KOMBUCHA

The 300 BIN pressure vessel is a mobile stainless steel unit designed for transferring liquid and semi-liquid products by applying controlled internal pressure. It also serves as a mobile container for moving batches within the production facility. It is suitable for hygienic food processing environments where pumping is not possible or practical.

- Designed for operating pressures up to 0.5 bar, allowing for vertical transfer of liquids without a pump.

- Six hand-tightened lid screws ensure secure sealing during pressurized or vacuum operation.

- Mounted on caster wheels for easy movement within the production area.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

Universal cooking kettle with a built-in steam generator up to 0.5 bar, frame stirring device and an automatic tilt and unloading system is a convenient and safe solution for processing various liquid products in large volumes.

- Safe design with a jacket (duplicator) and outer casing with insulation

- Intensive steam heating through the jacket using the built-in electric steam generator

- Automatic multi-stage tilt and unloading system

- Frame stirring device for dissolving, mixing, kneading ingredients

- Unloading of the product into rolling carts is possible due to the offset tilted axis

- Heating: Mixed

- Material: Stainless steel

- Country of origin: Slovakia

- Total power, kW: 13,5

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

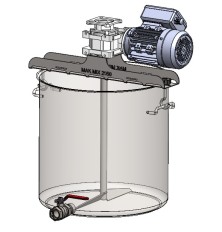

A detachable lid with an automatic food stirrer for stainless steel 40 cm pots, suitable for volumes of 50 and 100 liters. An automatic stirrer allows you to mix and stir various products, including during thermal processing. The type of mixing device can be additionally selected depending on the required process.

- Professional industrial single-phase motor for 220-230 Volts

- The control is located directly on the motor housing or on the drive cable

- Easy and simple installation and fixation of the lid on the pan

- Suitable for standard 40 cm pots with a capacity of 50 or 100 liters

- The lid and stirrer are made entirely out of stainless steel

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Voltage: 220-230V

A universal vessel for mixing, whipping and stirring any products using a blade mixing device operating at high speeds.

- Crescent shaped mixing device with three sharpened blades (cutter knives)

- Special high speed drive

- Sandwich bottom for all types of heating surfaces (electricity, gas, induction).

- Productivity: 50l/ 100l

- Material: Stainless steel

- Engine power, kW: 0,18/

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Diameter, mm: 400/ 500/ 600

A vacuum distillation system is used for controlled separation of liquids based on the evaporation of the liquid and subsequent condensation of its vapors.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 5l

The conveyor for transferring empty as well as filled bottles and jars. Widely used within packaging lines for various liquids.

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: EU

The price is indicated for the basic version of the vacuum reactor without additional options, the final cost depends on the modifications

The vacuum homogenizer is an ideal solution for the production of food, for example mayonnaise, it is also suitable for the cosmetics industry - the production of toothpaste. This model of the homogenizer is based on a vacuum reactor with an external homogenizer and an external circulation circuit, the parameters of which are selected as options.

- Tilted design - 25% more efficient mixing

- Easily disassembled reinforced frame mixer, for thick and viscous products

- Jacket for the coolant around the bottom and walls of the working reactor

- The vacuum reactor can withstand a vacuum up to -0.8 Bar

- A large number of options to choose from to suit various requirements

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 650l

- Total power, kW: 0,55

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The atmospheric tank with an inclined design is used for mixing, stirring, and dissolving various products. By supplying a thermal carrier to the unitŌĆÖs jacket (duplicator) from an external source, thermal processing such as heating or cooling can occur (i.e. heating or cooling from an external coolant source with an inlet pressure of up to 0.5 bar). These units are widely utilized in the food and cosmetic industries.

- Inclined design: 50% more efficient mixing

- Due to the inclination angle of the working tank, rapid and complete (100%) emptying is achieved.

- Efficient heat transfer through the heating/cooling jacket

- No dead zones during mixing!

- Modular system with a wide range of additional options

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Working volume: 100l/ 200l/ 300l/ 450l/ 600l/ 900l

The plate heat exchanger is designed for cooling/heating and transfer liquid products such as milk, water, juices, syrups etc.

- Type of the equipment: Individual machine

- Country of origin: EU

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

We offer wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments. Price depends on the chosen option.

- Heating: Gas Steam

- Productivity: 300 l 600 l 1000 l

- Operation mode: Automatic

- Type of the equipment: Individual machine

The device is designed for the pasteurization of a wide range of products in various types of packaging material such as cans and jars.

- Heating: Mixed

- Productivity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

The tubular pasteurizer is typically designed for pasteurizing cream in butter production lines. These pasteurizers are commonly used in dairy processing industrial facilities, especially in butter production and other related sectors.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A chiller is a cooling machine that removes heat from a liquid through vapor compression and absorption in a cyclic manner.

- Principle of operation: Continuous mode

- Cooling performance l/h: 100 / 200 l/ 300

A vacuum deaerator is extensively used in the food industry to remove gases from products that may retain some bubbles post-processing. Additionally, a flow deaerator is utilized to minimize foaming in products, ensuring a denser structure, especially prior to packaging. Vacuum deaerators play a crucial role in eliminating specific odors from the products, such as in the production of juices, purees, and herbal drinks. This process significantly contributes to enhancing the overall quality and taste of the final product.

- Enhances product quality, structure, and shape

- Prevents oxidation by removing gases

- Preserves organoleptic properties and extends the shelf life

- Suitable for thick and viscous products

- The flow principle allows for the installation of this equipment in existing production lines

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The manual bottle filler is designed to fill liquids in glass bottles.┬Ā

- Productivity: 650 psc/h

- Material: Stainless steel

- Operation mode: Manual

Semi-automatic dosing machine, designed for filling and capping different spouted pouches with various liquids.

- Material: Stainless steel

- Operation mode: Semi-automatic

4 Heads vacuum bottle filling machine serves as a professional semi-automatic filling and dosing machine for filling glass bottles with various fluids.

- Material: Stainless steel

- Operation mode: Manual

- Type of the equipment: Individual machine

Centrifugal impeller pumps are ideal for various industrial applications such as food processing, manufacturing, washing and surface treatment of metal pieces, boxes, containers, glass jars and vessels. These pumps are also suitable for dishwashers, bottle washing lines, painting processes, and pumping liquids into various chambers.

- Principle of operation: Continuous mode

Stainless steel low-speed rotary pumps with flexible impeller; particularly suitable for transfer of delicate, fragile and viscous fluids, also with solid parts in suspension.

- Principle of operation: Continuous mode