GRAIN

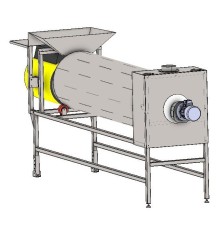

The rotary drum cooler is designed for efficient pre-cooling, stopping the cooking process, and cooling of boiled, blanched, fried, baked, or thermally processed foods. The rotating perforated drum ensures uniform cooling together with the additional water supply.

- Uniform cooling

- Adjustable drum speed

- Made entirely out of stainless steel

- Suitable for a wide range of food products

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 1,1

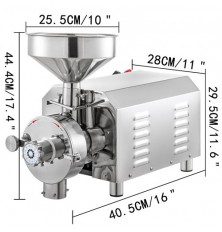

This is a highly efficient equipment designed for fine grinding and homogenization of solid products. Thanks to its unique design and high speed, the mill provides fine mixing and crushing of particles, which makes it indispensable in a variety of industries.

- Compact design - tabletop installation

- Possibility of using different feeder models

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Voltage: 220-230V

Convective rotary drum dryers are used for drying granular, loose and bulk materials. They can be used for drying salt, coffee, various granules, powders, grain, nuts, seeds, fruit/vegetable bagasse, and many other products. When used in other industries, the dryer allows for the drying of salt, sand, expanded clay granules, and other similar non-flammable substances. For more information, send us a request.

The drum dryer can be configured to operate with either electric heating or gas heating (which can offer a lot more power), depending on your specific requirements and preferences.

Warning: It is not recommended to use the gas heating option for drying substances that are highly flammable, as doing so could pose a significant fire risk.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The nut grinding machine is used for processing sesame seeds to produce a tahini or a sesame paste.

- Material: Stainless steel

- Country of origin: Slovakia

The continuous rotary mixer is a professional solution for mixing, stirring powder and bulk materials.

- Allows precise dosing of components during continuous mixing

- Low energy consumption with high processing volumes

- Made entirely out of stainless steel

- Adjustable working drum tilt

- Special blades for mixing bulk and fragile materials

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

This powder making machine is made out of stainless steel. All parts that are in contact with food are made out of food grade 304 stainless steel for health and safety reasons.

- Material: Stainless steel

- Engine power, kW: 2,2

The price is set for the model with an area of 7 m┬▓

Compact condensate dryer, heat pump powered dehydrator for drying vegetables, fruits, berries, mushrooms, legumes and grains.

- Energy saving, low consumption model (consumption up to 0.9 kW/h)

- Possibility of increasing the drying area in this model up to 14 m┬▓ (optional)

- Intensive drying, each section is equipped with a heat pump

- Automatic drying system control

- Delicate drying at low temperatures

- Preservation of most nutrients and the products natural color

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 0,9

- Voltage: 220-230V

- Area, m┬▓: 7

- Number of shelves: 22

This compact nuts and seeds roaster is ideal for efficiently and evenly processing nuts and seeds to perfection.

- Productivity: 5-15 kg

- Material: Stainless steel

- Principle of operation: Batch mode

The incline screw conveyor is used for transporting a wide range of bulk, powdery, fine-grained, and dusty products in food, chemical, construction, or agro-industries.

- Material: Stainless steel

- Engine power, kW: 0,75 1,1/ 1,5 / 2,2

The big bag discharge station is designed for the efficient handling of bulk products stored in big bags up to 1500 kg. The machine is a perfect solution for the food, chemical, pharmaceutical, and construction industries. This type of equipment is suitable for a wide range of bulk products from seeds, cocoa, beans up to construction materials such as dry gypsum, cement, etc.

Device for tipping barrels with products

- A locking hook under the barrel protects and holds the steel barrel

- Safety drawbar with a single-hand operation and 3 functions (lifting/lowering/moving)

- Foot pedal ensures precise lifting

- Optimum operator protection thanks to the extended handle and protective grid

- Material: Steel

- Operation mode: Manual

- Type of the equipment: Individual machine

The cyclone dust collection system is ideal for food processing facilities looking to prevent contamination by airborne particles, reduce product loss, and maintain a cleaner work environment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

Used for blanching products in water, it is suitable for processing various vegetables, legumes, grains, mushrooms and other products. This versatile machine also functions as a water separator centrifuge which is activated after the blanching processes.

- Productivity: 30l/ 90l

- Material: Stainless steel

A grain mill made out of stainless steel, it is sturdy and durable grinder, with increased wear resistance.

- Material: Stainless steel

- Engine power, kW: 3

The bucket elevator is designed for transporting loose bulk materials, such as grain and seeds in a vertical position. It's an ideal solution for transporting various products for the baking industry as well as animal feed and other granular productions.

- Principle of operation: Continuous mode

The screw conveyor with heating is a device designed for the transportation of material using a screw mechanism, while heat is applied to the product to facilitate easier transfer. This type of conveyor is often used to simplify the transfer of various bulk materials.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A universal conveyor with a PVC belt with horizontal sections, a volumetric storage, adjustable in height and angle of inclination, which can easily be adapted to existing installations for lifting the product to a certain height. The conveyor has its own independent drive, the speed of which can be adjusted using an inverter (optional).

- Lightweight: the supporting structure of the conveyor is made out of aluminum profiles

- Hopper made out of food grade stainless steel

- Bearing frame on wheeled supports with position locks

- High sidewalls made out of stainless steel

- White PVC tape for transporting products with temperatures of up to 80 degrees

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Volume: 50l/

We offer different types of dryers for different products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Type of the equipment: Individual machine

- Country of origin: Slovakia

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. The price depends on the product as well as the size of the conveyor.

- Material: Stainless steel

- Engine power, kW: 0,25

- Working Area Width: 300 mm

- Voltage: 380-400V

The price is indicated without the frequency converter

A twin-screw mixer for fast and intensive mixing, stirring of bulk solid products, such as granules, muesli with various powder additives.

- The mixing blades carefully move while thoroughly mixing the product

- The mixing mode allows you to move the product cyclically in a circle

- High mixing efficiency due to the counter-movement of the 2 shafts

- Compact design

- Possibility to install scrapers on each blade (optional)

- Reinforced drive, can be used for products saturated with moisture as well

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 500l

- Total power, kW: 3

Lowering the temperature and humidity protects the product even without chemical treatment. The device is also used for continuous air cooling after heat treatment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The cyclone filter effectively separates particles and contaminants from air or gas streams, ensuring product quality and maintaining equipment efficiency, particularly important in the food industry.

- Material: Stainless steel

- Volume: 150l

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Engine power, kW: 0,25

- Weight: 100

The sorting and transporting table or conveyor is suitable for manually sorting and delivering products to the next processing stage.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 530 mm

Wheat washer, huller and separator is used for the preparation of grain for milling. Price depends on your production capacity.

- Productivity: 1500 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product as well as size of the conveyor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

We offer different types of dryers for different products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Country of origin: Slovakia

- Weight: 255 kg

- Volume: 500l

- Voltage: 380-400V

- Geometric volume: 170 l

- Dimensions, mm: 2350 x1500 x2000

We offer different capacity multi belt dryers and roasting ovens.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

We offer different capacity infrared dryers.

- Productivity: 250 kg/h/ 1000 kg/h/ 1500 kg/h/ 2000 kg/h / 3000 kg/h / 6000 kg/h

This multi layer belt dryer with integrated cooling system works as a dryer and cooler in one installation.

- Material: Stainless steel

- Principle of operation: Continuous mode

It is possible to order tubs with four perforated walls and bottom, with or without outlet drain or with a tap.

- Material: Stainless steel

- Volume: 120l 200l/ 300l