ICE CREAM

Homogenizer for the production of whipped cream, ice cream, and much more. It allows you to obtain stable liquid emulsions of food mixtures.

- The homogenizer can be installed directly into the container with the product

- High productivity - in just 8 minutes, it is possible to whip up to 60 liters of milk mixture

- The peripheral speed of the knives is 16 m/s

- Material: Stainless steel

- Engine power, kW: 0,37/ 2,2

- Country of origin: EU

- Voltage: 380-400V

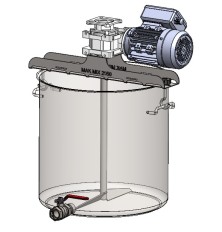

A detachable lid with an automatic food stirrer for stainless steel 40 cm pots, suitable for volumes of 50 and 100 liters. An automatic stirrer allows you to mix and stir various products, including during thermal processing. The type of mixing device can be additionally selected depending on the required process.

- Professional industrial single-phase motor for 220-230 Volts

- The control is located directly on the motor housing or on the drive cable

- Easy and simple installation and fixation of the lid on the pan

- Suitable for standard 40 cm pots with a capacity of 50 or 100 liters

- The lid and stirrer are made entirely out of stainless steel

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Voltage: 220-230V

Fat block melter Fastmelter refers to the equipment of periodic action for melting butter and other frozen fats within the food industry.

- Material: Stainless steel

- Principle of operation: Batch mode

MP cooker is a reliable and extremely functional solution for cooking, pasteurizing in the same tank thus saving equipment cost, space. All material are most reliable in European market so guarantee a long and trouble free operation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

Electric heating panel with three different power possibilities: 12, 24 and 48 KW ŌĆō excellent product manufactured by people who perfectly know the secret of product storage, maintenance and processing.

- Heating power, kW: 12/ 24/ 48

- Country of origin: EU

The price is indicated for the basic version of the set of equipment with a homogenizer

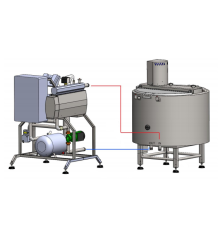

The equipment for the production of ice cream mixtures is based on a universal vacuum reactor with a coolant jacket and a multi-stage dispersant/homogenizer in an external circulation loop.

- Special type of a stirring device for easy disassembly and cleaning

- Processing with minimal product loss

- The bottom outlet valve is included in the basic version of the installation

- Multi-stage disperser for intensive wetting and homogenization of the flowing mixture

- External circulation circuit with a three-way valve for operation/washing of the equipment

- Reinforced agitator drive for thick and viscous mixtures

- Built-in vacuum pump

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 3

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

A vat or cooking kettle for milk is a large container or vessel used for heating and processing milk, typically in dairy production, to pasteurize, cook, or produce various dairy products such as cheese or yogurt.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 500l/ 1000l

Intense fat melting machines MixMelters are designed for melting frozen, solid blocks of animal and vegetable fat such as butter and margarine as well as to maintain them in a melted state at a given temperature. Working volume up to, l: 200 l.

- Material: Stainless steel

- Heating power, kW: 12/ 24/ 48

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 200 l

Used in chemical, construction, cosmetic or food industries.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 85

- Volume: 50l

- Voltage: 380-400V

We offer different types of dairy pasteurizers. Tell us if you are producing cheese, milk, yoghurt or ice cream and we will help you pick the right pasteurizer for you.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

- Volume: 200l/ 300l/ 500 l/ 800 l / 1000l

Tell us if you are producing cheese, milk, yoghurt or ice cream. The difference between the milk pasteurizer and the yoghurt pasteurizer is that the yoghurt pasteurizer is equipped with a detachable arm with a detachable big stirrer and two half lids.

- Material: Stainless steel

- Country of origin: EU

- Volume: 50l/ 100l/ 200l/ 300l/ 400l/ 500 l/ 650l 800 l / 1000l/ 1250l/ 1500l