Vacuum crystallizer with cooling

The vacuum crystallizer-cooler is specifically designed for sweetened condensed milk. Crystallization with cooling is one of the most important stages in the production of condensed milk according to GOST and is necessary before dosing and packing the finished product.

- After crystallization, condensed milk has a delicate structure with small crystals

- Condensed milk has a homogeneous shape and attractive consumer properties

- The shelf life of condensed milk is extended without changing the quality of the product

Vacuum crystallizer-coolers for sweetened condensed milk are widely used in food production, as they guarantee not only high-quality, but also fast crystallization in highly hygienic conditions ensured by the vacuum. The process is usually divided into two stages: rapid cooling down to a set temperature to add lactose and direct crystallization according to the sample (size of lactose crystals) of the product.

A distinctive feature of this installation is the combination of vacuum cooling with additional forced cooling from the coolant (refrigerant) in the duplicator, thereby increasing the cooling efficiency in each part of the process.

It is recommended to cool sweetened condensed milk immediately after the evaporation process, this is due to the negative properties of sucrose, which reduces the dissolution of lactose in the mixture. Lactose within the mixture does not completely dissolve in water; some of it, when the solution is supersaturated, is deposited in the form of large centers of crystals on the walls of the containers. The crystallization of sugars is a natural process, so to ensure that it does not negatively affect the final product with its granularity, it is recommended to carry out rapid cooling to form small crystals of lactose, thereby controlling the crystallization processes and obtaining a homogeneous crystallized product with similarly sized, small crystals. For milk and canned milk with sugar, it is recommended to focus on the size of lactose crystals in milk - up to 10 microns. The addition of the so-called seed is vital; sometimes about 0.02-0.05% of the mass of the product (condensed crystallized milk) from the previous batch is used as a seed. The size of crystals up to 10 microns does not in any way affect the taste of condensed milk, since it is not felt or recognized by the receptors of the tongue. To obtain a final product of 10 microns in condensed milk, it is recommended to add lactose of a maximum size of 3-4 microns. In addition to lactose, other crystal formation activators can be added to intensify the crystallization process.

Condensed milk with sugar is crystallized and cooled to room temperature, approximately 20┬░C, after which the condensed milk can be unloaded and transported for packaging. It is recommended to store condensed milk at a temperature of 0-10 degrees. Manufacturing control departments typically store small amounts of product from each batch for a year, periodically testing it for safety, including testing for the crystal size.

Advantages:

- Vacuum cooling in combination with forced cooling allows you to quickly and effectively cool the mixture by lowering the boiling point of water inside the working container due to vacuum conditions, and the additional source ice water circulating through the ŌĆ£jacketŌĆØ of the installation.

- For high-quality crystallization, it is necessary to get rid of air bubbles that can arise during constant stirring; the vacuum draws air voids to the surface and removes gases from the installation.

- The frame mixing device has a powerful electric drive, since during crystallization and cooling, condensed milk becomes highly viscous in its structure. The mixing device has special scrapers made out of fluoroplastic, which help not only with mixing but also to remove newly formed centers of small crystals from the walls of the installation, which are mixed into the total mass and evenly distributed in the product.

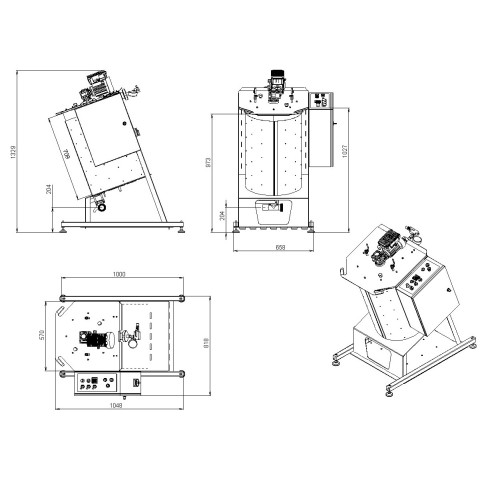

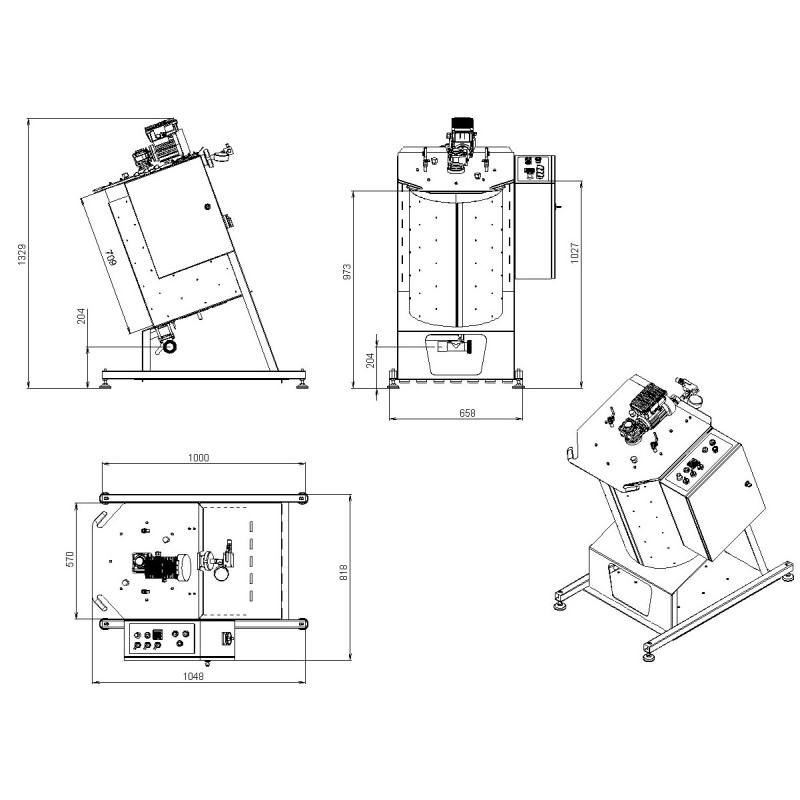

- Inclined design with gravity mixing is a know-how of our industrial design, which allows you to increase the mixing efficiency by at least 2 times, which is very important both for the rapid cooling of condensed milk in the crystallizer and for the controlled crystallization process.

- The inclined design also makes it possible to improve the unloading of a thick and viscous product from the crystallizer, such as sweetened condensed milk after crystallization and cooling. The outlet valve is located at the lowest point; with the 100 model, a bottom valve is already installed in the basic version. Even with a small crystallizer volume, product losses will be minimal.

- A special feature of these types of crystallizers is the "in-flow feed", which ensures a high percentage of rapid dissolution of the added seed crystals as they enter the installation below the liquid level through the circulation circuit from below. A forced circulation circuit is recommended, as it allows for the potential increase in forced cooling capacity by installing a heat exchanger in the external circulation circuit.

- To create a vacuum, various vacuum pumps can be used; in the basic version as well as for small volumes of the processed product, vacuum ejector pumps operating on compressed air are used. Thanks to the modular modification of the installation, the customer can choose a vacuum generator as an option (water ring vacuum pump, oil vacuum pump).

- The jacket is located along the entire height of the vacuum container as well as the bottom, which guarantees a high heat transfer area and intensive forced cooling (heat transfer).

- The upper housing can be completely removed; it is mounted on special bolts, which makes the maintenance and service of the installation easy.

- On the upper body, there is a hatch and an inspection window for visual control.

- A special professional stainless steel product temperature sensor is installed in the bottom of the container for precise temperature control of the product inside.

Operating principle

The liquid product from the vacuum evaporation unit is fed into the crystallizer-cooler using a pump, following the same process utilized in our production line for sweetened condensed milk according to GOST. After loading, by turning on the ejectors, a rarefied environment is created and the boiling point of water decreases. Due to the decrease in pressure, the product begins to cool. It should be taken into account that the cooling crystallizer also causes some additional evaporation of the product as a side effect. To increase the efficiency of the cooling process, ice water from an external source is supplied to the crystallizer's jacket (duplicator). This combined cooling method significantly reduces the time required to reach the "add seed" temperature. The temperature for adding lactose crystals may vary depending on the product formulation; on average, it is 32 degrees. After adding lactose, the crystallization process during cooling continues until the product reaches a temperature of about 20 degrees. For controlled crystallization during cooling, rapid and intense cooling is required, so an additional forced source of heat transfer can be provided - a heat exchanger in an external circulation circuit, where the product circulating in the opposite direction meets the cooling circuit. To facilitate forced cooling through the system's jacket and the heat exchanger, it is necessary to have a source of ice water with a temperature ranging from 5 to 6 ┬░C.

After processing, condensed milk, other than packaging, can also be sent to the next processing section - simmering to obtain the so-called cooked condensed milk. Simmering can be carried out on a special line of double-case cooking kettles of the Double cook series.

Basic version

The basic version of the crystallizer-cooler comprises a two-layer vacuum tank installed on an inclined supporting structure, featuring a jacket covering the walls and bottom of the reactor for coolant (up to 0.5 Bar). It also includes a frame mixing device with scrapers. The upper body features a hatch and an inspection window, while a vacuum generator, specifically a vacuum pump for compressed air, is also part of the setup. The control panel is equipped with a thermal controller for temperature regulation and a soft start system for the mixing device. To ensure proper operation of the installation, a source of compressed air with a pressure of 6-10 bar and a volume of about 300 l/min is necessary, alongside a source of ice water with a temperature of 5-6 degrees (not included in the basic version of the installation).

Recommended options

- External forced circulation circuit with a pump

- Lactose loading system below the liquid level

- Quiet compressor (compressed air source)

- Ice water station (chiller with buffer tank and cooling circuit pump)

- Mixer frequency converter

- HMI control panel

- Vacuum retention and regulation system

- Foot valve for the 300 l model

- CIP cleaning heads (rotary)

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar