NUTS, SEEDS

The combination of the compact 400/1100/12 fryer with the secondary upper pressure conveyor, allows you to expand the variety of products that can be fried on it. It ensures uniform, high-quality frying of fresh and semi-finished products in small to medium scale, making it suitable for small-scale production, professional kitchens and street food businesses. The fryer fully submerges the product in oil throughout the whole frying process with the help of the second pressure conveyor that forces the product beneath the oil's surface.

- The maximum height of the fried product is - up to 50 mm

- Immersion thermometer for visual monitoring of the oil temperature

- Frying time can be set from a few seconds up to an hour!

- High temperature ŌĆō up to 200┬░C

- The conveyor belt is made out of a food-grade stainless steel thin mesh

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ŌĆō the double conveyor fryer and the paddle conveyor fryer ŌĆō we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

We offer different types of continuous fryers, let us know which product you wish to fry and we will help you choose the right fryer for your business.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

A rotating drum unit designed for continuous coating and seasoning operations as well as product saturation with spices and flavor additives, utilized in production lines for chips, snacks, and various semi-finished products.

- Adjustment of the Drum Tilt Angle

- Hygienic design and execution: mirror-polished inner surface of the drum

- Various blade options for gently turning the product (optional)

- Dispensers for dry and wet flavorings (optional)

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 0,25

- Voltage: 380-400V

USED PRODUCT - 1 LEFT IN STOCK

Continuous deep fryer OIL MINI is designed for gastronomy and catering. It is ideal for deep frying of meat, ravioli, meatballs, seafood, poultry and vegetables. It ensures continuous frying and stable frying results. The heating elements are located in a double thick aluminum bottom, the so-called "sandwich bottom", which prevents the product from sticking to the heating elements and burning, thus you can use the oil many times more!

Basic price - 5960Ōé¼. The possibility of adding an oil spraying / pouring module (combifry), for an additional cost of 3980 Ōé¼ (RECOMMENDED OPTION)

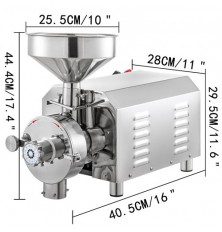

The knife mill is used for grinding products such as sugar, pepper, dry leaves and other products that are used during the production of spices and sauces.

- Adjustable grinding size

- Easy maintenance

- Support structure

- Large capacity hopper

- Material: Stainless steel

- Engine power, kW: 5,5

- Principle of operation: Continuous mode

- Voltage: 380-400V

- Hopper volume, l: 30

The periodic drum coating/seasoning machine is designed to saturate and infuse a diverse range of products with flavorful aromas, vitamins, and various taste additives. It is utilized in the production of snacks, chips, cereals, and nuts, offering a wide array of flavor enhancements.

- Mechanical system for tilting the working bowl with fixation points in intermediate positions

- Special perforated blades for gentle product turning

- Powerful drum rotation drive

- Entirely made out of food grade stainless steel AISI304

- Easy control via an inverter (optional): speed control and reverse

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 0,55

Convective rotary drum dryers are used for drying granular, loose and bulk materials. They can be used for drying salt, coffee, various granules, powders, grain, nuts, seeds, fruit/vegetable bagasse, and many other products. When used in other industries, the dryer allows for the drying of salt, sand, expanded clay granules, and other similar non-flammable substances. For more information, send us a request.

The drum dryer can be configured to operate with either electric heating or gas heating (which can offer a lot more power), depending on your specific requirements and preferences.

Warning: It is not recommended to use the gas heating option for drying substances that are highly flammable, as doing so could pose a significant fire risk.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

This industrial hybrid drying cabinet combines two drying principles: heat pump (condensation) and convection (forced circulation of heated air). This dryer is designed for fast, efficient, energy-saving, and "cold" drying of vegetables, fruits, berries, mushrooms, legumes, herbs, meat, fish, and even liquid or semi-liquid products by replacing the shelves with standard GN 2/1 containers. The size of one shelf is 530 x 650 mm.

- Dual technology: condensation drying + hot air convection

- Energy-efficient with optimized consumption (approx. 0.9ŌĆō1.3 kWh depending on mode)

- Drying area expandable up to 14 m┬▓ (optional)

- Uniform drying thanks to forced air flow and controlled moisture removal

- Gentle operation at low temperatures for maximum preservation of nutrients and color

The price is set for the basic version, without additional options.

The industrial infrared dryer is suitable for drying a wide range of products: nuts, apples, plums, strawberries, raspberries, blueberries, mushrooms, carrots, onions, garlic, herbs, meat, figs, bananas, marshmallows. If additional options are selected, it can also be used for curing and drying whole meat and fish.

- Compact installation

- Fast and efficient drying

- Possibility of selecting individual settings for drying

- Made entirely out of stainless steel

- The interior surface of the cabinet has a mirror coating

- Quiet operation of the installation

- Low energy consumption per drying cycle

- Heating: Electricity

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 7l/ 10l/ 14l

- Total power, kW: 10/ 15/ 20

- Area, m┬▓: 3,5/ 5,2/ 6,9

- Number of shelves: 10/ 15/ 20

The modular cooling conveyor is produced as a standard tabletop version with a section length of 1000 mm; in addition to it, you can order a stainless table or a frame supporting structure. The air cooling conveyor can be sectionally increased in length by the required number of sections.

- Compact, easy to install on any work surface

- Features a fine-grained stainless steel mesh for high temperatures and small-sized products

- Easily combined in line with a tabletop fryer 400/1100/12

- Easy maintenance and cleaning

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

- Material: Stainless steel

- Type of the equipment: Optional equipment

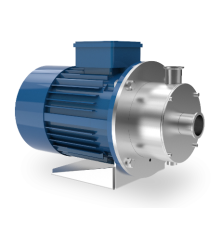

The nut grinding machine is used for processing sesame seeds to produce a tahini or a sesame paste.

- Material: Stainless steel

- Country of origin: Slovakia

Atmospheric food processing and cutting machine with a stainless steel design and a 60 L bowl with a cutter (grinding knife)

- Material: Stainless steel

- Engine power, kW: 9,2

- Principle of operation: Batch mode

This continuous conveyor deep fryer is a reliable and versatile solution suitable for high-performance frying of a wide range of products by immersing them in hot oil.

- Universal application

- Quick transition for frying new types of products

- Possibility of using special frying modes

- Minimal amount of oil in the system

- Trouble-free oil filtration

- High oil exchange ratio

- High efficiency and productivity with compact design

- Manufactured to the highest quality standards using materials and components made in Europe.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

The continuous rotary mixer is a professional solution for mixing, stirring powder and bulk materials.

- Allows precise dosing of components during continuous mixing

- Low energy consumption with high processing volumes

- Made entirely out of stainless steel

- Adjustable working drum tilt

- Special blades for mixing bulk and fragile materials

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

This powder making machine is made out of stainless steel. All parts that are in contact with food are made out of food grade 304 stainless steel for health and safety reasons.

- Material: Stainless steel

- Engine power, kW: 2,2

The price is set for the model with an area of 7 m┬▓

Compact condensate dryer, heat pump powered dehydrator for drying vegetables, fruits, berries, mushrooms, legumes and grains.

- Energy saving, low consumption model (consumption up to 0.9 kW/h)

- Possibility of increasing the drying area in this model up to 14 m┬▓ (optional)

- Intensive drying, each section is equipped with a heat pump

- Automatic drying system control

- Delicate drying at low temperatures

- Preservation of most nutrients and the products natural color

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 0,9

- Voltage: 220-230V

- Area, m┬▓: 7

- Number of shelves: 22

We offer new compact continuous infrared oven that is designed for backing different variants of products such as falafel, meat and vegetable balls, chicken wings, nuts, pizza, baguettes, toasts, croutons and many other snacks.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Length: 340 mm

- Working Area Width: 300 mm

- Voltage: 380-400V

This compact nuts and seeds roaster is ideal for efficiently and evenly processing nuts and seeds to perfection.

- Productivity: 5-15 kg

- Material: Stainless steel

- Principle of operation: Batch mode

The incline screw conveyor is used for transporting a wide range of bulk, powdery, fine-grained, and dusty products in food, chemical, construction, or agro-industries.

- Material: Stainless steel

- Engine power, kW: 0,75 1,1/ 1,5 / 2,2

The big bag discharge station is designed for the efficient handling of bulk products stored in big bags up to 1500 kg. The machine is a perfect solution for the food, chemical, pharmaceutical, and construction industries. This type of equipment is suitable for a wide range of bulk products from seeds, cocoa, beans up to construction materials such as dry gypsum, cement, etc.

We offer professional infrared dryers from 8 to 56 trays with a capacity of 200 to 3000 kg/day for vegetables, fruits, tea, herbs, mushrooms, medicinal herbs and other products. The dryers of this type is a turnkey solution based on two technologies - direct infrared and air convection drying.

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

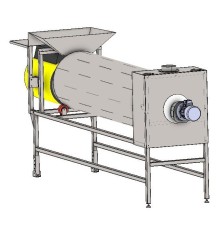

The pistachio paste mill is a colloid type mill. Its operating principle is based on grinding nut kernels between a rotor and stator to achieve colloid-sized particles.

Pistachio paste obtained using this type of mill has a uniform fine texture, natural taste and aroma.

Advantages:

- Easy to operate

- High productivity

- Compact size

- Flexible adjustment settings

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

Device for tipping barrels with products

- A locking hook under the barrel protects and holds the steel barrel

- Safety drawbar with a single-hand operation and 3 functions (lifting/lowering/moving)

- Foot pedal ensures precise lifting

- Optimum operator protection thanks to the extended handle and protective grid

- Material: Steel

- Operation mode: Manual

- Type of the equipment: Individual machine

A drying chamber for vegetables and fruits is a specialized enclosure designed to gently remove moisture from produce, preserving its natural flavors and nutrients while extending its shelf life.

- Type of the equipment: Individual machine

- Weight: 215

- Area, m┬▓: 14

- Number of shelves: 40

Used for blanching products in water, it is suitable for processing various vegetables, legumes, grains, mushrooms and other products. This versatile machine also functions as a water separator centrifuge which is activated after the blanching processes.

- Productivity: 30l/ 90l

- Material: Stainless steel

A grain mill made out of stainless steel, it is sturdy and durable grinder, with increased wear resistance.

- Material: Stainless steel

- Engine power, kW: 3

The conveyor is made out of strong and highly-resistant stainless steel. It is also additionally reinforced for reliability during operation.

- Material: Stainless steel

- Principle of operation: Continuous mode

This 9L cutter is a robust and reliable device used for processing various foods.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 9

- Voltage: 220-230V

The bucket elevator is designed for transporting loose bulk materials, such as grain and seeds in a vertical position. It's an ideal solution for transporting various products for the baking industry as well as animal feed and other granular productions.

- Principle of operation: Continuous mode

The screw conveyor with heating is a device designed for the transportation of material using a screw mechanism, while heat is applied to the product to facilitate easier transfer. This type of conveyor is often used to simplify the transfer of various bulk materials.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A universal conveyor with a PVC belt with horizontal sections, a volumetric storage, adjustable in height and angle of inclination, which can easily be adapted to existing installations for lifting the product to a certain height. The conveyor has its own independent drive, the speed of which can be adjusted using an inverter (optional).

- Lightweight: the supporting structure of the conveyor is made out of aluminum profiles

- Hopper made out of food grade stainless steel

- Bearing frame on wheeled supports with position locks

- High sidewalls made out of stainless steel

- White PVC tape for transporting products with temperatures of up to 80 degrees

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Volume: 50l/

We offer different types of dryers for different products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Type of the equipment: Individual machine

- Country of origin: Slovakia

EcoFry is designed for frying onion rings, seafood, dumplings, spring rolls, pies, vegetables, nuggets and hamburgers with the help of pouring hot oil. A smaller capacity, efficient frying equipment intended for small to medium sized┬Āproduction facilities.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 36

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Protective decorative cover for colloid mill 132 (additional option)

- Material: Stainless steel

- Country of origin: Slovakia

Lowering the temperature and humidity protects the product even without chemical treatment. The device is also used for continuous air cooling after heat treatment.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

This air cooler and heater is multifunctional. It can be used as air cooler, heater. The compact and lightweight air cooler / heater contains. 4 caster wheels make it easy to move the unit.

A vacuum diffuser is a device used in the food industry to remove oxygen from a product under vacuum conditions, primarily employed for enhancing the preservation of food by reducing oxidation and extending shelf life.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 200l/ 1000l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Vacuum coater is ideal for the application of salt and sugar solutions, enzyme, vitamin and anti-oxidants on water or oily basis as it ensures even distribution of small amounts of additives between the total product volume.

The price depends on the production capacity as well as the product being processed.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Max vacuum: -0,8 Bar

Vacuum diffusion - the process in which the air inside the product is removed by vacuum and the released pores are filled with flavor, vitamins or other ingredients.

- Material: Stainless steel

- Country of origin: Slovakia

- Geometric volume: 350 l/ 700 l

Feeding conveyors optimally transport your product to another processing facility to maximize output and improve downstream performance. Price depends on the product and size of the conveyor.

- Material: Stainless steel

- Engine power, kW: 0,25

- Weight: 100

The sorting and transporting table or conveyor is suitable for manually sorting and delivering products to the next processing stage.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 530 mm

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The coating machine is designed for uniform application, impregnation of oil and fat mixture, dyes and flavors, enzymes, vitamins and other additives, various products with a high level of hygiene.

- Material: Stainless steel

- Engine power, kW: 2,2

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

We offer different types of dryers for different products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Country of origin: Slovakia

- Weight: 255 kg

- Volume: 500l

- Voltage: 380-400V

- Geometric volume: 170 l

- Dimensions, mm: 2350 x1500 x2000

We offer different capacity multi belt dryers and roasting ovens.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

We offer different capacity infrared dryers.

- Productivity: 250 kg/h/ 1000 kg/h/ 1500 kg/h/ 2000 kg/h / 3000 kg/h / 6000 kg/h

This multi layer belt dryer with integrated cooling system works as a dryer and cooler in one installation.

- Material: Stainless steel

- Principle of operation: Continuous mode

We can help you choose the right continuous fryer suited for your needs.

- Productivity: nuts 400 kg/h

- Material: Stainless steel

- Heating power, kW: 30/ 60

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Country of origin: EU

- Weight: 245 kg

- Working Area Width: 250 mm

- Oil volume: 100 l

We sell different types of deep fryers, for a price quote or for a free consultation, please contact us by sending a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

- Voltage: 380-400V

We have various types of continuous or batch fryers. Just tell us what kind of product you wish to fry and we will help you choose the right deep fryer.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia