SOUR CREAM

Professional cooking boiler with a stirrer for particularly thick and viscous products. An excellent technical solution for the production of caramel, syrups and sugar paste for sugaring. The heating source is selected separately.

- The kettle can be used on all types of cooking surfaces, including induction

- The basic version has easily removable, self-aligning stainless steel scrapers

- High torque of the stirrer with 14-18 revolutions per minute

- Professional 3-phase industrial motor

- The stirrer is turned on independently using a remote control with IP66 protection, connected to the boiler using quick-release connectors

- The unit can be connected to a 220-230 volt network even with a 3-phase motor!

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Volume: 20l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

The cream-cooking kettle with manual tilting is designed for controlled heating, concentration, and thermal treatment of cream and cream-based products. Its adjustable temperature control, gentle handling, and uniform heat distribution enable processes such as thickening, reduction, pasteurization, and the preparation of dessert bases.

- 6-stage heating intensity adjustment

- Uniform heat distribution for a consistent product consistency

- Manual tilting system for complete and convenient emptying

- Suitable for cream, dairy desserts, sauces, and similar products

- Smooth stainless steel interior for easy cleaning and maintenance

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

Universal cooking kettle for thick mixtures: it works on the principle of a water bath and can be used in confectionery shops, bakeries and other catering establishments. Offers a wide variety of models.

- Mechanical tilting system for unloading

- Safety grill for the mixer drive

- Built-in electric heating up to 150 degrees

- Mobile support structure on wheels

- Heating: Electricity

- Principle of operation: Batch mode

- Volume: 30l/ 60l/ 80l/ 120l

Vane pumps are used for pumping high viscosity products such as syrups, honey, mayonnaise, sauces, cream and many other products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Type of pump: rotary vane

This premium cooking kettle is gas-fired and has a volume of 160 liters. Ideal for preparing a wide variety of dishes in professional kitchens.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l

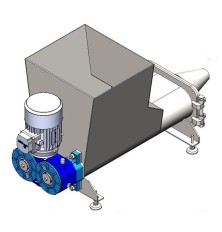

The screw pump is used for transferring "un-pumpable" products. A great choice for those who work with hard to move liquids and need to move them as quickly as possible.

- Material: Stainless steel

- Voltage: 380-400V

The pump provides a delicate straight-streaming┬Āpumping of a wide range of liquids with or without solid fragments with viscosity up to 150 Pa.s.┬Ā

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

This electric cooking pot has a volume of 60 liters and is used to prepare a large number of dishes. It is comfortable to use and easy to clean.

- Material: Stainless steel

- Volume: 60l/

- Voltage: 380-400V

The price is indicated without the control unit

The heat exchanger is designed for efficient and gentle heat treatment: heating and cooling liquid and pasty products, including those with a high viscosity, such as jam, chocolate, caramel, glazes, creams, marinades, baby food, honey, fish or meat stuffing and many similar products.

- Uniform thermal processing of thick and viscous products thanks to the supply of the coolant into the duplicator

- Efficient heat transfer due to especially shaped blades

- Continuous operation that does not allow the product to locally overheat or overcool

- Intensive heat transfer due to the internal mixing of the product with scrapers

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 250l/ 500l

- Voltage: 380-400V

- Heat transfer area, m┬▓: 2,7/ 5,4/

The portable vertical pump is designed for pumping fluent or viscous liquids in the range from 1-2300 m2/s at a temperature of around 25┬░C. The pump cannot be used in potentially explosive atmospheres.

- Material: Stainless steel

- Engine power, kW: 0,25

- Voltage: 380-400V

This 550 l professional tilting kettle is gas-fired and is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams. With this tilting version, you can make your life even easier.

- Heating: Gas

- Productivity: 500 l

- Material: Stainless steel

A modern cooking and mixing device with a wide range of applications in confectionery, bakeries, catering establishments.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

The atmospheric tank with an inclined design is used for mixing, stirring, and dissolving various products. By supplying a thermal carrier to the unitŌĆÖs jacket (duplicator) from an external source, thermal processing such as heating or cooling can occur (i.e. heating or cooling from an external coolant source with an inlet pressure of up to 0.5 bar). These units are widely utilized in the food and cosmetic industries.

- Inclined design: 50% more efficient mixing

- Due to the inclination angle of the working tank, rapid and complete (100%) emptying is achieved.

- Efficient heat transfer through the heating/cooling jacket

- No dead zones during mixing!

- Modular system with a wide range of additional options

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Working volume: 100l/ 200l/ 300l/ 450l/ 600l/ 900l

MP cooker is a reliable and extremely functional solution for cooking, pasteurizing in the same tank thus saving equipment cost, space. All material are most reliable in European market so guarantee a long and trouble free operation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

Vertical shell and tube heat exchanger is designed to heat and cool such viscous/pasty products as sauces, mayonnaise, creams yogurts, jams, caramel, baby food, honey etc.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Shell-and-tube or tabular heat exchanger is designed to heat and cool viscous/pasty products such as sauces, mayonnaise, creams yogurts, jams, caramel, baby food, honey etc. Shell-and-tube heat exchangers are one of the most widely used units due to their robust design and a variety of options to suit different operating conditions.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

Highly efficient production of a high viscosity pharmaceutical and cosmetic products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Geometric volume: 500 l/ 800 l

The VMG S 650P vacuum homogenizing unit can be used for making toothpaste as well as a variety of similar products with complex production requirements.

- The vacuum ensures effective air removal, eliminating the conditions for the development of bacteria and other pathogenic organisms.

- The special shape of the mixing device is tailored for the thickest and most viscous products.┬Ā

- The Ultra Shear submersible homogenizer creates a stable emulsion.

- The cavitation processes aid in activating hydrodynamic mixing.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 29

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 52

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The tubular pasteurizer is typically designed for pasteurizing cream in butter production lines. These pasteurizers are commonly used in dairy processing industrial facilities, especially in butter production and other related sectors.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

This kettle with a radiator cooling system ranging from 30 to 500 liters is ready to cook according to the principle of a water bath.

- Material: Stainless steel

- Volume: 30l/ 60l/ 80l/ 120 l/ 200l/ 300l

- Voltage: 380-400V

Filling machine is designed for pumping and filling high viscosity liquids, such as jams, confiture, sauces, dressings, syrups, and like products.

- Productivity: 200ŌĆō600 bottles per hour

- Material: Stainless steel

- Principle of operation: Continuous mode

The professional cooking vat is designed for dairy products processing. The machine can be used by farms and small dairy factories.

- Material: Stainless steel

- Heating power, kW: 24

- Volume: 150l/ 300l/ 500l

The industrial mixing and homogenizing equipment is well-suited for small and medium-sized production enterprises engaged in the processing of food, cosmetics, and various chemicals.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 300 l

Used in chemical, construction, cosmetic or food industries.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 85

- Volume: 50l

- Voltage: 380-400V

Running of various production processes such as cutting, mixing, crushing, refining and emulsifying different types of product in a single unit.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 359 kg

- Volume: 150l

Our company offers equipment for whipping honey with a new design which includes gravity mixing. The main advantage of the technique is the ability to produce creamy honey in 4 hours! The device is designed for 450 kg of honey per batch.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 300l

The semi-closed separator for purification, normalization and separation of whole milk into cream and skim milk.┬Ā

- Engine power, kW: 2,2

- Principle of operation: Continuous mode

An open-type cream separator with a capacity of 1,000 l/h is designed for continuous separation of whole milk into cream and skim milk. The separator allows the purification of milk from impurities and milk mucus.

- Productivity: 1000 l

- Engine power, kW: 0,55

- Principle of operation: Continuous mode

- Weight: 71

- Voltage: 380-400V

The AA50 adjustable industrial mixer is designed for efficient, high-performance mixing of liquid, viscous and pasty products, as well as for dispersing dry ingredients (pigments, dyes and other materials) in a liquid medium to obtain highly dispersed suspensions, emulsions and pastes.

- Material: Stainless steel