Honey creaming machine CH profi

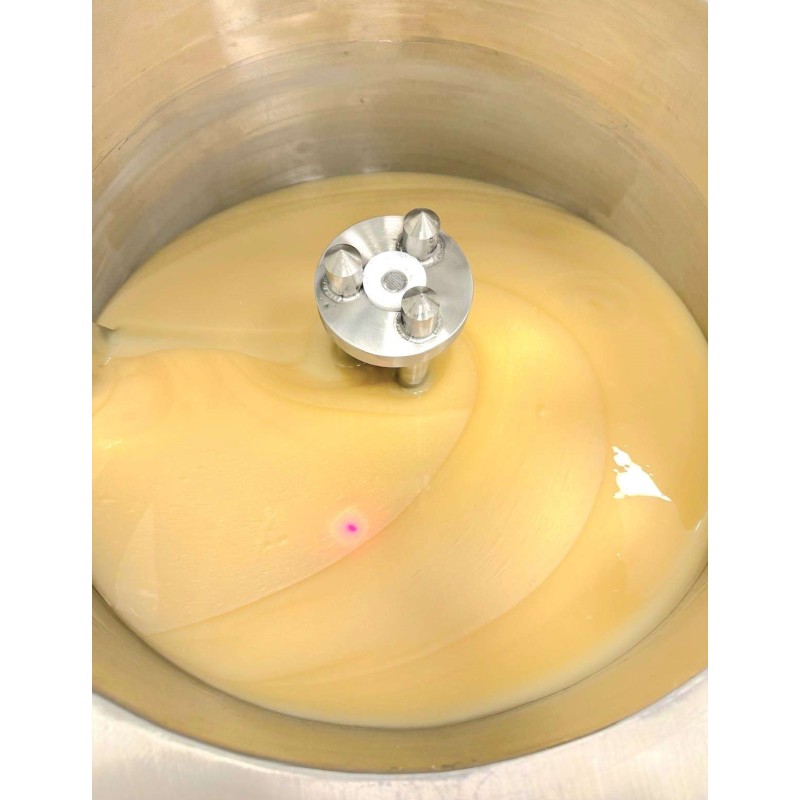

Equipment for the production of creamed honey, souffl├® honey, whipped creamy honey. The machine is produced both in atmospheric and vacuum versions, the loading capacity ranges from 70 to 3500 kg of honey.

The main advantage of a vacuum honey creaming machine is the ability to get cream honey in 3-4 hours!

The creamer is used for the controlled crystallization of honey with periodic processing and mixing at a given temperature. This includes such processes as recrystallization (decrease the proportion of crystals), controlled crystallization (their growth according to a set pattern), improvement in texture (homogeneity) and consumer (organoleptic) characteristics without losing the medicinal properties of the product. Cream honey does not change its creamy structure, which is why it is so convenient and loved by customers.

The devices are produced both in atmospheric and vacuum versions. There are many modifications available for our controlled crystallization and creaming plants, additional options depend on the individual preferences and choice of the customer.

The smallest model is the CH70 PROFI, a 50 liter atmospheric vertical tank (70 kg of honey) equipped with a built-in cooling system and a motorized agitator. The compact version of the plant can be used directly in the apiaries, and even a small batch of honey after pasteurization and filtration can be processed into a creamy structure.

We also offer the CH70 PROFI model in a vacuum version, this version is part of the professional modifications for the models, and is used both in small production facilities and for laboratory purposes. The basic versions of professional modifications consist of an inclined tank (reactor) on a supporting structure with a jacket for a coolant, equipped with a special-shaped frame mixer (gravitational type) with a drive (motor-reducer) and stainless steel scrapers. Scrapers help to cut off the newly formed centers of crystals from the surfaces of the container, after which the agitator evenly distributes them in the product.

The equipment can also be used to dissolve the remaining crystals after preliminary melting. Both cold water and hot water can be supplied to the duplicator, depending on the required process. It is not recommended to heat honey to a temperature above 40 degrees, since a rise in temperature, causes enzymes to be destroyed and carcinogenic substances to form, in particular, hydroxymethylfurfural begins to form.

A characteristic feature of the new series of vacuum creamers is gravity mixing, which is 20-25% more efficient than usual!

The inclined design also makes it easier to unload the product after processing, since gravity is added to the centrifugal force!

┬Ā

┬Ā

Processes:

- decrystallization

- recrystallization (decrease in the proportion of crystals)

- controlled crystallization

- homogenization

The humidity of honey before processing should be no higher than 17%, it is recommended to initially filter and pasteurize "raw" honey, as well as to pre-dry in case it has high humidity. You can choose the pasteurizing, filtering and drying systems for honey on our website, in the respective product categories!

The vacuum version of the unit can be equipped with a vacuum generator of your choice:

- Vacuum water ring pump, or

- VENTURI vacuum ejector (depending on the type of energy, we offer ejectors for water or compressed air)

- When processed under vacuum, honey is partially deaerated (air bubbles are removed from it), and the cooling process, which is necessary for creaming, becomes faster.

- With the vacuum version of the installation, you can get a thicker and more dense cream honey!

As additional options we can offer:

- heads for washing the product using CIP stations (both standard 180/360 degrees and rotary ones are offered to choose from);

- a closed heating system, most often used for service purposes, when it is necessary to remove product residues after processing for cleaning and washing;

- various types of heat generators;

- refrigeration machines (in the absence of a built-in refrigeration machine, or if there is a source of ice water). For the creaming process, it is necessary to supply a cold coolant with a temperature of 5-7 degrees and a pressure of up to 0.5 bar into the jacket;

- IBC containers with thermal insulation for use as a buffer tank for the cooling system. It is used for continuous operation and maintenance of the operating temperature for the cold coolant in the buffer tank. It saves the resources of the refrigeration machine and extends its service life;

- control of the mixing device using a frequency converter in the form of an independent control panel with IP66. No additional electrical cabinet required!

- control the operation of the mixing device using a controller for programming;

- "quiet" compressor for creating compressed air (when choosing a vacuum generator - VENTURI ejector for compressed air) for vacuum models. Creates compressed air with a constant pressure of 6-10 bar, necessary to generate a vacuum).

- pump for forced circulation of the coolant (mandatory option when choosing a vacuum generator - VENTURI ejector on water) for vacuum models;

- pump for unloading the product (pump-product) for pumping the finished cream honey and feeding it into packaging;

- and many others.

Advantages:

- absence of blind spots and easy unloading of the product after processing (in vacuum models) starting from the CH140 model, the bottom valve is installed in the basic version!

- efficient mixing,

- easily removable agitator.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia