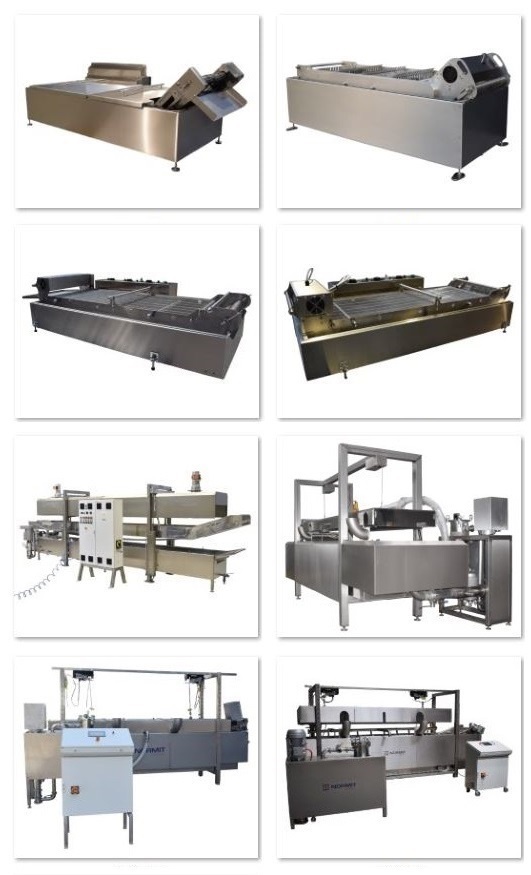

FRYERS

Fryers are used for achieving a consistent and crispy structure of food products fried in oil. Frying machines allow you to achieve the ideal texture, taste and appearance of meat, vegetables, chips, fried snacks and semi-finished goods. This comprehensive guide explores the types of fryers, their functionality, and role in creating the tasty fried snacks people enjoy every day.

a

The process of frying

Frying is a culinary technique that has been perfected over time, resulting in the golden-brown, crispy food products enjoyed worldwide. Fryers are designed to master this technique, ensuring that foods are cooked uniformly and they retain their beneficial characteristics. Fryers are used for products ranging from crispy fries to succulent fried chicken, allowing you to achieve consistent and mouthwatering results.

Key features of a frying machine

- Temperature Control: Fryers maintain precise temperatures, a crucial factor in ensuring even cooking and preventing oil absorption.

- Oil Filtration: Advanced fryers incorporate filtration systems that remove debris, extending oil lifespan and improving food quality.

- Efficiency: Fryers are designed for rapid heat recovery, allowing batches of food to be fried consistently without temperature fluctuations.

- Safety: Many fryers feature safety features such as auto-shutoff and temperature alarms to prevent overheating and accidents.

Types of fryers

- Deep Fryers: Ideal for submerging foods in hot oil, producing crispy exteriors and tender interiors.

- Paddle Fryers: Equipped with paddles to automatically move and turn the foods over, ensuring even frying for light products that float on the surface.

- Vacuum Fryers: Employing the healthiest frying method, these fryers operate under vacuum conditions, preserving the natural color, flavor, and nutritional qualities of the products while also reducing oil absorption.

- Pressure Fryers: Prepare foods under pressure, allowing for faster cooking times and enhanced moisture retention.

- Countertop Fryers: Compact fryers suitable for smaller kitchens or establishments with limited space.

Applications across the food industry

Fryers can be used for a diverse array of applications:

- Fast Food: Iconic dishes like French fries, chicken nuggets, and onion rings, croquettes and other frozen semi-finished snacks.

- Fried Snack Industry: Popular fragile and light-weight snacks like potato chips, tortilla chips, and extruded snacks.

- Canteens and Cafeterias: Large-scale kitchens, including school cafeterias and other communal dining spaces, that require high production capacity.

- Fine Dining: Gourmet establishments use fryers to achieve exquisite coatings on seafood, vegetables, and desserts.

- Healthy Snacks: Vacuum fryers are used to make low-oil snacks like vegetable chips and fruit crisps, preserving their color, flavor, and nutrients thanks to lower frying temperatures.

Partnering with FoodTechProcess for optimal frying results

FoodTechProcess offers a range of fryers, each tailored to the different needs of the food industry, including deep fryers for semi-finished goods, fryers for fragile floating products like chips, and even vacuum fryers for small to medium-sized businesses. Our fryers maintain consistent results, and meet the highest standards of food safety. Collaborate with FoodTechProcess to deliver exceptional fried snacks that satisfy your customers.

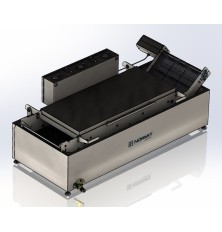

The combination of the compact 400/1100/12 fryer with the secondary upper pressure conveyor, allows you to expand the variety of products that can be fried on it. It ensures uniform, high-quality frying of fresh and semi-finished products in small to medium scale, making it suitable for small-scale production, professional kitchens and street food businesses. The fryer fully submerges the product in oil throughout the whole frying process with the help of the second pressure conveyor that forces the product beneath the oil's surface.

- The maximum height of the fried product is - up to 50 mm

- Immersion thermometer for visual monitoring of the oil temperature

- Frying time can be set from a few seconds up to an hour!

- High temperature ‚Äď up to 200¬įC

- The conveyor belt is made out of a food-grade stainless steel thin mesh

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ‚Äď the double conveyor fryer and the paddle conveyor fryer ‚Äď we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

We offer different types of continuous fryers, let us know which product you wish to fry and we will help you choose the right fryer for your business.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

This industrial deep fryer, with its independent support structure, is designed for batch deep-frying of various products, such as potatoes, vegetables, meat, prepared and semi-finished foods, snacks, and baked goods.

- Even frying: The basket ensures complete and uniform immersion of the products in oil.

- Increased productivity: By swapping baskets, loading and unloading can occur simultaneously, boosting efficiency.

- Fast cooking: Intensive and even heat transfer from the bottom electric sandwich heating ensures rapid and uniform frying.

- Mobility: The unit is easy to move and position as needed.

- Ease of maintenance and cleaning: Designed for simple upkeep and hygiene.

- Heating: Electricity

- Material: Stainless steel

- Volume: 50l/ 100l

- Voltage: 380-400V

This commercial frying pan with mixing and a tilt function is designed for frying, sautéing, searing, and cooking foods in small amounts of oil in large batches. An independent support frame with a tilt mechanism ensures easy unloading. The pan features adjustable heating with 6 intensity levels, making it suitable for professional kitchens and small food production businesses.

- Efficient heat distribution for even cooking.

- High performance for continuous batch processing.

- Rapid heating thanks to bottom electric contact heating.

- Mobile design allows for easy movement across the work area.

- Easy cleaning and maintenance.

The price is set based on the basic built-in heating option of 24 kW.

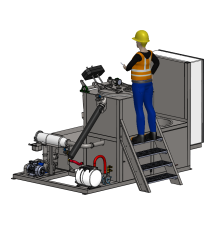

The vacuum fryer is designed for frying foods in oil at low temperatures, allowing for the production of healthy snacks such as vegetable and fruit chips. The vacuum feature enables you to reduce the frying temperature of oil down to 110-120 degrees!

- ¬ęCold roast¬Ľ is a tasty and healthy method of processing the product

- Drying and frying without caramelizing the sugars contained in the product

- Large frying tank - for processing foods with a higher water content

- Modular heating system which allows you to increase the heating power up to 108 kW (optional)

- Circulating heating of oil through a heat exchanger minimizes oil spoilage and prevents localized overheating

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l

- Oil volume: 200l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

USED PRODUCT - 1 LEFT IN STOCK

Continuous deep fryer OIL MINI is designed for gastronomy and catering. It is ideal for deep frying of meat, ravioli, meatballs, seafood, poultry and vegetables. It ensures continuous frying and stable frying results. The heating elements are located in a double thick aluminum bottom, the so-called "sandwich bottom", which prevents the product from sticking to the heating elements and burning, thus you can use the oil many times more!

Basic price - 5960‚ā¨. The possibility of adding an oil spraying / pouring module (combifry), for an additional cost of 3980 ‚ā¨ (RECOMMENDED OPTION)

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The price is set for the combination of a basic fryer model and an additional module with rotating paddles.

The universal modular SnackPro fryer equipped with an additional paddle module is designed for frying thin slices of products that require immersion beneath the oil level.

- Adjustable frying time from a few seconds up to an hour

- Compact, tabletop version

- The paddle conveyor is installed on top of the basic fryer

- Safety thermostats on each heating element

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The compact tabletop paddle fryer can be used for the production of a variety of snacks, including vegetable and fruit chips fried in oil. It is also suitable for frying extruded chips and snacks.

- Innovative design: a compact continuous paddle fryer for professional kitchens

- Intensive three-zone heating using thermal controllers for each heating element

- Specially designed blades along the entire length of the fryer to immerse the product in oil

- Frying time can be set from a few seconds up to an hour

- Product agitation system during loading for product separation

- Thermal insulation of the working body to reduce heat loss and for safer operation

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Voltage: 380-400V

Optional module for the 400/1100/12 universal tabletop Modular Fryer - Pressure Conveyor for frying foods that require forced immersion in oil.

- Material: Stainless steel

The automatic donut forming and frying machine is a high-quality device that is suitable for high productivity and daily usage.

- Tabletop system

- Includes a depositing attachment

- Compact design

- Completely out of stainless steel

- Material: Stainless steel

- Principle of operation: Continuous mode

- Weight: 40

- Total power, kW: 3

- Voltage: 220-230V

- Dimensions, mm: 965 x 330 x 650

For frying foods in oil, deep-frying, suitable for frying onions, seeds, nuts, vegetable snacks and chips, and other products, including breaded or covered in liaison. Can also be used as an oil separating centrifuge for deep fryer.

- Two in one: a deep fryer and a centrifuge to remove excess oil

- Possibility of frying small and fragile products

- Obtaining a ‚Äúdry product‚ÄĚ after frying

- Low carbonization of oil due to the cleaning feature after frying

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l/ 90l

- Total power, kW: 11

- Voltage: 380-400V

The digitally controlled continuous conveyor system ensures the frying of a wide range of products at a consistent level. Thanks to the possibilities of deep frying, this model is suitable for a wide range of products from spring rolls, onion bhajis and falafel to fish fingers, burgers and chicken nuggets. The fryer is available in widths of 200, 300, 400 and 600 mm.

- Material: Stainless steel

- Voltage: 380-400V

An adjustable electric donut fryer with a continuous conveyor system is specially designed for small confectionery shops, pastry production and catering establishments. It is capable of frying a variety of products similar to donuts.

- Material: Stainless steel

- Heating power, kW: 12

- Country of origin: Slovakia

Multifunctional pans function as a frying, cooking, and mixing device in one installation.

- Material: Stainless steel

- Principle of operation: Batch mode

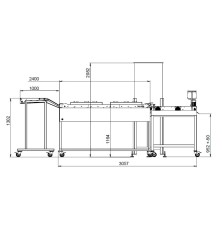

The extended version of the modular conveyor fryer with a large number of optional accessories, significantly expands the production capacity for deep-frying various products by increasing both the frying area and heating power.

- Frying time can be adjusted from several minutes up to an hour!

- Overheating safety sensors are installed on each heating element

- Compact support structure on a mobile support

- Fine-mesh conveyor grid allows for frying small and fragile products

- A large number of additional options in the form of automatic oil top-up system, loading conveyor, filtration system, cooling conveyor, etc.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

Production line for vegetarian vegetable-based formed or molded products such as falafel. The line is based on the classical method of producing semi-finished products for their subsequent freezing and packaging.

- Compact line suitable for both professional kitchens and industrial production.

- Fully automatic operation with minimal manual labor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

This continuous conveyor deep fryer is a reliable and versatile solution suitable for high-performance frying of a wide range of products by immersing them in hot oil.

- Universal application

- Quick transition for frying new types of products

- Possibility of using special frying modes

- Minimal amount of oil in the system

- Trouble-free oil filtration

- High oil exchange ratio

- High efficiency and productivity with compact design

- Manufactured to the highest quality standards using materials and components made in Europe.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

- Material: Stainless steel

- Type of the equipment: Optional equipment

The continuous production line for deep-frying and the subsequent cooling of semi-finished products includes:

- modular deep fryer with the option of choosing the conveyor type: a secondary conveyor for forced immersion of the product in oil or a conveyor with paddles for frying light floating products, such as chips;

- stainless steel table under the deep fryer with the option of installing an oil container and an oil filtration system inside it;

- cooling conveyor for removing excess oil and surface cooling of the product after frying it in the deep fryer.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

The working surface is made out of food-grade stainless steel, on top of which the deep fryer can be installed. It is quipped with wheels for ease of movement.

- Material: Stainless steel

EcoFry is designed for frying onion rings, seafood, dumplings, spring rolls, pies, vegetables, nuggets and hamburgers with the help of pouring hot oil. A smaller capacity, efficient frying equipment intended for small to medium sized production facilities.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 36

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The series of Continuous Fryers Pour Oil is the boom in the market of frying and roasting equipment. The new construction designed by our engineers, based on existing practical experience in the production and use of conveyor fryers, provides the best example of environmental friendliness.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The continuous pouring fryer is designed to fry meat, fish, vegetables and pasta products as well as chicken drumsticks, cutlets, nuggets, croutons, sliced zucchini or eggplant, and etc. using immersion frying and hot oil pouring methods.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Our continuous fryer is designed for frying cutlets, potatoes, meatballs, croquettes, fish, vegetables and many other products. Working volume up to l: 300 l.

- Material: Stainless steel

- Heating power, kW: 40

- Principle of operation: Continuous mode

- Oil volume: 300 l

- Voltage: 380-400V

A pouring fryer is a specialized equipment used in commercial kitchens for frying foods using a continuous pouring method which helps to close down the pores of the product to prevent excessive oil absorption. It offers precise control over the frying process by continuously pouring oil over the food, ensuring even cooking and consistent results.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

A vacuum frying unit designed for frying vegetables and other snacks at low temperatures, thus making them healthier and less saturated with oil.

- Productivity: 160 kg/15 min

- Material: Stainless steel

- Heating power, kW: 90/ 110/ 180

- Country of origin: Slovakia

Automatic donut fryers are extremely efficient machines designed for easier production of doughnuts.

- Material: Stainless steel

- Operation mode: Automatic

- Type of the equipment: Individual machine

We can help you choose the right continuous fryer suited for your needs.

- Productivity: nuts 400 kg/h

- Material: Stainless steel

- Heating power, kW: 30/ 60

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Country of origin: EU

- Weight: 245 kg

- Working Area Width: 250 mm

- Oil volume: 100 l

We sell different types of deep fryers, for a price quote or for a free consultation, please contact us by sending a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

- Voltage: 380-400V

We have various types of continuous or batch fryers. Just tell us what kind of product you wish to fry and we will help you choose the right deep fryer.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Our continuous fryer is ideally used for frying escalopes, potatoes, croquettes and many other products.

- Material: Stainless steel

- Heating power, kW: 72

- Principle of operation: Continuous mode

- Working Area Width: 420 mm

Semi-automatic donut fryers are extremely efficient machines designed for easier donut production.

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

The VFB vacuum fryer with a built-in blancher is intended for drying and frying a wide range of products as well as for the production of chips and crisps from potatoes, carrots, onions, celery, parsley, beetroot and many other types of fruits, vegetables, and different snacks made out of meat, pork skin and fish.

- Material: Stainless steel

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l