COTTAGE CHEESE

The cost is specified for the basic modification without a heating system

Fat block melters are designed for melting frozen, solid blocks of animal or vegetable fat, as well as maintaining them in a molten state at a specified temperature. We produce models with the option to connect steam as a coolant to the melting grid, separate electric heating systems, or configurations with built-in electric heating for supply into the jacket and melting grid.

- Large area of the melting grid where the coolant circulates

- Special shape of the melting grid, cutting blocks during melting

- Greater versatility in terms of the coolant and its source

- Mirror surface of the melting grid, ensuring high hygiene

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 200l/ 300l/ 500l/ 1000l

The price depends on the required capacity.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350 l

- Total power, kW: 1,5

The vacuum homogenizer with an inclined design is designed for processing and manufacturing a wide range of liquid, pasty and viscous products with different requirements for their production conditions and other products including those with a high viscosity.

- Material: Stainless steel

- Engine power, kW: 1,5 KW

- Principle of operation: Batch mode

- Country of origin: Slovakia

Highly efficient production of a high viscosity pharmaceutical and cosmetic products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Geometric volume: 500 l/ 800 l

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

The price is indicated for the basic version of the vacuum reactor without additional options, the final cost depends on the modifications

The vacuum homogenizer is an ideal solution for the production of food, for example mayonnaise, it is also suitable for the cosmetics industry - the production of toothpaste. This model of the homogenizer is based on a vacuum reactor with an external homogenizer and an external circulation circuit, the parameters of which are selected as options.

- Tilted design - 25% more efficient mixing

- Easily disassembled reinforced frame mixer, for thick and viscous products

- Jacket for the coolant around the bottom and walls of the working reactor

- The vacuum reactor can withstand a vacuum up to -0.8 Bar

- A large number of options to choose from to suit various requirements

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 650l

- Total power, kW: 0,55

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The butter texturizer FBHG is intended for mechanical processing of frozen blocks of butter, animal fat, margarine and other plan fats, without prior defrosting.

- Material: Stainless steel

- Principle of operation: Continuous mode

A twin-screw mixer with a homogenizer is an ideal solution for the production of creamy cheese, such as feta cheese, including with various flavors and seasonings. Thanks to mechanical homogenization, the cheese acquires a delicate structure without changing the individual taste properties of the product. It is used for plasticizing, creaming and softening butter, margarine and other fats.

- Capacity of the receiving hopper 50L

- Compact tabletop design for convenient operator maintenance

- A powerful independent drive for each screw with a reverser

- Easy maintenance and cleaning of the equipment

- Productivity: 250 kg/h/ 1500 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 3,5

- Voltage: 380-400V

The inline homogenizer is designed for mixing, emulsifying, dispersing, and homogenizing thick and viscous products in the production of mayonnaise, soy milk, toothpaste, yogurt, and much more. It can be installed in an external circulation circuit of reactors, production lines, or used independently with a loading hopper for processing small volumes of products.

- Creates stable emulsions and suspensions

- Reduces particle size

- Quickly dissolves solids

- Accelerates chemical reactions

- Does not require an additional pump

- Material: Stainless steel

- Engine power, kW: 5,5/ 7,5/ 9/ 11/ 15

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

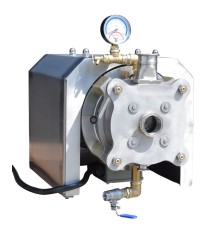

The circulation type homogenizer is designed for emulsifying thick fluids and other viscous materials within the food, chemical and cosmetic industries. Its working principle is based on the rotor/stator principle.┬Ā

- Material: Stainless steel

- Engine power, kW: 1,1/ 7,5 kW

- Country of origin: Slovakia

The atmospheric tank with an inclined design is used for mixing, stirring, and dissolving various products. By supplying a thermal carrier to the unitŌĆÖs jacket (duplicator) from an external source, thermal processing such as heating or cooling can occur (i.e. heating or cooling from an external coolant source with an inlet pressure of up to 0.5 bar). These units are widely utilized in the food and cosmetic industries.

- Inclined design: 50% more efficient mixing

- Due to the inclination angle of the working tank, rapid and complete (100%) emptying is achieved.

- Efficient heat transfer through the heating/cooling jacket

- No dead zones during mixing!

- Modular system with a wide range of additional options

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Working volume: 100l/ 200l/ 300l/ 450l/ 600l/ 900l

MP cooker is a reliable and extremely functional solution for cooking, pasteurizing in the same tank thus saving equipment cost, space. All material are most reliable in European market so guarantee a long and trouble free operation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

The cheese boiler is used in the dairy industry for the production of cheese grains during the production of natural hard, semi-hard, soft cheeses, and other cheese or curd products. The cheese maker is equipped with a special knife-mixer (lyre) for cutting the cheese curd. Suitable for both small and large scale production. Using this cheese-cooking boiler you can also pasteurize other dairy products, produce yogurt, cottage cheese kefir, fermented baked milk, varenets, sour cream and more.

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 300 l

The tubular pasteurizer is typically designed for pasteurizing cream in butter production lines. These pasteurizers are commonly used in dairy processing industrial facilities, especially in butter production and other related sectors.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The professional cooking vat is designed for dairy products processing. The machine can be used by farms and small dairy factories.

- Material: Stainless steel

- Heating power, kW: 24

- Volume: 150l/ 300l/ 500l

A vat or cooking kettle for milk is a large container or vessel used for heating and processing milk, typically in dairy production, to pasteurize, cook, or produce various dairy products such as cheese or yogurt.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 500l/ 1000l

Twin-screw extruder is designed for effective extruding, homogenization, pumping over of plastic masses (butter, margarine, honey, curd products, confectionery mixtures), and forming it into bars and rolls.

- Productivity: 400 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Weight: 115 kg

The price is indicated without the frequency converter

A twin-screw mixer for fast and intensive mixing, stirring of bulk solid products, such as granules, muesli with various powder additives.

- The mixing blades carefully move while thoroughly mixing the product

- The mixing mode allows you to move the product cyclically in a circle

- High mixing efficiency due to the counter-movement of the 2 shafts

- Compact design

- Possibility to install scrapers on each blade (optional)

- Reinforced drive, can be used for products saturated with moisture as well

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 500l

- Total power, kW: 3

Used in chemical, construction, cosmetic or food industries.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 85

- Volume: 50l

- Voltage: 380-400V

Running of various production processes such as cutting, mixing, crushing, refining and emulsifying different types of product in a single unit.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 359 kg

- Volume: 150l

Our company offers equipment for whipping honey with a new design which includes gravity mixing. The main advantage of the technique is the ability to produce creamy honey in 4 hours! The device is designed for 450 kg of honey per batch.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 300l