CONVEYORS

Conveyors are used for seamless transportation of raw materials and finished goods

Conveyors are essential for the transportation of goods in food processing factories, facilitating the smooth and efficient movement of raw materials and finished products throughout the production line. This comprehensive guide explores the functionality, types, and diverse applications of conveyors, explaining their role in optimizing the workflow of the food production line.

Functionality and types

Conveyors are designed to transport a wide range of materials, from bulk ingredients to packaged or finished goods. They eliminate the need for manual handling, reducing the risk of contamination and improving operational efficiency by reducing inconsistencies in the production process. Different conveyor types cater to specific requirements:

- Belt Conveyors: Utilizing a continuous belt to move items, they are ideal for transporting larger loads and various product shapes.

- Screw Conveyors: Employing a helical screw blade, they are suitable for moving fine, granular materials in confined spaces.

- Feeding Conveyors: Engineered for feeding, these conveyors facilitate a steady and controlled flow of materials, optimizing downstream processes.

- Sorting Conveyors: Specifically designed for sorting, these conveyors enhance efficiency in material handling processes.

- Cooling Conveyors: Tailored for cooling, these conveyors contribute to temperature control in various production stages.

Applications across industries

Conveyors find widespread use across different sectors of the food industry:

- Processing: Efficiently move raw ingredients through various processing stages, ensuring a continuous and controlled workflow.

- Packaging: Transport finished products to packaging stations for accurate and efficient packaging.

- Sorting and Distribution: Facilitate the sorting and distribution of products into different categories and destinations.

- Production Lines: Ensure seamless transfer of products between processing stages, to maintain a consistent production workflow.

Advantages of transportation conveyors

- Efficiency: Conveyors streamline production processes, reducing manual labor and ensuring consistent movement.

- Hygiene: Automated movement minimizes human contact, reducing the risk of contamination.

- Flexibility: Conveyors can be customized to fit specific layouts and adapt to changing production needs.

- Reduced Labor Costs: Automation with conveyors leads to reduced labor requirements and increased productivity.

Strategic conveyor integration to streamline production

As a prominent supplier of food processing equipment, FoodTechProcess offers a comprehensive range of conveyors designed to transport all types of products in the food industry. Our conveyors serve to enhance the production efficiency, maintain high hygiene standards, and offer adaptability, ensuring that your production line runs at peak performance.

The modular cooling conveyor is produced as a standard tabletop version with a section length of 1000 mm; in addition to it, you can order a stainless table or a frame supporting structure. The air cooling conveyor can be sectionally increased in length by the required number of sections.

- Compact, easy to install on any work surface

- Features a fine-grained stainless steel mesh for high temperatures and small-sized products

- Easily combined in line with a tabletop fryer 400/1100/12

- Easy maintenance and cleaning

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

Optional module for the 400/1100/12 universal tabletop Modular Fryer - Pressure Conveyor for frying foods that require forced immersion in oil.

- Material: Stainless steel

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

- Material: Stainless steel

- Type of the equipment: Optional equipment

The conveyor for transferring empty as well as filled bottles and jars. Widely used within packaging lines for various liquids.

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: EU

The incline screw conveyor is used for transporting a wide range of bulk, powdery, fine-grained, and dusty products in food, chemical, construction, or agro-industries.

- Material: Stainless steel

- Engine power, kW: 0,75 1,1/ 1,5 / 2,2

The screw elevator is intended for transporting grape marc / bagasse. It also suitable for processing olives. This type of an elevator is great for food production facilities focusing on fruit processing as well as wine and olive oil production. The machine is made in two models with 3000 and 4000 mm length.┬Ā

- Productivity: 2-10 ton/h

- Engine power, kW: 1,5 KW

- Principle of operation: Continuous mode

The conveyor is made out of strong and highly-resistant stainless steel. It is also additionally reinforced for reliability during operation.

- Material: Stainless steel

- Principle of operation: Continuous mode

The bucket elevator is designed for transporting loose bulk materials, such as grain and seeds in a vertical position. It's an ideal solution for transporting various products for the baking industry as well as animal feed and other granular productions.

- Principle of operation: Continuous mode

The screw conveyor with heating is a device designed for the transportation of material using a screw mechanism, while heat is applied to the product to facilitate easier transfer. This type of conveyor is often used to simplify the transfer of various bulk materials.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A universal conveyor with a PVC belt with horizontal sections, a volumetric storage, adjustable in height and angle of inclination, which can easily be adapted to existing installations for lifting the product to a certain height. The conveyor has its own independent drive, the speed of which can be adjusted using an inverter (optional).

- Lightweight: the supporting structure of the conveyor is made out of aluminum profiles

- Hopper made out of food grade stainless steel

- Bearing frame on wheeled supports with position locks

- High sidewalls made out of stainless steel

- White PVC tape for transporting products with temperatures of up to 80 degrees

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Volume: 50l/

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. The price depends on the product as well as the size of the conveyor.

- Material: Stainless steel

- Engine power, kW: 0,25

- Working Area Width: 300 mm

- Voltage: 380-400V

An air cooling conveyor is used to rapidly cool products in food processing industries by circulating cool air over them as they move along a conveyor belt. This efficient cooling process helps preserve product quality and reduce the time between processing stages, facilitating smoother production workflows.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

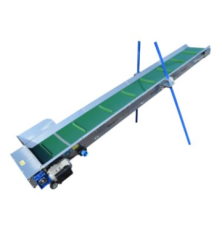

Variable belt conveyor with wide use not only in the food industry. The length of the conveyor can be selected from 2 to 6 m. The width of the belt is 200 and 400 mm.

- Engine power, kW: 0,75

- Principle of operation: Continuous mode

Vibrating conveyors suitable for arranging the product before further processing.

- Working Area Width: 720 mm

- Voltage: 380-400V

Adjustable conveyors made out of stainless steel construction with a large 100 L loading hopper suitable for the food industry.

- Material: Stainless steel

- Engine power, kW: 0,25

- Working Area Width: 300 mm

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Engine power, kW: 0,25

- Weight: 100

The sorting and transporting table or conveyor is suitable for manually sorting and delivering products to the next processing stage.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 530 mm

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product as well as size of the conveyor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

CAC Air cooling conveyors are designed for intensive cooling and removal of excess water or oil (air knife section) from products after frying, cooking or blanching.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Voltage: 380-400V

An air cooling conveyor is a system that uses moving belts and airflow to cool down products as they are transported along the conveyor line.

For additional information or a price quote, send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 500 mm

The inspection conveyor is designed for inspection and manual removal of unsuitable pieces of root vegetables, fruits and berries.┬Ā

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

It is intended for pre-cooling after cooking or frying vegetables and fruit, meat, fish and seafood and other products.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 600 mm

Air cooling conveyor with MULTI AIR KNIFE is a system for┬Ā intensive┬Āremoving excess water or oil and preliminary cooling.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm