Obsah tГ©to strГЎnky byl pЕҷeloЕҫen do ДҚeЕЎtiny automatickГҪm pЕҷekladem. PЕҜvodnГӯ verze je v angliДҚtinДӣ. DДӣkujeme za pochopenГӯ.

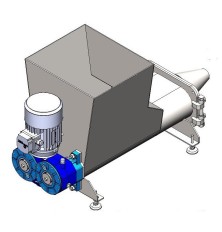

Stroj je pohГЎnДӣn vzduchem a je urДҚen k plnДӣnГӯ a uzavГӯrГЎnГӯ flexibilnГӯch sГЎДҚkЕҜ (s existujГӯcГӯ hubicГӯ) obsahujГӯcГӯch tekutГ© nebo polotekutГ© produkty. VyuЕҫГӯvГЎ objemovou pГӯstovou plniДҚku s rozsahem dГЎvkovГЎnГӯ 50-1300 ml a uzavГӯrГЎ sГЎДҚky plastovГҪmi ЕЎroubovacГӯmi uzГЎvДӣry stejnГ© velikosti.

VЕЎechny souДҚГЎsti, kterГ© pЕҷichГЎzejГӯ do styku s vГҪrobkem, jsou vyrobeny z nerezovГ© oceli AISI 316 L a z potravinГЎЕҷskГҪch tДӣsnДӣnГӯ. VГӯДҚko se utahuje pomocГӯ pneumatickГ©ho motoru s regulacГӯ toДҚivГ©ho momentu.

Tato jednotka mЕҜЕҫe plnit viskГіznГӯ produkty obsahujГӯcГӯ mДӣkkГ© ДҚГЎstice nebo vlГЎkna a je vhodnГЎ pro plnДӣnГӯ za tepla (100 В°C).

TechnickГ© vlastnosti

VГҪroba: maximГЎlnГӯ produkce aЕҫ 500 kusЕҜ za hodinu 90 ml sГЎДҚkЕҜ, v zГЎvislosti na rychlosti obsluhy.

HlavnГӯ rГЎm stroje je vyroben z nerezovГ© oceli AISI 304 a je namontovГЎn na kolech. VЕЎechny souДҚГЎsti zaЕҷГӯzenГӯ, kterГ© pЕҷichГЎzejГӯ do styku s vГҪrobkem, vДҚetnДӣ hЕҷГӯdele, jsou vyrobeny z nerezovГ© oceli AISI 304. PlnicГӯ a uzavГӯracГӯ stroj mГЎ ruДҚnГӯ polohovГЎnГӯ sГЎДҚkЕҜ.

UzavГӯrГЎnГӯ s jednou hlavou:

- SpotЕҷeba vzduchu se pohybuje kolem 250 Nl/min.

- PoЕҫadavky: stlaДҚenГҪ vzduch 2Г·6 barЕҜ.

PlnicГӯ jednotka se sklГЎdГЎ z:

ObjemovГЎ dГЎvkovacГӯ jednotka od 50 do 1300 ml, nerezovГЎ ocel AISI 316 L

- Sada tДӣsnДӣnГӯ pro potravinГЎЕҷskГ© ГәДҚely

- TЕҷГӯcestnГҪ otoДҚnГҪ ventil

- PneumatickГҪ dvoucestnГҪ ventil bez kapky s vypГӯnacГӯ tryskou

- PotravinГЎЕҷskГЎ flexibilnГӯ hadice

- koncovka hadice, kterГЎ spojuje jednotku s nГЎdrЕҫГӯ.

UzavГӯracГӯ jednotka s jednou hlavou se sklГЎdГЎ z:

- PneumatickГҪ motor

- NerezovГ© sklГӯДҚidlo pro jednu velikost plastovГ©ho ЕЎroubovacГӯho uzГЎvДӣru

- RuДҚnГӯ ovlГЎdГЎnГӯ pro nastavenГӯ vГҪЕЎky zaЕҷГӯzenГӯ

- Jednotka pro vstЕҷikovГЎnГӯ dusГӯku

JAK TO FUNGUJE

Obsluha stroje nasadГӯ sГЎДҚek na lГӯmec a pomocГӯ ruДҚnГӯho koleДҚka nastavГӯ plniДҚku tak, aby regulovala kapacitu plnДӣnГӯ vГҪrobku. Rychlost plnДӣnГӯ i sГЎnГӯ lze jemnДӣ nastavit tak, aby splЕҲovaly velmi specifickГ© poЕҫadavky. Po ruДҚnГӯm posunutГӯ pГЎky zaДҚne pracovat plnicГӯ ventil a zamДӣstnanec stisknutГӯm tlaДҚГӯtka zahГЎjГӯ proces plnДӣnГӯ.

KdyЕҫ se proces plnДӣnГӯ blГӯЕҫГӯ ke konci, stroj vstЕҷГӯkne do prГЎzdnГ©ho prostoru sГЎДҚku dusГӯk. TГӯmto krokem se vГҪrobek rozЕЎГӯЕҷГӯ a zakonzervuje, ДҚГӯmЕҫ se ГәДҚinnДӣ prodlouЕҫГӯ jeho trvanlivost. Dobu vstЕҷikovГЎnГӯ a prЕҜtok dusГӯku lze pЕҷesnДӣ nastavit pomocГӯ regulГЎtoru tlaku. NГЎslednДӣ pracovnГӯk nasadГӯ uzГЎvДӣr na hubici, pomocГӯ pГЎkovГ©ho mechanismu umГӯstГӯ uzavГӯracГӯ hlavu do polohy pro uzavГӯrГЎnГӯ a ЕҷГӯdГӯ proces utahovГЎnГӯ uzГЎvДӣru, aby zajistil sprГЎvnГ© uzavЕҷenГӯ.

MOЕҪNOSTI

- S/ocelovГҪ lГӯmec pro uchycenГӯ jinГ© velikosti a tvaru vГҪtoku

- S/ocelovГ© sklГӯДҚidlo vyrobenГ© na zakГЎzku pro 1 velikost plastovГ©ho ЕЎroubovГ©ho uzГЎvДӣru

- PЕҷГӯplatek za rozsah plnДӣnГӯ 200-5000 ml (mГӯsto 50-1300 ml)

- 15 litrЕҜ kuЕҫelovГ© nГЎsypky AISI 316

- 30 litrЕҜ kuЕҫelovГ© nГЎsypky AISI 316

You might also like

PoloautomatickГҪ balicГӯ stroj pro plnДӣnГӯ a uzavГӯrГЎnГӯ sklenic.

Pro dalЕЎГӯ informace nГЎs prosГӯm kontaktujte na adrese sales@foodtechprocess.com

Stroj na vakuovГ© plnДӣnГӯ lahvГӯ se 4 hlavami slouЕҫГӯ jako profesionГЎlnГӯ poloautomatickГҪ plnicГӯ a dГЎvkovacГӯ stroj pro plnДӣnГӯ sklenДӣnГҪch lahvГӯ rЕҜznГҪmi tekutinami.

Pro dalЕЎГӯ informace nГЎs prosГӯm kontaktujte na adrese sales@foodtechprocess.com

PoloautomatickГҪ dГЎvkovaДҚ urДҚenГҪ k plnДӣnГӯ a uzavГӯrГЎnГӯ rЕҜznГҪch sГЎДҚkЕҜ s vГҪlevkou rЕҜznГҪmi kapalinami.

PГӯstovГЎ plniДҚka je urДҚena k dГЎvkovГЎnГӯ rЕҜznГҪch typЕҜ kapalnГҪch produktЕҜ v potravinГЎЕҷskГ©m, chemickГ©m, farmaceutickГ©m a kosmetickГ©m prЕҜmyslu.

Еҳada pneumatickГҪch vertikГЎlnГӯch plnicГӯch strojЕҜ pro dГЎvkovГЎnГӯ kapalin s viskozitou podobnou vodДӣ.

Е roubovГ© ДҚerpadlo se pouЕҫГӯvГЎ pro pЕҷeДҚerpГЎvГЎnГӯ "neДҚerpatelnГҪch" produktЕҜ. SkvДӣlГЎ volba pro ty, kteЕҷГӯ pracujГӯ s tДӣЕҫko pohyblivГҪmi kapalinami a potЕҷebujГӯ je co nejrychleji pЕҷemГӯstit.

Pro vГӯce informacГӯ o produktu kontaktujte prosГӯm obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com

MechanickГЎ vakuovГЎ plniДҚka, regulovanГЎ elektronickГҪm systГ©mem s frekvenДҚnГӯm mДӣniДҚem.

NabГӯzГӯme rЕҜznГ© kapacity zГЎsobnГӯkЕҜ, pro cenovou nabГӯdku nebo bezplatnou konzultaci nГЎm zaЕЎlete e-mail na adresu sales@foodtechprocess.com

Tento poloautomatickГҪ plnicГӯ stroj se pouЕҫГӯvГЎ k plnДӣnГӯ medu i jinГҪch produktЕҜ. NabГӯzГӯme mnoho rЕҜznГҪch druhЕҜ plnicГӯch strojЕҜ pro rЕҜznГ© aplikace.

Pro vГӯce informacГӯ nГЎm poЕЎlete e-mail na adresu sales@foodtechprocess.com

NabГӯzГӯme rЕҜznГ© typy strojЕҜ na plnДӣnГӯ masa pro domГЎcГӯ i komerДҚnГӯ pouЕҫitГӯ.

Pro vГӯce informacГӯ nГЎm poЕЎlete e-mail na adresu sales@foodtechprocess.com

ProdГЎvГЎme mnoho rЕҜznГҪch plnicГӯch strojЕҜ pro rЕҜznГ© vГҪrobky. Pro vГӯce informacГӯ nГЎm zaЕЎlete e-mail na adresu sales@foodtechprocess.com

AutomatickГЎ plniДҚka Bag-in-Box urДҚenГЎ k plnДӣnГӯ sГЎДҚkЕҜ bag-in-box hotovГҪmi vГҪrobky (teplГҪmi i studenГҪmi) - s objemem sГЎДҚku 3 aЕҫ 20 litrЕҜ.

Stroj na mytГӯ a plnДӣnГӯ sudЕҜ slouЕҫГӯ k mytГӯ a plnДӣnГӯ sudЕҜ a sudЕҜ na pivo, cider, vГӯno a dalЕЎГӯ nГЎpoje.

PneumatickГҪ dГЎvkovaДҚ kapalin s pГӯstem je poloautomatickГҪ plniДҚ pouЕҫГӯvanГҪ k dГЎvkovГЎnГӯ rЕҜznГҪch kapalin s nГӯzkou viskozitou o objemu od 10 do 100 ml.

- KompaktnГӯ stolnГӯ instalace

- JednoduchГ© ovlГЎdГЎnГӯ se dvДӣma provoznГӯmi reЕҫimy: manuГЎlnГӯm a poloautomatickГҪm.

- VhodnГ© pro kapalnГ© produkty s nГӯzkou viskozitou (od vody po olej).

- VolitelnДӣ je k dispozici kompresor stlaДҚenГ©ho vzduchu

- MateriГЎl: Nerez

- ReЕҫim provozu: PoloautomatickГҪ

- Princip provozu: KontinuГЎlnГӯ reЕҫim

HydraulickГҪ stroj na plnДӣnГӯ klobГЎs je ideГЎlnГӯm zaЕҷГӯzenГӯm pro plnДӣnГӯ klobГЎs rЕҜznГҪch specifikacГӯ a je vhodnГҪ pro plnДӣnГӯ do rЕҜznГҪch druhЕҜ stЕҷГӯvek.

NabГӯzГӯme rЕҜznГ© stroje na zpracovГЎnГӯ masa, pro vГӯce informacГӯ nГЎm zaЕЎlete e-mail na adresu sales@foodtechprocess.com

ZaЕҷГӯzenГӯ je urДҚeno k plnДӣnГӯ sГЎДҚkЕҜ v krabicГӯch. VhodnГ© pro plnДӣnГӯ horkГҪch neviskГіznГӯch vГҪrobkЕҜ. ZaЕҷГӯzenГӯ lze zakoupit samostatnДӣ nebo s dalЕЎГӯmi moЕҫnostmi - vozГӯkem a zГЎsobnГӯkem.

Pro vГӯce informacГӯ nebo cenovou nabГӯdku kontaktujte sales@foodtechprocess.com

PГӯstovГЎ plniДҚka je urДҚena k dГЎvkovГЎnГӯ rЕҜznГҪch typЕҜ kapalnГҪch produktЕҜ v potravinГЎЕҷskГ©m, chemickГ©m, farmaceutickГ©m a kosmetickГ©m prЕҜmyslu.

HydraulickГ© pГӯstovГ© plniДҚky pro potravinГЎЕҷskГҪ prЕҜmysl, plniДҚky masa a uzenin, ideГЎlnГӯ zaЕҷГӯzenГӯ pro vГҪrobce masa a ЕҷeznГӯky.

Pro dalЕЎГӯ informace nГЎs prosГӯm kontaktujte na adrese sales@foodtechprocess.com

- Produktivita: 20 l

PlnicГӯ a uzavГӯracГӯ stroj urДҚenГҪ k plnДӣnГӯ a uzavГӯrГЎnГӯ tekutГҪch nebo polotekutГҪch produktЕҜ do flexibilnГӯch sГЎДҚkЕҜ doypack s vГҪlevkou.

VBF je rychlГЎ, robustnГӯ a vЕЎestrannГЎ vakuovГЎ plniДҚka lahvГӯ. Tento plnicГӯ stroj hledГЎte, pokud chcete zvГҪЕЎit objem vГҪroby svГҪch domГЎcГӯch produktЕҜ a profesionalizovat stГЎДҚenГӯ vГӯna, oleje, piva, ovocnГҪch ЕЎЕҘГЎv nebo jinГҪch produktЕҜ.

Chcete-li zГӯskat cenovou nabГӯdku, kontaktujte nГЎs na adrese sales@foodtechprocess.com

NГЎkladovДӣ efektivnГӯ systГ©m pro plnДӣnГӯ sudЕҜ na zГЎkladДӣ vГЎhy pro plnДӣnГӯ vГҪrobku pomocГӯ ДҚerpadla.

Pro vГӯce informacГӯ kontaktujte naЕЎe obchodnГӯ oddДӣlenГӯ na adrese sales@foodtechprocess.com