They offer a user-friendly interface that allows for the creation of high-quality food products to satisfy the ever-evolving market.

The compact model of the screw press is designed for quickly and efficiently squeezing honey from wax.┬Ā

- Reinforced design

- The press allows you to separate 100% of honey from the wax at a speed of 100 kg/h

- Simple and easy maintenance

- Compact installation on a supporting structure

- Made from food grade stainless steel

- Productivity: 100kg/h

- Principle of operation: Continuous mode

- Country of origin: EU

- Total power, kW: 0,55

- Voltage: 220-230V

- Outlet valve, inches: 5/4

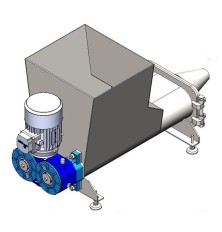

A sturdy extruder machine, with a tank made from AISI 304 stainless steel, ideal for extruding and mixing, and the production of protein bars. For a mini line for making boilie, you can purchase our boilie rolling machine.

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

A twin-screw mixer with a homogenizer is an ideal solution for the production of creamy cheese, such as feta cheese, including with various flavors and seasonings. Thanks to mechanical homogenization, the cheese acquires a delicate structure without changing the individual taste properties of the product. It is used for plasticizing, creaming and softening butter, margarine and other fats.

- Capacity of the receiving hopper 50L

- Compact tabletop design for convenient operator maintenance

- A powerful independent drive for each screw with a reverser

- Easy maintenance and cleaning of the equipment

- Productivity: 250 kg/h/ 1500 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 3,5

- Voltage: 380-400V

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V

Twin-screw extruder is designed for effective extruding, homogenization, pumping over of plastic masses (butter, margarine, honey, curd products, confectionery mixtures), and forming it into bars and rolls.

- Productivity: 400 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Weight: 115 kg