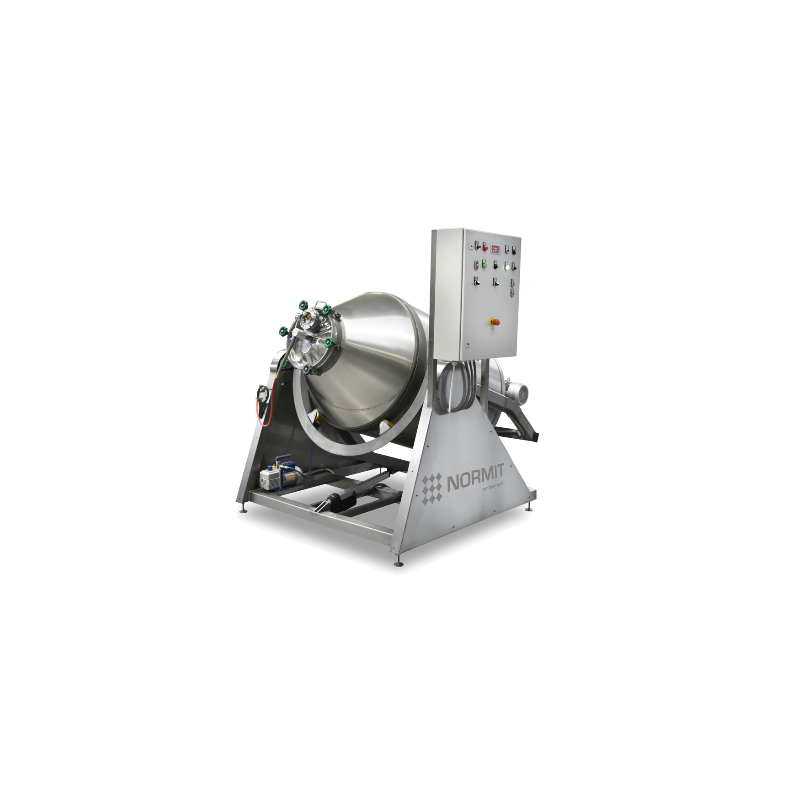

Vacuum diffuser & coating machine VC 1000

Vacuum coater is ideal for the application of salt and sugar solutions, enzyme, vitamin and anti-oxidants on water or oily basis as it ensures even distribution of small amounts of additives between the total product volume.

The price depends on the production capacity as well as the product being processed.

Vacuum Diffusion

A process in which the air inside the product is removed by vacuum and the released pores filled with flavors, vitamins or other substances. The VC 1000 Vacuum Diffuser is designed to carry out a vacuum diffusion process for a wide range of low and high density products. It ensures even distribution of small amounts of additives within the total product volume.

Products:

- Animal feed

- Nuts

- Seeds

- Granules

- Cereal products and others

Vacuum diffuser is ideal for the application of salt and sugar solutions, enzyme, vitamin and anti-oxidants on water or oily basis as it ensures even distribution of small amounts of additives between the total product volume. The addition of the substances is carried out under constant stirring, allowing even distribution of the whole product volume even under vacuum conditions. In contrast to traditional coating, the additive does not just remain on the surface of the product but penetrates deep into the pores, significantly enhancing the flavor properties of the product.

WORKING PRINCIPLE

The dry product is poured into the vessel. Vacuum is switched on, air is removed from the vessel and from the product pores. After removal of the air during continuous mixing, an additive is introduced into the vacuum vessel and mixed uniformly throughout the product.┬Ā

Features and advantages of diffuser VC 1000

- Absence of mixing equipment. Thanks to the special construction, the product is mixed by rotating the drum, without the stirrer - as in conventional diffusers. This makes it possible to increase the uniformity of mixing and prevent damage to the product.

- Addition of the vitamins during mixing. Even distribution of a small amount of the substance into the entire product volume.

- Adjustable vacuum pressure. Allows you to select the optimal diffusion mode for any product.

- Economical. There is no additive loss (important especially for expensive vitamins and similar preparations).

- Comfortable use. All required processes are carried out in one device.

Optional

If necessary, the VC 1000 diffuser can be equipped with a heating system, a product dispensing system for loading, an additive feed system from the container, an automatic control system with programmable recipes for various product types. Reliable design. The equipment is manufactured in the EU in production facilities using European materials and components.

More about the vacuum coater

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Max vacuum: -0,8 Bar