ACCESSORIES

Accessories - additional options that allow you to expand the capabilities of your equipment, and to increase the comfort of operation or maintenance.

As a rule, the device or installation comes with a basic configuration designed to perform a specific food processing equipment function. Accessories - additional options that help to optimize or improve the efficiency of specific aspects of the equipment, whether in small details and technical solutions or in the selection of the degree of automation, additional modules or equipment.

The food processing technology and the equipment itself are based on the functions that must be carried out during production. For processing lines designed for a specific customer, these are almost always customized solutions that are modified and configured based on additional options, in accordance with the recipe requirements, the production capabilities of the workshop, and the desired method of service automation.

Accessories or options also include sets of spare parts and consumables that must be periodically replaced during equipment maintenance to ensure its correct and uninterrupted operation. It is recommended to request a set of spare parts as a mandatory-recommended option when purchasing each installation to avoid potential downtime during operation.

The available variety of accessories always depends on the specific type of equipment. Our company strives to produce modular devices, where by adding an additional option - a module, it expands the equipment's functionality, as is the case with vacuum reactors or conveyor fryers.

The main principle for defining an additional option is its ability to be physically separated from the equipment without compromising or reducing the quality of the function performed by the unit itself.

A separate specific category of accessories is the automation of control and maintenance processes. For certain equipment, at least two options are provided: a semi-automatic control panel or a control panel based on a programmable controller, both of which can have their own additional options - accessories. These also include control and measuring devices, such as level, position, volume, or weight sensors, allowing you to automate processes using a programmable controller.

An independent category comprises of additional equipment designed to reduce the degree of manual labor required by the operator: automated feeding systems in the form of lifts, pumps, attachments, as well as automated cleaning and washing processes for installations.

Thanks to a large number of additional options, the customer can receive a highly individualized configuration - a modification of the equipment model selected and tailored to their specific needs or technical capabilities.

Accessories can be purchased in addition to already acquired equipment to modernize the production process, expand technological processing capabilities, and enhance service safety and control.

Our equipment undergoes regular modernization to meet the increasing demands for efficiency, safety, as well as the introduction of new technologies in the field of food production. We aim to carry out most of the modernization through a range of additional accessories, allowing the customer to choose modifications based on their budget.

Compact and powerful gas stove with 3 rings designed for the connection to standard LPG cylinders. Ideal for heating large volumes of liquid, cooking soups or sauces in cooking kettles, and maintaining meal temperatures during preparation or service. The sturdy, open-frame design ensures excellent stability and high load capacity for everyday use in catering and food processing.

Stainless steel mesh baskets designed for use with our cooking kettles, blanchers, evaporators, fryers and pasteurizers. Ideal for thermal processing, subsequent draining, and unloading of products such as vegetables, fruits, pasta, meat, or jars after cooking, blanching, or pasteurization.

Available in multiple sizes ranging from 30├Ś30 to 40├Ś40 cm.

The sturdy mobile base for large pots, with a diameter ranging from 405 mm to 625 mm, is designed to support and easily transport our 50L, 100L and 150L cooking kettles.

- Made out of stainless steel

- Features casters with brakes on each wheel for secure handling

- Universal model for pots with diameters from 405 to 625 mm

- High load capacity - up to 200 kg

- Material: Stainless steel

- Type of the equipment: Optional equipment

Designed for a load of up to 200 kg!

The 5 kW induction cooker is the best alternative to traditional electric and gas stoves. It reduces energy costs, improves safety, and minimizes air pollution, making it suitable for both stationary kitchens and mobile catering setups. Its compact design also makes it a practical choice for small kitchens where space and efficiency matter.

- 10-step power (500ŌĆō5000 W) or 10-step temperature (60ŌĆō280 ┬░C) control

- Connection - 230 Volt

- Compact dimensions: 410x500x200 mm

- Temperature range from 60 to 280 degrees

- Heating power, kW: 5

- Voltage: 220-230V

Optional module for the 400/1100/12 universal tabletop Modular Fryer - Pressure Conveyor for frying foods that require forced immersion in oil.

- Material: Stainless steel

Steel balls for grinding chocolate are essential components used in ball/bead mills. These 6 mm diameter balls are made out of hardened steel and are considered as consumables required for operating the BALL MILL 5.

- Spherical shape with a diameter of 6 mm

- High hardness steel

- Supplied in 10 kg boxes

- The mill requires 2 boxes (20 kg in total).

- Type of the equipment: Spare parts

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

- Material: Stainless steel

- Type of the equipment: Optional equipment

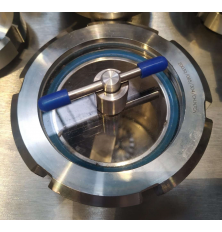

Contact pressure gauge with a Bourdon tube, and a bottom connection.

- Type of the equipment: Optional equipment

Rechargeable and portable, ideal for measuring sugar content in fruit juices and beverages, ergonomic design.

A large three-section basket for vacuum fryers, cooking kettles and other batch processing equipment.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Stainless steel baskets for cooking kettles, autoclaves, pasteurizers.

- Material: Stainless steel

- Principle of operation: Batch mode

Analogue refractometers offer an efficient, accurate, and easy-to-use solution for measuring Brix levels and ensuring product quality in the food industry.

- Type of the equipment: Optional equipment

The expansion tank is an additional component of the heating system circuit, where flow-through electric heating is used as an independent closed system for heating the hot water, serving as a heat transfer medium circulating in the duplicator of food cooking boilers, reactors, pasteurizers, and other food processing equipment. In heating systems with water heaters operating at temperatures up to 110┬░C, the expansion tank is necessary to accommodate the increased volume of the heat transfer medium as it expands when heated.

- Special high-pressure vessel ŌĆō allows to withstand pressure of up to 5 bar in the system.

- Allows the use of a heat generator with superheated water up to 110┬░C.

- Has different volume options, depending on the volume of the heat transfer medium, selected additionally.

- Type of the equipment: Optional equipment

Within seconds, the device measures the refractive index of the sample and converts it to % of solids using the concentration unit.

The refractometer is ready for use after a simple user calibration with deionized or distilled water.

The IBC container insulation cover is designed for use in ice water stations with IBC containers to maintain the cold coolant at a set temperature.

- Allows you to reduce energy costs of the refrigeration machine - chiller

- Protects from short-term fluctuations in ambient temperature, reflects sunlight (up to 97%)

- The cover is easy to install, with valve holes are installed with hook-and-loop fasteners (Velcro)

- Type of the equipment: Optional equipment

Designed for the demanding requirements of the beer and beverage processing industry, this pressure suction food hose offers exceptional safety, durability, and compliance with international food standards. It is ideal for the transportation of high-quality raw, pasteurized, and organic beer, as well as a variety of other beverages, including wine, soft drinks, and alcoholic drinks.

- Type of the equipment: Optional equipment

In the production of condensed milk, a refractometer is used to accurately determine the solids content of the product, which is essential for meeting production standards and ensuring compliance with legal regulations.

- Type of the equipment: Optional equipment

Various installation types are possible: in-line, directly into the product tank or via a bypass connector.

- Type of the equipment: Optional equipment

Industrial refractometers are used to measure the concentration level of liquids in a continuous flow across various industries, applications, and industrial setups. They provide real-time measurement data, ensuring precise process control and maintaining the desired concentration of liquids. This enables industrial automation by eliminating the need for manual sampling and adjustments, allowing for consistent and accurate production.

- Type of the equipment: Optional equipment

A set of additional paddles for transporting and unloading the product from the working area of ŌĆŗŌĆŗthe universal 400/1100/12 fryer.

This rack is typically used as car mat holders at car washes. It can also serve as a universal stand for use in other enterprises.

- Material: Stainless steel

Compact, reliable, and easy to use. The frequency converter ensures smooth starting and stopping of the device's motor, reducing inrush currents, and adjusting the motor speed. It can also be connected to your smartphone via Bluetooth for convenient configuration and parameter adjustment.

Key benefits:

- Precise digital control at the touch of a button.

- Application macros.

- Switch between Industrial, Pump, and Fan modes for optimized operation.

- It is used and mounted directly on the equipment, eliminating the need for electrical cabinets. It can also be wall-mounted.

We also offer programming and installation of the frequency converter to ensure seamless integration and optimal functionality for your equipment.

- Type of the equipment: Optional equipment

Additional option to VMG laboratory vacuum homogenizer 20/50.

- Type of the equipment: Optional equipment

Hygienic linear internal stainless steel drainage system for food production, professional kitchens, pharmaceutical enterprises, restaurants and many others. The drain trap has a stainless steel bath and a connection to the sewer.

- Grate with a frame

- The load class of the grate can withstand being runover with a car

- Fixed height drain

- Built-in grease trap (optional)

- Material: Stainless steel

- Country of origin: Slovakia

A hydraulic crane hoist with a hook is a mechanical device designed to lift and move heavy machinery or engines, commonly used in industrial settings as well as automotive repair for safe and efficient handling of heavy loads.

- Type of the equipment: Optional equipment

The cyclone dust collection system is ideal for food processing facilities looking to prevent contamination by airborne particles, reduce product loss, and maintain a cleaner work environment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

A thermometer is a precision tool used to measure product temperature in food processing, ensuring accurate control during cooking, mixing, and other food production processes. It helps to maintain consistency, optimize processing conditions, and meet safety standards in industrial food processing equipment like cooking kettles, blanchers and fryers.

- Material: Stainless steel

- Type of the equipment: Optional equipment

A hot oil filter for continuous industrial tabletop fryers allows you to quickly and effectively filter oil immediately after the frying process.

- Hot oil filtration - oil temperature up to 200 ┬░C.

- Optional filter material - paper, stainless steel

- Material: Stainless steel

- Country of origin: Slovakia

A frequency converter is an electrical device that adjusts the frequency of an input power source to control the speed and torque of electric motors, commonly used in industrial applications like pumps, fans, and conveyor systems.

- Power: 0.75 kW

- Input Voltage: 1 phase, 230 V, 50/60 Hz

- Rated Output Current: 4.5 A

- Output Frequency: 0 to 999.9 Hz

- Protection Rating: IP65

- Type of the equipment: Optional equipment

- Voltage: 380-400V

The AISI 304 stainless steel oil drain system is suitable for use with most deep fryers. It allows you to filter the oil directly when draining it from the fryer.

- Material: Stainless steel

- Weight: 13,5

The oil-free four-cylinder piston compressor is the ideal solution for those who value both performance and silence.

- Equipped with two twin-piston units with separate engines

- Four air filters

- Mechanical pressure switch

- Quiet operation (at least 25% quieter than traditional compressors)

- Carrying handle and mobile wheel support

- Principle of operation: Continuous mode

- Total power, kW: 1,5

- Voltage: 220-230V

The durable single gas stove serves a versatile purpose, suitable for heating large cooking kettles. 7 kW.

- Heating: Gas

- Heating power, kW: 7

The working surface is made out of food-grade stainless steel, on top of which the deep fryer can be installed. It is quipped with wheels for ease of movement.

- Material: Stainless steel

Additional option to VMG laboratory vacuum homogenizer 20/50.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Additional option for the VMG laboratory vacuum homogenizer 20/50.

- Type of the equipment: Optional equipment

A chiller is a cooling machine that removes heat from a liquid through vapor compression and absorption in a cyclic manner.

- Principle of operation: Continuous mode

- Cooling performance l/h: 100 / 200 l/ 300

Set of 4 height adjustable legs+/- 100 mm.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Supporting structure on wheels with locks (brakes), 2 swivel wheels, 2 swivel wheels with a brake.

- Type of the equipment: Optional equipment

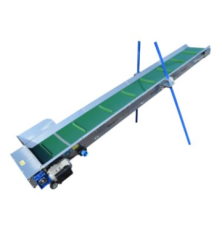

Variable belt conveyor with wide use not only in the food industry. The length of the conveyor can be selected from 2 to 6 m. The width of the belt is 200 and 400 mm.

- Engine power, kW: 0,75

- Principle of operation: Continuous mode

Protective decorative cover for colloid mill 132 (additional option)

- Material: Stainless steel

- Country of origin: Slovakia

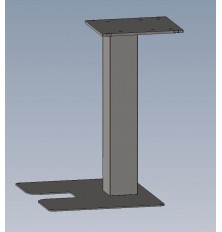

Stand (support structure) for colloid mill machine - additional option for the colloid mill 132

- Type of the equipment: Optional equipment

Thermal insulation of the drying cabinet body to reduce heat loss during product drying. Additional option for the MAK DRYER 7-14.

- Type of the equipment: Optional equipment

The set consists of 20 shelves from AISI304 stainless steel.┬ĀAdditional option for MAK DRYER 7-14.

- Material: Stainless steel

- Type of the equipment: Optional equipment