Honey creaming machine 600 kg

The atmospheric unit for whipping and creaming honey, featuring a new design with gravity mixing, represents the second generation of the successful CH Light creaming unit model. Gravity mixing honey is 40% more effective than traditional methods, particularly in the production of cream honey, where the mixing mode and cyclogram play crucial roles. The slanted design aids in quickly emptying the work tank with minimal product loss.

- Sloped design - 40% more efficient mixing

- Powerful agitator drive

- Collapsible frame mixer with movable scrapers made out of fluoroplastic

- Lid opening sensor - a guarantee of high safety for the operator

The atmospheric creaming machine is employed to produce cream honey with a less dense structure than that achievable with a vacuum installation. This type of cream honey is well-suited for creating soufflƩ-style creamed honey or cream honey with the addition of berries, fruits, or other flavor enhancers. Creamed honey has a smooth, flowing consistency and a lighter color compared to liquid honey. The sloped honey creaming device significantly reduces processing time compared to the widely available equipment on the market.

The creamer allows for the processing of honey with different crystal sizes, resulting in a paste-like honey with uniformly small crystals, which is more appealing to the consumer, featuring a stable shape and a delicate creamy structure.

Advantages:

- Built-in controller with an cyclogram for automatic operation of the installation!

- High productivity, the capacity of the installation allows you to process up to 600 kg of honey in one cycle!

- Large heat transfer area, the installation is equipped with a jacket for the bottom as well as the walls along the entire height of the working tank.

- Intensive mixing, incorporation and uniform distribution of newly formed crystals throughout the entire mass of the product.

- Special scrapers with spring pressure ensure thorough cleaning of the walls and bottom of the creamer, cutting off newly formed centers of honey crystallization.

- Simple and convenient maintenance, the presence of several reserve connections on the upper housing for the installation of CIP heads for washing.

Basic version

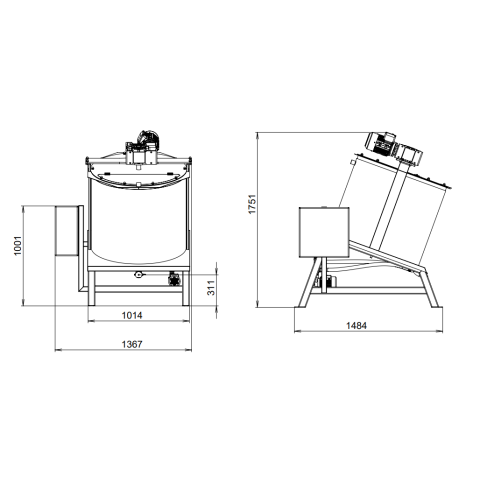

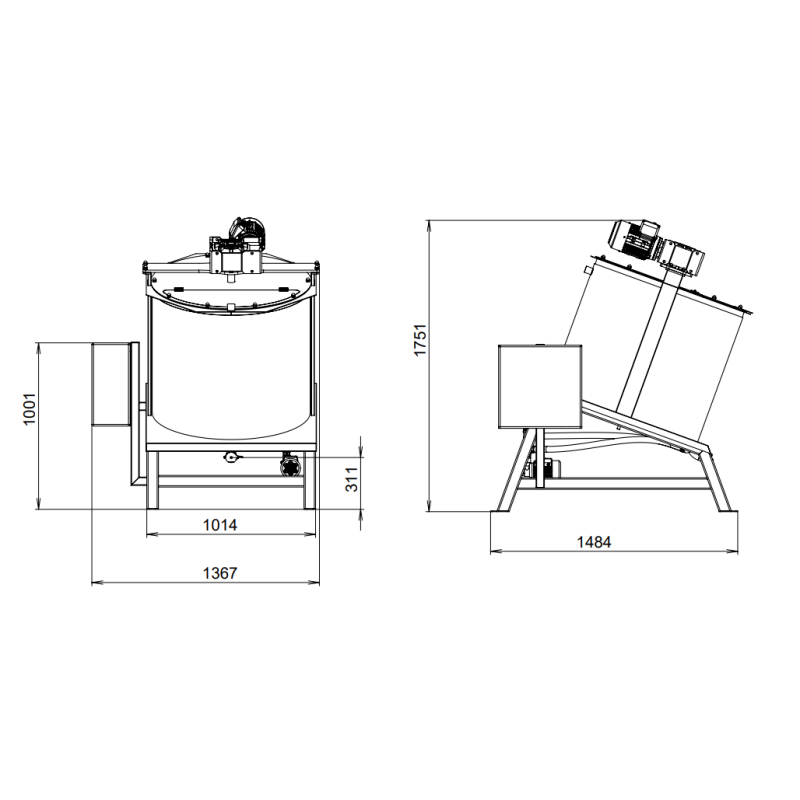

The creaming machine consists of an inclined atmospheric reactor mounted on a supporting structure, equipped with a heating/cooling ājacketā (for the coolant from an external source, with a maximum input pressure of up to 0.5 bar), a frame mixer with specially shaped scrapers with a powerful electric drive, a control panel based on a controller for automatic operation. The creamer is equipped with a built-in temperature sensor for the product inside and a safety sensor on the units hatch cover.

Principle of operation

The process involves recrystallization (reduction in crystal size), improving the characteristic texture without losing the medicinal properties of the product. The inclined design of the device helps to unload the product after processing, utilizing not only centrifugal but also gravitational force. Gravity mixing uses the earth's gravity to cause the processed product to spontaneously fall from the walls to the bottom of the tank, where a frame mixing device lifts the product and mixes it into the total mass.

Options:

- Heat generators

- Cooling machines and forced cooling circuits of cooling systems

- Ice water stations

- Buffer tanks for cooling systems and ice water stations

- Thermal insulation for the buffer tanks

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 400l/600 kg

- Total power, kW: 1,5

- Voltage: 380-400V