FILLING MACHINES

Filling machines for precise and efficient dosing of liquids or viscous products

Filling machines in the packaging industry, are used for dosing and filling liquids, powders, or viscous substances into containers with consistent accuracy. They ensure that products are efficiently dosed, filled and sealed to prepare them for distribution. This comprehensive guide explores the realm the types, functionality, and applications of filling machines in various industries.

What are filling and dosing machines

Filling machines, also often referred to as dosing machines, are designed to automate the task of accurately filling bottles, bags or other containers with liquid and semi-liquid products. They are used in a wide range of industries, including food and beverages, pharmaceuticals, cosmetics, and chemicals. Filling systems ensure that the right amount of product is dispensed into each container, ensuring consistency and minimizing waste.

Types of filling machines

- Liquid Filling Machines: These machines are used to fill containers with liquids, such as beverages, oils, and sauces. They employ different methods, such as volumetric or gravimetric filling, to ensure accurate measurements.

- Viscous Filling Machines: These machines handle thick, viscous substances like creams, pastes, and gels, ensuring uniform filling and maintaining the desired thick texture.

- Powder Dosing Machines: Ideal for adding powdered products like spices, flours, and powdered supplements, these machines ensure precise dosing to prevent wastage.

- Volumetric Filling Machines: These machines fill containers based on a specific volume, ensuring accurate and consistent measurements for various liquid products.

- Tensometric Filling Machines: These machines dispense products by weight, offering precise measurements in filling applications, especially for powders and granular substances.

Advantages of dosing and filling equipment

- Accuracy: Filling machines deliver precise quantities of product, reducing the risk of underfilling or overfilling containers.

- Efficiency: Automating the filling process enhances production speed and efficiency, optimizing overall production.

- Consistency: Filling machines ensure uniformity in product volume, appearance, and quality across all batches.

- Hygiene: These machines are designed for easy cleaning and maintenance, meeting the stringent hygiene standards.

Applications across industries

Filling machines find applications in various sectors:

- Food and Beverage: From bottling beverages to packaging sauces, filling machines ensure accurate and efficient packaging results.

- Pharmaceuticals: Filling machines dispense medications into vials, capsules, and syringes with precision to maintain dosage accuracy.

- Cosmetics: The cosmetic industry relies on filling machines for packaging creams, lotions, and serums to maintain product integrity.

- Chemicals: In chemical industries, filling machines handle the accurate dispensing of chemicals into containers, enhancing safety and minimizing spillage.

Partnering with FoodTechProcess for filling equipment solutions

FoodTechProcess offers an array of accurate filling machines designed to for the food and related industries. Our solutions ensure optimal doses of products before packaging or further processing. The filling machines are designed to handle a variety of product viscosities and dosing volumes, ensuring flexibility in production.

The pneumatic piston filler for pastes and liquids is a semi-automatic dispenser designed for dosing various liquids with a low, medium or high viscosity.

- Tabletop compact model

- Includes a built-in 26 l conical storage tank

- A wide dosing range from 300-2500 ml

- Can also be used for products with a high degree of viscosity

- High dosing speed

- Possibility of working in manual or automatic mode

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 300-2500 ml

- Voltage: 220-230V

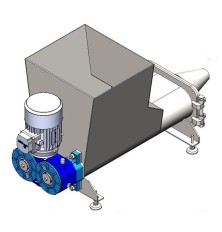

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V

Compact digital filling machine for accurate dosing of viscous liquids such as honey, pastes, sauces, and oils. Designed with food-grade materials, easy-to-clean components, and precise digital control, it is ideal for small production, workshops, and laboratories.

- Operation mode: Semi-automatic

Normit AP tensometric filling machine is a weight-based system for filling honey into barrels.┬Ā

- Material: Stainless steel

- Country of origin: Slovakia

The filling and filtering machine serves as a reliable source for the liquid product supply while also keeping it in a liquid state.

- Productivity: 1000 kg/h/

Designed for accurate feeding and packaging of liquids under pressure.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 80l/

Dosing tank for filling and measuring oil designed as an oil reservoir with the ability to adjust the required volume.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Working volume: 80 l

The honey dosing machine is a precise filling machine with a gear pump, it is easy to use and is suitable for filling honey as well as a large number of other different liquids - ranging from thinner ones such as drinking yogurt, to high-viscosity products such as mustard.

- Fast operation

- Easy to use

- Easy to clean

- Accuracy

- Compact design

- Productivity: 200 l

The Bag in Box Filler is designed for filling hot and cold liquids into Bags in Boxes and for Stand Up Pouch packaging.

- The machine fills the bags up automatically.

- Material: Stainless steel

- Principle of operation: Continuous mode

Filling machine is designed for pumping and filling high viscosity liquids, such as jams, confiture, sauces, dressings, syrups, and like products.

- Productivity: 200ŌĆō600 bottles per hour

- Material: Stainless steel

- Principle of operation: Continuous mode

Vibrating conveyors suitable for arranging the product before further processing.

- Working Area Width: 720 mm

- Voltage: 380-400V

The device is designed for filling Bags In Boxes. Suitable for filling hot non-viscous products. The device can be purchased separately or with additional options - trolley and magazine.

- Material: Stainless steel

- Operation mode: Automatic

Cost-effective system for filling barrels on the basis of a scale for filling the product with a pump.

A simple mobile filler is an economically advantageous solution for filling barrels. We also offer barrel top filler.

- Material: Stainless steel

A filler is a device designed for dosing and pumping honey. It guarantees comfortable and professional honey processing.

- Material: Stainless steel

- Engine power, kW: 0,18

- Voltage: 220-230V

VBF is a fast, robust, and versatile vacuum bottle filler.┬ĀThis is the filling machine you are looking for if you desire to increase the production volume of your homemade products, and professionalize the bottling of wine, oil, beer, fruit juices, or other products.

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

This head capping machine has a magnetic clutch, ribbed spindle. It is semi-automatic and closes bottles or jars with PFP aluminum caps, twist off caps or plastic screws. The price depends on the cap, product you are filling, and capacity.

Price depends on the lid, the product you are filling, and the container.

- Productivity: 400-700 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

TEPF is a pneumatic dispenser for dosing several kind of products. The machine allows the filling of food, chemical, cosmetic, or pharmaceutical products into diverse type of bottles and jars.

Price depends on the product used.

- Material: Stainless steel

- Operation mode: Automatic Manual

- Type of the equipment: Individual machine

Automatic Bag-in-Box filler intended for filling the bag-in-box bags with finished products (both hot and cold) - with a bag volume of 3 to 20 liters.

- Productivity: 180 -240 psc/h

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Voltage: 220-230V

Filling and capping machine designed for the filling and capping of liquid or semi-liquid products into flexible doypack bags with a spout.

- Material: Stainless steel

- Voltage: 220-230V

The manual bottle filler is designed to fill liquids in glass bottles.┬Ā

- Productivity: 650 psc/h

- Material: Stainless steel

- Operation mode: Manual

The piston filler is designed for dosing different types of liquid products in the food, chemical, pharmaceutical and cosmetic industries.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

The piston-operated pneumatic liquid dispenser is a semi-automatic filler used for dispensing various low viscosity liquids ranging from 10 to 100 ml in volume.

- Compact tabletop installation

- Simple control with two operating modes: manual and semi-automatic

- Suitable for liquid products with low viscosity (from water to oil)

- Optional compressed air compressor available

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

- Voltage: 220-230V

Semi-automatic dosing machine, designed for filling and capping different spouted pouches with various liquids.

- Material: Stainless steel

- Operation mode: Semi-automatic

Keg washing and filling machine used for washing and filling kegs and barrels for beer, cider, wine and other beverages.

- Material: Stainless steel

- Engine power, kW: 0,75

- Operation mode: Manual

- Voltage: 220-230V 380-400V

4 Heads vacuum bottle filling machine serves as a professional semi-automatic filling and dosing machine for filling glass bottles with various fluids.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

Semi automatic packaging machine for filling and capping jars.

- Material: Stainless steel

Hydraulic piston fillers for the food processing industry, filling machines for meat and sausages, ideal equipment for meat industry producers and butchers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 20l/ 30l/ 50l

- Material: Stainless steel

- Engine power, kW: 0,18/

- Operation mode: Automatic

- Country of origin: EU

- Voltage: 220-230V

We sell many different filling machines for different products.

- Material: Stainless steel

- Country of origin: EU

We offer different types of meat stuffing machine for domestic and commercial use.

- Weight: 10 / 12

- Dimensions, mm: 630 x220x230 / 820x220/230

A filling machine for stuffing meat to make sausages. We offer many different dosing machines for different applications.

- Material: Stainless steel

- Operation mode: Manual

- Weight: 27/ 28/ 30

- Dimensions, mm: 710x280x390 / 790x280x390 / 820x280x390 /

This semi-automatic filling machine is used for filling honey as well as other products. We offer many different kinds of filling machines for different applications.

- Material: Stainless steel

- Operation mode: Semi-automatic

We offer different types of sausage filling and stuffing machines. This version is a simple tabletop filling device with hydraulic filling.

- Material: Stainless steel

- Engine power, kW: 0,18/

- Country of origin: EU

- Weight: 46

- Volume: 15 l

- Dimensions, mm: 320 x400x1260

Mechanical vacuum filler, regulated by an electronic system, with a frequency converter.

We offer different hopper capacities.

- Material: Stainless steel

- Operation mode: Automatic

- Country of origin: EU

- Volume: 40/ 90/ 125 / 200l

Hydraulic sausage filling machine is the ideal equipment to fill sausage of various specifications and is suitable for filling in different kinds of casings.

We offer different meat processing machines.

- Material: Stainless steel

- Engine power, kW: 0,37

- Weight: 92 / 135

- Voltage: 380-400V

Chocolate fountain attracts the attention of customers thanks to its stylish design, and can be used to top ice cream cones, to fill cups with hot chocolate drinks etc. Price is for the machine only. You can purchase additional mobile counter, covering rings or various nozzles.

- Material: Stainless steel

- Voltage: 220-230V

A range of pneumatic vertical filling machines for dosing liquids with viscosity is similar to water.

- Type of the equipment: Individual machine