READY TO COOK, PREPARED MEALS

Professional cooking boiler with a stirrer for particularly thick and viscous products. An excellent technical solution for the production of caramel, syrups and sugar paste for sugaring. The heating source is selected separately.

- The kettle can be used on all types of cooking surfaces, including induction

- The basic version has easily removable, self-aligning stainless steel scrapers

- High torque of the stirrer with 14-18 revolutions per minute

- Professional 3-phase industrial motor

- The stirrer is turned on independently using a remote control with IP66 protection, connected to the boiler using quick-release connectors

- The unit can be connected to a 220-230 volt network even with a 3-phase motor!

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Volume: 20l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

The combination of the compact 400/1100/12 fryer with the secondary upper pressure conveyor, allows you to expand the variety of products that can be fried on it. It ensures uniform, high-quality frying of fresh and semi-finished products in small to medium scale, making it suitable for small-scale production, professional kitchens and street food businesses. The fryer fully submerges the product in oil throughout the whole frying process with the help of the second pressure conveyor that forces the product beneath the oil's surface.

- The maximum height of the fried product is - up to 50 mm

- Immersion thermometer for visual monitoring of the oil temperature

- Frying time can be set from a few seconds up to an hour!

- High temperature ‚Äď up to 200¬įC

- The conveyor belt is made out of a food-grade stainless steel thin mesh

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ‚Äď the double conveyor fryer and the paddle conveyor fryer ‚Äď we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

A tilting frying pan with a stirrer and indirect electric heating using thermal oil is designed for processing small batches of raw materials, making it suitable for stewing and frying various foods. The automatic stirring feature enhances the preparation of vegetables, fish, meat, and sauces.

- Compact model

- Uniform heating due to the thermal oil

- Simple controls

- Electric tilt of the working bowl

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 140l

- Total power, kW: 19

The price is stated including the unheated conical side panels

The frying pan of the WOK type with direct electric heating is designed for fast and intensive heat treatment of products with a maximum heating temperature of up to 220 degrees. This equipment allows you to sauté, fry, stew, boil, cook and concentrate various products, including thick and viscous ones thanks to the frame mixing device and an automatic tilting system for unloading the final product.

- Fast and efficient heating of up to 220 degrees

- Automatic tilting and unloading system

- Lid opening sensors for safe operation

- Safe steam exhaust system on the top lid

- Lid latches in the open position

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 45

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 46

- Voltage: 380-400V

This commercial frying pan with mixing and a tilt function is designed for frying, sautéing, searing, and cooking foods in small amounts of oil in large batches. An independent support frame with a tilt mechanism ensures easy unloading. The pan features adjustable heating with 6 intensity levels, making it suitable for professional kitchens and small food production businesses.

- Efficient heat distribution for even cooking.

- High performance for continuous batch processing.

- Rapid heating thanks to bottom electric contact heating.

- Mobile design allows for easy movement across the work area.

- Easy cleaning and maintenance.

A rotating drum unit designed for continuous coating and seasoning operations as well as product saturation with spices and flavor additives, utilized in production lines for chips, snacks, and various semi-finished products.

- Adjustment of the Drum Tilt Angle

- Hygienic design and execution: mirror-polished inner surface of the drum

- Various blade options for gently turning the product (optional)

- Dispensers for dry and wet flavorings (optional)

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 0,25

- Voltage: 380-400V

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

Stainless steel jam cooking pot with agitator 50l and electric stove 5kW, ideal and affordable cooking solution.

- Heating: Electricity

- Material: Stainless steel

- Engine power, kW: 0,18/

- Heating power, kW: 5

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

USED PRODUCT - 1 LEFT IN STOCK

Continuous deep fryer OIL MINI is designed for gastronomy and catering. It is ideal for deep frying of meat, ravioli, meatballs, seafood, poultry and vegetables. It ensures continuous frying and stable frying results. The heating elements are located in a double thick aluminum bottom, the so-called "sandwich bottom", which prevents the product from sticking to the heating elements and burning, thus you can use the oil many times more!

Basic price - 5960‚ā¨. The possibility of adding an oil spraying / pouring module (combifry), for an additional cost of 3980 ‚ā¨ (RECOMMENDED OPTION)

For frying foods in oil, deep-frying, suitable for frying onions, seeds, nuts, vegetable snacks and chips, and other products, including breaded or covered in liaison. Can also be used as an oil separating centrifuge for deep fryer.

- Two in one: a deep fryer and a centrifuge to remove excess oil

- Possibility of frying small and fragile products

- Obtaining a ‚Äúdry product‚ÄĚ after frying

- Low carbonization of oil due to the cleaning feature after frying

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l/ 90l

- Total power, kW: 11

- Voltage: 380-400V

The compact tabletop paddle fryer can be used for the production of a variety of snacks, including vegetable and fruit chips fried in oil. It is also suitable for frying extruded chips and snacks.

- Innovative design: a compact continuous paddle fryer for professional kitchens

- Intensive three-zone heating using thermal controllers for each heating element

- Specially designed blades along the entire length of the fryer to immerse the product in oil

- Frying time can be set from a few seconds up to an hour

- Product agitation system during loading for product separation

- Thermal insulation of the working body to reduce heat loss and for safer operation

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Voltage: 380-400V

The modular cooling conveyor is produced as a standard tabletop version with a section length of 1000 mm; in addition to it, you can order a stainless table or a frame supporting structure. The air cooling conveyor can be sectionally increased in length by the required number of sections.

- Compact, easy to install on any work surface

- Features a fine-grained stainless steel mesh for high temperatures and small-sized products

- Easily combined in line with a tabletop fryer 400/1100/12

- Easy maintenance and cleaning

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

The price is set for the combination of a basic fryer model and an additional module with rotating paddles.

The universal modular SnackPro fryer equipped with an additional paddle module is designed for frying thin slices of products that require immersion beneath the oil level.

- Adjustable frying time from a few seconds up to an hour

- Compact, tabletop version

- The paddle conveyor is installed on top of the basic fryer

- Safety thermostats on each heating element

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

This electric cooking pot has a volume of 60 liters and is used to prepare a large number of dishes. It is comfortable to use and easy to clean.

- Material: Stainless steel

- Volume: 60l/

- Voltage: 380-400V

Breadcrumb breading has never been easier. This device is available in various belt width configurations of 200, 300, 400 and 600 mm.

- Material: Stainless steel

- Working Area Width: 300 mm 400 mm 600 mm

- Voltage: 380-400V

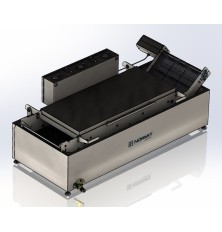

This continuous conveyor deep fryer is a reliable and versatile solution suitable for high-performance frying of a wide range of products by immersing them in hot oil.

- Universal application

- Quick transition for frying new types of products

- Possibility of using special frying modes

- Minimal amount of oil in the system

- Trouble-free oil filtration

- High oil exchange ratio

- High efficiency and productivity with compact design

- Manufactured to the highest quality standards using materials and components made in Europe.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

The universal bath pasteurizer is used for processing a wide range of different food products, such as ready meals, sausages, hams or liquid products. Effective temperature regulation and a hygienic stainless steel design.

An adjustable electric donut fryer with a continuous conveyor system is specially designed for small confectionery shops, pastry production and catering establishments. It is capable of frying a variety of products similar to donuts.

- Material: Stainless steel

- Heating power, kW: 12

- Country of origin: Slovakia

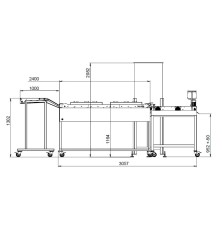

The extended version of the modular conveyor fryer with a large number of optional accessories, significantly expands the production capacity for deep-frying various products by increasing both the frying area and heating power.

- Frying time can be adjusted from several minutes up to an hour!

- Overheating safety sensors are installed on each heating element

- Compact support structure on a mobile support

- Fine-mesh conveyor grid allows for frying small and fragile products

- A large number of additional options in the form of automatic oil top-up system, loading conveyor, filtration system, cooling conveyor, etc.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

The device was primarily designed to increase dough adhesion (adhesion) by using a thin layer of dust - flour. The device is available in four widths of 200, 300, 400 and 600 mm.

Production line for vegetarian vegetable-based formed or molded products such as falafel. The line is based on the classical method of producing semi-finished products for their subsequent freezing and packaging.

- Compact line suitable for both professional kitchens and industrial production.

- Fully automatic operation with minimal manual labor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

The digitally controlled continuous conveyor system ensures the frying of a wide range of products at a consistent level. Thanks to the possibilities of deep frying, this model is suitable for a wide range of products from spring rolls, onion bhajis and falafel to fish fingers, burgers and chicken nuggets. The fryer is available in widths of 200, 300, 400 and 600 mm.

- Material: Stainless steel

- Voltage: 380-400V

This is a cost-effective solution that meets the special cooking requirements of the Horeca segment. Fitted with a built-in mixer to reduce manual labor and prevent the product from sticking.

- Material: Stainless steel

- Heating power, kW: 4

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 19

Multifunctional pans function as a frying, cooking, and mixing device in one installation.

- Material: Stainless steel

- Principle of operation: Batch mode

The atmospheric batch cooker model UniCook E or UniCook S, featuring a stirrer, is tailored to meet the diverse cooking needs of various food production businesses in industrial settings.

- Heating: Steam

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 1000l

The continuous production line for deep-frying and the subsequent cooling of semi-finished products includes:

- modular deep fryer with the option of choosing the conveyor type: a secondary conveyor for forced immersion of the product in oil or a conveyor with paddles for frying light floating products, such as chips;

- stainless steel table under the deep fryer with the option of installing an oil container and an oil filtration system inside it;

- cooling conveyor for removing excess oil and surface cooling of the product after frying it in the deep fryer.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

This 265 liter stainless steel cooker is great for boiling or roasting a variety of ingredients. It is made of stainless steel and equipped with a convenient drain valve.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 135 +135 / 220+220

Equipment for mixing multi-component mixtures of products, such as vegetable salads with various dressings, including thick and viscous ones like mayonnaise, thick sour cream and other similar sauces.

- Hydraulic tilting system is included in the basic version

- The controls are located directly on the frame supporting structure

- Eccentrically offset working shaft for rotating/tilting the working tank

- Low loading height

- The installation is made entirely out of food grade stainless steel

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 600l/ 1000l

Used for blanching products in water, it is suitable for processing various vegetables, legumes, grains, mushrooms and other products. This versatile machine also functions as a water separator centrifuge which is activated after the blanching processes.

- Productivity: 30l/ 90l

- Material: Stainless steel

The conveyor is made out of strong and highly-resistant stainless steel. It is also additionally reinforced for reliability during operation.

- Material: Stainless steel

- Principle of operation: Continuous mode

A rotary defroster is a device used to thaw or defrost frozen food products by rotating them gently in a heated chamber, allowing for even and efficient thawing without damaging the food's texture or integrity.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The continuous pouring fryer is designed to fry meat, fish, vegetables and pasta products as well as chicken drumsticks, cutlets, nuggets, croutons, sliced zucchini or eggplant, and etc. using immersion frying and hot oil pouring methods.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Tilting pans with mixers cook the product with continuous stirring and subsequently discharge the food into receiving trolleys, ensuring the discharge spout remains at a constant height from the ground. Designed for the catering industry, large kitchens, school cafeterias, restaurants, and other food production businesses.

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Engine power, kW: 0,75

- Heating power, kW: 24/ 36/ 48

- Volume: 200l/ 300l/ 500l

- Steam consumption, kg/h: 85/ 100/ 115

Cooking kettles for cooking under pressure are designed for highly efficient heat treatment of a wide range of food products at temperatures up to 110 ¬įC and pressure up to 0.5 bar.

- Heating: Electricity Steam

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 220 l/ 500l/ 600l/

The electric cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, broths, pasta, milk dishes, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. The equipment is not suitable for roasting or baking.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 100l/ 150l/ 200l/ 300l

Heating boilers are designed to cook sausages, hams and offal. Technology for superior performance and hygiene.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l/ 400l/ 500l/ 600l/ 800 l / 1000l/ 1200l/

This is a 400 l capacity heating boiler, we offer different capacity commercial cooking boilers.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 25

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 400l

- Voltage: 380-400V

We can help you choose the right continuous fryer suited for your needs.

- Productivity: nuts 400 kg/h

- Material: Stainless steel

- Heating power, kW: 30/ 60

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Country of origin: EU

- Weight: 245 kg

- Working Area Width: 250 mm

- Oil volume: 100 l

Blanching helps keeping the vitamins and nutritional properties of the product, as well as an outer appearance with bright and natural color.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

We have various types of continuous or batch fryers. Just tell us what kind of product you wish to fry and we will help you choose the right deep fryer.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

These gas boiling cookers are manufactured for professional kitchens and also for other food processing factories. We offer 100l, 150l, 250l and 300l.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l/ 200l/ 300l

This automatic cooking machine is made for continuous production. Different types of food can be boiled, like pasta, rice (minimum 1.5 mm in size), vegetables, meat etc., thanks to the basket’s design.

- Material: Stainless steel

- Operation mode: Automatic

- Volume: 300l/ 600l/

- Voltage: 380-400V

Croquettes production line for making and batter breading croquettes, preparing them for frying. Croquettes from 15 to 55 grams. Produces up to 12,000 pieces/hour. We also offer a range of fryers.

Price depends on your production capacity.

- Productivity: 12 000

- Material: Stainless steel

- Principle of operation: Continuous mode