SPICES

A rotating drum unit designed for continuous coating and seasoning operations as well as product saturation with spices and flavor additives, utilized in production lines for chips, snacks, and various semi-finished products.

- Adjustment of the Drum Tilt Angle

- Hygienic design and execution: mirror-polished inner surface of the drum

- Various blade options for gently turning the product (optional)

- Dispensers for dry and wet flavorings (optional)

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 0,25

- Voltage: 380-400V

This is a highly efficient equipment designed for fine grinding and homogenization of solid products. Thanks to its unique design and high speed, the mill provides fine mixing and crushing of particles, which makes it indispensable in a variety of industries.

- Compact design - tabletop installation

- Possibility of using different feeder models

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Voltage: 220-230V

The laboratory vacuum cutter mixer is designed for uniform grinding, emulsifying and mixing of food, cosmetic and pharmaceutical products, chemical mixtures with the addition of oil, dyes, concentrates or liquid flavors.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The knife mill is used for grinding products such as sugar, pepper, dry leaves and other products that are used during the production of spices and sauces.

- Adjustable grinding size

- Easy maintenance

- Support structure

- Large capacity hopper

- Material: Stainless steel

- Engine power, kW: 5,5

- Principle of operation: Continuous mode

- Voltage: 380-400V

- Hopper volume, l: 30

The salting machine is designed for the continuous feeding and dispensing of salt or seasoning onto food products, it is recommended to install it above a conveyor belt.

- Simple controls

- Spacious hopper - up to 25 kg

- Simple and easy installation

- Height-adjustable salting machine supports

- Built-in control panel for adjusting the speed and volume of salt supplied

- Material: Stainless steel

- Engine power, kW: 0,55

- Working Area Width: 500 mm

- Voltage: 220-230V

The nut grinding machine is used for processing sesame seeds to produce a tahini or a sesame paste.

- Material: Stainless steel

- Country of origin: Slovakia

The continuous rotary mixer is a professional solution for mixing, stirring powder and bulk materials.

- Allows precise dosing of components during continuous mixing

- Low energy consumption with high processing volumes

- Made entirely out of stainless steel

- Adjustable working drum tilt

- Special blades for mixing bulk and fragile materials

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

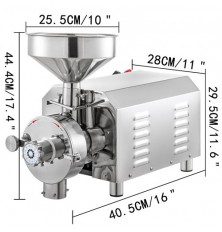

This powder making machine is made out of stainless steel. All parts that are in contact with food are made out of food grade 304 stainless steel for health and safety reasons.

- Material: Stainless steel

- Engine power, kW: 2,2

The incline screw conveyor is used for transporting a wide range of bulk, powdery, fine-grained, and dusty products in food, chemical, construction, or agro-industries.

- Material: Stainless steel

- Engine power, kW: 0,75 1,1/ 1,5 / 2,2

The big bag discharge station is designed for the efficient handling of bulk products stored in big bags up to 1500 kg. The machine is a perfect solution for the food, chemical, pharmaceutical, and construction industries. This type of equipment is suitable for a wide range of bulk products from seeds, cocoa, beans up to construction materials such as dry gypsum, cement, etc.

The cyclone dust collection system is ideal for food processing facilities looking to prevent contamination by airborne particles, reduce product loss, and maintain a cleaner work environment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

A grain mill made out of stainless steel, it is sturdy and durable grinder, with increased wear resistance.

- Material: Stainless steel

- Engine power, kW: 3

The bucket elevator is designed for transporting loose bulk materials, such as grain and seeds in a vertical position. It's an ideal solution for transporting various products for the baking industry as well as animal feed and other granular productions.

- Principle of operation: Continuous mode

We offer different types of dryers for different products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The price is indicated without the frequency converter

A twin-screw mixer for fast and intensive mixing, stirring of bulk solid products, such as granules, muesli with various powder additives.

- The mixing blades carefully move while thoroughly mixing the product

- The mixing mode allows you to move the product cyclically in a circle

- High mixing efficiency due to the counter-movement of the 2 shafts

- Compact design

- Possibility to install scrapers on each blade (optional)

- Reinforced drive, can be used for products saturated with moisture as well

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 500l

- Total power, kW: 3

The Y-shaped food mixer contains a double vessel with a 90┬░ apex angle. This mixing system is designed for mixing, pre-mixing liquid, viscous, dry and bulk components to obtain homogeneous mixtures.

- Special shape designed for fragile products that may break when exposed to centrifugal force

- Effective mixing of products with different components to obtain a homogeneous structure quickly and with minimal energy consumption

- Gentle mixing and tumbling due to complex random trajectories of product movement

- Compact installation

- Easy maintenance and high level of safety - safety bar with a position sensor

- Material: Stainless steel

- Engine power, kW: 0,75

- Volume: 150l

Paddle Mixer type is designed for fast and precise mixing for meat-mass production in meat processing factories. Can also be used for mixing products such as spices or tea.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 90/ 150l/ 200l/ 300l/ 400l/ 600l/ 850/ 2000 3000

Vacuum paddle mixers are designed for fast and precise mixing meat-mass in a vacuum. Used in meat production in meat processing factories.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l/ 200l/ 300l/ 400l/ 600l/ 850/ 3000